Durable filter element of water purification equipment and preparation method of durable filter element

A kind of water purification equipment and durable technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of short replacement cycle of the second-stage filter element and the third-stage filter element, high cost of water purification equipment, and clean Water equipment can not be accepted by consumers and other problems, to achieve the effect of improving water source filtration efficiency, complete and sufficient modification treatment, and good spraying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

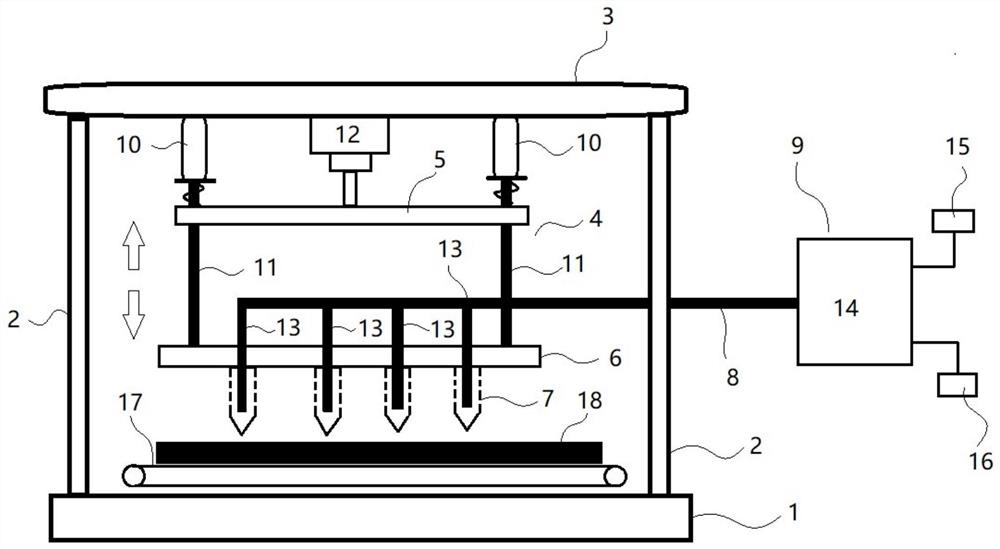

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0031] A method for preparing a durable filter element for water purification equipment, comprising the following steps:

[0032] 1) Polymer melt spinning is used to form the initial spunbond fiber web, and the general spunbond preparation equipment in the prior art can be used to carry out the processing of this step. The type of polymer used in the present invention includes but is not limited to: polyparaphenylene Diformic acid oxalic acid, polyamide 6, polyamide 66, polyacrylonitrile, polypropylene, polyethylene, cellulose diacetate, cellulose triacetate, viscose, cellulose, polyvinyl alcohol, polyvinyl chloride, polycaprolactam , the number average relative molecular mass of the polymer used in the present invention is 16000-300000;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com