Intelligent food safety detection analyzer

A food safety and analyzer technology, applied in the field of food analyzers, can solve problems such as difficult removal of cuvettes, and achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] see Figure 1-Figure 6 , the present invention provides a technical solution for an intelligent food safety detection analyzer:

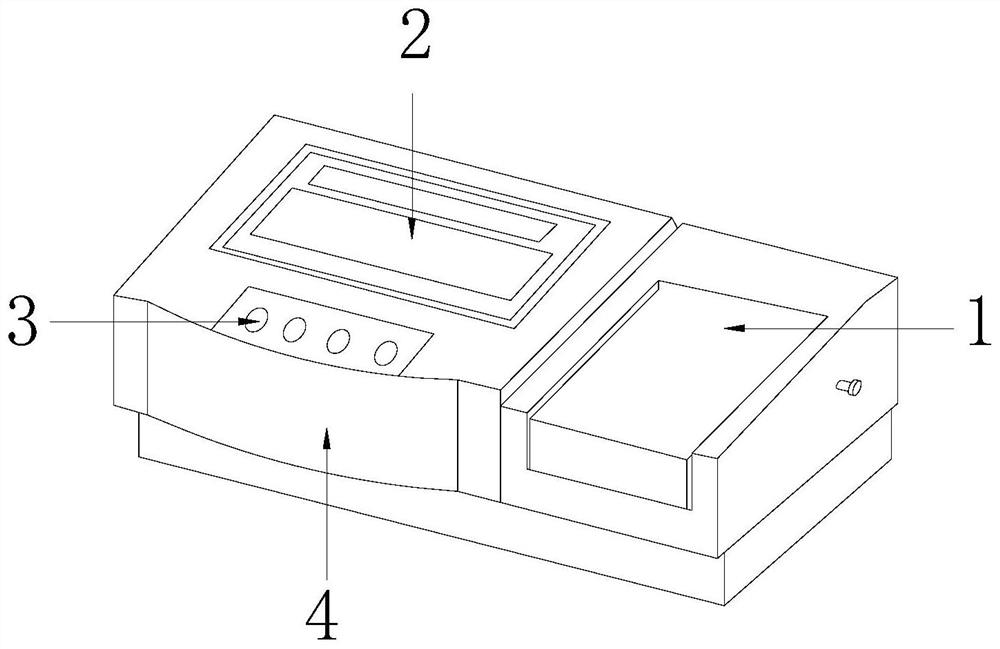

[0029] Such as figure 1 As shown, a kind of intelligent food safety detection analyzer, its structure comprises: detection module 1, display panel 2, control button 3, analyzer body 4, described detection module 1 is arranged on the right side of analyzer body 4 and through button The display panel 2 is fixed on the surface of the analyzer body 4 and connected by nesting, and the control button 3 is installed inside the analyzer body 4 and connected by nesting.

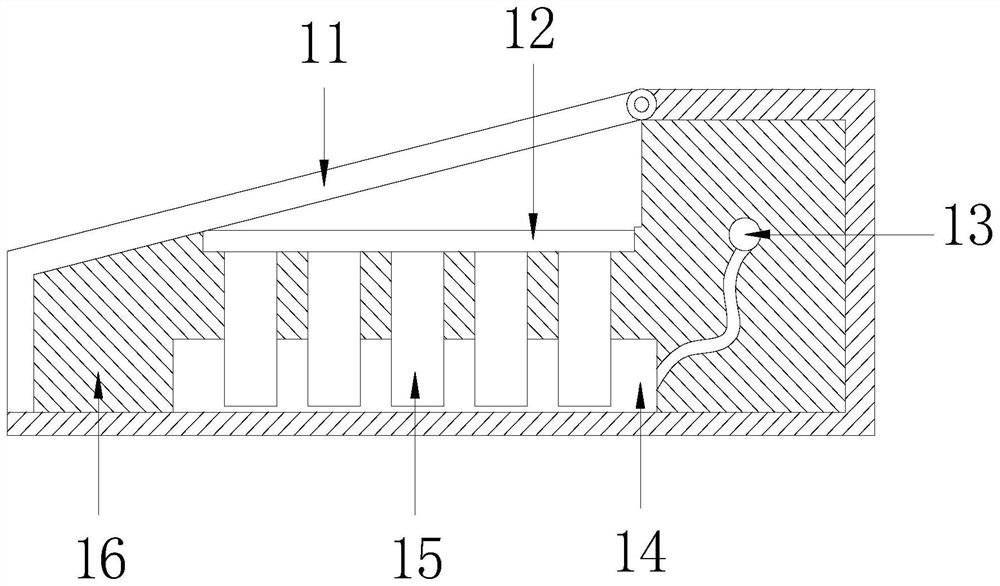

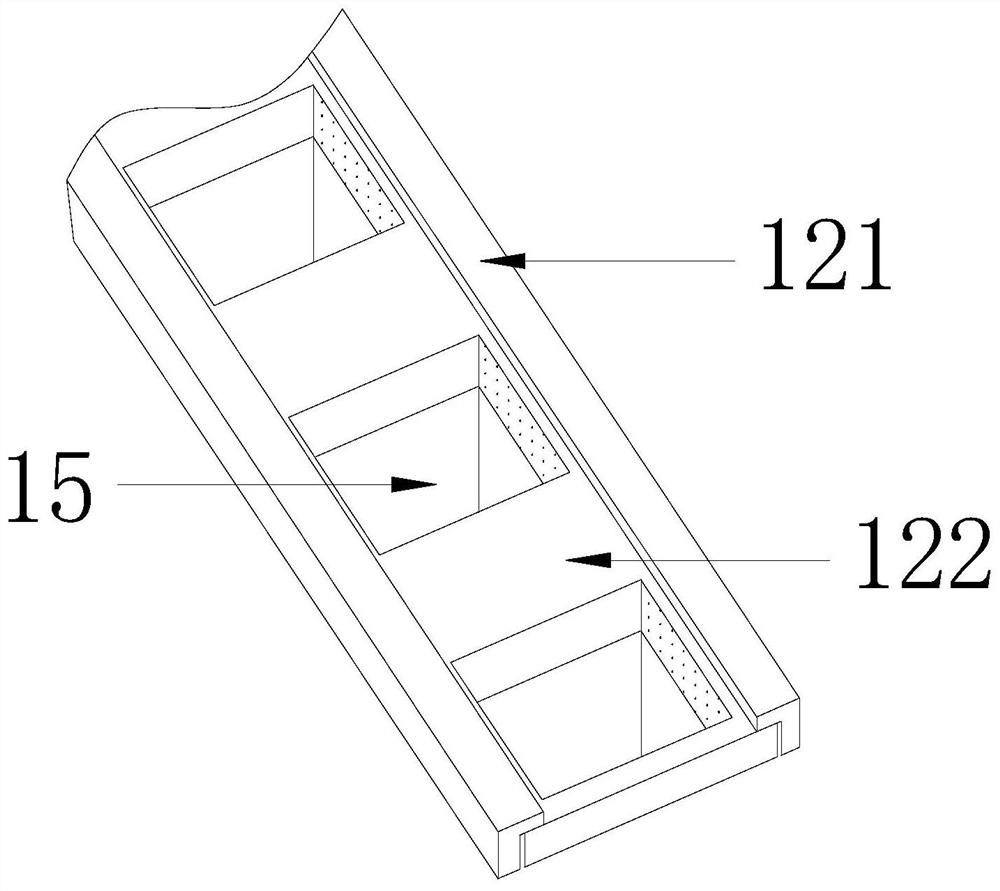

[0030] Such as figure 2 As shown, the detection module 1 includes a protective cover 11, a wiper block 12, an activation rod 13, a lifting mechanism 14, a detection slot 15, and a housing 16. The protective cover 11 is in an inclined structure and passes through the top of the housing 16. Bolts are connected, the wiper block 12 is installed inside the housing 16 and connected by...

Embodiment 2

[0033] see Figure 1-Figure 6 , the present invention provides a technical solution for an intelligent food safety detection analyzer:

[0034] Such as figure 1 As shown, a kind of intelligent food safety detection analyzer, its structure comprises: detection module 1, display panel 2, control button 3, analyzer body 4, described detection module 1 is arranged on the right side of analyzer body 4 and through button The display panel 2 is fixed on the surface of the analyzer body 4 and connected by nesting, and the control button 3 is installed inside the analyzer body 4 and connected by nesting.

[0035] Such as figure 2 As shown, the detection module 1 includes a protective cover 11, a wiper block 12, an activation rod 13, a lifting mechanism 14, a detection slot 15, and a housing 16. The protective cover 11 is in an inclined structure and passes through the top of the housing 16. Bolts are connected, the wiper block 12 is installed inside the housing 16 and connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com