Combined riveting test clamp easy to rivet and disassemble

A test fixture and combined technology, applied in the field of machinery, can solve the problems of low efficiency, poor riveting test stability and high labor intensity, and achieve the effects of improving test efficiency, improving stability and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation, structure, features and effects of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0029] Purpose of the present invention and its main technical problem of solving are to adopt following technical scheme to realize:

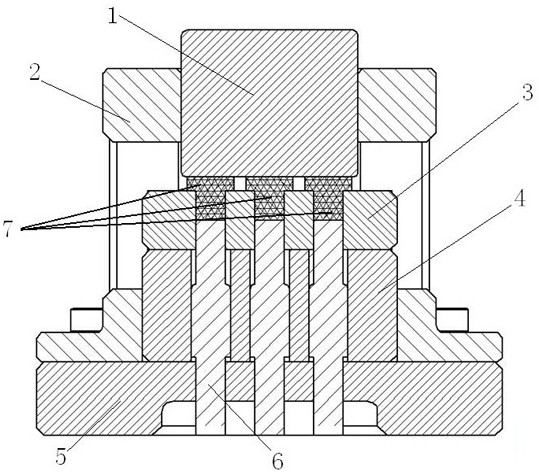

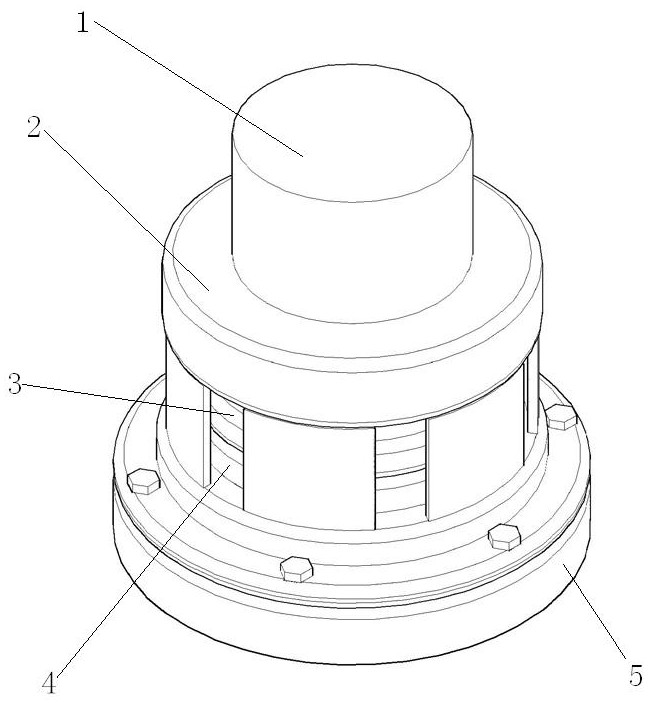

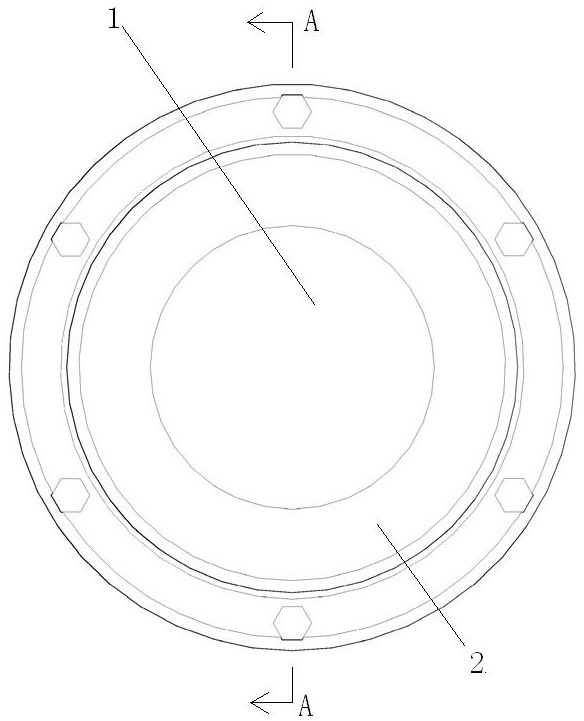

[0030] A combined easy-riveting and easy-to-disassemble riveting test fixture of the present invention is characterized in that: the pressure block 1 is inserted into the upper end of the jacket 2, and the lower end of the jacket 2 is connected to the base 5 through bolts, and the inner core 4 is placed on the base 5, and the inner core The lower end of 4 is inserted into the inner lower end of the jacket 2, the middle parts of several ejector rods 6 are respectively inserted into the inner core 4, and the two ends of the inner core 4 are respectively inserted into the riveting plate 3 and the base 5.

[0031] Several rectangular observation throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com