A kind of ferromagnetic metal material and its preparation method and application

A ferromagnetic metal, press forming technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of weak electronic transition, low temperature of ferromagnetic long program, limited application, etc., and achieve good magnetic anisotropy characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

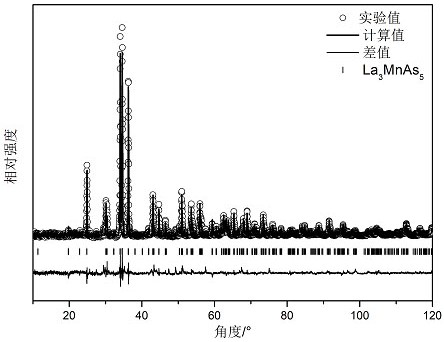

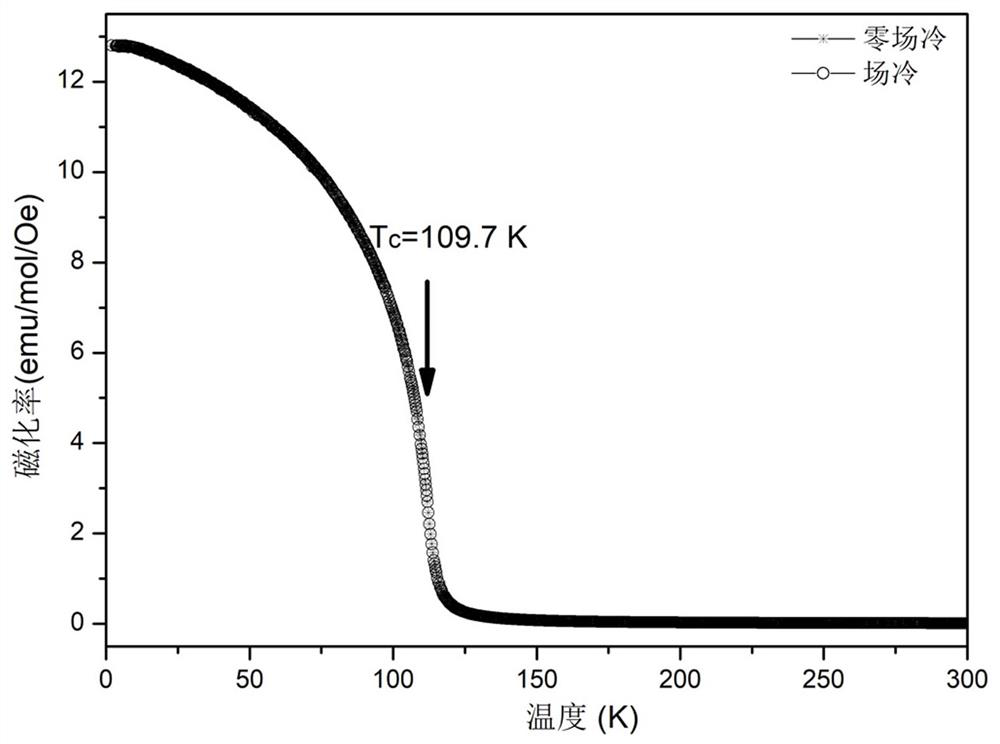

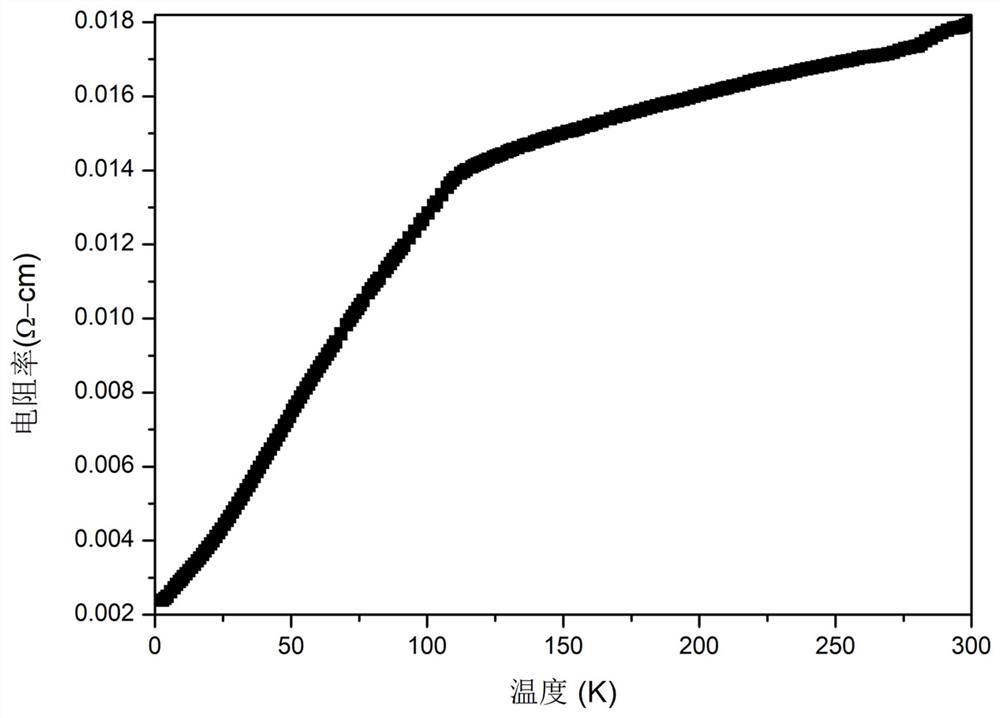

[0025] Using high-purity La powder, Mn powder and As powder as raw materials, accurately weigh the three according to the La:Mn:As molar ratio of 3:1:5, and fully and uniformly grind and mix to obtain a mixture, and use a mold to grind and mix the obtained The mixture was pressed into a cylinder with a diameter of 6 mm and a height of 3 mm under a tablet press, and then the obtained cylinder was put into a high-pressure synthesis assembly block, and sintered under high temperature and high pressure at a pressure of 5 GPa and a temperature of 1300 ° C. The sintering time was After 0.5h, the sintered product was naturally cooled to room temperature to obtain ferromagnetic metal material A.

Embodiment 2

[0027] Using high-purity La powder, Mn powder and As powder as raw materials, accurately weigh the three according to the La:Mn:As molar ratio of 3:1:5, and fully and uniformly grind and mix to obtain a mixture, and use a mold to mix the uniform powder in the Press the tablet machine into a cylinder with a diameter of 6 mm and a height of 3 mm, then put the obtained cylinder into a high-pressure synthesis assembly block, and perform high-temperature and high-pressure sintering at a pressure of 4 GPa and a temperature of 1200 ° C. The sintering time is 1 hour, and the sintered product is natural. Ferromagnetic metal material B was obtained after cooling to room temperature.

Embodiment 3

[0029] Using high-purity La powder, Mn powder and As powder as raw materials, accurately weigh the three according to the La:Mn:As molar ratio of 3:1:5, and fully and uniformly grind and mix to obtain a mixture, and use a mold to mix the uniform powder in the Press the tablet machine into a cylinder with a diameter of 6 mm and a height of 3 mm, and then put the obtained cylinder into a high-pressure synthesis assembly block, and perform high-temperature and high-pressure sintering at a pressure of 6 GPa and a temperature of 1400 ° C. The sintering time is 0.5 h. The sintered product Ferromagnetic metal material C was obtained after natural cooling to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com