TYPE-C connector capable of allowing large current to pass through

A TYPE-C, connector technology, applied in the direction of connecting parts, protective grounding/shielding devices, contact parts, fixed/insulated contact components, etc., can solve problems such as weak ability to withstand large currents, large use limitations, and affect user experience , to achieve the effect of increasing the ability to withstand large currents, a wide range of applications, and avoiding charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

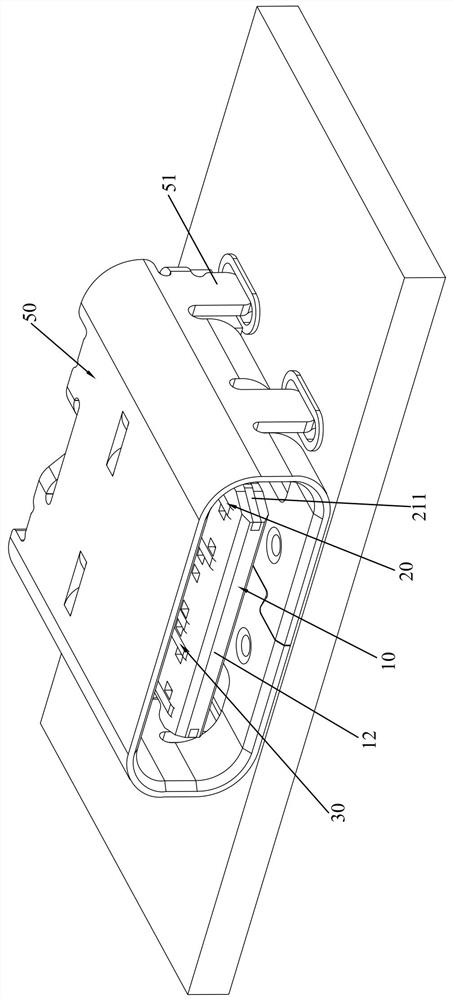

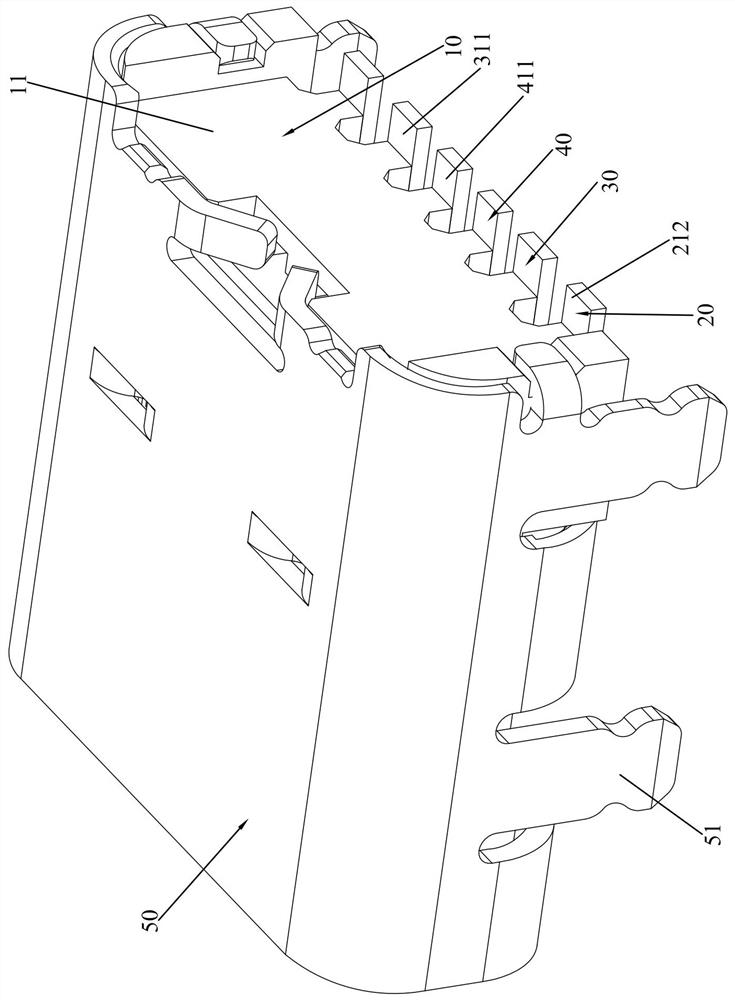

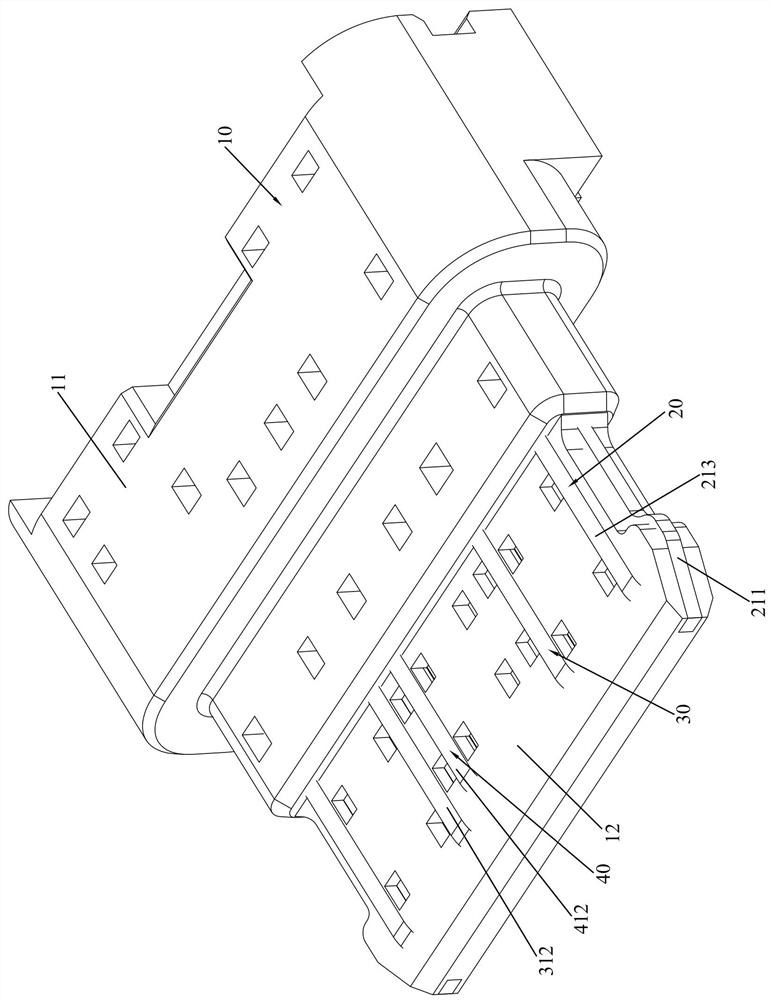

[0043] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the first preferred embodiment of the present invention, which includes an insulating housing 10 , ground terminals 20 , power terminals 30 and signal terminals 40 .

[0044] The insulating body 10 includes a base 11 and a tongue 12 extending from the base 11; A fixing foot 51 extends downward from a side of the shell 50 .

[0045] The ground terminal 20 , the power terminal 30 and the signal terminal 40 are arranged side by side and are all embedded and fixed in the insulating housing 10 .

[0046] The ground terminal 20 includes a first main body 21 and a second main body 22; the first main body 21 is embedded in the insulating body 10, and a hook 211 extends from the front end of the first main body 21, and the hook 211 is exposed. On the side of the tongue plate 12, a first welding part 212 extends from the tail end of the first main body part 21, and the first welding part 212 prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com