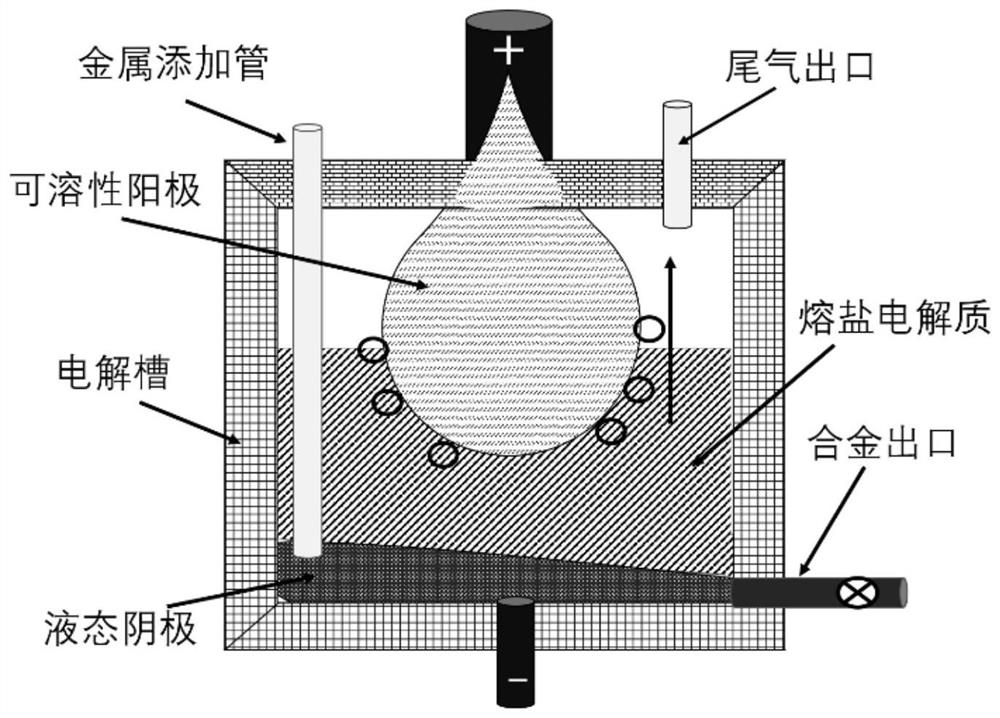

Method for preparing titanium alloy based on direct electrolysis of a liquid cathode and a soluble titanium-containing anode

A liquid cathode, soluble technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of long reduction time, equipment corrosion, environmental pollution, etc., achieve high electrolytic preparation and in-situ alloying, low cost, high current The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 50g of metallic aluminum is added to the bottom of the alumina electrolytic tank from the feeding port. Using NaCl-KCl as the molten salt electrolyte, TiC and TiO with a weight of 1 kg were calcined at 1400 °C to synthesize Ti 2 The CO solid solution is used as the anode, and it is processed and shaped; the current density is 0.3A cm at 750°C under the protection of an inert atmosphere -2 Electrolyze for 4 hours; after the end of electrolysis, lift the anode from the molten salt to separate from the electrolyte, and continue to raise the temperature by 50°C, and siphon out the prepared low melting point alloy. After the titanium-aluminum alloy is suction-filtered, continue to add aluminum from the feeding port and put it into a soluble anode for electrolysis to prepare the titanium-aluminum alloy.

Embodiment 2

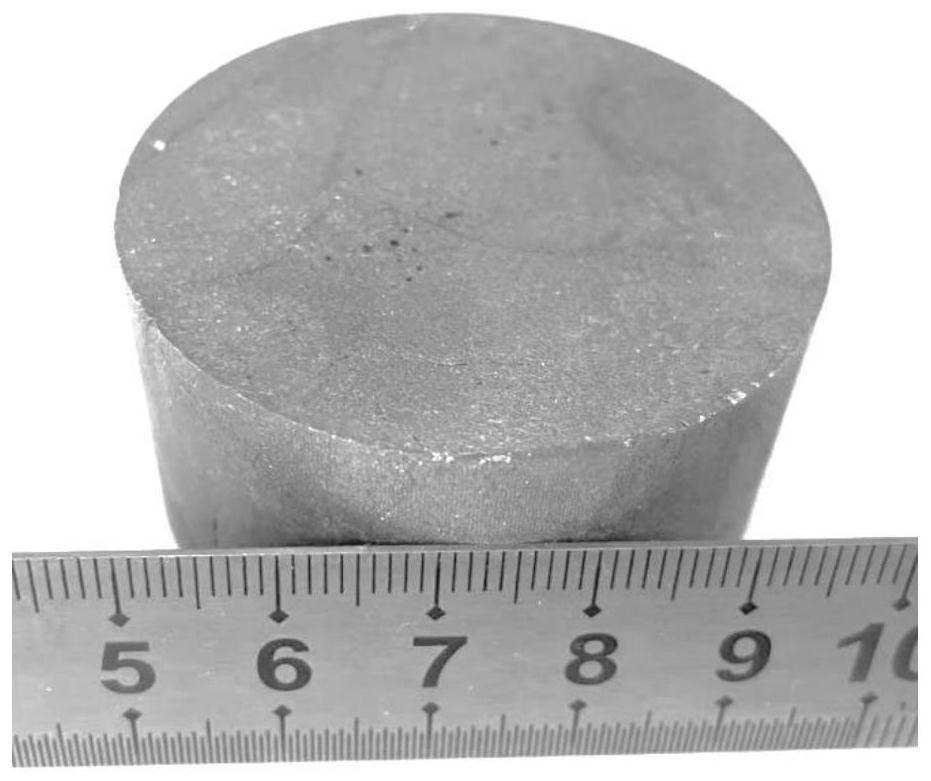

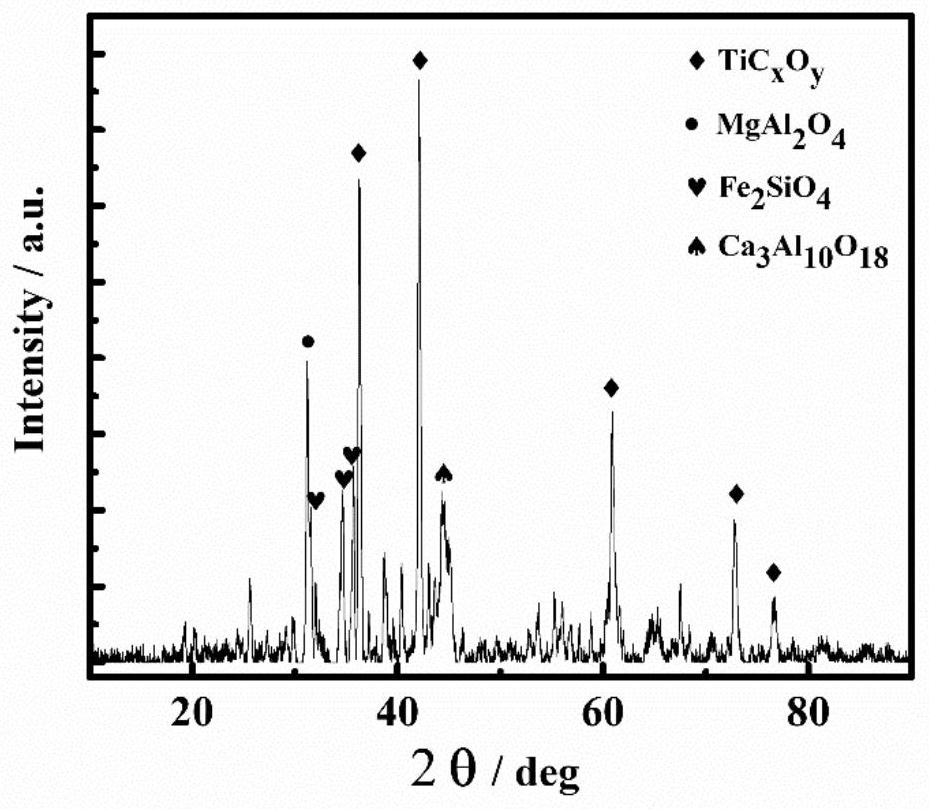

[0034] 50g of bismuth metal is added to the bottom of the alumina electrolytic tank from the feeding port. With NaCl-KCl-LiCl as the molten salt electrolyte, TiO with a weight of 2kg 2 TiC synthesized by high-temperature calcination of C and C in argon atmosphere at 1400 °C x o ysolid solution, and use an electric arc furnace to melt and cast it into an anode with a dense structure, and carry out the current density of 0.4A cm -2 Electrolysis for 2 hours; after the electrolysis, lift the anode from the molten salt to separate from the electrolyte, and continue to raise the temperature by 50°C, and discharge the prepared alloy from the alloy overflow port. After the alloy is discharged, continue to add the alloy from the feeding port and put it into the soluble anode for electrolysis to prepare the titanium-bismuth alloy.

Embodiment 3

[0036] 50g metal tin is added to the bottom of the boron nitride electrolytic tank from the feed port. with MgCl 2 -KCl-CsCl is a molten salt electrolyte, using TiO with a weight of 1kg 2 TiC synthesized by calcination of C and C at 1400 °C in a nitrogen atmosphere x o y N z solid solution, and use an electric arc furnace to melt and cast it into a dense anode, and carry out the current density of 0.1A cm in an inert atmosphere at 400 °C -2 Electrolysis for 3 hours; after electrolysis, lift the anode from the molten salt to separate from the electrolyte, and continue to raise the temperature by 50°C, and discharge the prepared alloy from the alloy overflow port. After the alloy is discharged, continue to add the alloy from the feeding port and put it into the soluble anode for electrolysis to prepare the titanium-tin alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com