Diaphragm and battery

A diaphragm and battery technology, applied in the field of diaphragms and batteries, can solve the problems of battery performance degradation, electrolyte viscosity increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

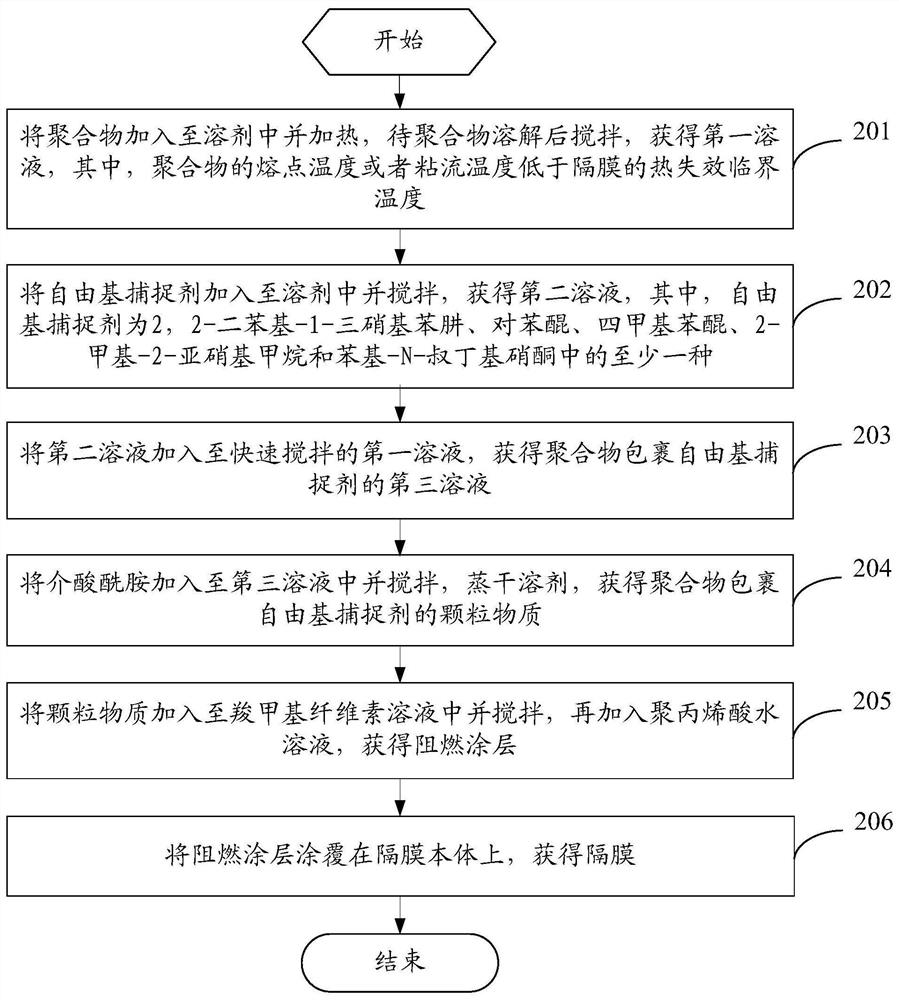

[0044] see figure 2 , figure 2 It is a flowchart of the preparation method of the diaphragm provided in the embodiment of the present application. The preparation method of this membrane comprises:

[0045] Step 201, adding the polymer into the solvent and heating, and stirring after the polymer is dissolved to obtain a first solution, wherein the melting point temperature or viscous flow temperature of the polymer is lower than the thermal failure critical temperature of the diaphragm;

[0046] Step 202, adding a free radical scavenger into the solvent and stirring to obtain a second solution, wherein the free radical scavenger is 2,2-diphenyl-1-trinitrophenylhydrazine, p-benzoquinone, tetramethyl At least one of benzoquinone, 2-methyl-2-nitrosomethane and phenyl-N-tert-butylnitrone;

[0047] Step 203, adding the second solution to the rapidly stirred first solution to obtain a third solution of polymer-coated radical scavenger;

[0048] Step 204, adding the acid amide ...

Embodiment 1

[0065] A conventional separator (that is, the separator body not coated with a flame-retardant coating), positive electrode sheet, and negative electrode sheet is wound into a battery. The pass rate of the security test is 40%.

Embodiment 2

[0067] Heat polyethylene in xylene to 120°C to dissolve at a concentration of 2% to obtain the first solution, and stir at high speed to dissolve 2,2-diphenyl-1-trinitrophenylhydrazine in the xylene solution, Obtain the second solution; add the second solution to the rapidly stirred first solution to obtain the third solution of the polymer-coated free radical scavenger, stir at a low speed, then add the acid amide, evaporate the solvent, and finally obtain the polyethylene-coated solution The free radical scavenger small particles; the small particles are dispersed in the CMC solution, evenly coated on the separator, and the final separator is prepared, and the positive electrode sheet and the negative electrode sheet are wound into a battery. The pass rate of the security test is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap