Pencil sharpener capable of cutting different shapes and different sizes of pen points

A technique for pencil sharpeners and cutting knives, applied in sharpening devices, printing, office supplies, etc., can solve problems such as low work efficiency, children's injuries, and pencil sharpeners that cannot meet the requirements, and achieve a simple structure, low cost, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

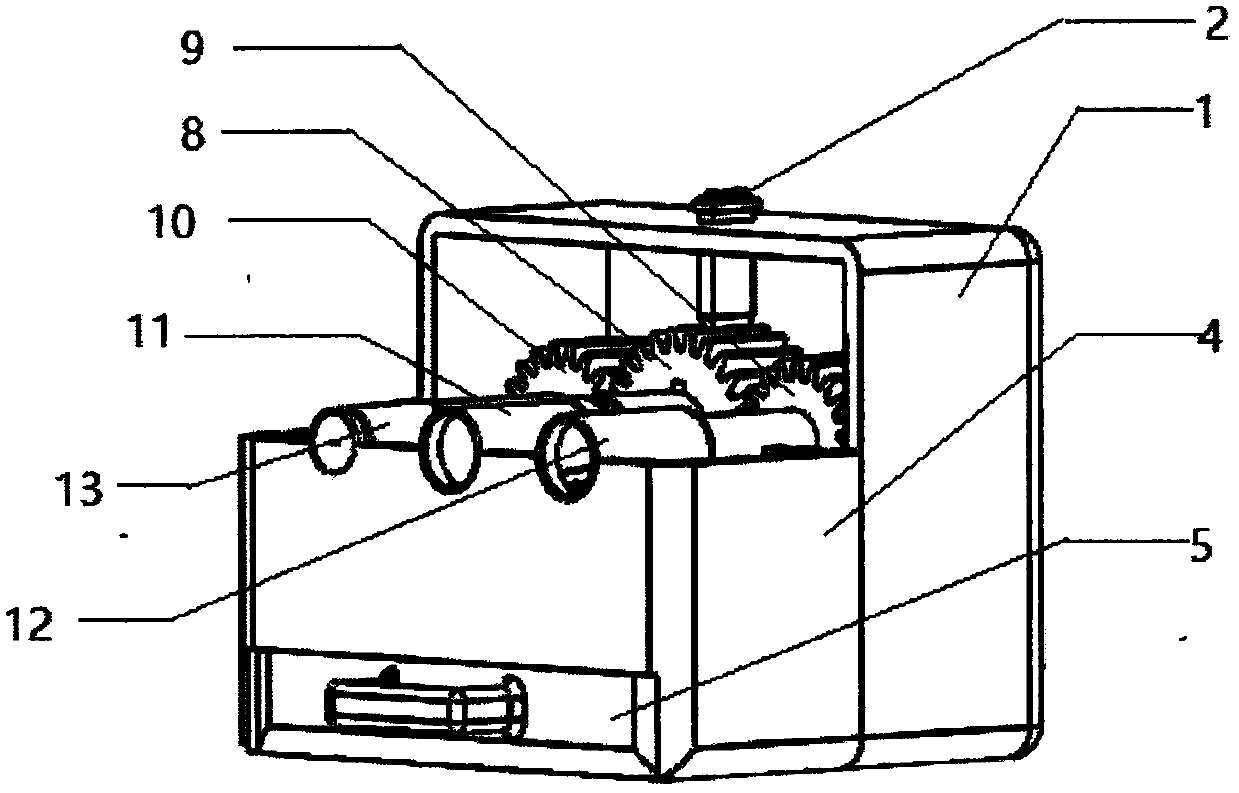

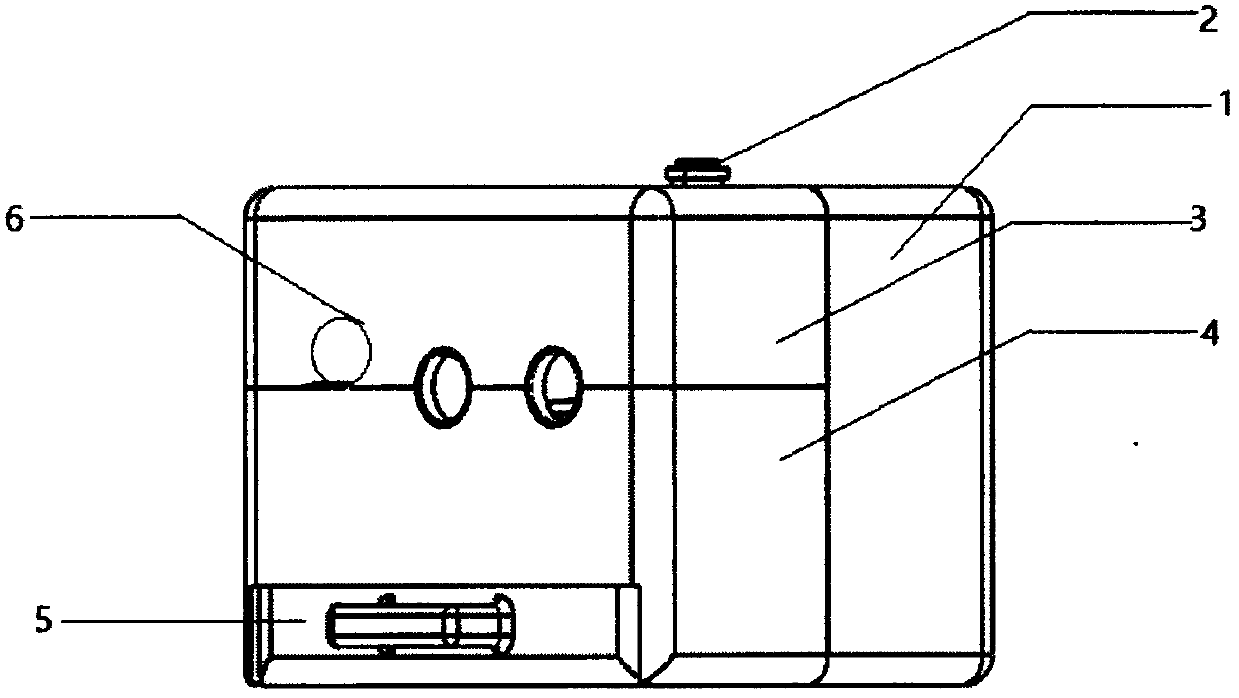

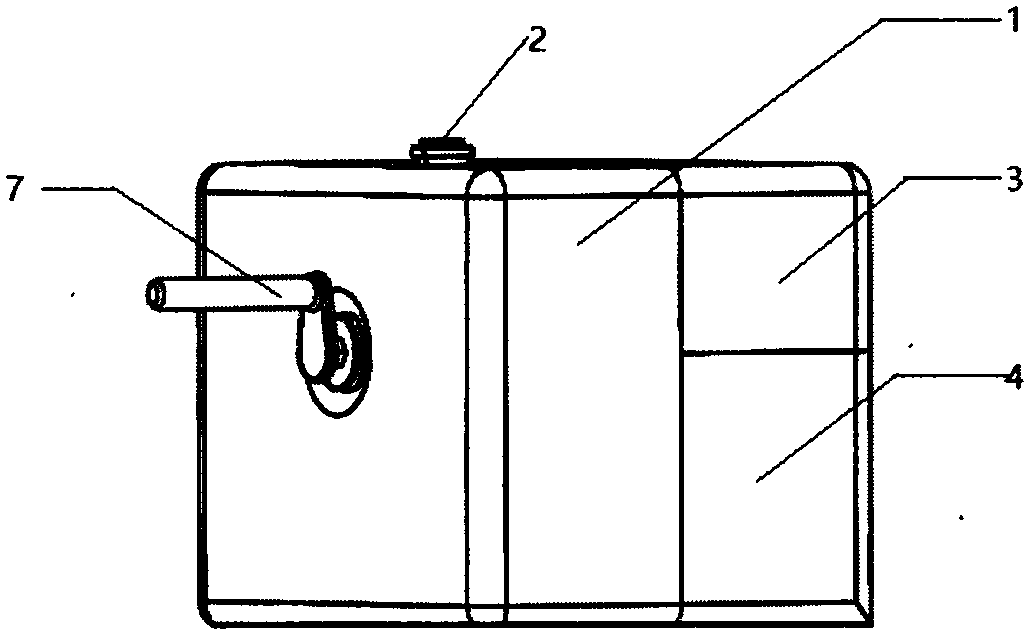

[0030] Such as Figure 1 to Figure 7 As shown, the pencil sharpener capable of cutting nibs of different shapes according to the present invention includes: a housing 1, a manual locking device 2, a transparent upper cover 3, a collecting base 4, a collecting drawer 5, a rolling bearing 6, a shaking handle 7, an active Gear shaft 8 , first driven gear shaft 9 , second driven gear shaft 10 , short cutting blade 11 , long cutting blade 12 , grinding blade 13 and filter screen 14 .

[0031] The specific structure and connection relationship are:

[0032] The housing 1, the transparent upper cover 3 and the collection base 4 are connected by bolts for easy disassembly. The manual locking device 2 is placed on the upper part of the housing 1 to lock the transmission structure by moving up and down. The collection base 4 is provided with a collection drawer 5 and The filter screen 14, the filter screen 14 is obliquely fixed in the collection base 4, the driving gear shaft 8 is resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com