High-efficiency filter element of water purification equipment and preparation method of high-efficiency filter element

A water purification equipment and high-efficiency technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of short replacement cycle of the second-stage filter element and third-stage filter element, high use cost of water purification equipment, Water purification equipment cannot be accepted by consumers, etc., to achieve the effect of improving water filtration efficiency, complete and sufficient modification treatment, and good spray uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

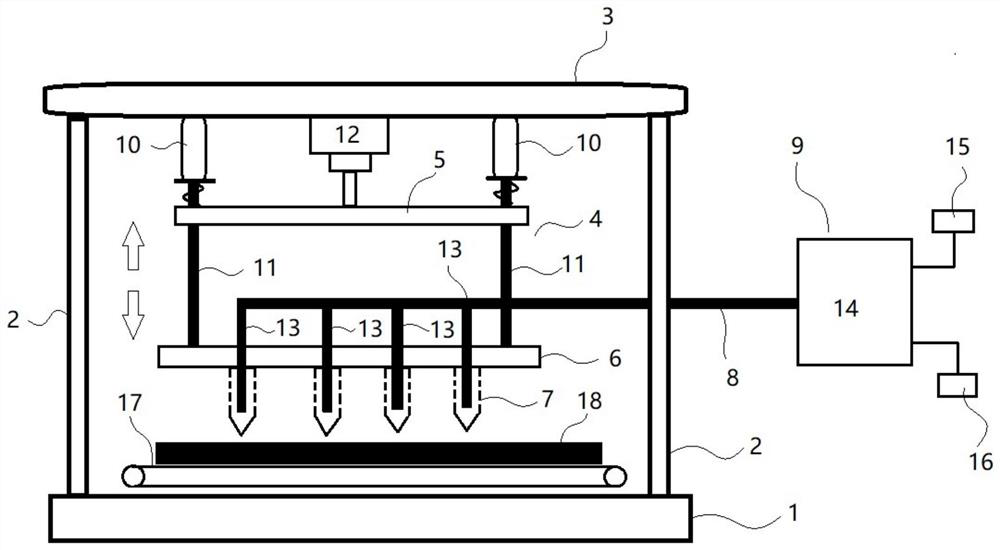

[0030] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific figures.

[0031] A preparation method of a high-efficiency filter element for water purification equipment, comprising the following steps:

[0032] 1) The polymer is used to form an initial melt-blown fiber web through a melt-blown process, the temperature of the cooling airflow is increased during the preparation of the initial melt-blown fiber web, and the melt-blown primary fibers are insufficiently cooled to obtain an initial melt-blown fiber web with a surface maintaining melt-adhesiveness. Spray fiber mesh.

[0033] In the prior art, under normal circumstances, in the preparation process of the melt-blown nonwoven fiber web, it is necessary to sufficiently cool the spun fibers from melt spinning to rapidly solidify them into a fiber form and form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com