Current sharing control device of DC/DC power supply module

A DC power supply and control device technology, which is applied in the direction of electrical components, support structure installation, and electrical equipment structural parts, etc., can solve problems such as damage to internal circuits, dust ingress, poor device sealing, etc., to achieve less electrical components, energy saving, little effect on stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

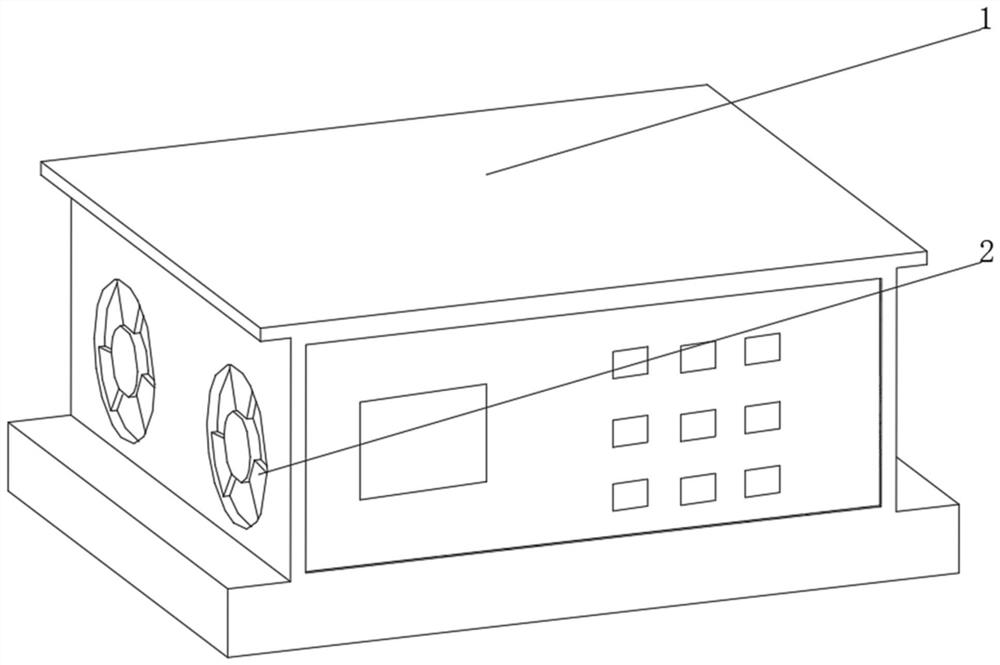

[0037] see Figure 1-3 , the present invention provides a technical solution: a current sharing control device for a DC / DC power module, specifically comprising:

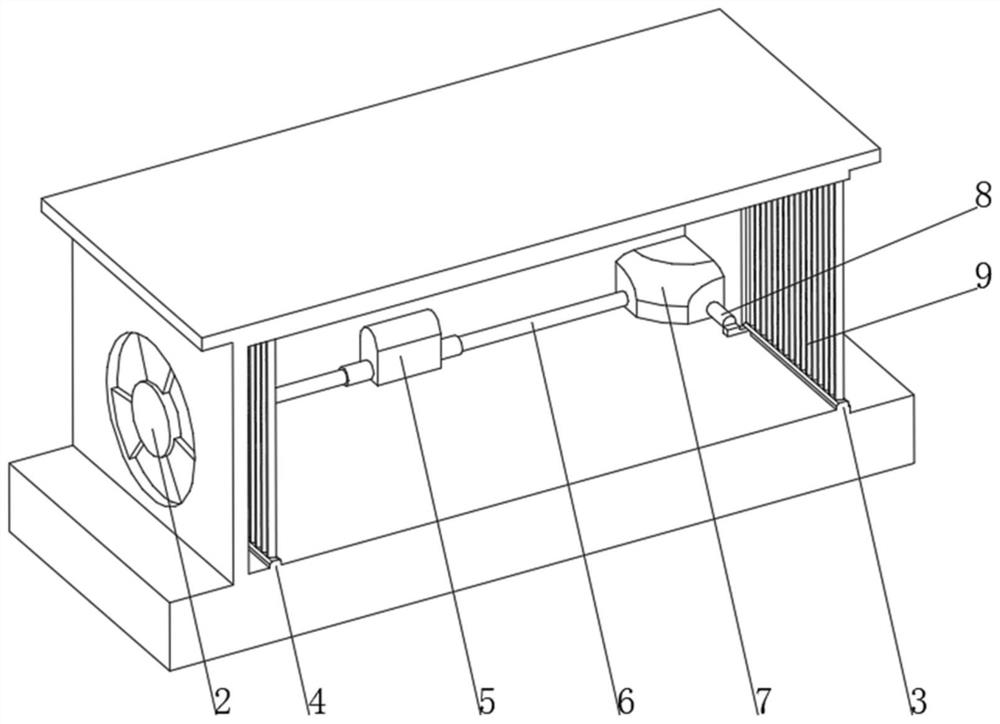

[0038] Control housing 1, a cooling fan 2 is provided on one side of the control housing 1, an air outlet window 3 is provided on the side of the control housing 1 away from the cooling fan 2, and an air inlet window 4 is provided on the side of the inner wall of the control housing 1 close to the cooling fan 2, Both the air outlet window 3 and the air inlet window 4 are provided with an air grid 9;

[0039] The control device 5 is provided with a push rod 6 on both sides of the control device 5, and the side of the push rod 6 away from the control device 5 is connected with a linkage device 7, and the side of the linkage device 7 is provided with a push rod 8, and the push rod 8 is far away from the linkage device One end of 7 is connected with air grid 9;

[0040] Control device 5 comprises:

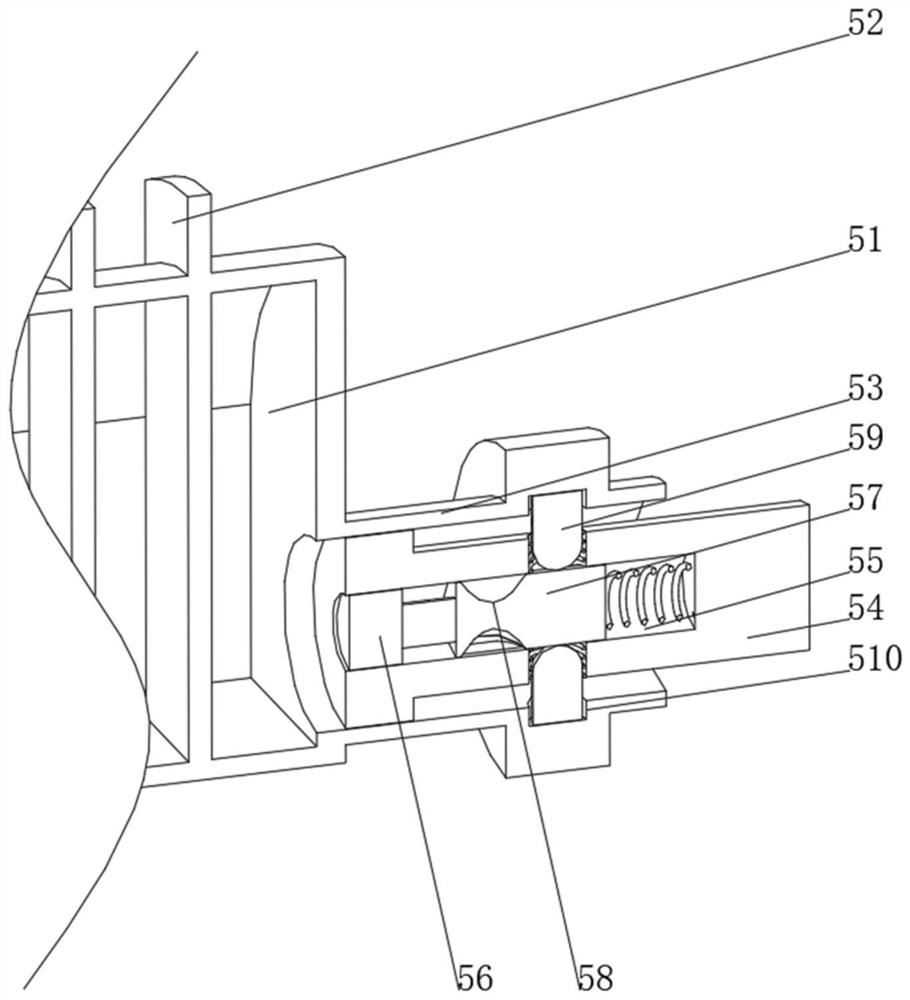

[0041] Heat colle...

Embodiment 2

[0044] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the linkage device 7 includes a fixed housing 71, the bottom of the inner wall of the fixed housing 71 is rotatably connected to a turntable 72, and one side of the turntable 72 is respectively provided with a driving seat 73 and a driven seat 74 One side of the driving seat 73 and the driven seat 74 are respectively connected with a driving rod 75 and a driven rod 76 through a rotating connecting rod, a limit buckle 77 is arranged on one side of the rotating disk 72, and a hairpin is arranged between the rotating disk 72 and the bottom of the inner wall of the fixed shell 71. Bar spring 78, the end of drive rod 75 away from drive seat 73 is fixedly connected with push rod 6, the end of driven rod 76 away from follower seat 74 is fixedly connected with push rod 8, and the inside of limit buckle 77 is provided with a main buckle and a secondary buckle And it is fixedly conn...

Embodiment 3

[0047] see Figure 1-5 On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the air grid 9 includes a base 91, the inner wall of the base 91 is rotatably connected with a gear 92 through a bearing, and the top of the gear 92 runs through the top of the base 91 and is fixedly connected with a stopper. Plate 93, the two sides of baffle plate 93 are respectively provided with sealing groove 94 and sealing strip 95, gear 92 one side meshes with rack 96, baffle plate 93 tops are rotatably connected with air outlet window 3 and the inner wall top of air inlet window 4, and rack 96 One end is fixedly connected with the push rod 8, and is provided with an air grid 9. When the driven rod 76 moves, it drives the push rod 8 to push the rack 96 to move, and the rack 96 drives the gear 92 to move, and the gear 92 drives the baffle plate 93 to rotate. The air outlet window 3 and the air inlet window 4 are opened. When the device is not in use, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com