LED chip and preparation method thereof

A LED chip and graphic technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of low light extraction efficiency, achieve the effects of improving safety performance, increasing reflectivity, and slowing down overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

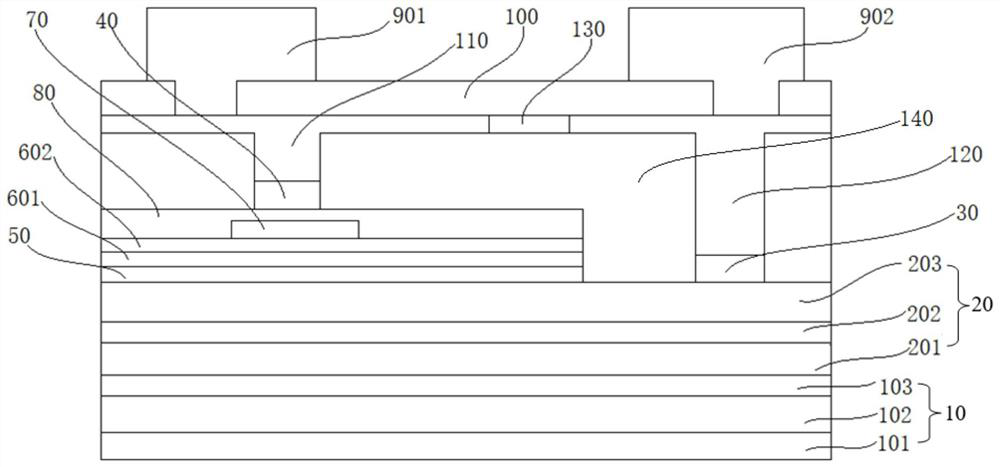

[0034] see figure 1 , which is a schematic structural diagram of the LED chip provided by the first embodiment of the present invention, the LED chip includes a composite substrate substrate 10, an epitaxial layer group and a contact layer group stacked in sequence, wherein:

[0035] The epitaxial layer set includes a first semiconductor layer 20 , a light-emitting layer 50 and a second semiconductor layer sequentially stacked on the composite substrate 10 . the conductive groove of the second semiconductor layer;

[0036]The contact layer set includes a current blocking layer 70 disposed on the second semiconductor layer, a current guiding layer 80 completely covering the current blocking layer 70, and a first patterned reflective layer 140 disposed in the conductive groove , and the first patterned reflective layer 140 is disposed on the first semiconductor layer 20 and the current guide layer 80. The purpose of setting the first patterned reflective layer 140 is to prevent...

Embodiment 2

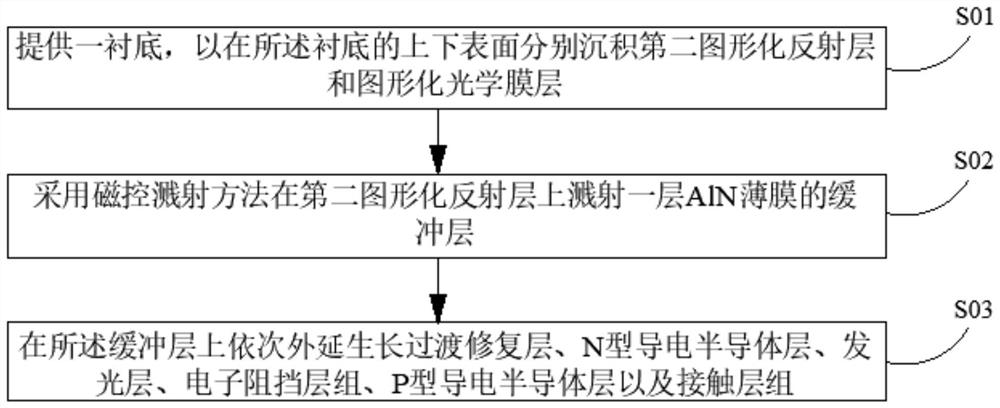

[0049] see figure 2 , which is a flow chart of a method for preparing an LED chip in the second embodiment of the present invention. The method is used to prepare the LED chip in the above-mentioned embodiment, and the method includes steps S01 to S03, wherein:

[0050] Step S01: providing a substrate for depositing a second patterned reflective layer and a patterned optical film layer on the upper and lower surfaces of the substrate respectively;

[0051] Specifically, a second patterned reflective layer is deposited on the upper surface of the substrate by means of PECVD (Plasma Enhanced Chemical Vapor Deposition). A plurality of grooves with a depth less than half of the thickness of the second patterned reflective layer are etched on the side of the second patterned reflective layer away from the substrate, and then PECVD (plasma enhanced chemical vapor deposition) method is used again on the substrate. Silicon dioxide layers and titanium pentoxide layers are alternately...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com