Movable dock leveler convenient for replacing non-slip mat

A technology of boarding bridge and anti-slip mat, which is applied in the field of transportation, can solve the problems of high cost of replacement, easy movement, hidden safety hazards, etc., and achieve the effect of easy replacement and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be further described below with reference to the accompanying drawings and specific embodiments.

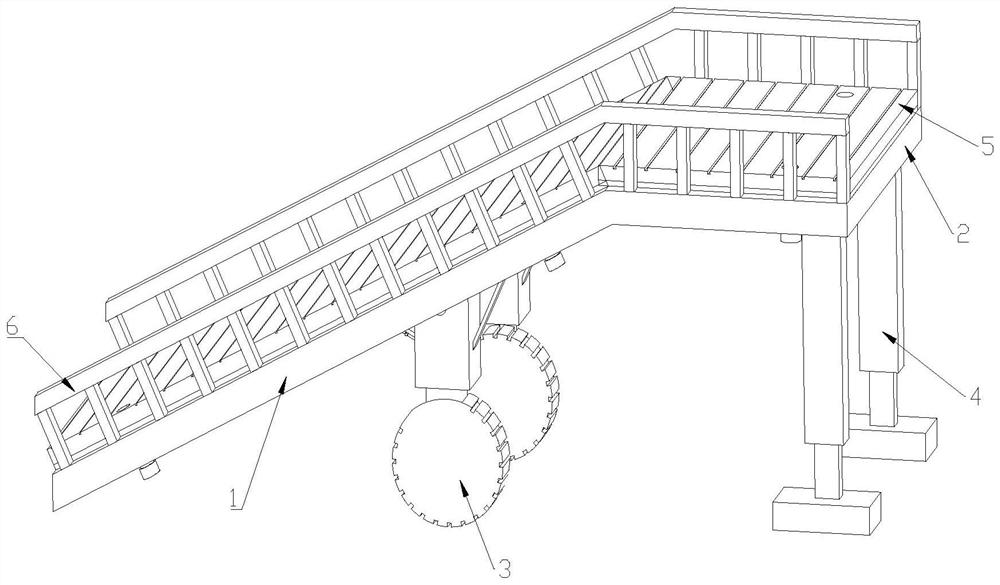

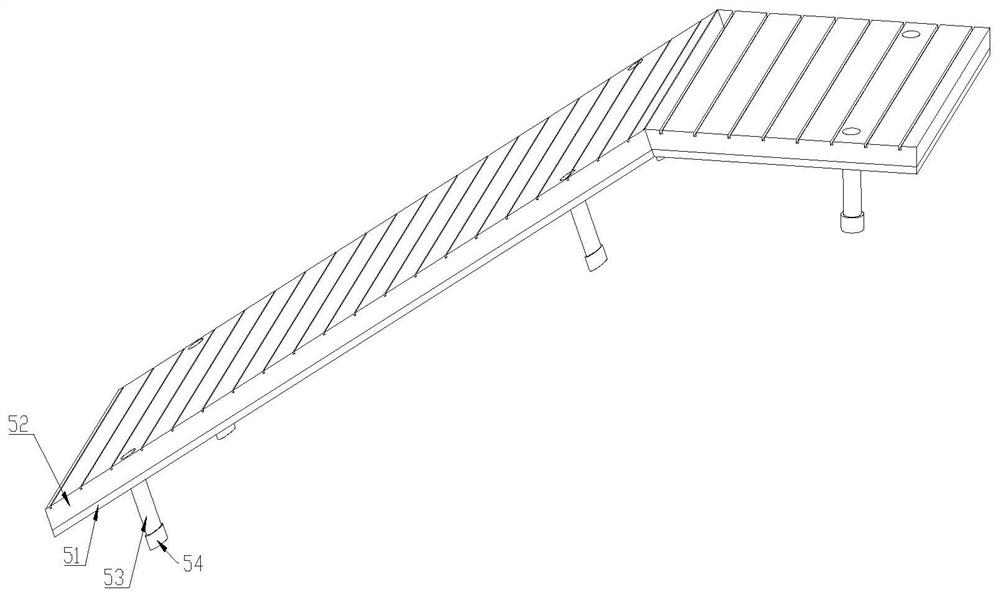

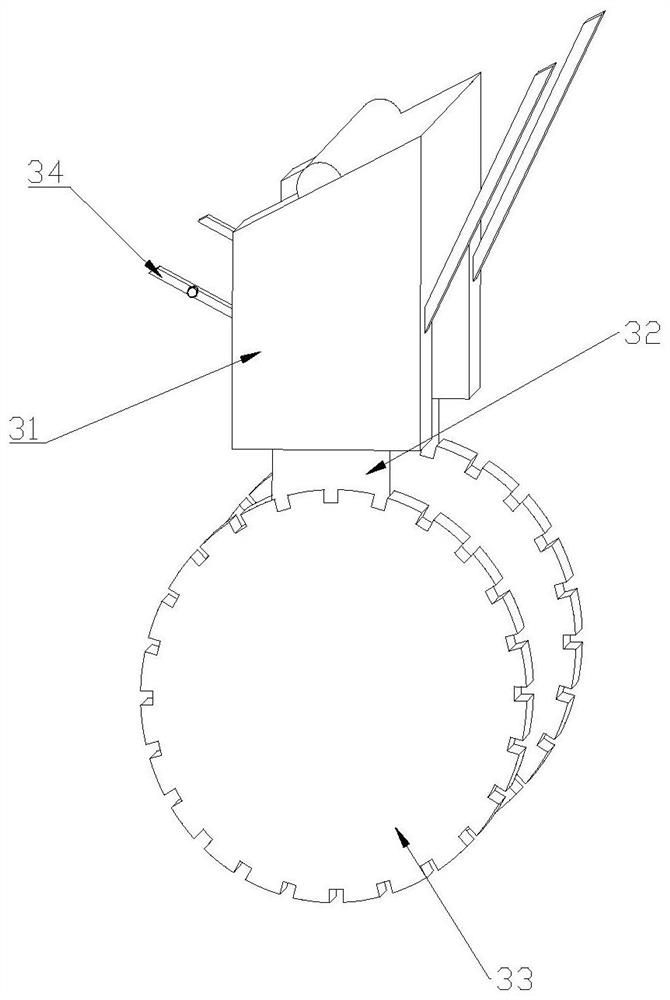

[0020] like figure 1 A mobile boarding bridge that facilitates the replacement of the non-slip pad, including a horizontal boarding bridge 2 and an inclined boarding bridge 1, and the horizontal boarding bridge 2 and the inclined boarding bridge 1 are integrated, the inclined A scalable foldable moving assembly 3 is provided below the axle, and the horizontal boarding bridge 2 is provided with a top rising assembly 4, and the upper end surface of the inclined boarding bridge 1 is detachably connected to a non-slip assembly 5. The retractable foldable moving assembly 3 is used to fold the moving assembly 3 when the boarding bridge does not need to move, preventing the moving assembly 3 from contacting the ground, resulting in the movement of the boarding bridge, thereby causing safety hazards The top rising assembly 4 is used to top the bicycle bridge such th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap