High-pressure spray can

A high-pressure spray and tank technology, which is applied in the field of liquid agent containers, can solve the problems of inability to spray liquid agent A and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

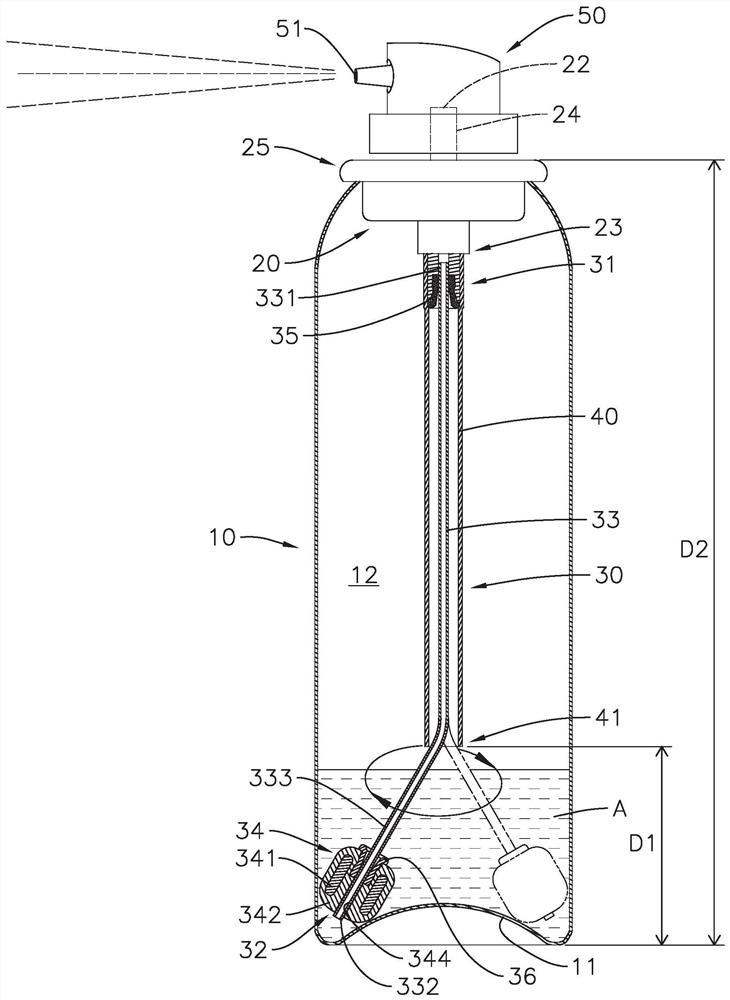

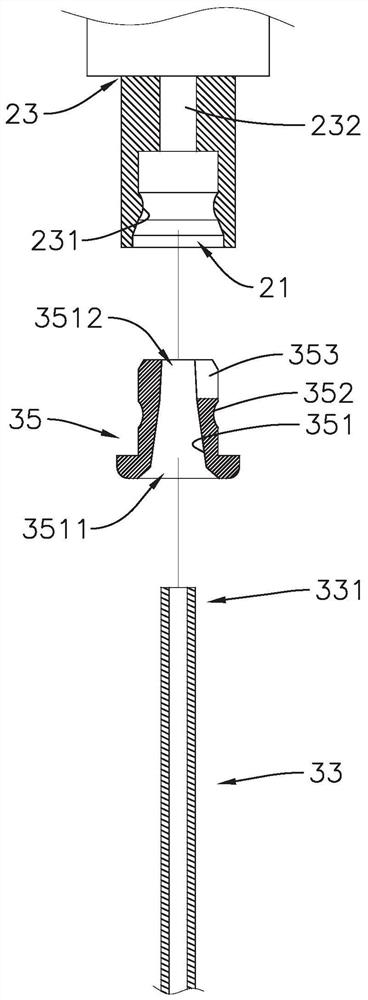

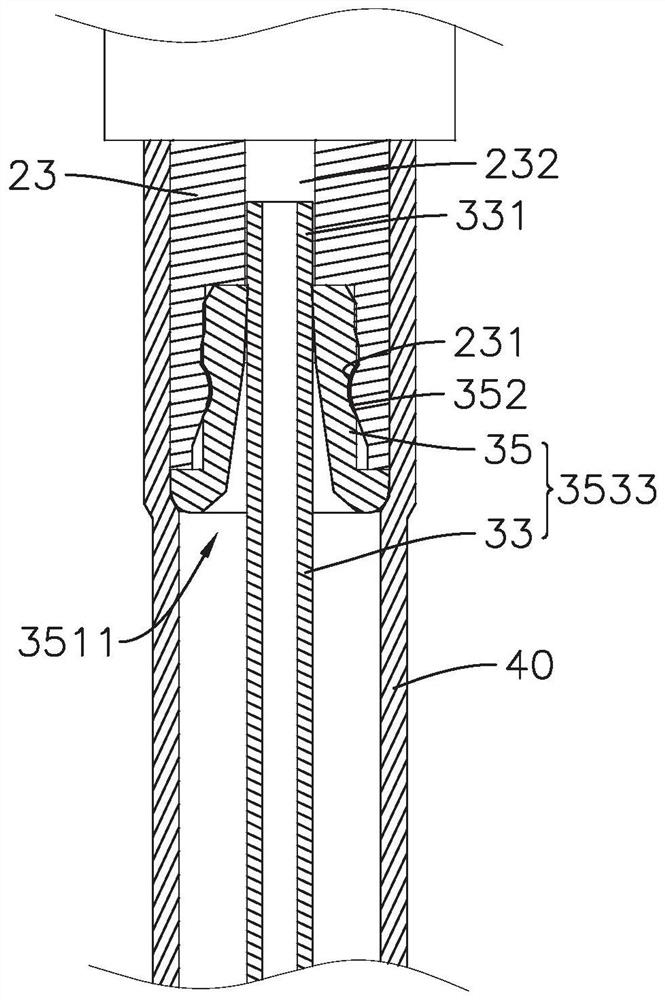

[0055] see figure 1 As shown, the first embodiment of the high-pressure spray tank of the present invention includes a tank body 10 , a valve assembly 20 , a suction pipe assembly 30 and a hard tube 40 .

[0056] The aforementioned tank body 10 is a hollow body and has an installation opening, and the installation opening is preferably a crimp opening; in this embodiment, the preferred material of the tank body 10 is metal, and the crimp opening is located at the tank body 10 In this embodiment, the bottom of the tank body 10 has an arc-shaped bottom wall 11, and the bottom wall 11 is recessed toward the inner space 12 of the tank body 10, so that the tank body 10 can pass through the bottom wall 11 Stand upright on the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com