A steel plate elasticity detection device

A technology of elasticity detection and steel plate, applied in the direction of measuring device, elasticity test, mechanical component test, etc., it can solve the problems of force change of steel plate, affecting the accuracy of test results, and surface wear of steel plate, so as to ensure stable force, The effect of improving the degree of automation, sensitivity, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

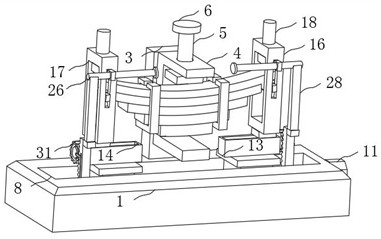

[0034] refer to Figure 1-4 , a steel plate elasticity detection device, including a workbench 1 and a steel plate detection piece 2, a clamping mechanism that matches the steel plate detection piece 2 is installed on the workbench 1.

[0035] Of note above are:

[0036] 1. The clamping mechanism consists of a support rod 3, a clamp seat 4, a threaded rod 5, a turntable 6 and a splint 7. The support rod 3 is fixedly installed on the workbench 1, the clamp seat 4 is fixedly installed on the support rod 3, and the threaded rod 5 Threaded on the upper end of the clamp seat 4, the turntable 6 is fixedly installed on the upper end of the threaded rod 5, the splint 7 is rotatably connected to the lower end of the threaded rod 5, and the splint 7 is located in the clamp seat 4, when the steel plate detection part 2 is elastically tested, its The center position is placed in the clamp seat 4, and then the turntable 6 is turned to drive the splint 7 down through the threaded connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com