Bagged cement loading system

A cement and crane technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of reducing the loading efficiency, troubles in the loading process, reducing the vehicle load, etc., so as to improve the loading efficiency and reduce the movement of equipment. The effect of connecting points, reducing equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

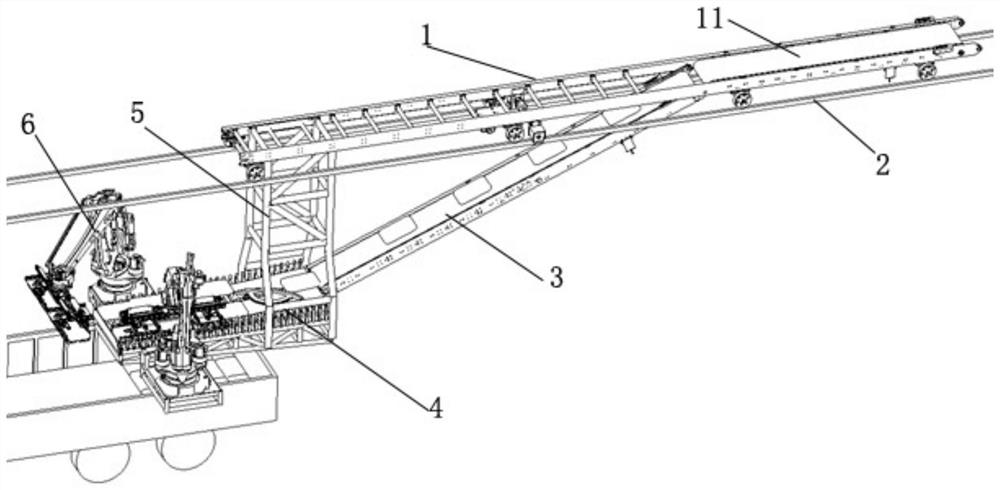

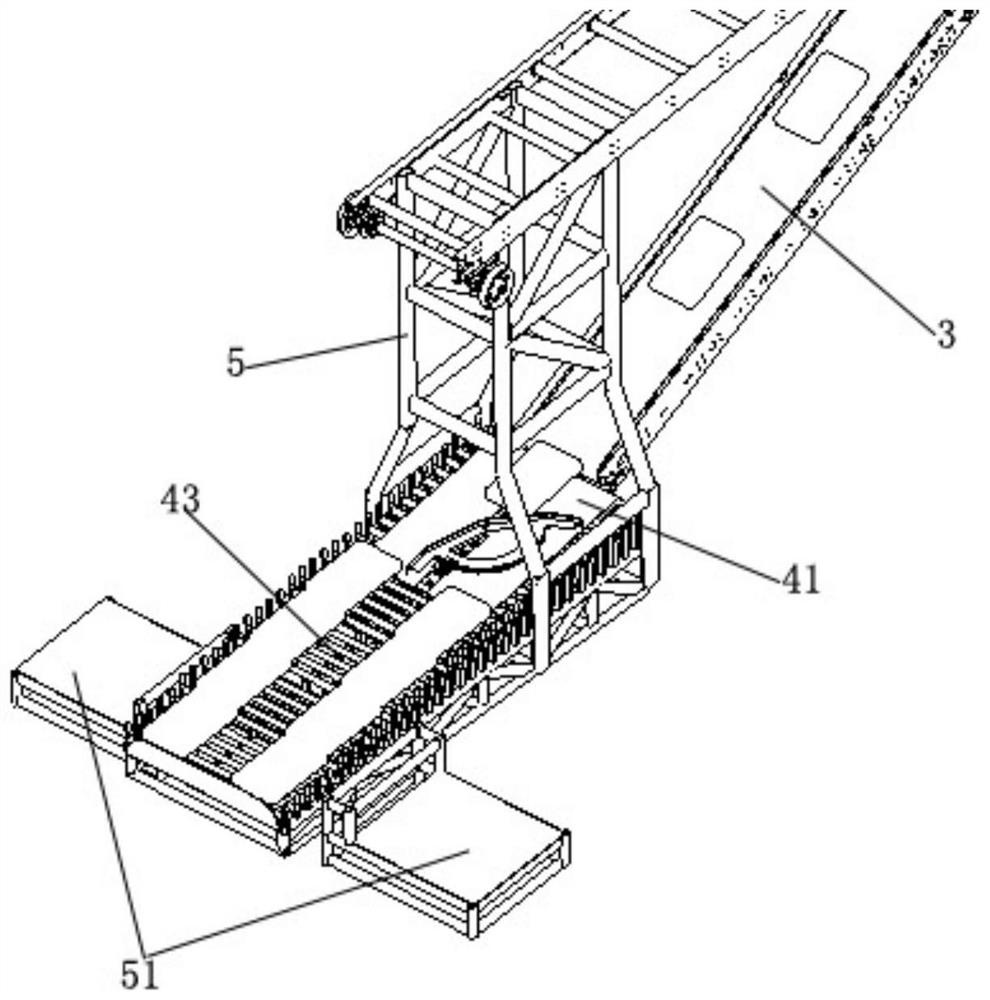

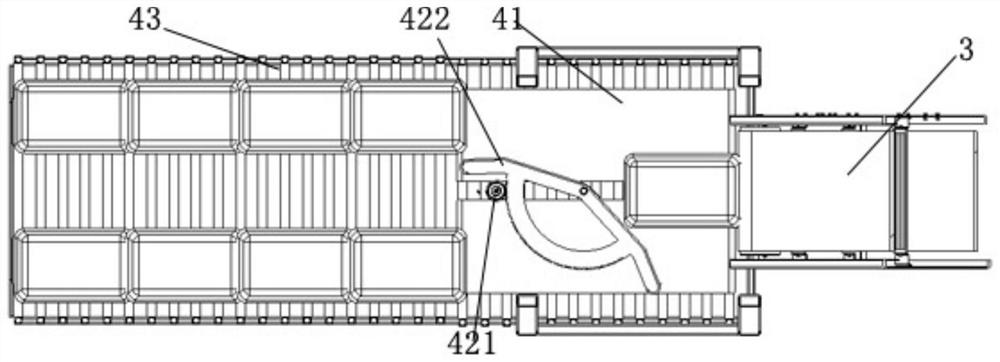

[0030] see figure 1 and figure 2 , A bagged cement loading system provided by the present invention is composed of a conveying crane 1, a track 2, an inclined belt conveyor 3, a subpackaging and stacking device 4, a load-bearing frame 5, and a stacking robot 6. Conveying crane 1 is made up of wheel, vehicle frame and horizontal belt conveyor 11, and wheel is equipped with on the lower end surface of vehicle frame, and wheel rolls on track 2, and track 2 is fixed on the factory building top. The lower side of the left end of the vehicle frame is fixedly connected with the load-bearing frame 5 upper ends, the right end of the vehicle frame is equipped with a horizontal belt conveyor 11, the left end of the horizontal belt conveyor 11 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com