Antibacterial and antiviral CoCrCuFeNi high-entropy alloy and in-situ alloying method employing selective laser melting and application thereof

A technology of laser selective melting and high-entropy alloys, which is applied in the field of high-entropy alloys, can solve the problems of complex shape or structure manufacturing limitations, antibacterial and antiviral high-entropy alloys are not significant, and achieve excellent inactivation effect and broad spectrum The effect of antibacterial and antiviral ability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

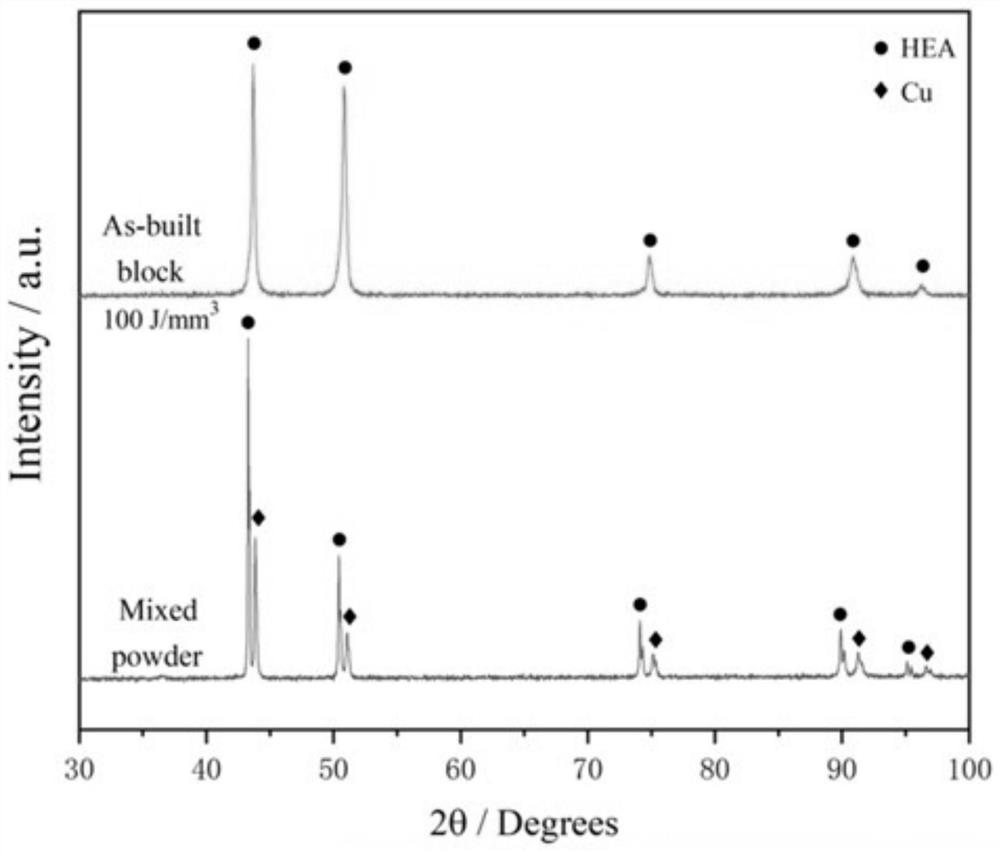

[0036] An antibacterial and antiviral CoCrCuFeNi high-entropy alloy laser selective melting in-situ alloying method, comprising the following steps:

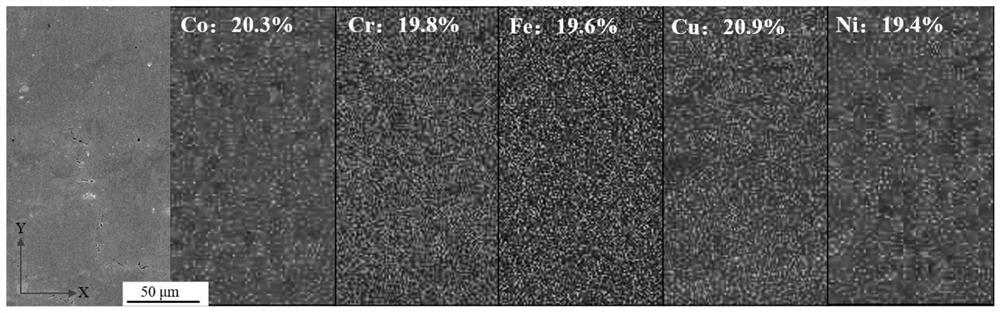

[0037] Mix the pre-alloyed CoCrFeNi powder and Cu powder to obtain a mixed powder; wherein, in the pre-alloyed CoCrFeNi powder, by molar ratio, Co:Cr:Fe:Ni=1:1:1:1; the added Cu powder The molar ratio of the pre-alloyed CoCrFeNi powder is Cu:Fe=1:1;

[0038] Spread the mixed powder on the surface of the base material. The base material used in this embodiment is stainless steel; wherein, the thickness of the powder spread is 0.03mm;

[0039] According to the anti-microbial corrosion and anti-virus component structure to be prepared, set the laser travel route, and use the laser to perform laser selective melting on the mixed powder, in which the laser power is 300W, the scanning speed is 2000mm / s, the line interval is 0.05mm, and the energy density is 100J / mm 3 , after the first layer of laser selective melting, on this basis...

Embodiment 2

[0044] An antibacterial and antiviral CoCrCuFeNi high-entropy alloy laser selective melting in-situ alloying method, comprising the following steps:

[0045] Mix the pre-alloyed CoCrFeNi powder and Cu powder to obtain a mixed powder; wherein, in the pre-alloyed CoCrFeNi powder, by molar ratio, Co:Cr:Fe:Ni=1:1:1:1; the added Cu powder The molar ratio of the pre-alloyed CoCrFeNi powder is Cu:Fe=1:1;

[0046] Spread the mixed powder on the surface of the base material. The base material used in this embodiment is stainless steel; wherein, the thickness of the powder spread is 0.03mm;

[0047] According to the anti-microbial corrosion and anti-virus component structure to be prepared, set the laser travel route, and use the laser to perform laser selective melting on the mixed powder, in which the laser power is 270W, the scanning speed is 1500mm / s, the line interval is 0.05mm, and the energy density is 120J / mm 3 , after the first layer of laser selective melting, on this basis...

Embodiment 3

[0049] An antibacterial and antiviral CoCrCuFeNi high-entropy alloy laser selective melting in-situ alloying method, comprising the following steps:

[0050] Mix the pre-alloyed CoCrFeNi powder and Cu powder to obtain a mixed powder; wherein, in the pre-alloyed CoCrFeNi powder, by molar ratio, Co:Cr:Fe:Ni=1:1:1:1; the added Cu powder The molar ratio of the pre-alloyed CoCrFeNi powder is Cu:Fe=1:1;

[0051] Spread the mixed powder on the surface of the base material. The base material used in this embodiment is stainless steel; wherein, the thickness of the powder spread is 0.03mm;

[0052] According to the anti-microbial corrosion and anti-virus component structure to be prepared, set the laser travel route, and use the laser to perform laser selective melting on the mixed powder, wherein the laser power is 150W, the scanning speed is 1000mm / s, the line interval is 0.05mm, and the energy density is 100J / mm 3 , after the first layer of laser selective melting, on this basis,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com