A kind of production method of sticky cloth

A production method and technology for sticking cloth, applied in the field of cleaning products, can solve the problems of increased cost, poor ash absorption performance, inability to clean and wipe very effectively, and achieve the effects of enhancing adsorption capacity, convenient use, and improving the quality of glue spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

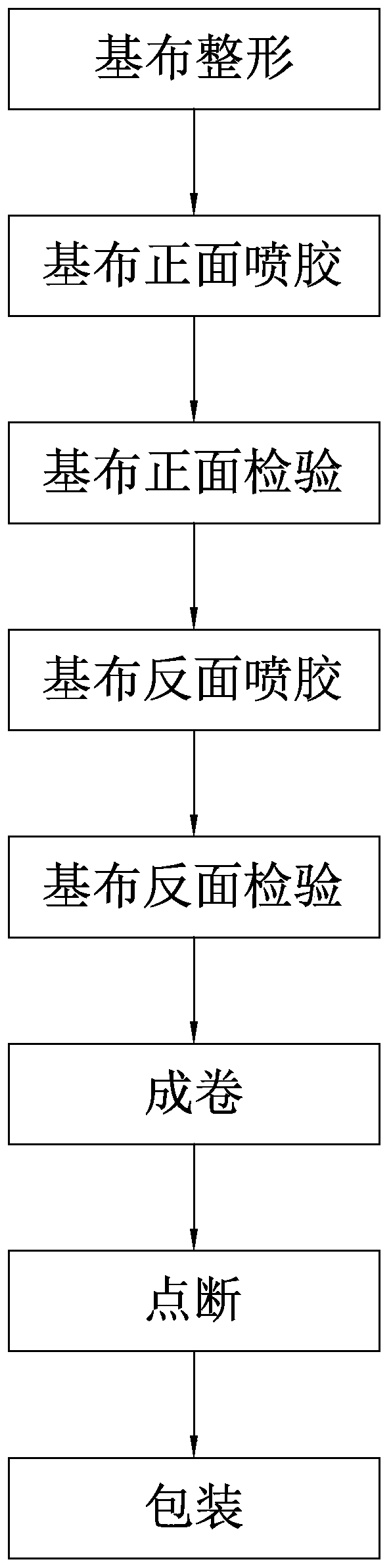

[0042] Such as Figure 1 to Figure 6 Shown, be a kind of production method of sticky cloth of the present invention, comprise the steps:

[0043] a. Base cloth shaping:

[0044] Put the base cloth on the frame, straighten the base cloth through the rollers to ensure that the base cloth is flat and free of wrinkles and deformation, and then control the rotation speed of the rollers by adjusting the speed of the electric motor.

[0045] b. Spray glue on the front of the base fabric:

[0046] Preheat the glue in the hot melt machine first, heat the glue in the hot melt machine to 150°C, and then heat the temperature of each nozzle to 160°C to ensure that the glue changes from solid to liquid.

[0047] Then spray glue on the front of the base cloth through the nozzles of the first group of glue spraying equipment, and each group of glue spraying equipment is provided with 14 nozzles. The amount of glue sprayed is controlled by the solenoid valve switch, and the amount of glue s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com