Abnormality discrimination type manipulator for automatic production

A technology for moving manipulators and manipulators, applied in manipulators, manufacturing tools, chucks, etc., can solve problems such as gas leakage, product inspection and identification, and achieve the effect of improving protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

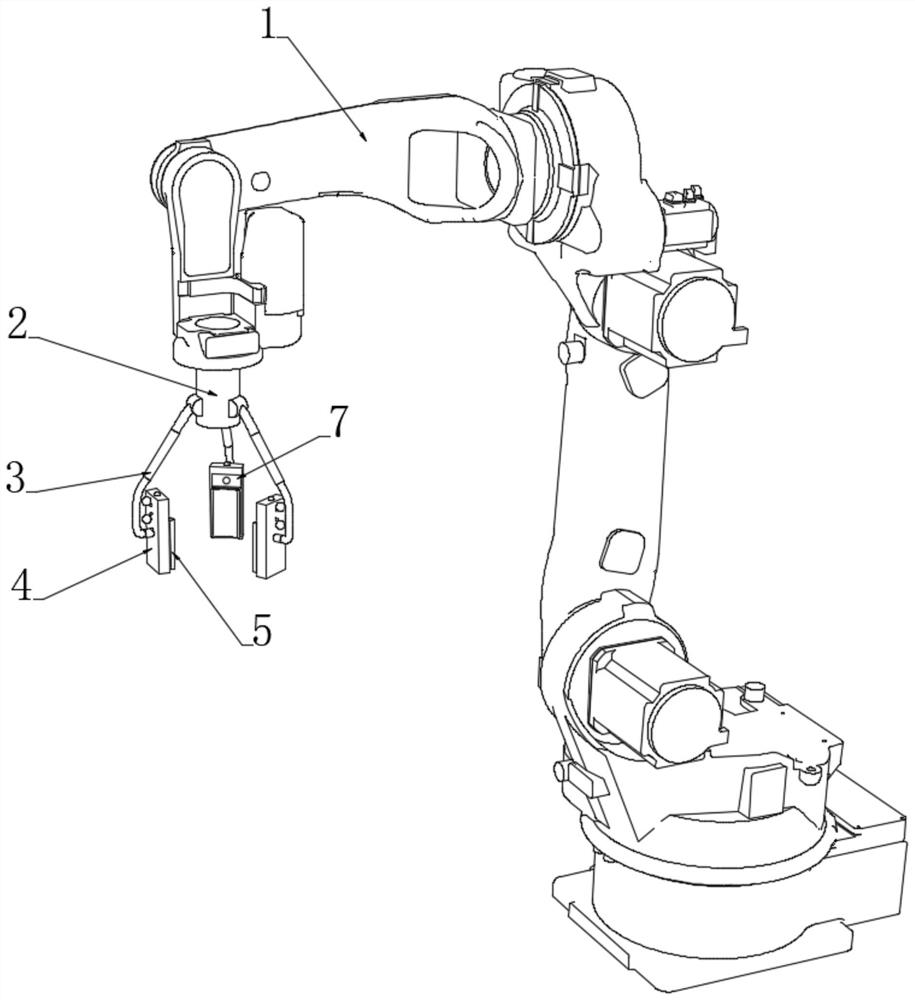

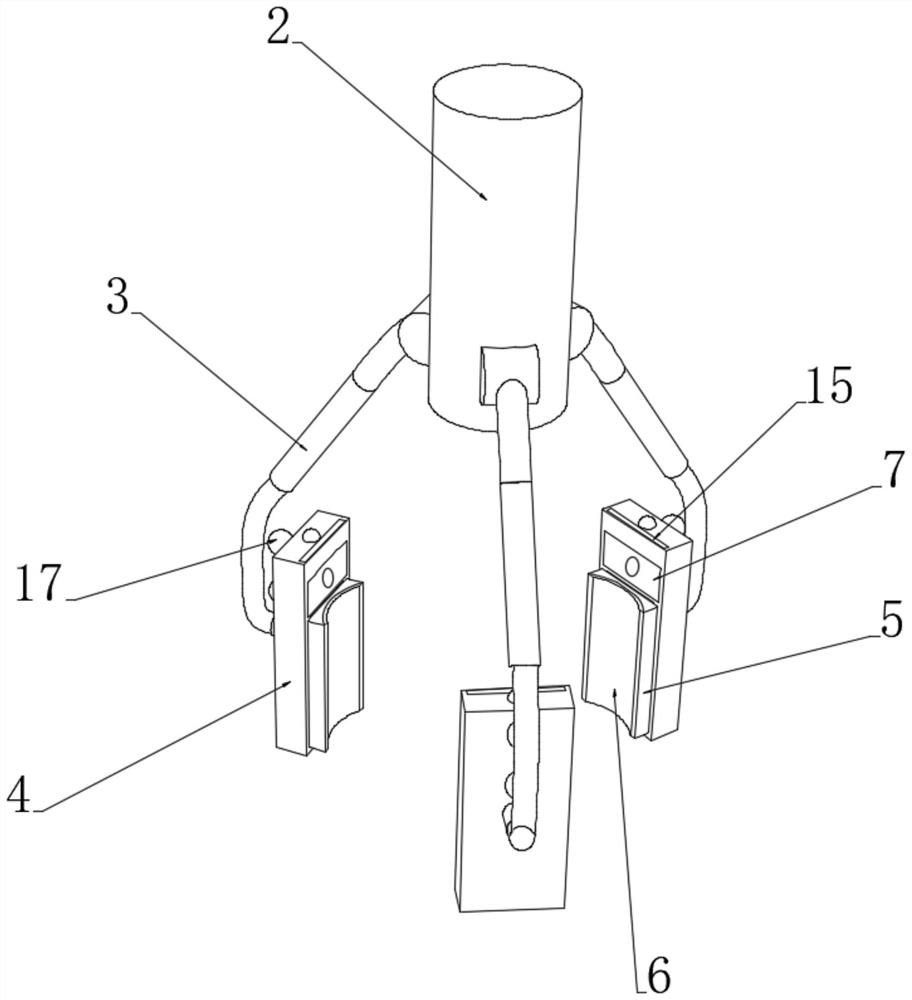

[0042] see figure 1 , an abnormality discrimination type manipulator for automated production, comprising a mobile manipulator 1, a main control head 2 is provided at the driving end of the mobile manipulator 1, a plurality of grasping manipulators 3 are distributed on the main control head 2, and the lower ends of the plurality of grasping manipulators 3 are A grasping identification body 4 is connected, and the mobile manipulator 1 and the main control head 2 are equipped with an industrial computer to facilitate the flexible grasping operation of the mobile manipulator 1 and the grasping manipulator 3. This is the prior art and will not be done here. More details.

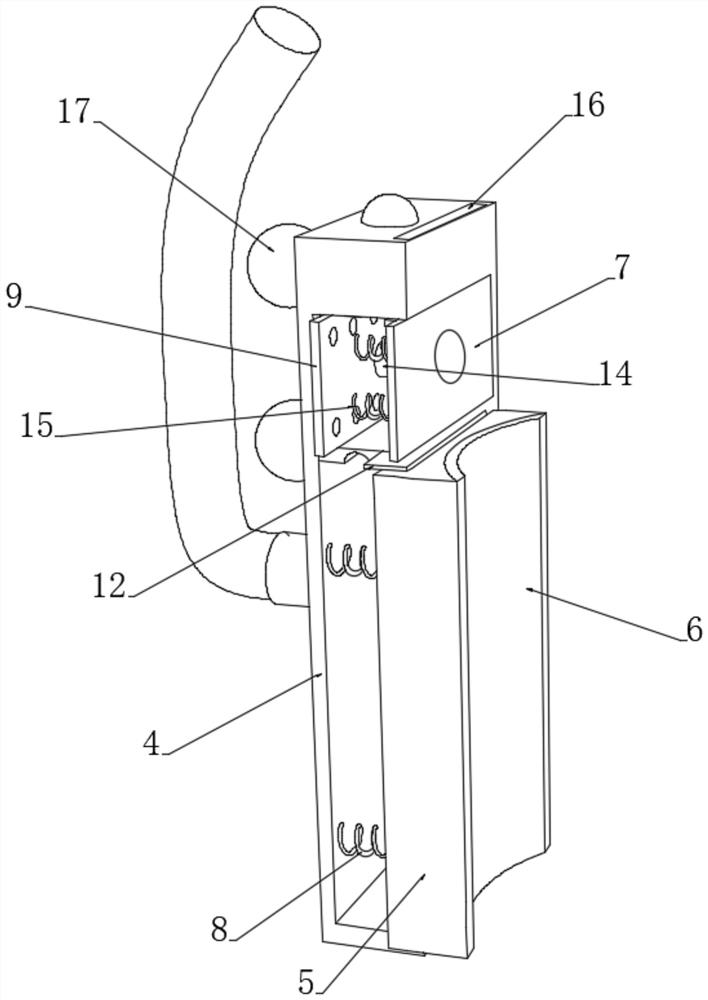

[0043] see Figure 2-4 The lower end of the grasping identification body 4 is provided with a buffer cavity, and the inner wall of the buffer cavity is connected with a grasping valve 5 through a plurality of lower compression springs 8, and the outer end of the grasping valve 5 extends to the outside of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com