Rubber deicing airbag for turboprop aircraft

An aircraft and airbag technology, applied in the field of deicing airbags for aviation, can solve the problems such as the inability to meet the requirements of elastic inflation, expansion and contraction, and achieve the effect of excellent low temperature and release of technical blockade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

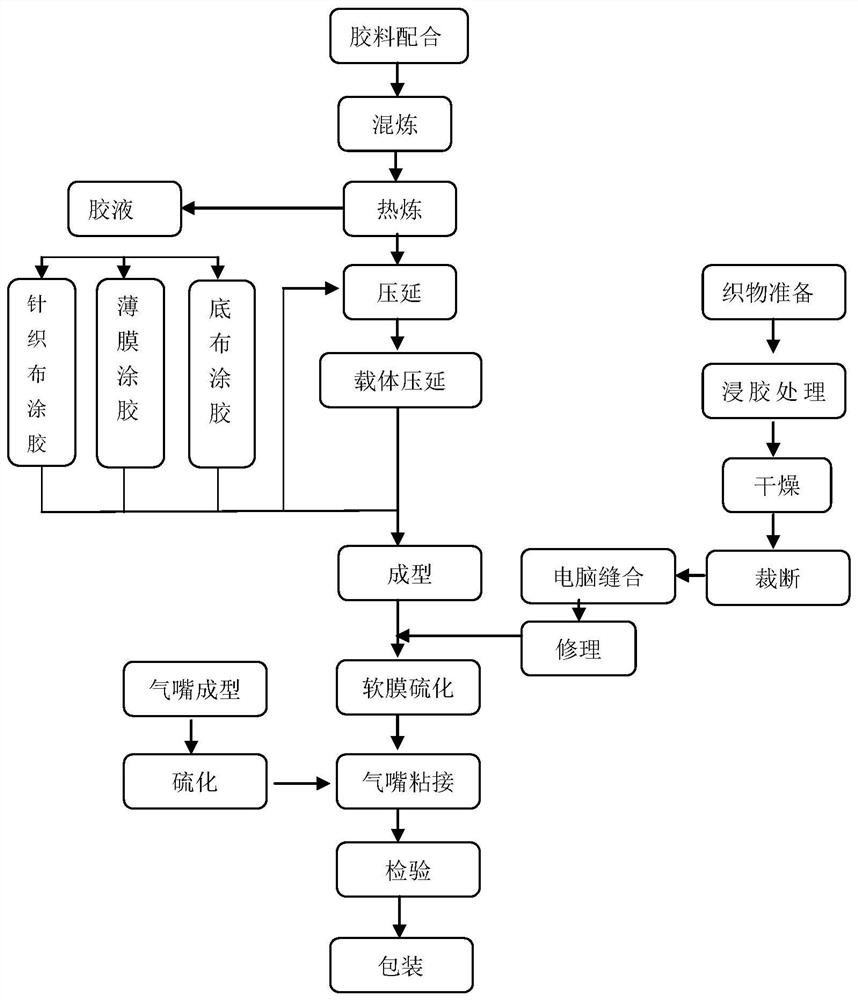

[0040] The invention provides a rubber deicing airbag used for deicing when the wing or tail of a turboprop fixed-wing aircraft freezes, and discloses the product structure, skeleton material, surface rubber layer, middle rubber layer and base fabric of the rubber deicing airbag The formula of the adhesive layer and the manufacturing process and process of the product, etc.

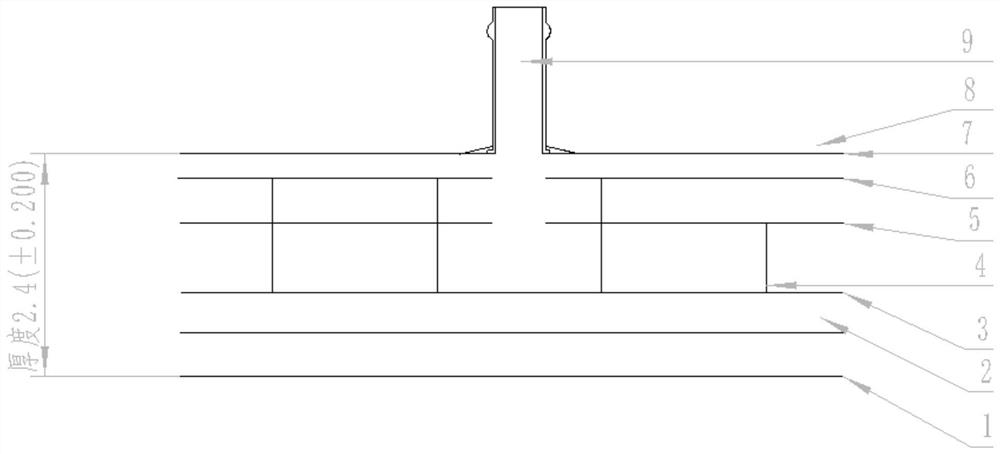

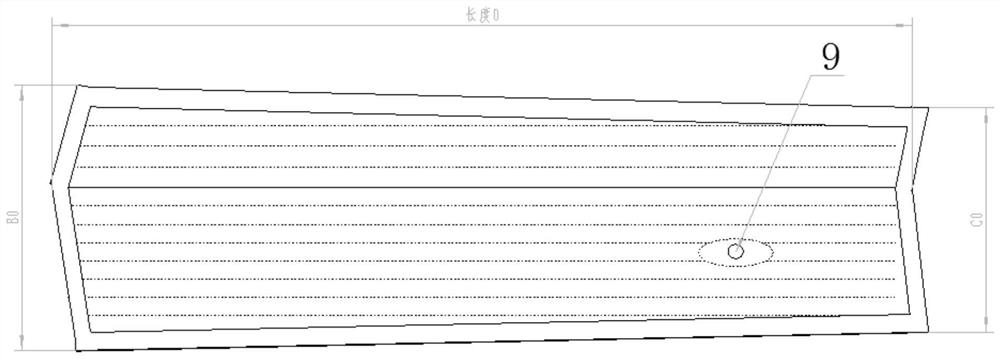

[0041] The shape of the deicing airbag is consistent with the deicing area of the aircraft wing or empennage. The total thickness is 2.2-2.6mm. Narrowed, with a composite skeleton layer distributed inside and an inflatable airway, the airway is a parallel structure with connected ends.

[0042] The section structure of the deicing airbag is as follows: figure 1 As shown, it includes an outer layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com