Highway engineering thickness detection equipment

A technology of thickness detection and engineering, which is applied in the field of thickness detection equipment for highway engineering, can solve problems such as broken cameras, gravel residues are easy to fall and pollute, and affect the clarity of camera shooting, so as to reduce impact deformation damage and ensure shrinkage reset efficiency , the effect of improving clarity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

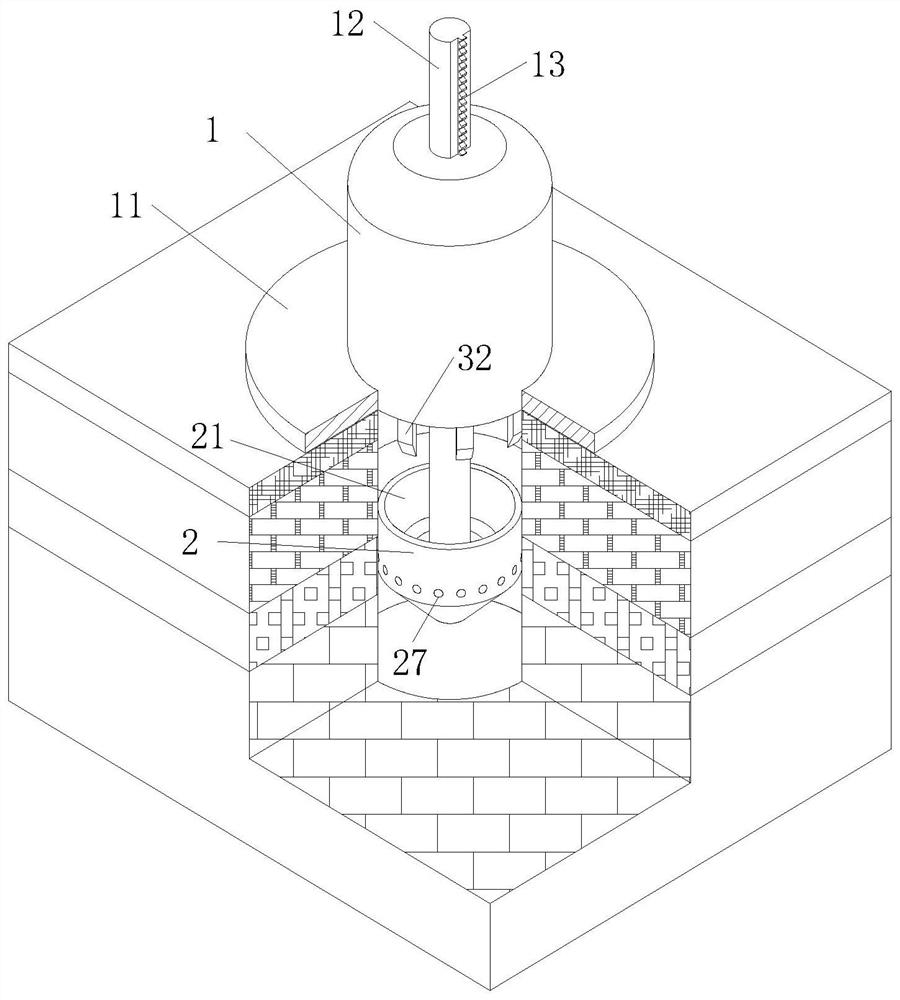

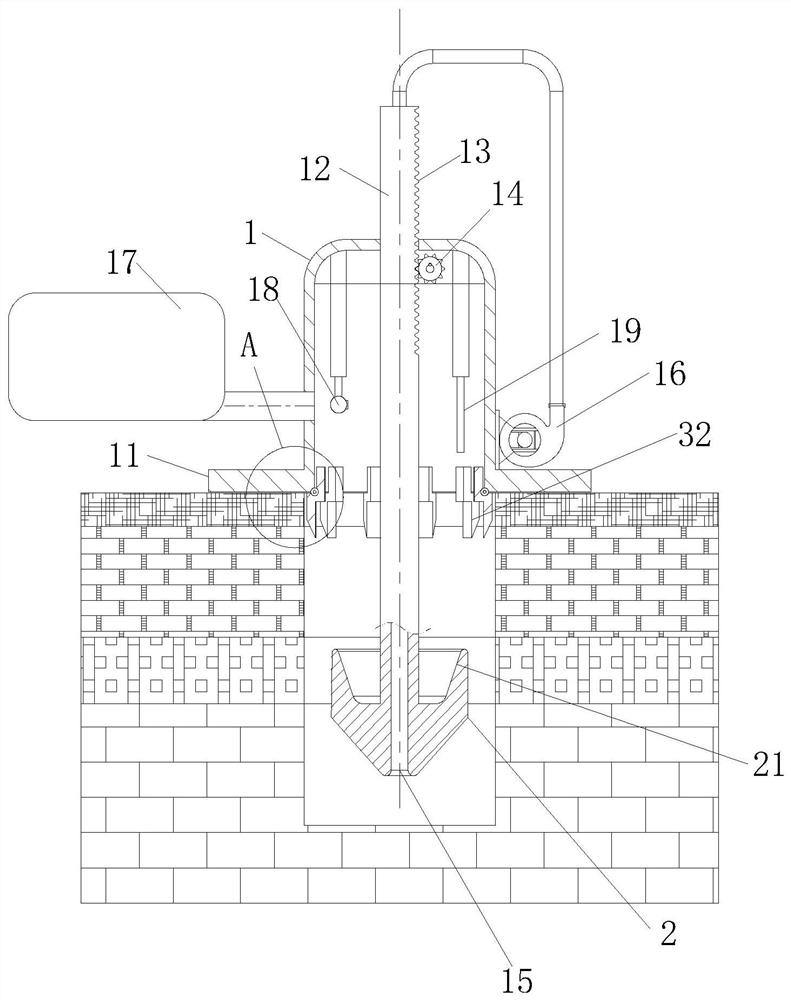

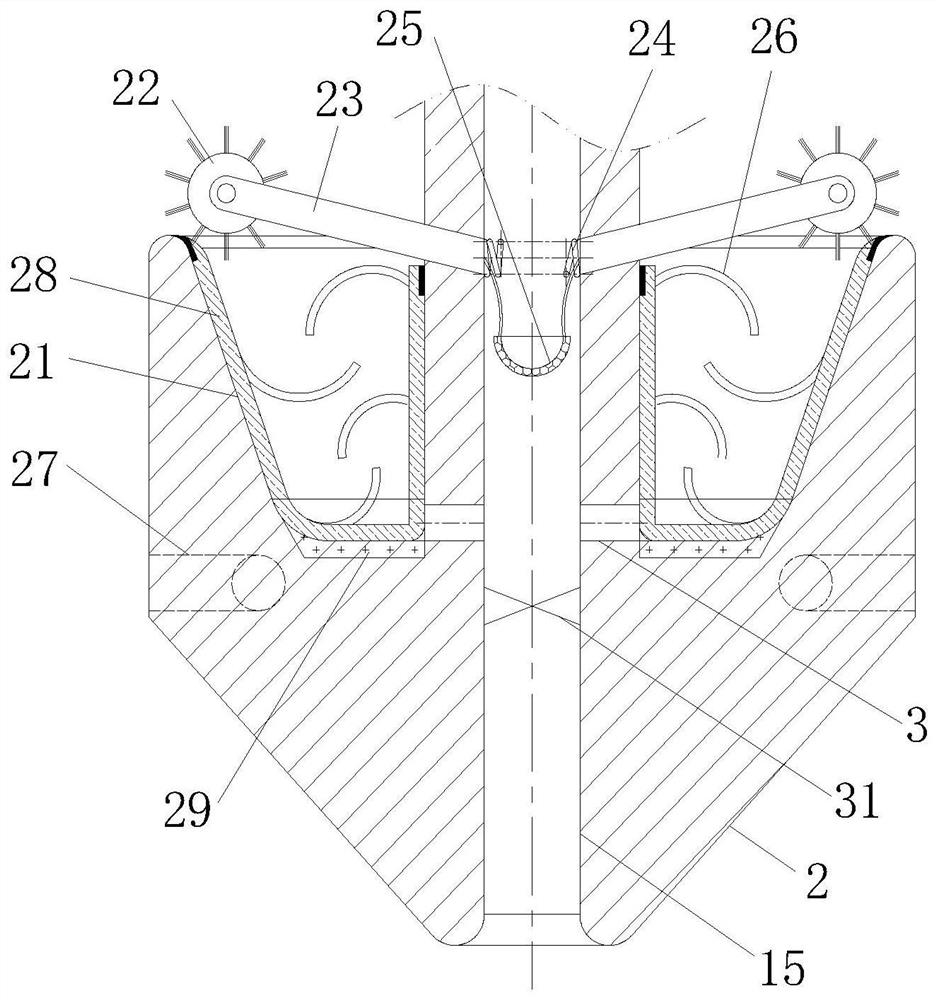

[0029] Such as Figure 1 to Figure 4 As shown, a thickness detection device for highway engineering according to the present invention includes a body 1 and a pressure plate 11; a vertical rod 12 is slidably connected to the body 1, and a rack 13 is provided on one side of the vertical rod 12, and a rack 13 is provided in the body 1 A gear 14 is rotationally connected to the corresponding position of the rack 13, and the gear 14 is driven to rotate by a motor; the pole 12 is provided with a No. 1 hole 15 that runs through the pole 12. The air blower 16 communicates; the side of the body 1 communicates with a dust bag 17 through an exhaust pipe; the body 1 is respectively fixedly connected with a camera 18 and a scale 19 through a pair of symmetrically arranged electric push rods; The telescopic mechanism drives the camera 18 to be inserted into the detection hole to take pictures and read the data of the scale 19 inserted into the detection hole, and then compare the data of t...

Embodiment 2

[0038] Such as Figure 5 As shown in Comparative Example 1, another embodiment of the present invention is: the side of the elastic rod 36 close to the elastic ring 38 is slidably connected with a shunt ring 4, the cross section of the shunt ring 4 is herringbone, and the shunt ring 4 There is a sealing groove on the inner periphery, and a damping ring 41 with an inner diameter slightly smaller than the elastic rod 36 is set inside the sealing groove; through the damping ring 41 and the diverter ring 4, the airflow ejected from the elastic ring 38 is evenly dispersed to further improve the compressed air flow rate. Clean up the efficiency of the rotating groove 34.

[0039] A group of C-shaped pieces 42 are evenly distributed on the side of the shunt ring 4 close to the elastic ring 38, and one end of the C-shaped piece 42 near the elastic rod 36 is embedded in the shunt ring 4, and the other end is suspended in the air; the free end of the C-shaped piece 42 The inner side is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com