Support of insulated drainage wire for live-line equipment maintenance operation

A live equipment and drainage wire technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of long time-consuming shielding process, potential safety hazards, and loose shielding, so as to achieve good fixing effect, prevent insufficient safety distance, and reliable support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

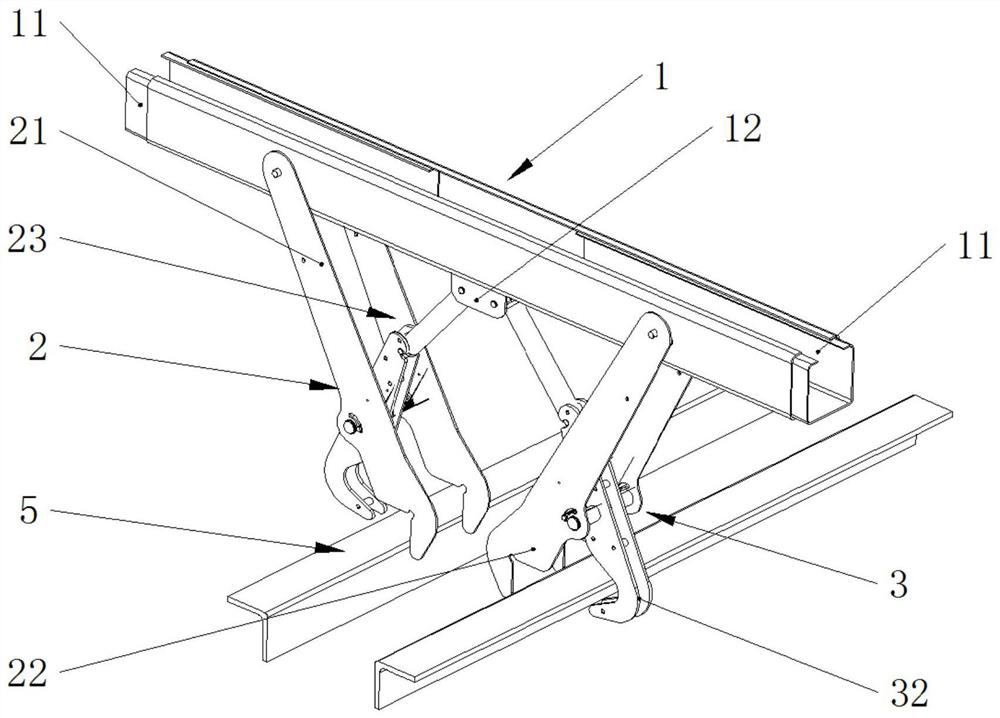

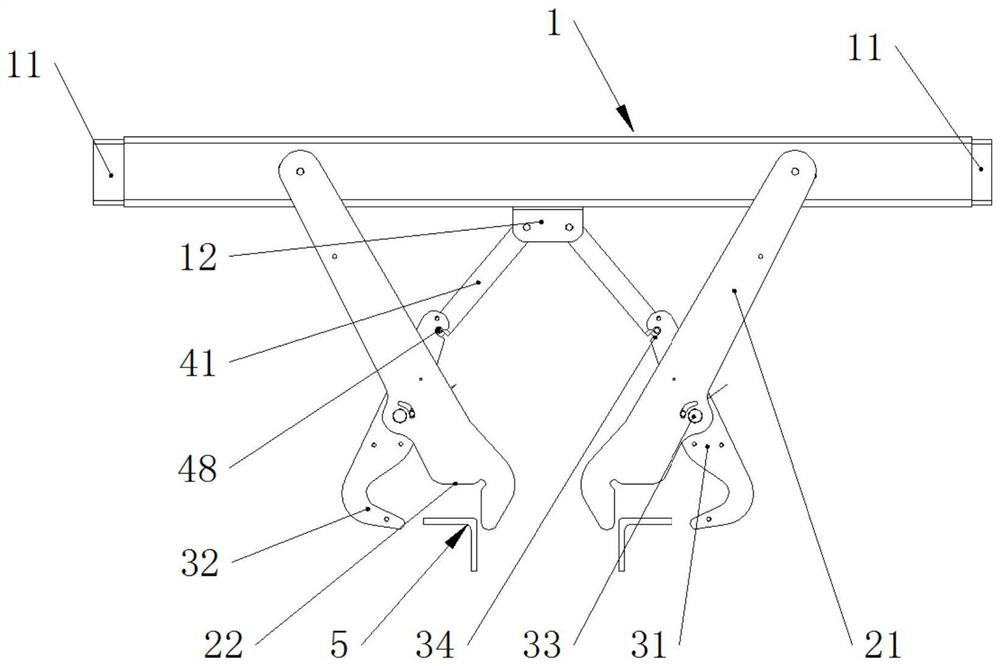

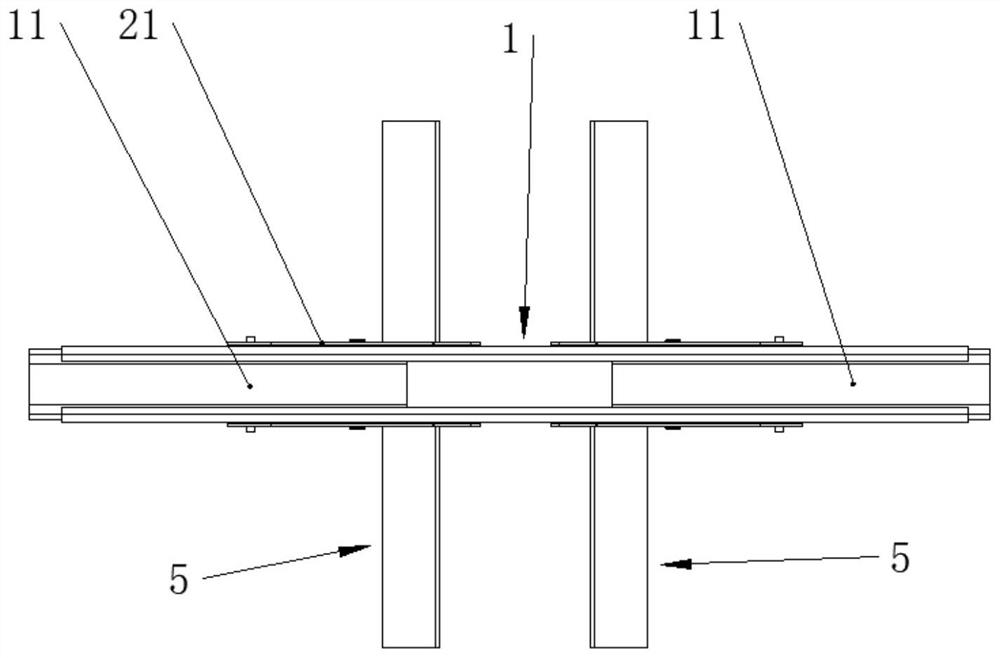

[0043] see Figure 1-8, a bracket for insulated drain wires for maintenance work on live equipment, comprising a horizontal main trunking 1 and a support frame with two upper ends hinged on the main trunking 1; the upper end of the main trunking 1 is set open; the middle part of the lower end of the main trunking 1 is fixed with a shaft seat 12. The two supporting frames are respectively mirror-symmetrically arranged on both sides of the shaft seat 12 along the length direction of the main trunking 1; the supporting frame includes a leg 2 and an adjustment mechanism 23 cross-hinged with the leg 2 in an "X" shape; the upper end of the leg 2 is connected to the main trunking 1 is hinged, and the lower part is provided with a limit groove 22 that can fit the outer circumference of the cross arm 5; the adjustment mechanism 23 includes a buckle 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com