Limitable B-type storage tank liquid collecting tank

A liquid collection tank and storage tank technology, applied in the field of liquid collection tanks, can solve problems such as inconvenient design and construction, easy to cross each other, and large engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

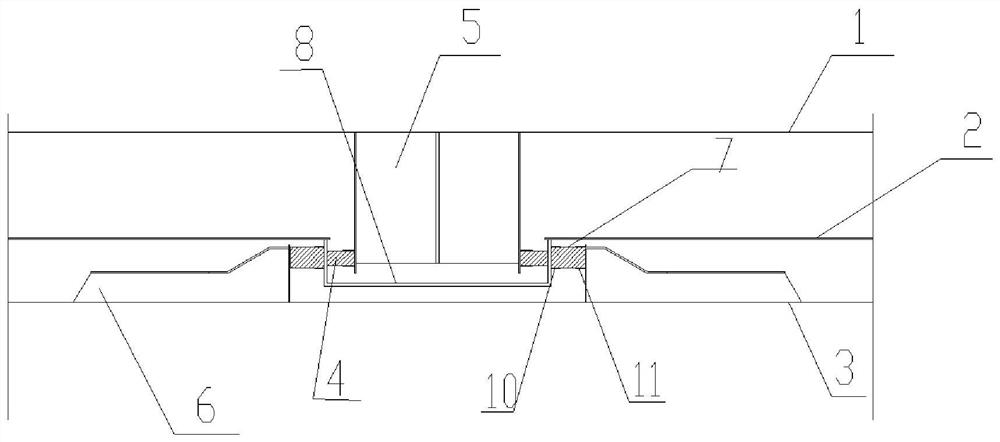

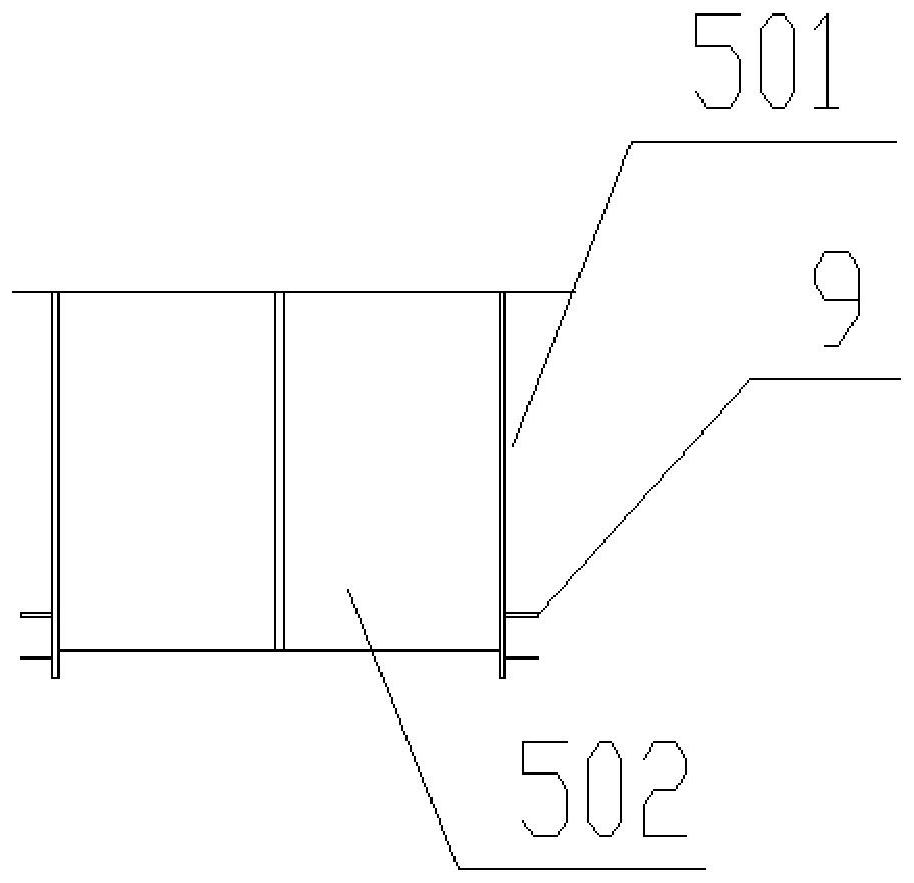

[0021] A B-type storage tank that can be limited. The hull structure 3 is provided with a B-type storage tank. The B-type storage tank has a main barrier wall 1 and a secondary barrier wall 2. The secondary barrier wall is fixed by a vertical support mechanism 6 Between the main screen wall and the hull structure, there are distances between the secondary screen wall and the main screen wall and the hull structure. A plurality of stoppers 5 are welded at equal intervals on the bottom of the B-type storage tank and on the main screen wall, and the stoppers are located on the horizontal central axis and the longitudinal central axis of the bottom of the B-type storage tank. like figure 2 As shown, the position-limiting member has two side plates 501 vertically arranged, a web 502 is welded in the middle of the side plates, and a first slot 9 is welded on the outer surface of the bottom of the two side plates. The limit piece composed of two side plates and a web plate is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com