Marinating and boiling equipment for processing sauced and marinated products

A technology of stewing and products, which is applied in the direction of food science, etc., can solve the problems of loss of raw materials, poor taste of raw materials, and affecting the quality of sauce stewed products, so as to achieve the effect of ensuring quality and good taste of stewed stew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

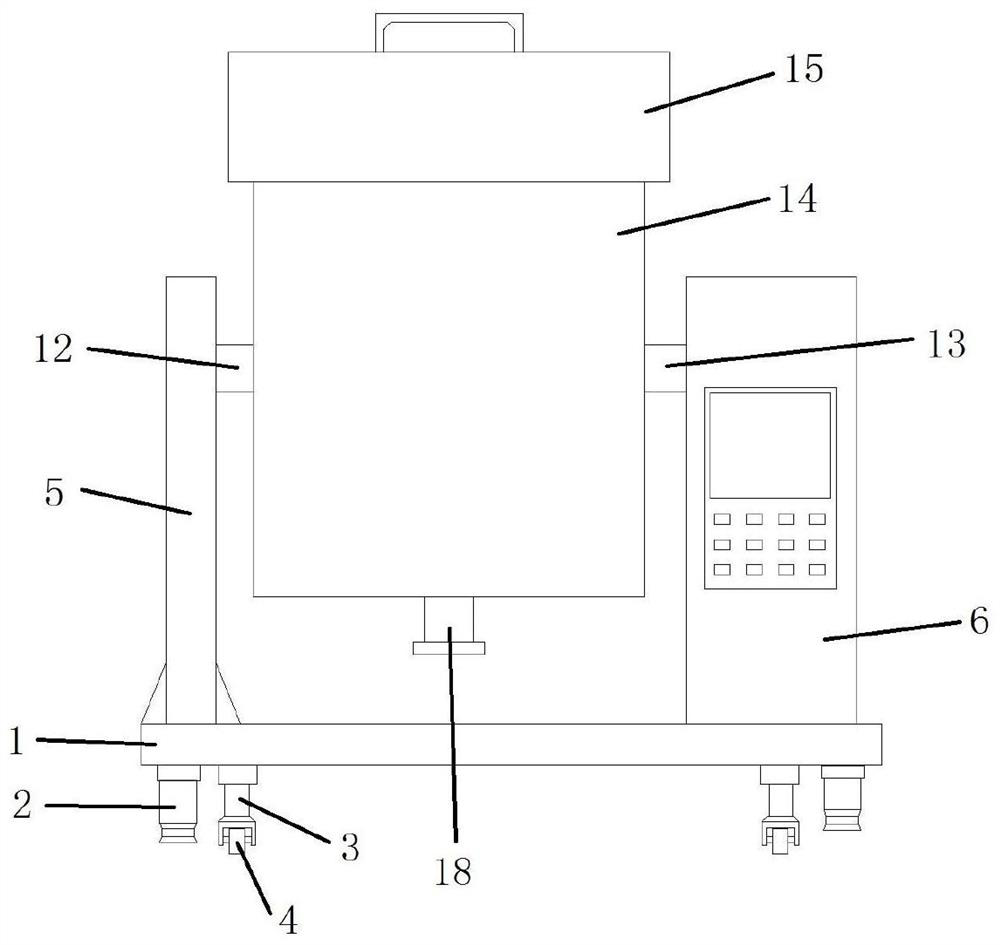

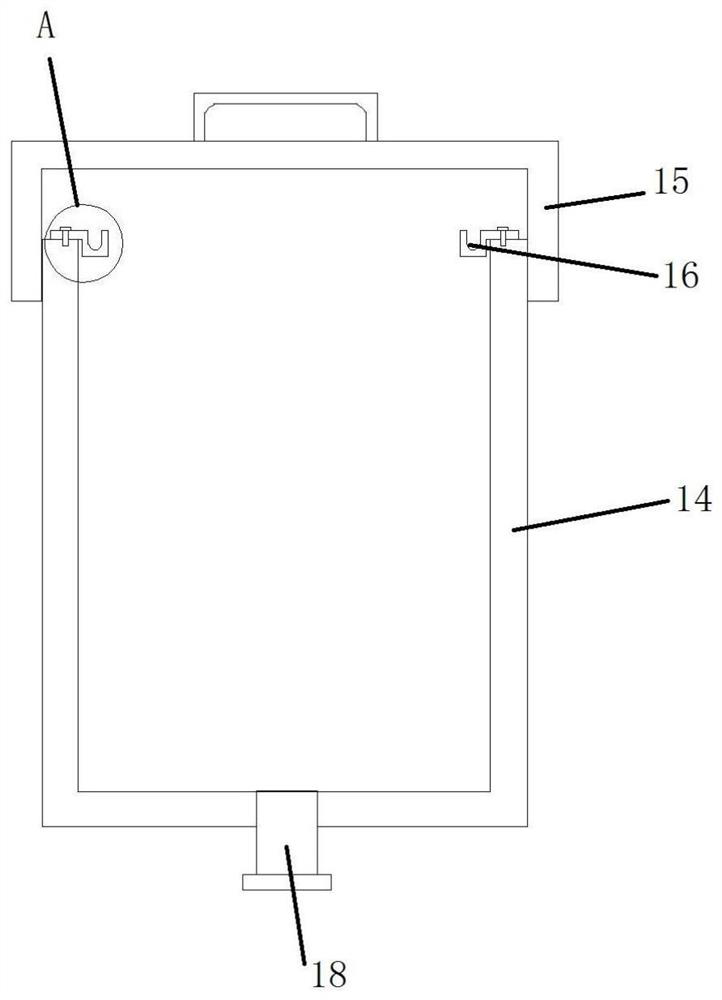

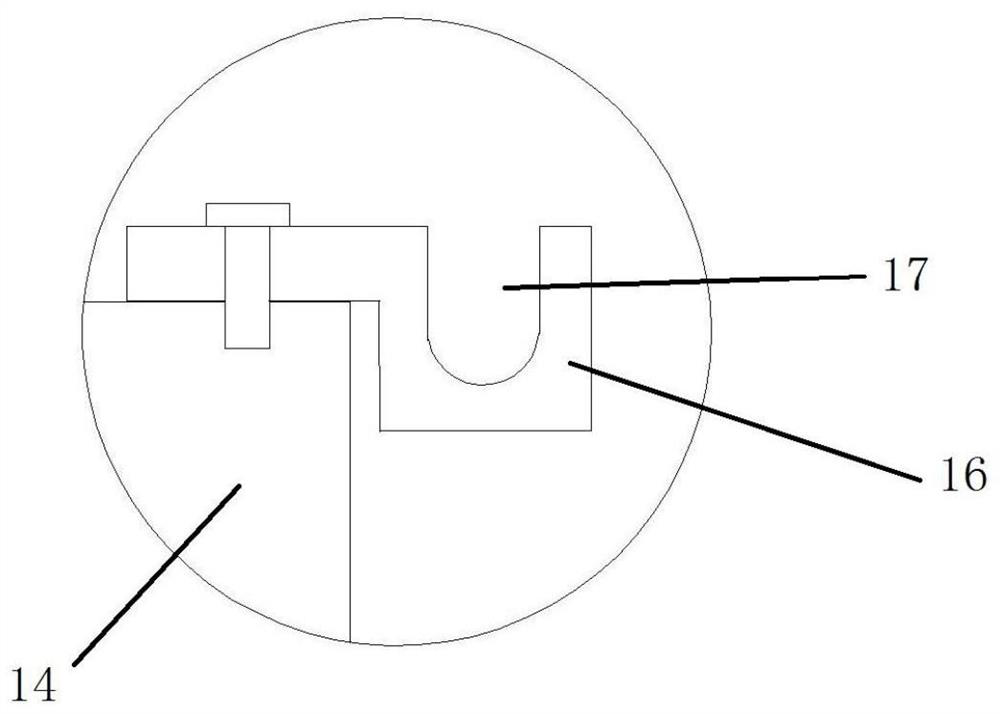

[0025] The embodiment of the present invention discloses a stewing equipment for processing soy sauce products, such as Figure 1 to Figure 5 As shown, it includes a base 1, a bracket 5, a box body 6, a first rotating shaft 12, a second rotating shaft 13, a stew pot body 14, a cover body 15, a layered object 19, a lifting member 23 and a snap-fit fixing member 16. , the top of the base 1 is installed with a vertically arranged bracket 5 and a box body 6, the stew pot body 14 is located between the bracket 5 and the box body 6, and the cross section of the stew pot body 14 is circular, oval, square , rectangular and other shapes, a heating plate is installed inside the side wall and bottom of the stew pot body 14, a discharge port 18 is opened at the bottom of the stew pot body 14, and the first rotating shaft 12 and the The second rotating shaft 13, the free end of the first rotating shaft 12 is rotatably mounted on the side of the bracket 5, the free end of the second rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com