A distributed grouting system for cast-in-place piles

A grouting system and distributed technology, applied in the field of post grouting of pile foundations, can solve the problems of inability to ensure the uniform distribution of grouting on the pile side, the inability to achieve differentiated grouting construction, and the inability to grouting the soil body on the pile side, etc. Achieve the effect of improving grouting construction efficiency, facilitating on-site engineering construction and reducing construction investment

Active Publication Date: 2022-06-03

南京东土建设科技有限公司 +1

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Pile foundation post-grouting is an important method to deal with the problems of sediment and hole wall softening caused by the construction of cast-in-place piles. A large number of engineering practices have been carried out, but there are still some problems in the current application technology: pile end grouting of pile foundation and pile Side grouting generally requires a separate grouting pipe, which leads to complex grouting pipelines in the reinforcement cage; pile side grouting is realized by pressing the grout into the top of the grouting pipe, and it is impossible to accurately grout the pile side soil at a certain depth. Moreover, the current method cannot ensure that the pile side grouting is evenly distributed along the pile length, let alone realize the controllable differential grouting construction; grouting pipes and grouting heads are customized according to the pile foundation, which involves complex on-site construction and affects the project schedule

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

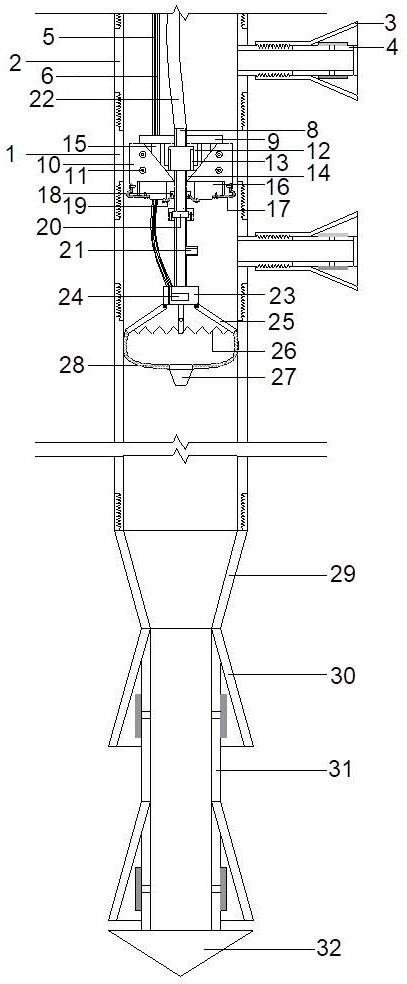

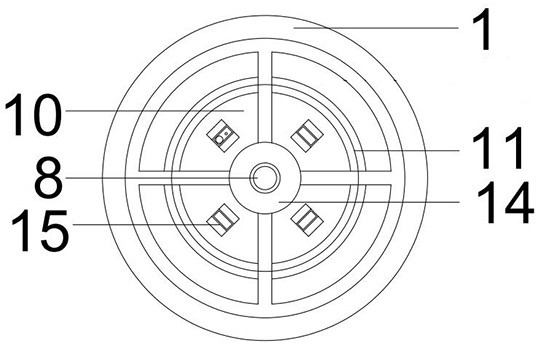

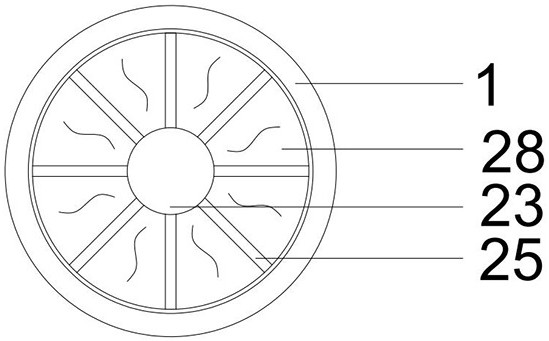

[0020] The technical solutions of the present invention are further explained below in conjunction with the accompanying drawings.

[0024] The grouting operation head of the present invention comprises: a middle pipe 8, an upper locking section, a lower locking section, a one-way valve 20, a slurry input pipe 22,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a distributed grouting system for cast-in-place piles, and relates to the technical field of post-grouting for pile foundations. The distributed grouting system for cast-in-place piles includes: a grouting pipe, a tee pipe, a side grouting head, an adapter, a lower grouting head, and a grouting operation head; one end of the adapter and the bottom of the grouting pipe are threaded connection, the other end of the adapter is threadedly connected with the lower grouting head, the grouting pipe is threaded with the side grouting head through a three-way pipe, and the grouting operation head is set in the grouting pipe. The grouting operation head is provided with a side grouting port. The distributed grouting system for cast-in-place piles of the present invention is suitable for grouting construction after bored piles, and realizes the reinforcement treatment of pile ends and pile side soils at different depths at the same time in one grouting pipe, combined with the lifting and lowering of the grouting head It can effectively improve the uniformity of grouting at different positions of the pile foundation and carry out differentiated grouting at different depths, which can significantly improve the bearing capacity of the pile foundation.

Description

A distributed grouting system for cast-in-place piles technical field [0001] The present invention relates to the technical field of post grouting of pile foundations, in particular to a distributed grouting system for cast-in-place piles. Background technique [0002] The pile foundation is a widely used deep foundation, which has the characteristics of high bearing capacity and low deformation compared to the shallow foundation. pile There are various types of foundations, which can be divided into bored piles and driven piles according to the construction method. Among them, the bored piles can be constructed in different forms. It is widely used in large-scale building foundations to form large-diameter, long-pile-length and other large-scale pile foundations. For large diameter long cast-in-place piles, pile foundation construction It will inevitably have some adverse effects, such as hole bottom sediment, hole wall softening and other phenomena, which will greatl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E02D15/04E02D5/34

CPCE02D15/04E02D5/34E02D2250/003Y02E10/10

Inventor 陈祉阳朱建民靳朋刘陈新奎周传金纯孙信锁尹恒龙魏成季万明常娇龙

Owner 南京东土建设科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com