Plastic bracket and battery pack

A technology for plastic brackets and battery packs, applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of fast heat dissipation of metal shells, which is not conducive to charging and discharging of battery cells, and is not conducive to heat dissipation of battery packs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

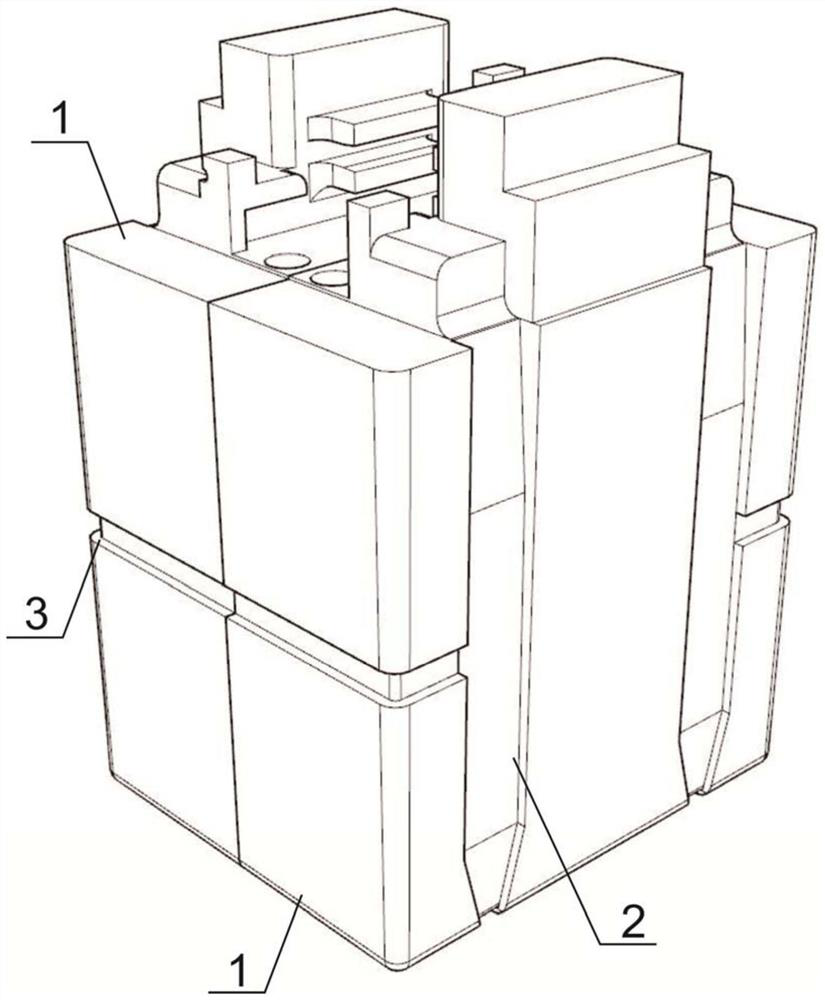

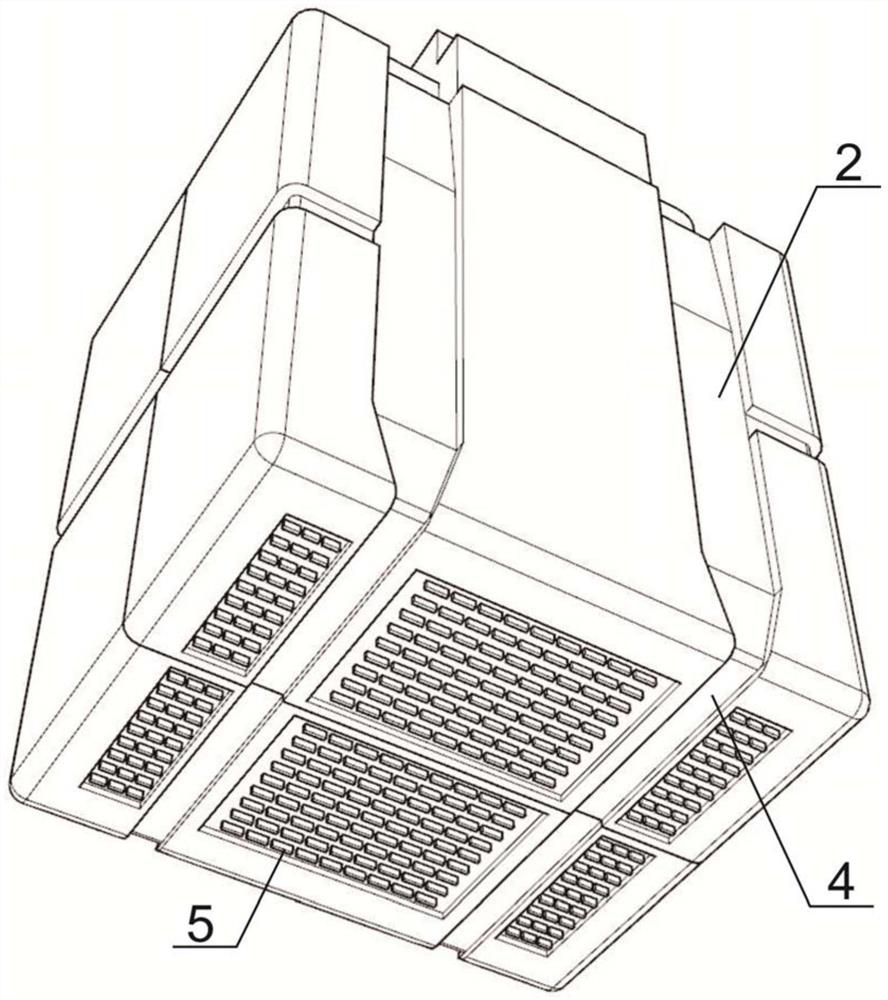

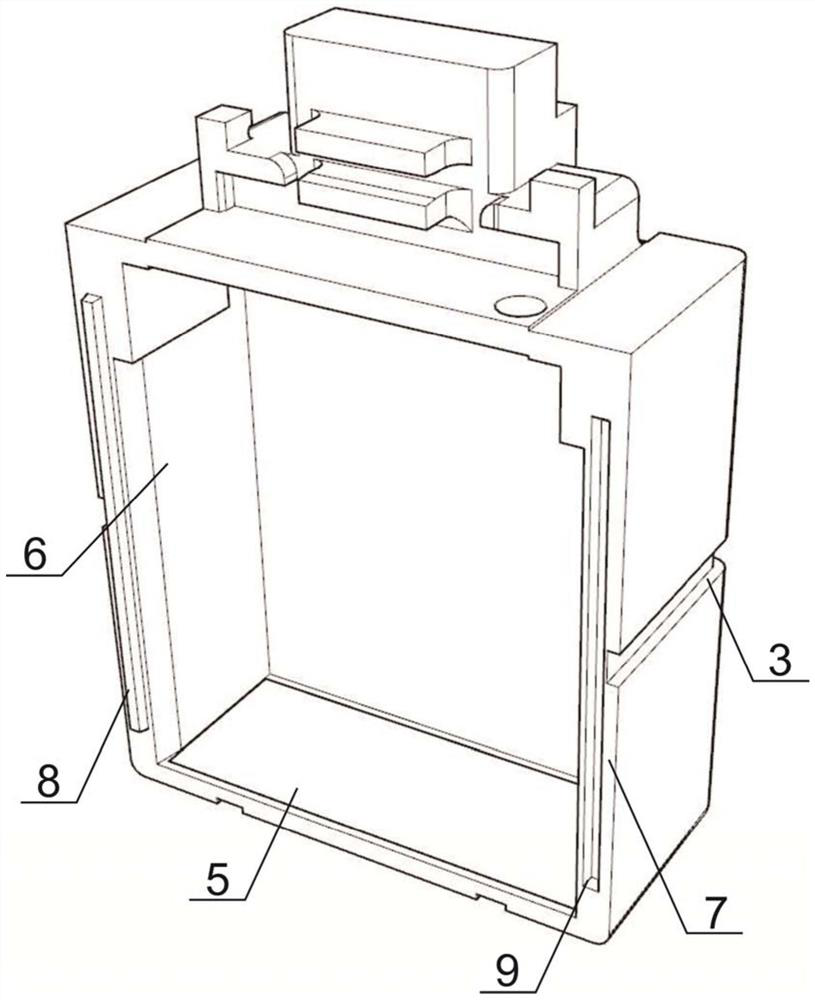

[0029] Figure 1-4 A plastic bracket provided by the present invention, the plastic bracket is made of foaming material, the plastic bracket is composed of left and right half shells 1, and through the splicing of the two half shells 1, the two half shells 1 An accommodating cavity 6 for accommodating the electric core is formed inside, and as figure 1 As shown, only the top of the entire plastic bracket is provided with a harness hole penetrating through the accommodating cavity 6, and the harness of the battery passes through the harness hole.

[0030] Specifically, the two half-shells 1 have longitudinal closed-loop joining surfaces 7; a raised fitting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com