Patents

Literature

41results about How to "Push in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

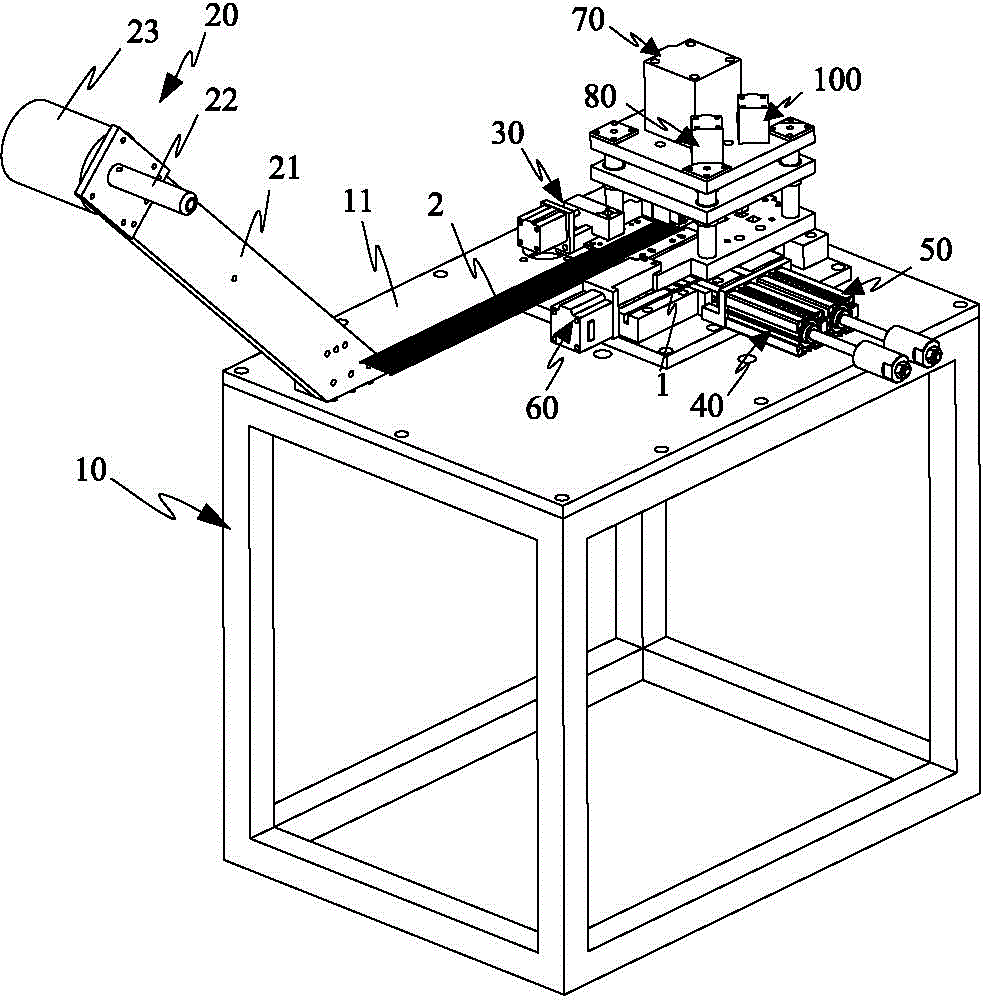

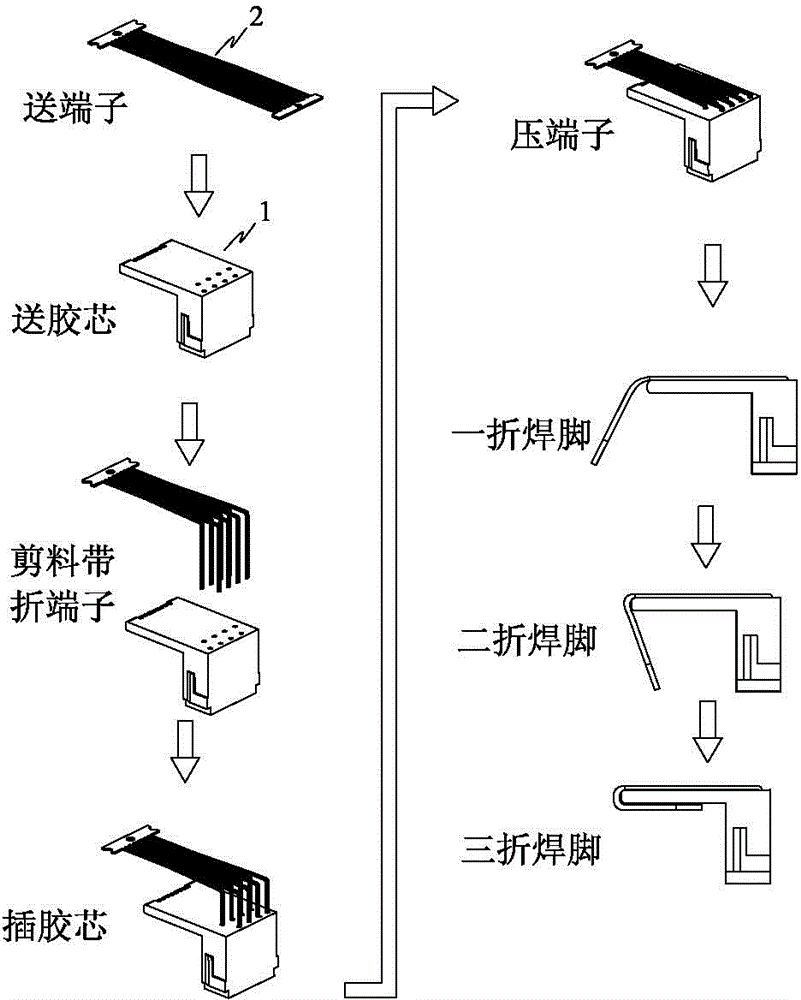

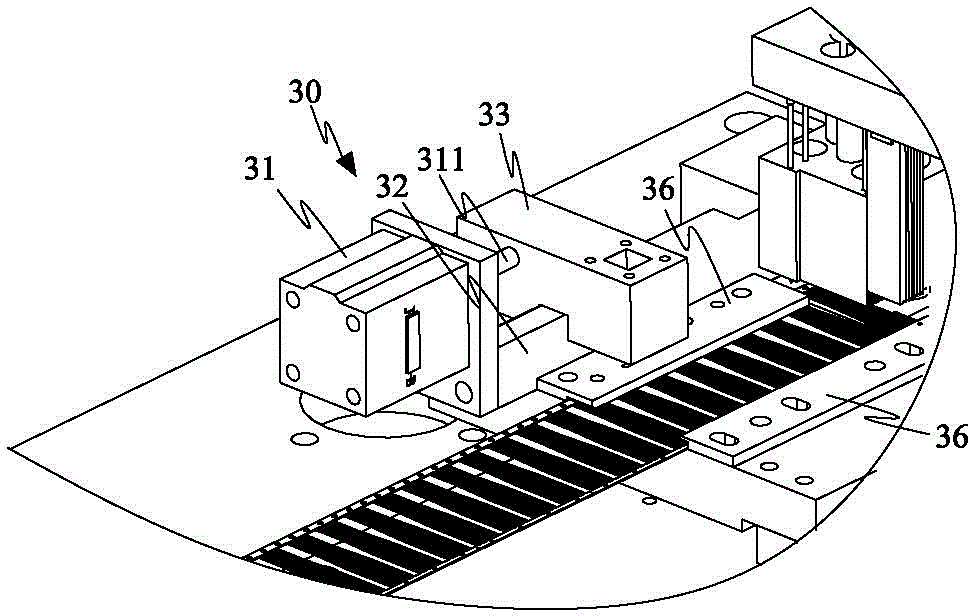

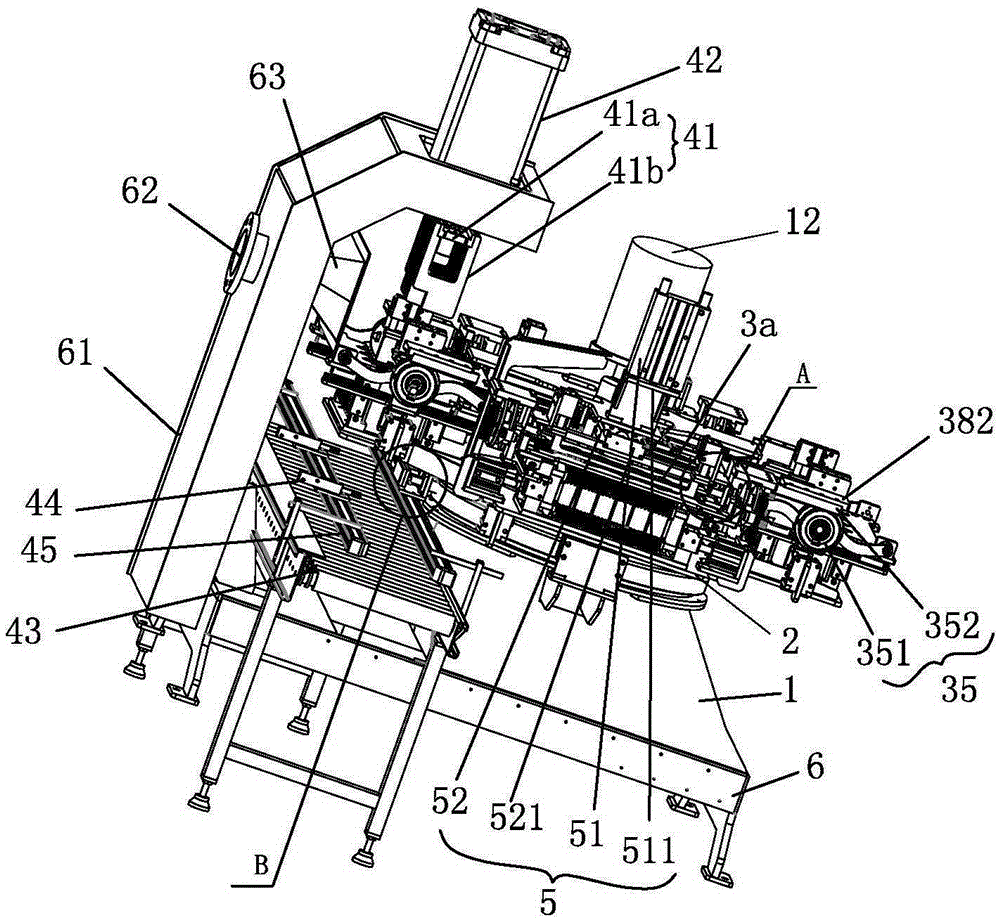

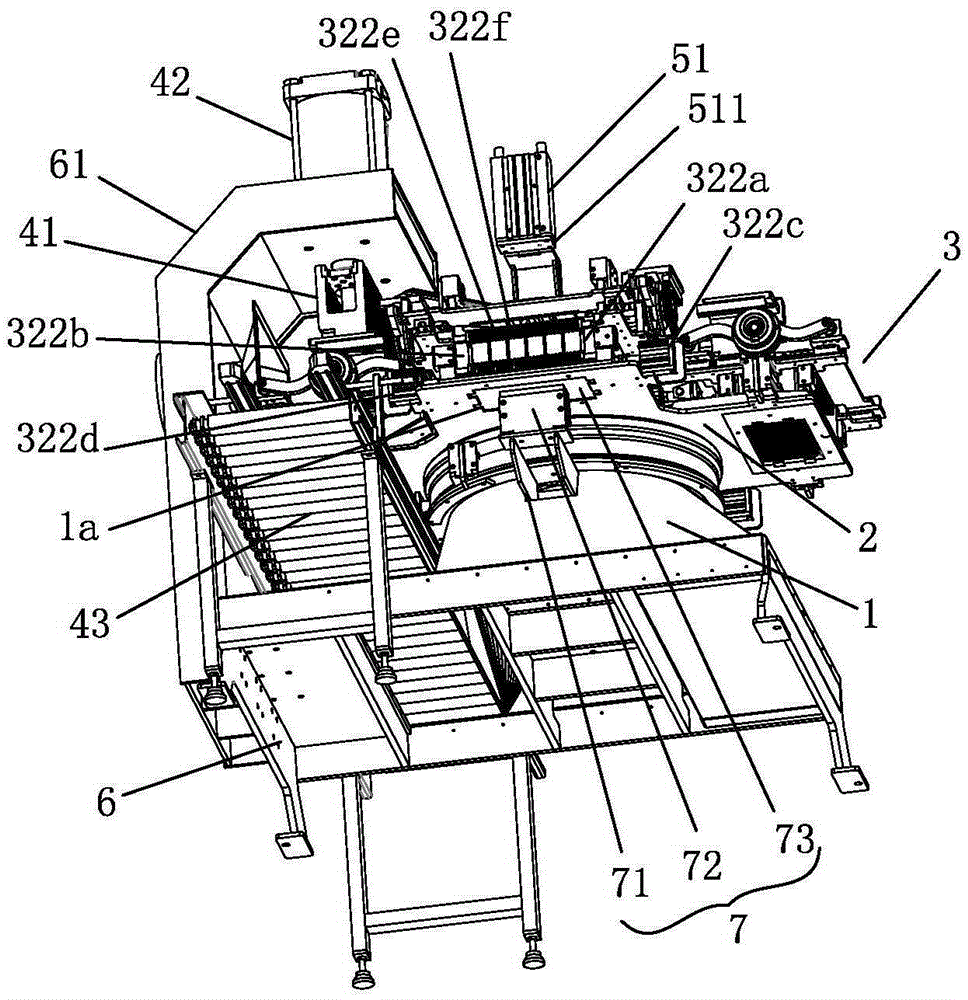

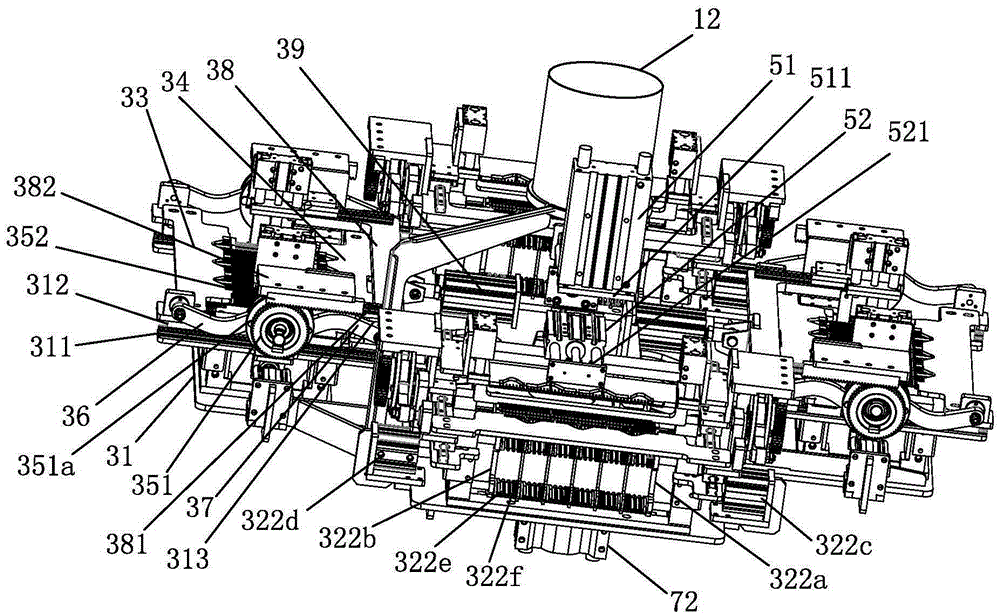

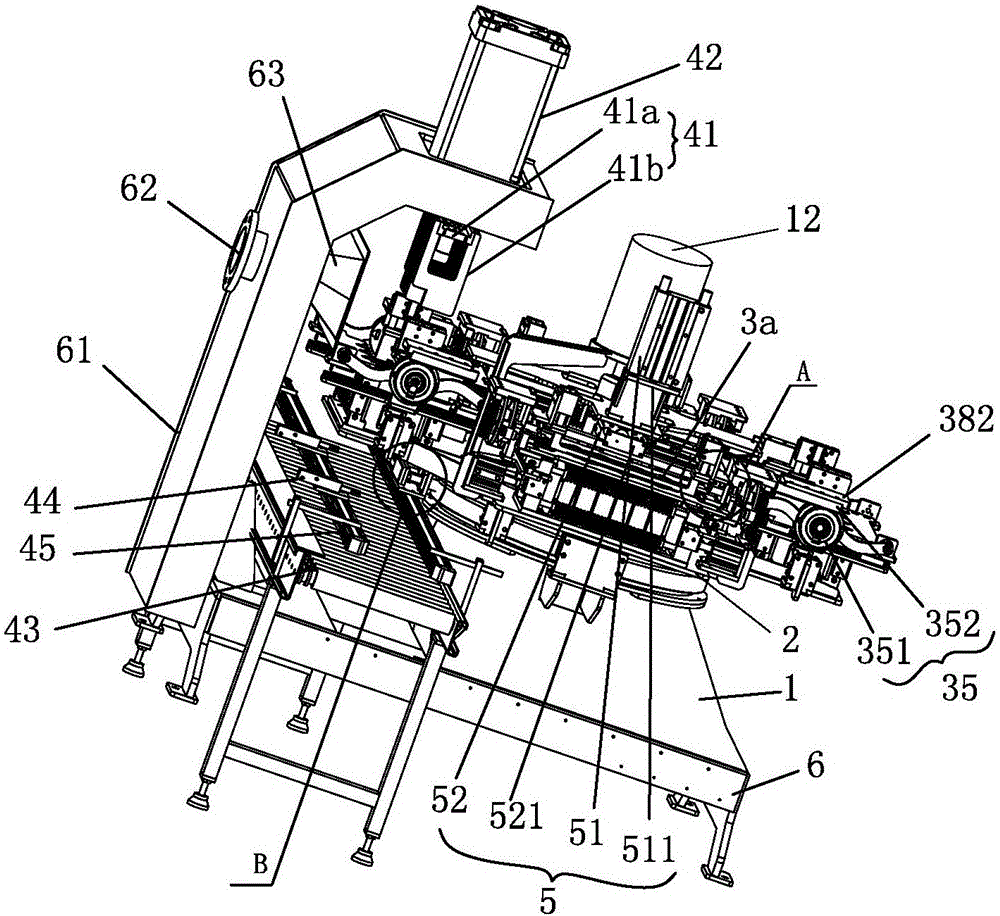

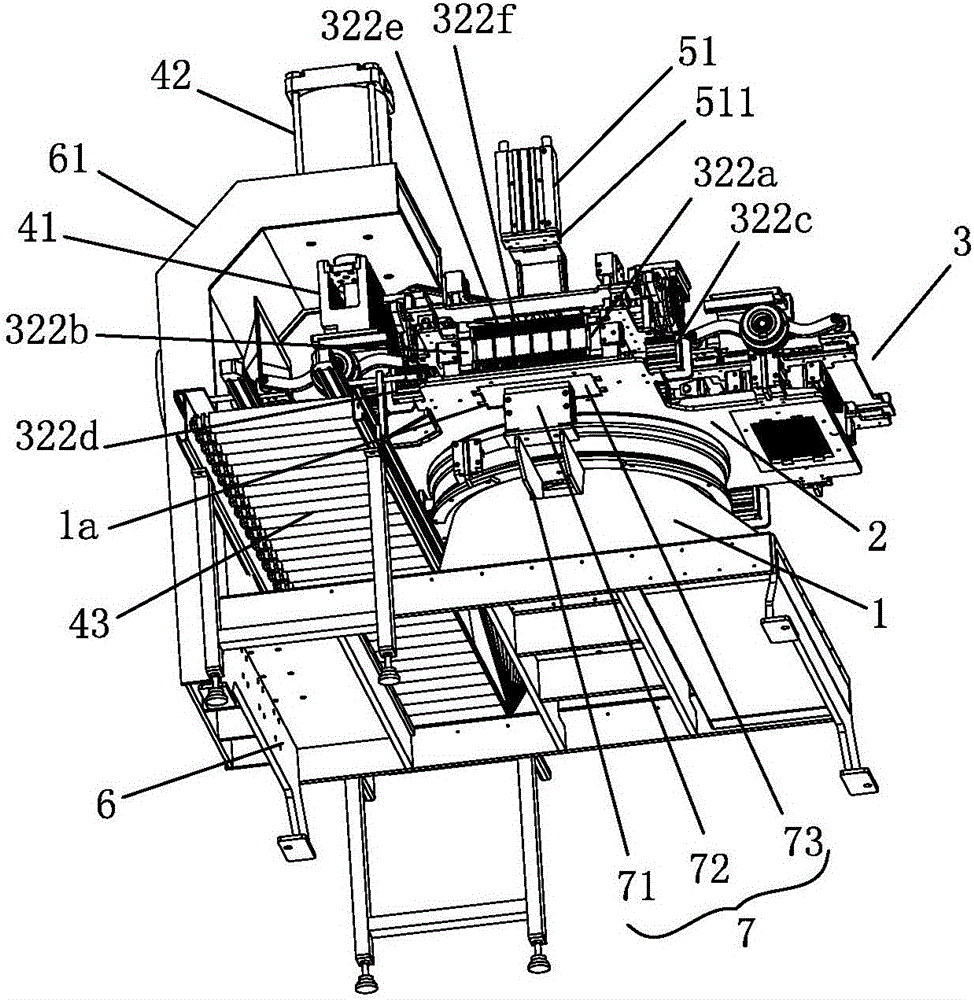

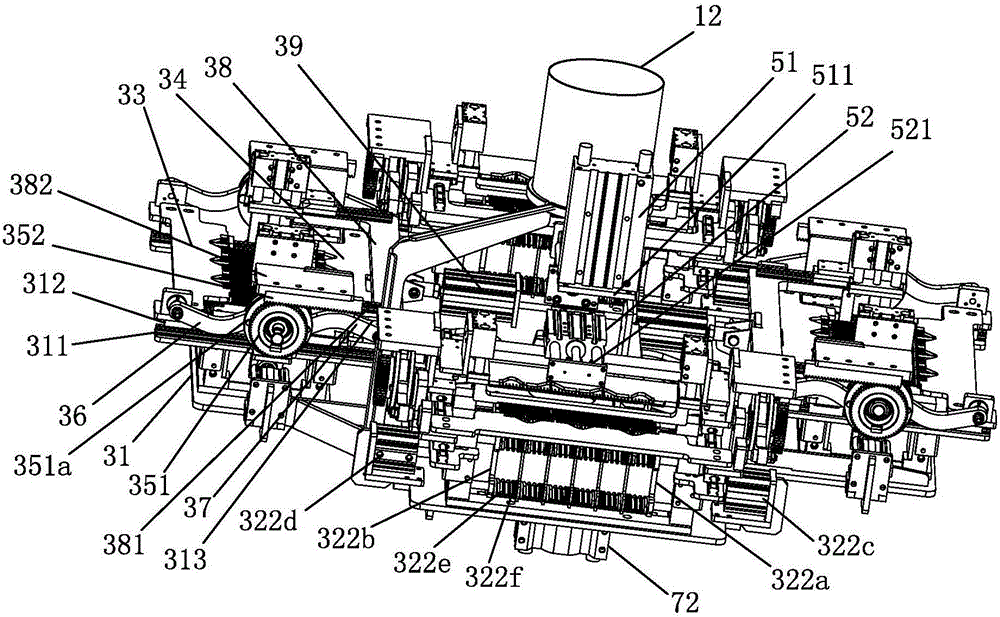

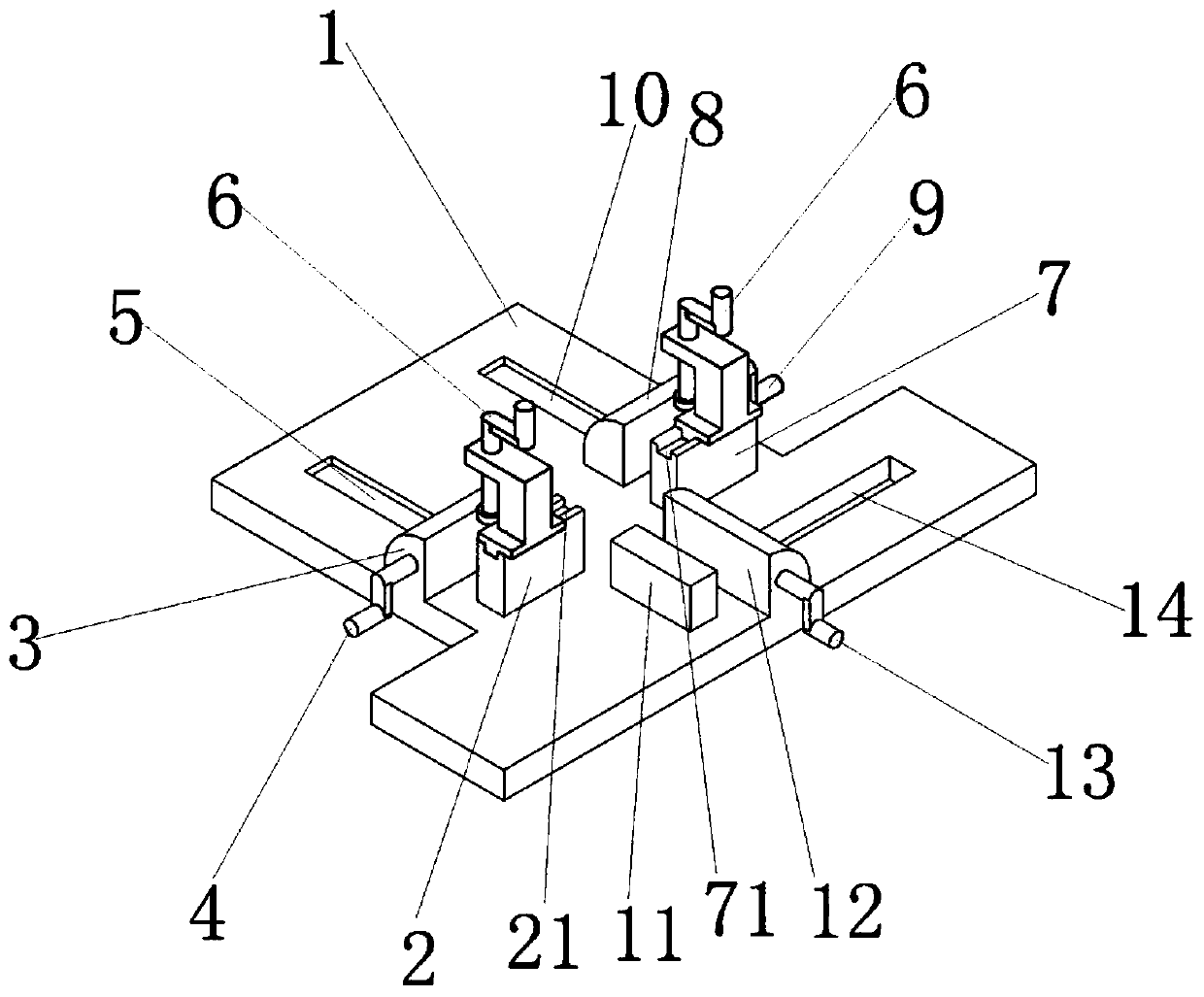

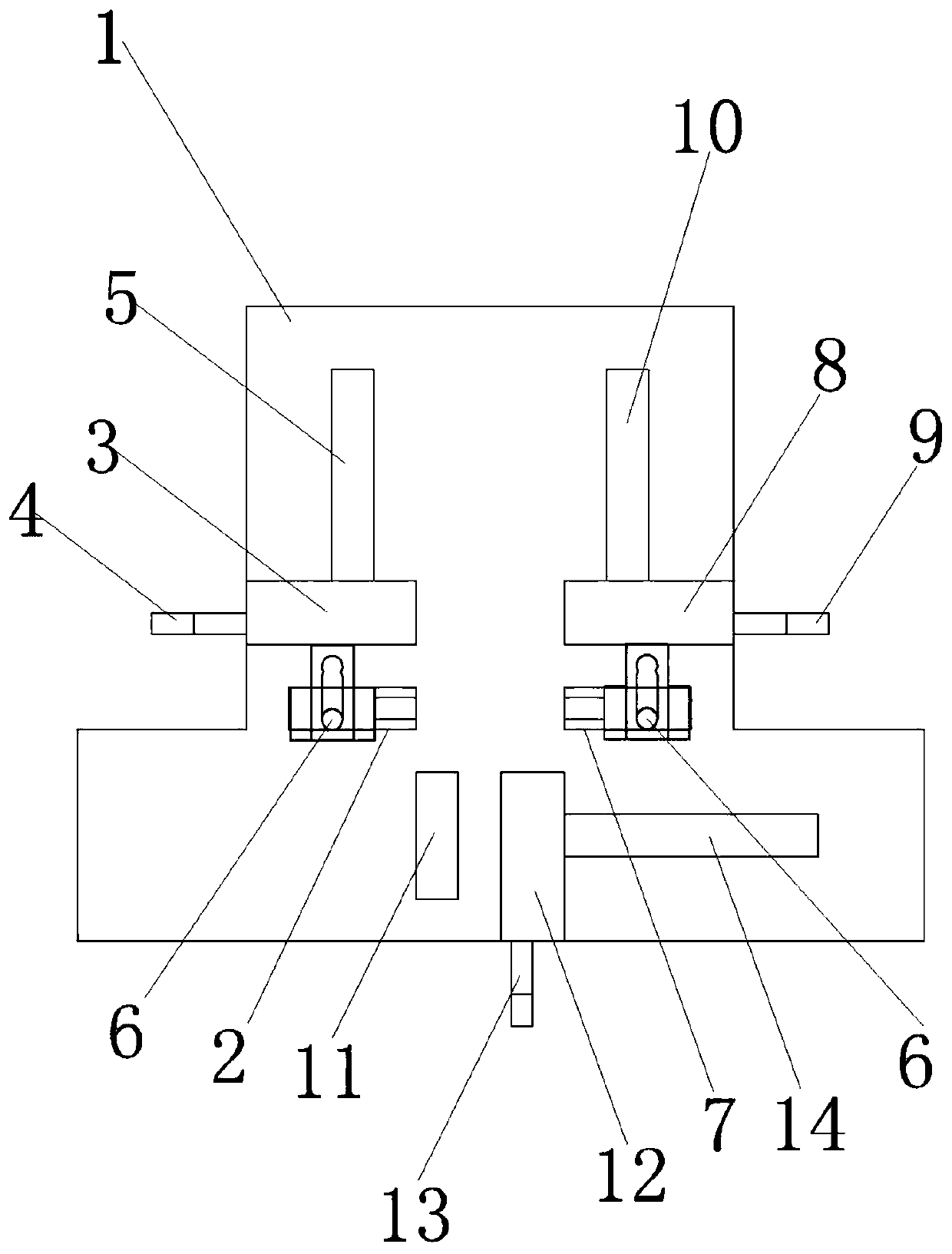

Automatic assembly machine for electric couplers

ActiveCN104009367ANo human intervention requiredImplement automatic truncationContact member assembly/disassemblyElectricityEngineering

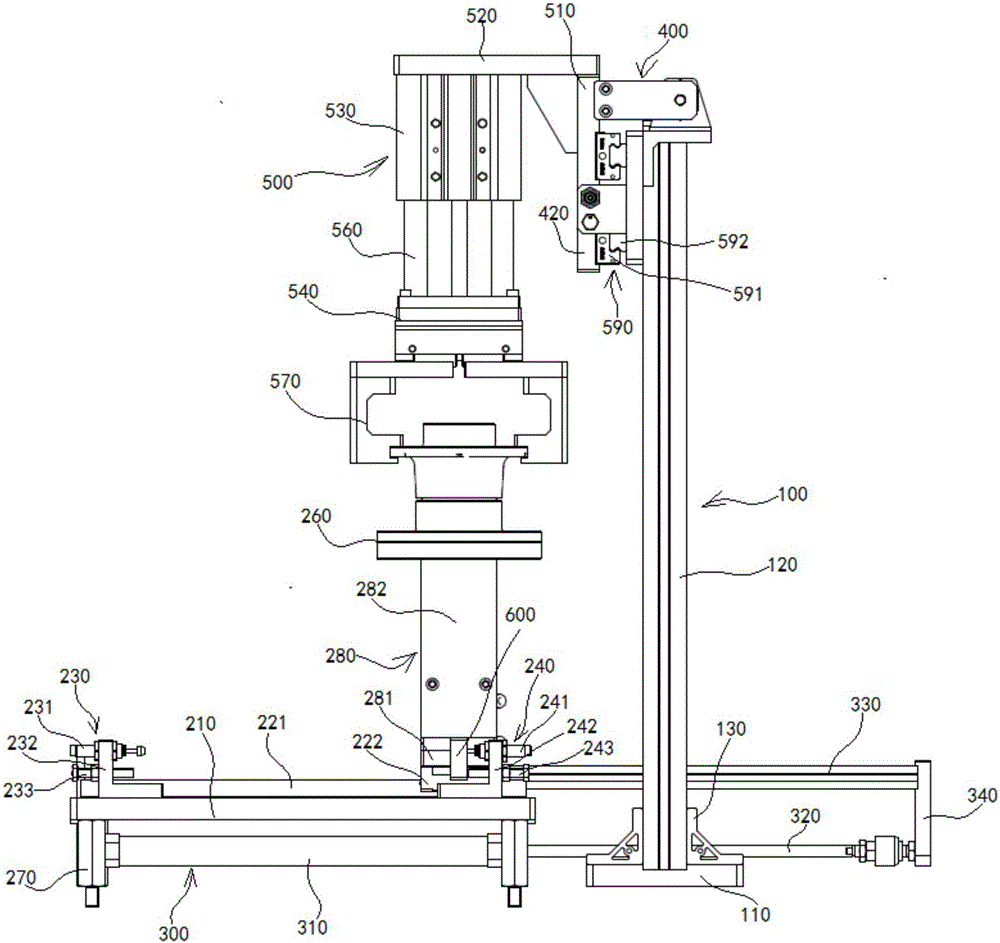

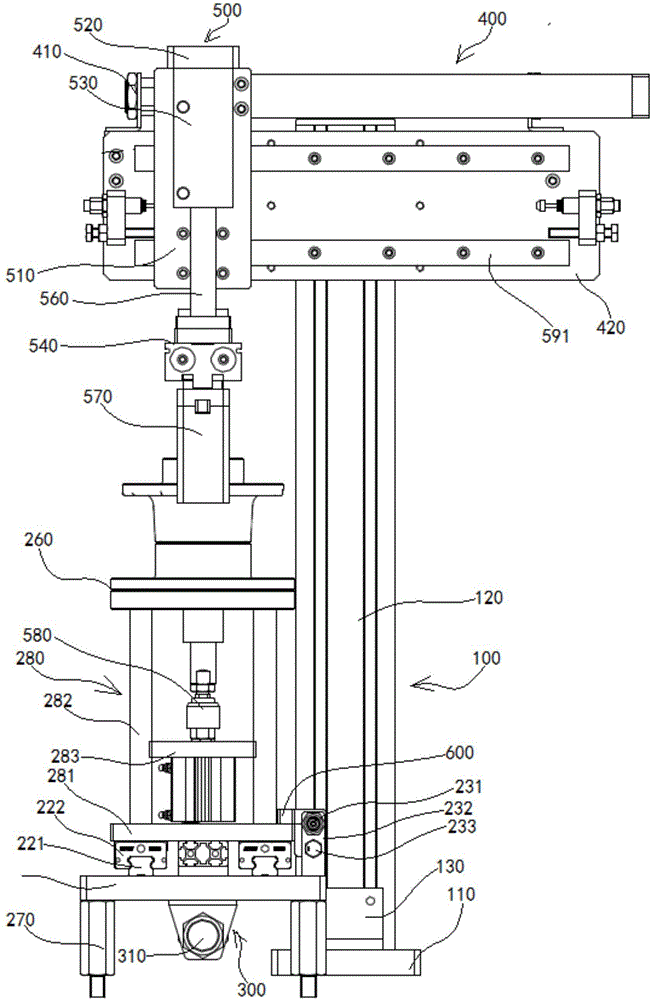

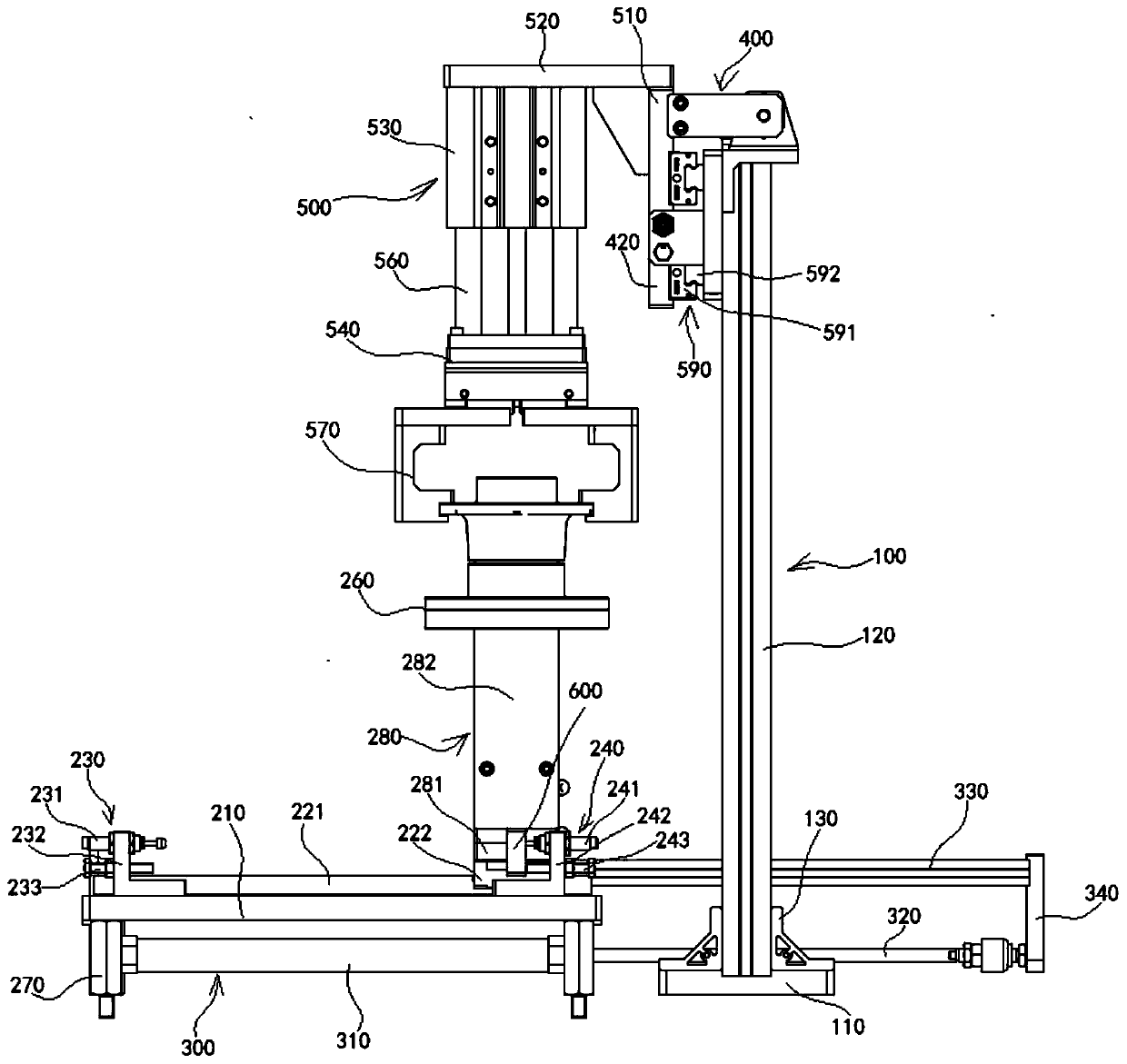

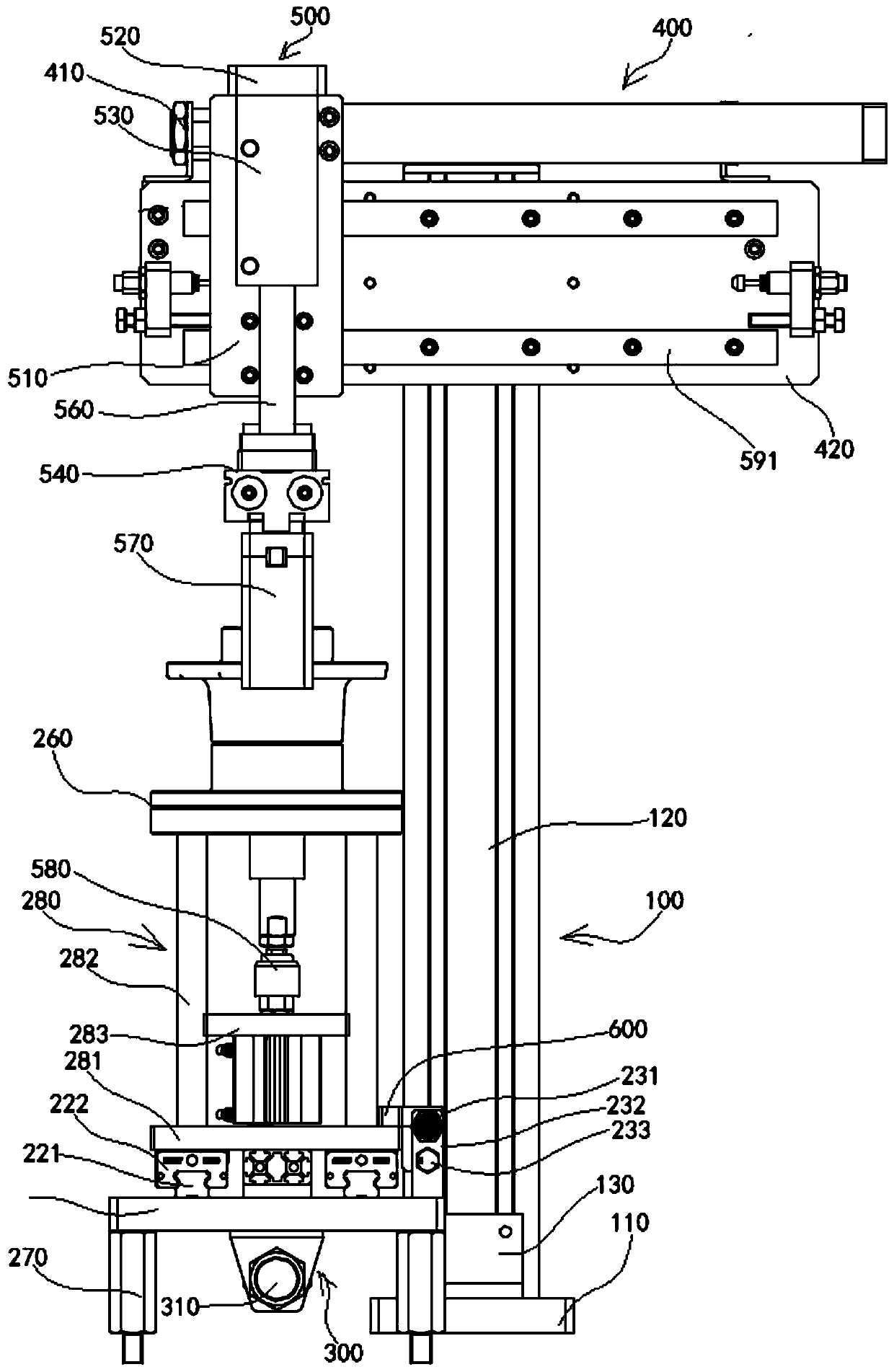

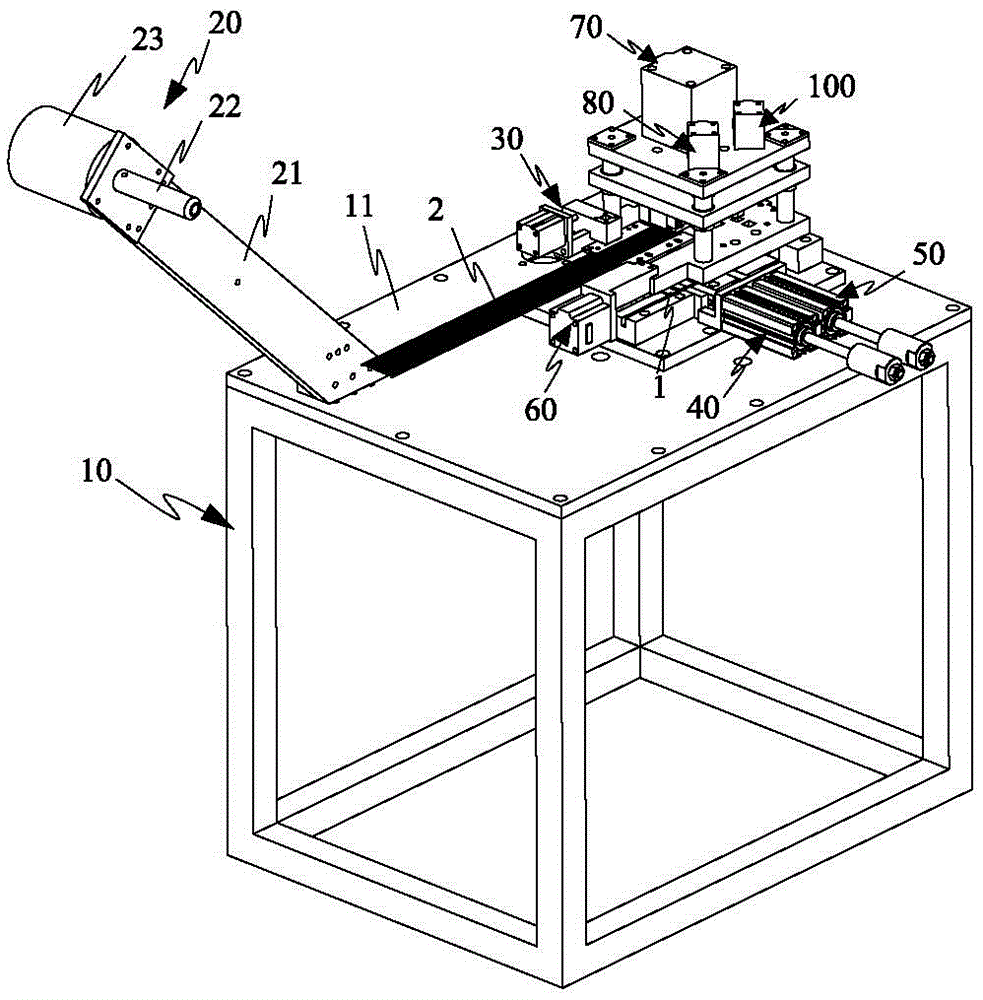

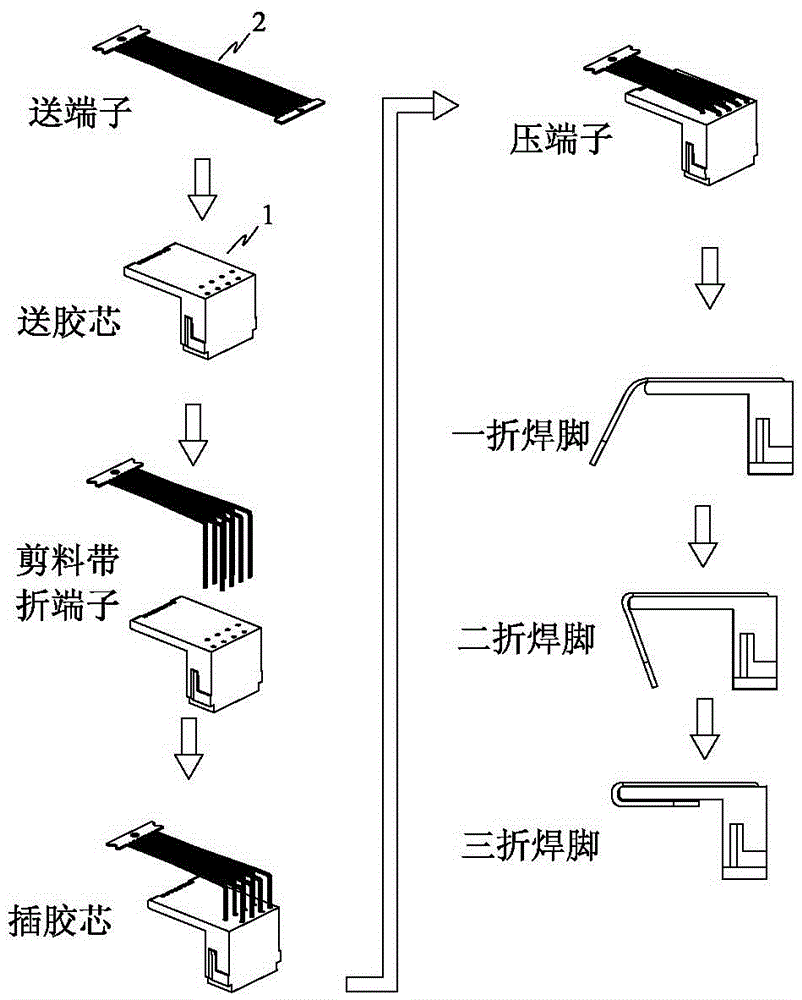

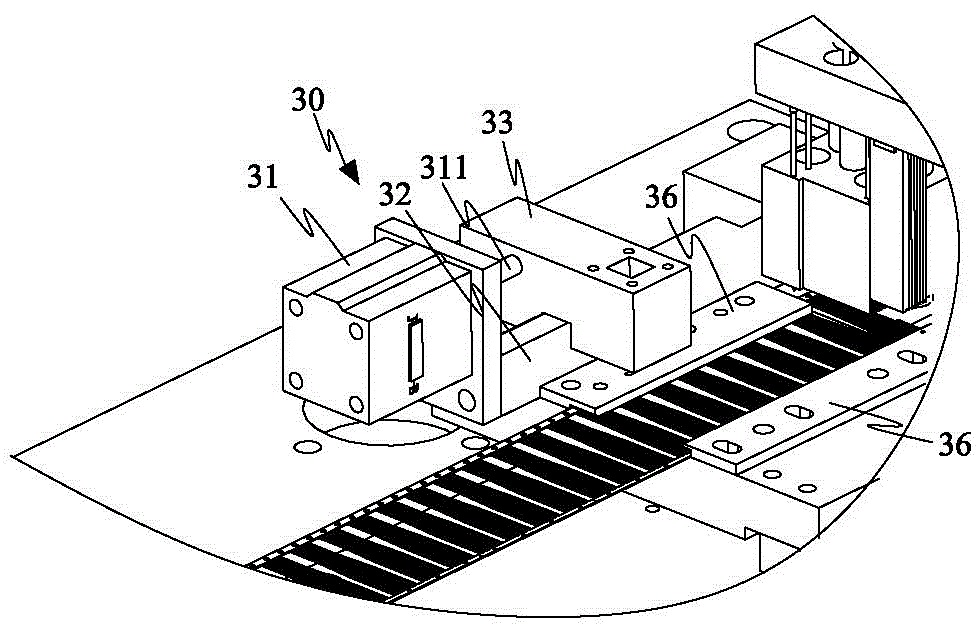

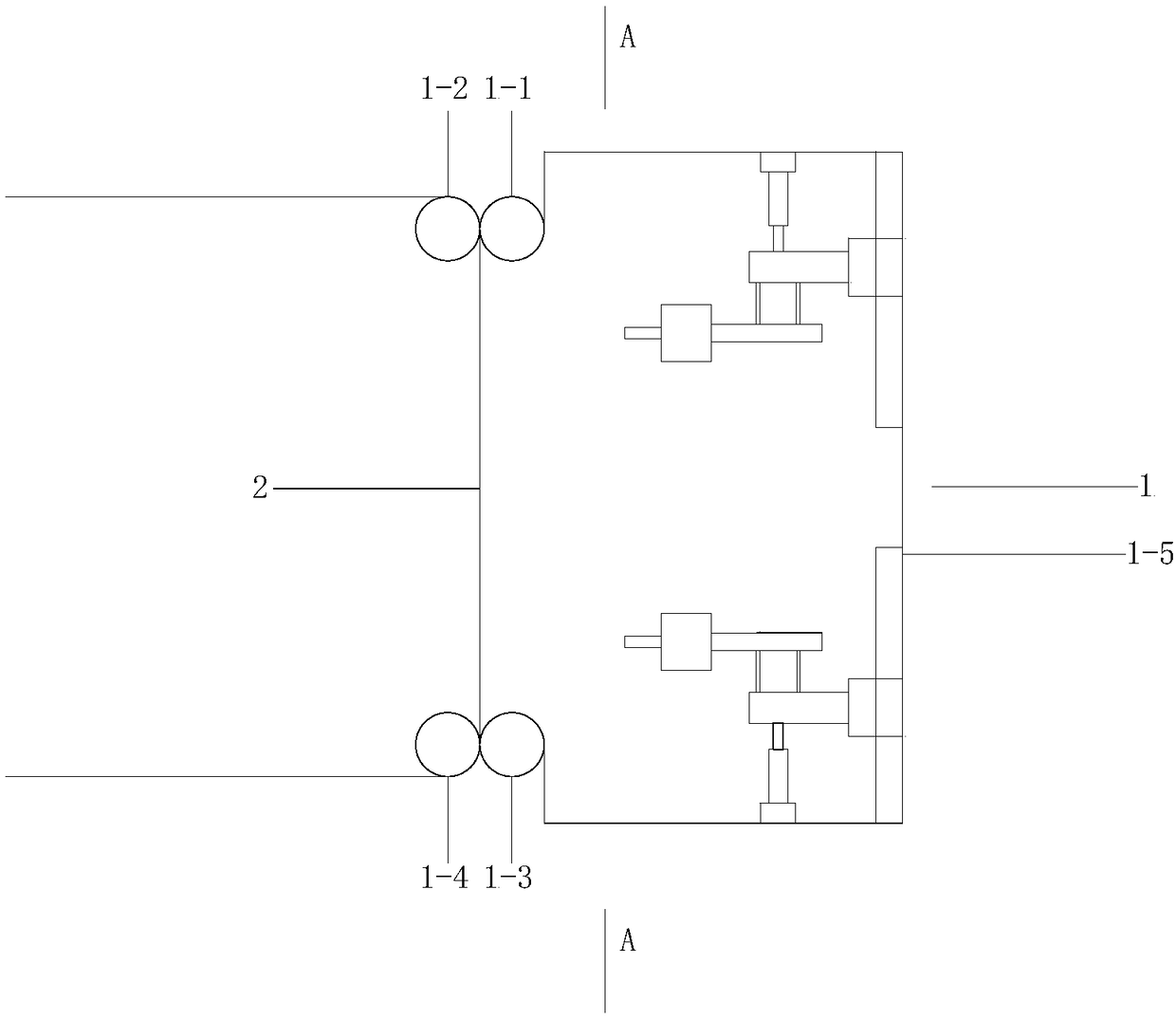

The invention discloses an automatic assembly machine for electric couplers. A terminal fixing device, a terminal conveying device, a first rubber core inlet device, a second rubber core inlet device, a rubber core pushing device, a terminal cutting device, a terminal pressing device, a primary weld leg bending device, a secondary weld leg bending device and a third weld leg bending device are integrated on a rack at the same time. By the adoption of the automatic assembly machine for the electric couplers, terminal material belts and rubber cores can be automatically conveyed, terminal material belts can be automatically cut off, bent and pressed, weld legs can be automatically bent, human involvement is not needed in the whole production process of the electric couplers, human cost is greatly reduced, the production speed is increased, and quality of products is improved.

Owner:JIANGSU ZHONGHAI HUA HE ENVIRONMENTAL PROTECTION CO LTD

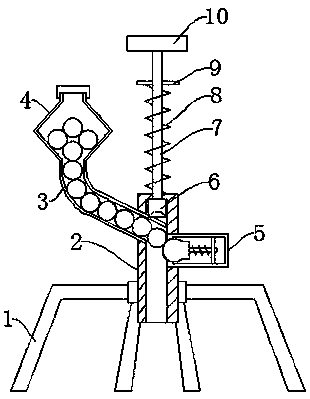

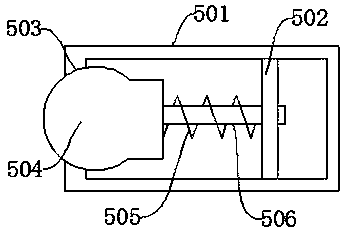

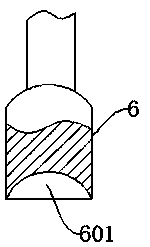

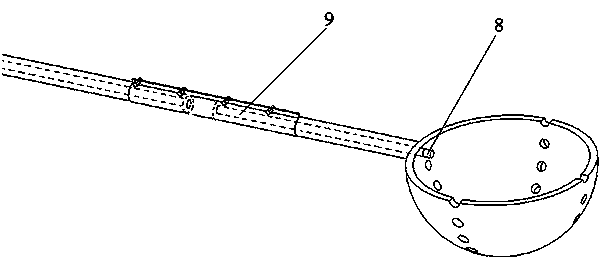

Steel ball feeding device for sealing lithium battery

ActiveCN109962207ARealize automatic deliveryPush inFinal product manufactureCell component detailsEngineeringMechanical engineering

The invention discloses a steel ball feeding device for sealing a lithium battery. The feeding device comprises a supporting frame, a storage bin and a discharging sleeve. The supporting frame is installed at the outer side of the discharging sleeve through threads. A vertically downward blanking channel is arranged in the discharging sleeve, and a feeding pipe is arranged at a side upper portionof the discharging sleeve. The feeding pipe is divided into two sections, wherein the upper section of the feeding pipe is vertically arranged, the top of the feeding pipe is communicated with the storage bin, and the lower section of the feeding pipe is inclined downwards and inserted into the discharging sleeve; a feeding channel in the feeding pipe is communicated with the discharging channel,and a material blocking device is arranged on the side face of the joint of the feeding channel and the discharging channel. The beneficial effects lie in that that the feeding device can achieve theautomatic feeding and pressing of steel balls, and the steel balls can be pressed into the liquid injection hole one by one; the feeding device is simple in structure and convenient to use, so the manual burden can be greatly reduced; meanwhile, the steel balls can be prevented from falling off, and the production efficiency of lithium batteries is improved.

Owner:湖南安德丰新能源科技有限公司

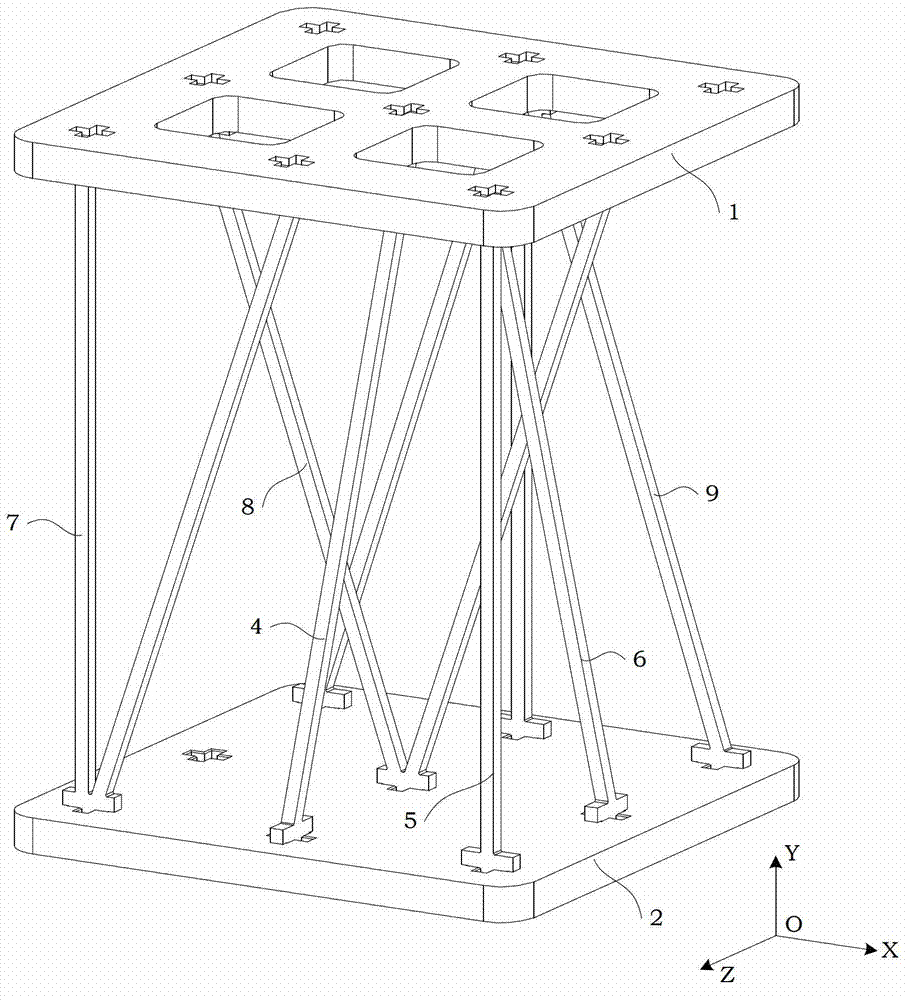

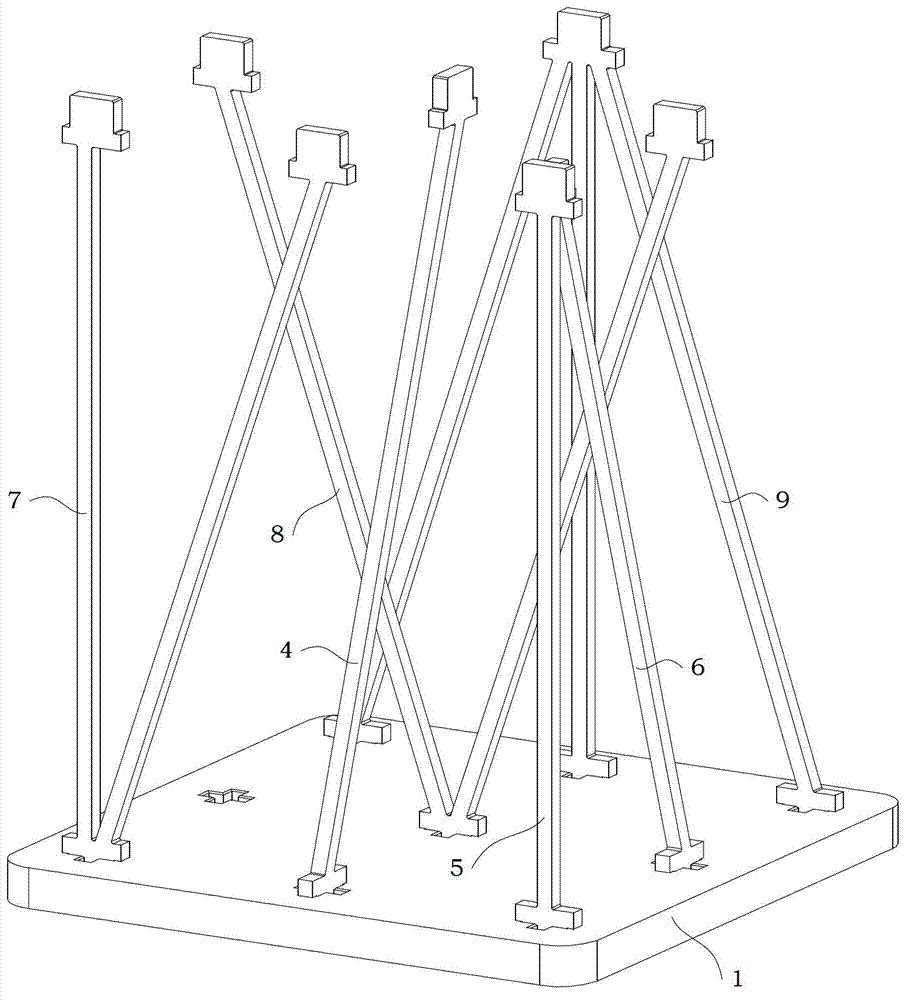

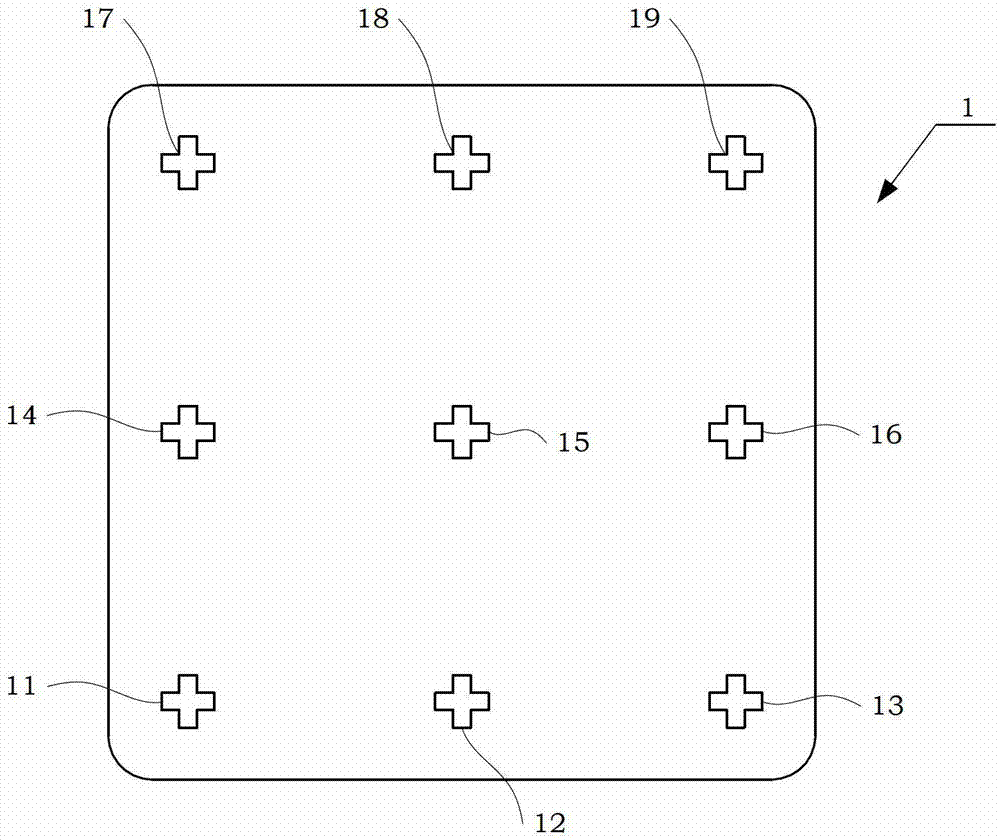

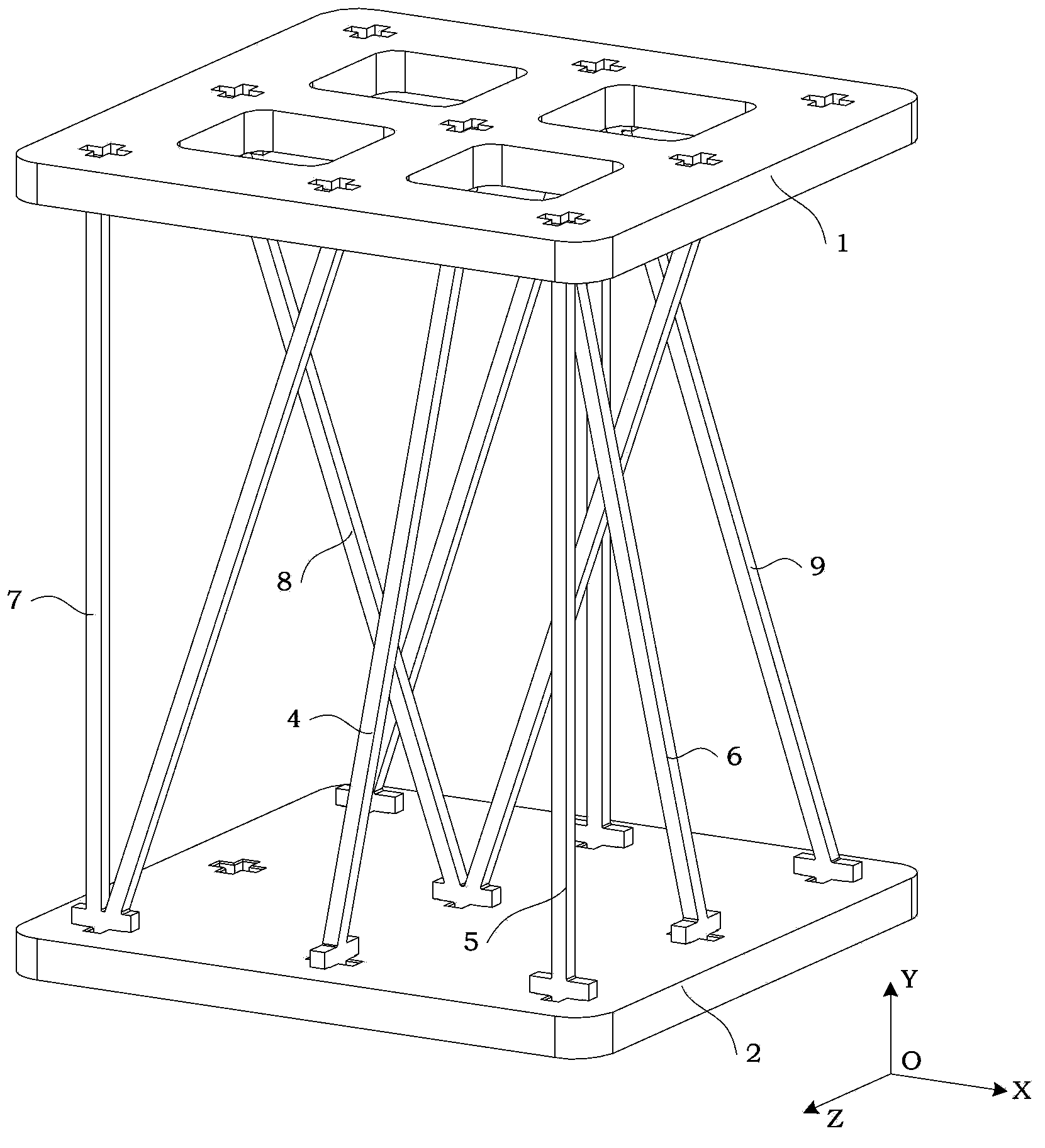

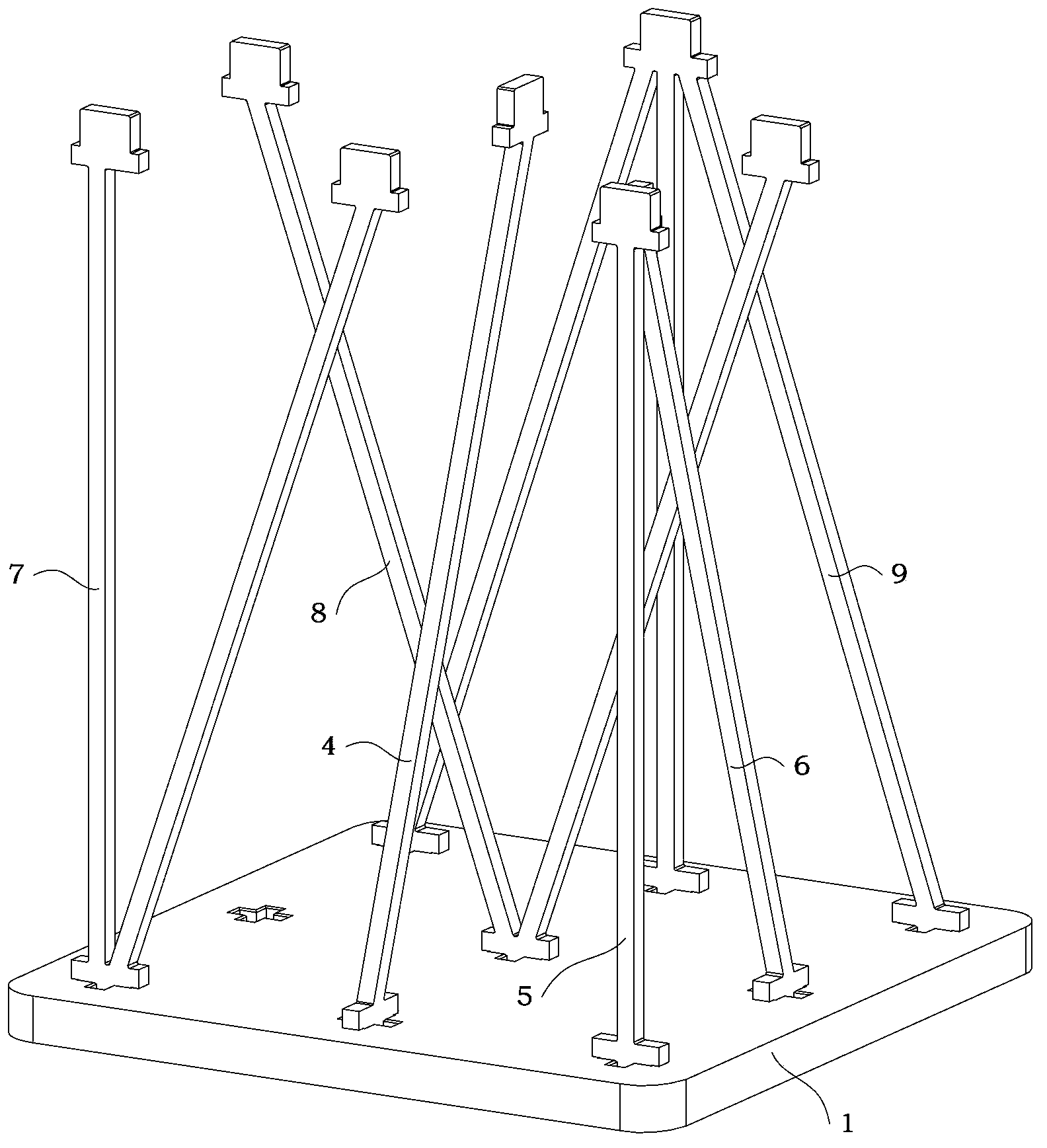

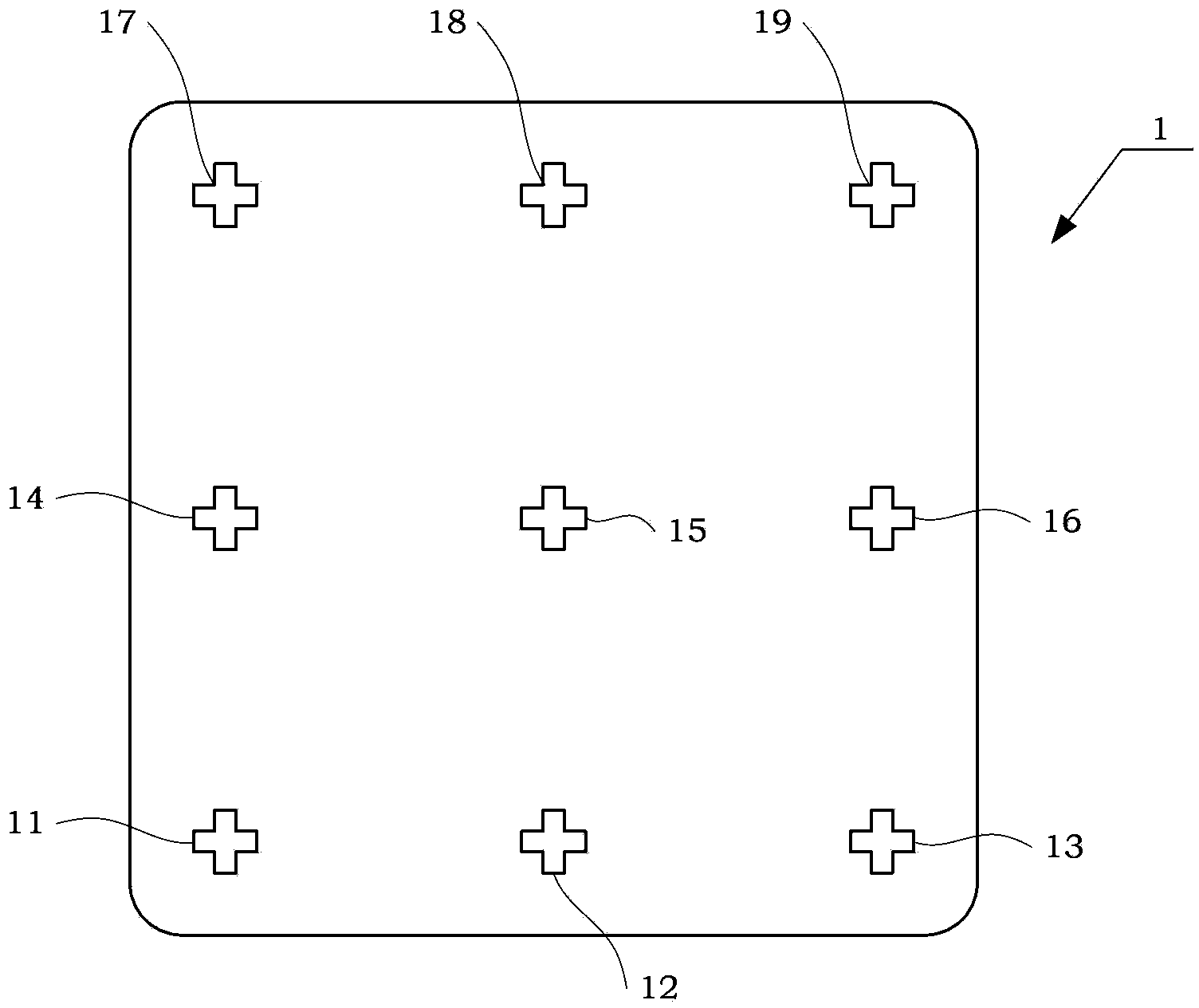

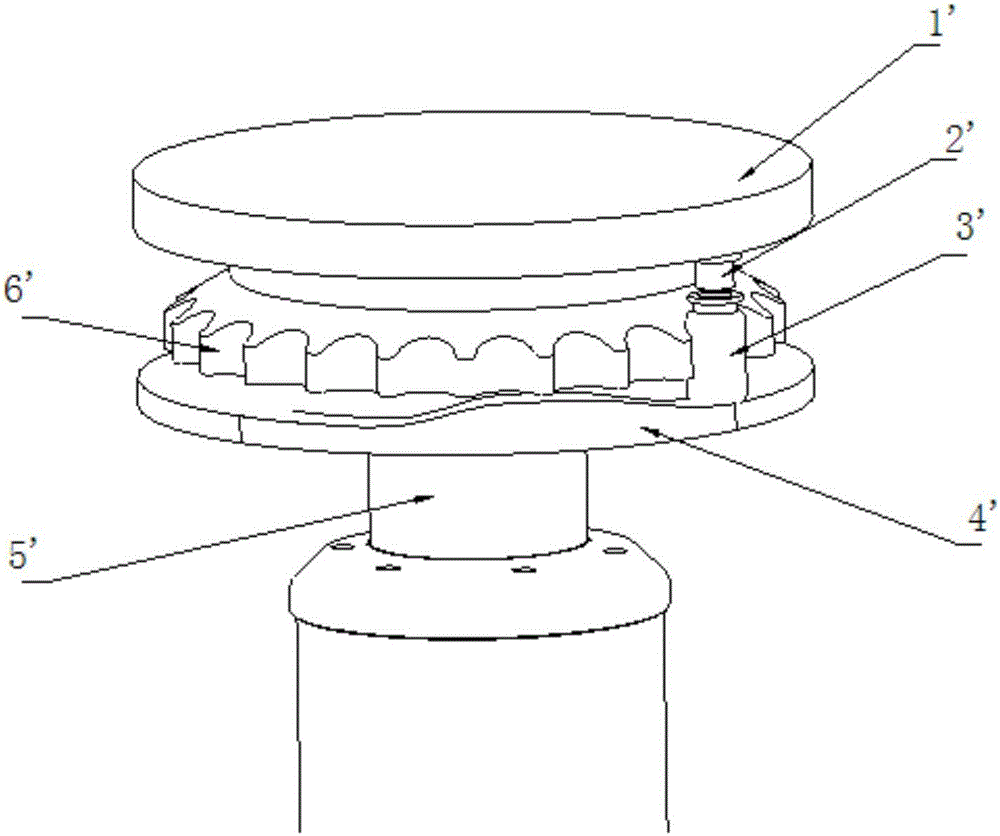

Reconfigurable flexible teaching aid for demonstrating the duality relation of freedom degree and restraint in mechanical principle teaching

The invention discloses a reconfigurable flexible teaching aid for demonstrating the duality relation of freedom degree and restraint in mechanical principle teaching. The teaching aid comprises a movable platform, a static platform and six rod pieces, wherein the six rod pieces are arranged between the movable platform and the static platform. According to the teaching aid designed, on one hand, teaching aid configurations with different freedom degrees can be lapped by utilizing the modularized rod pieces and the platforms, on the other hand, the duality relation between the freedom degree and the restraint can be verified by utilizing the lapped teaching aid configurations. Through the direct observation of the teaching aid, students can directly master the concepts of freedom degree and restraint and the like as well as the duality relation between the concepts.

Owner:BEIHANG UNIV

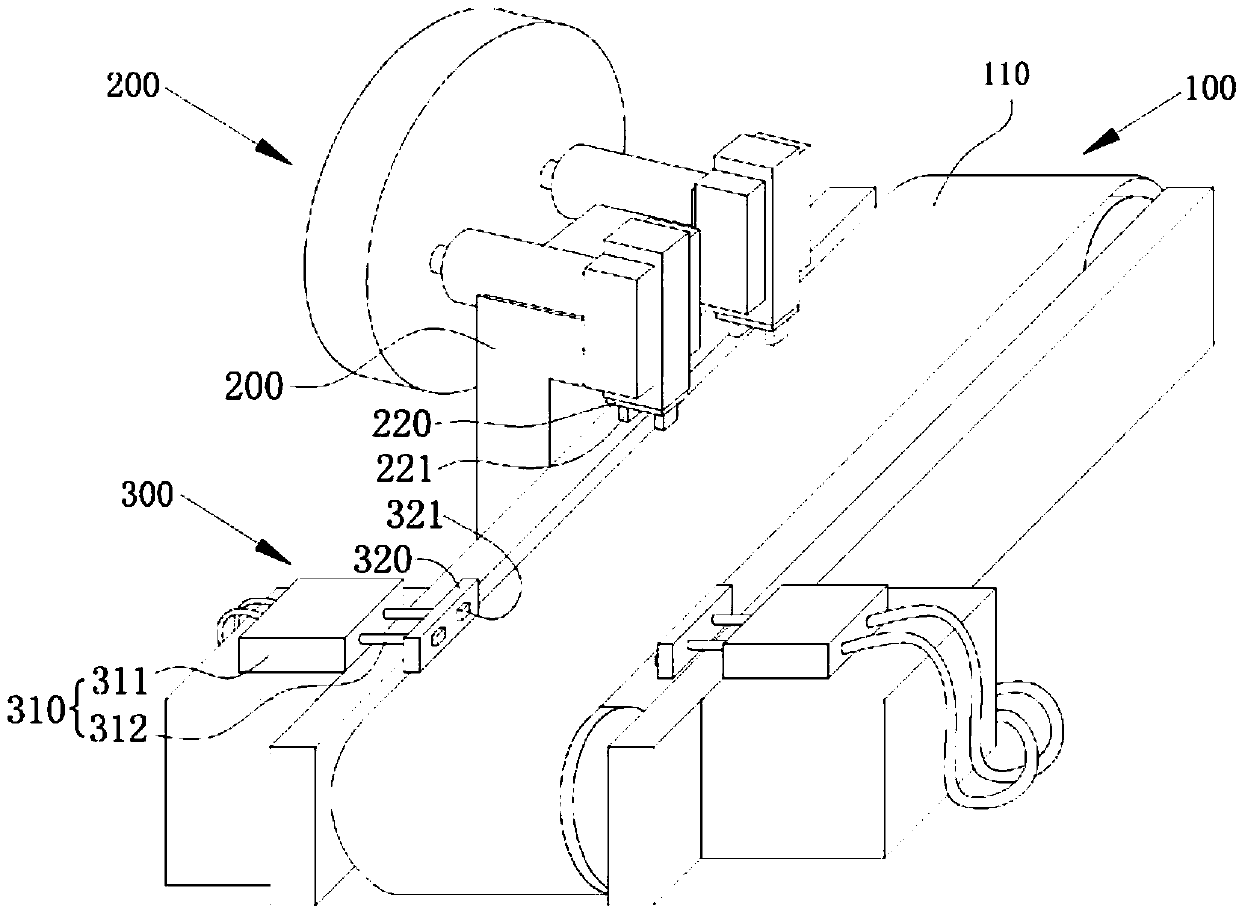

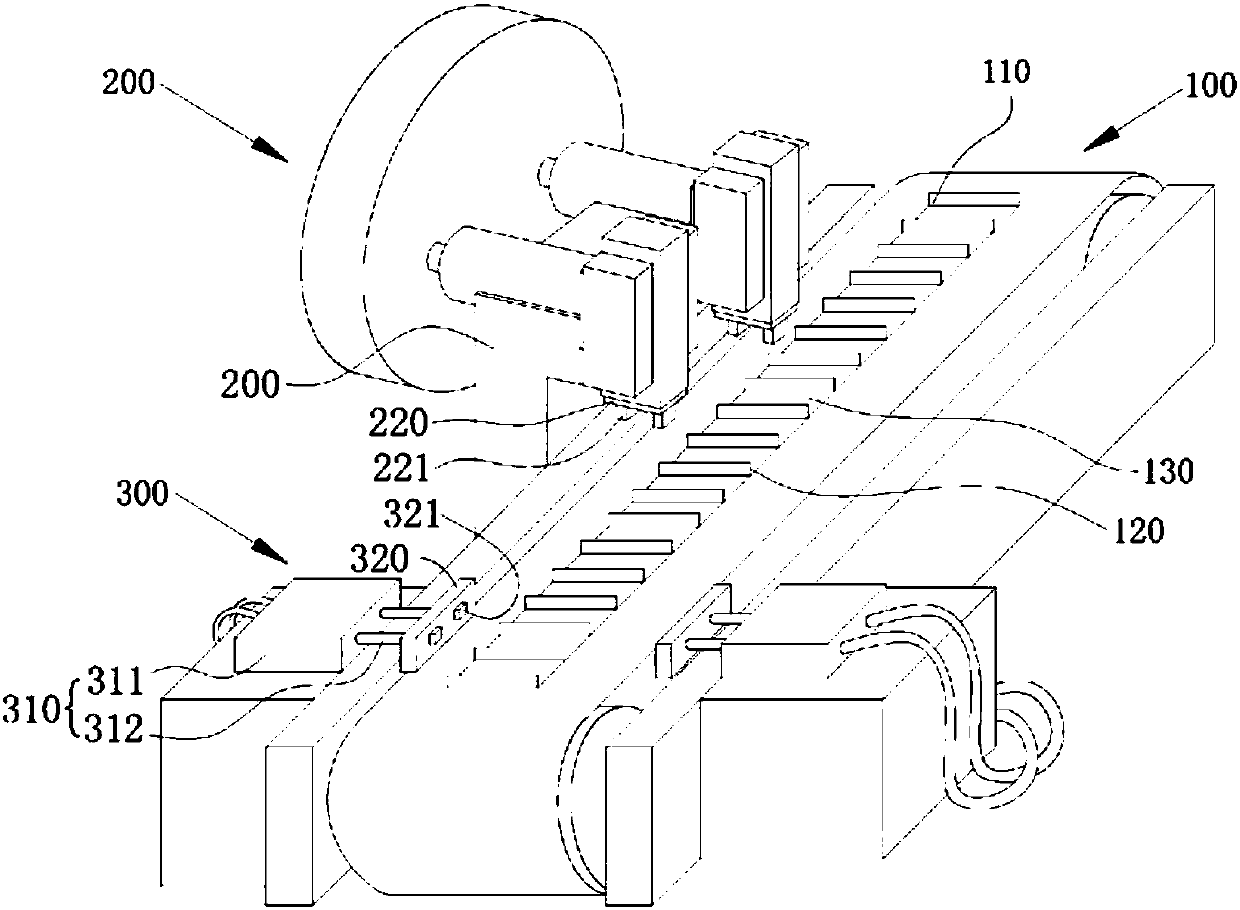

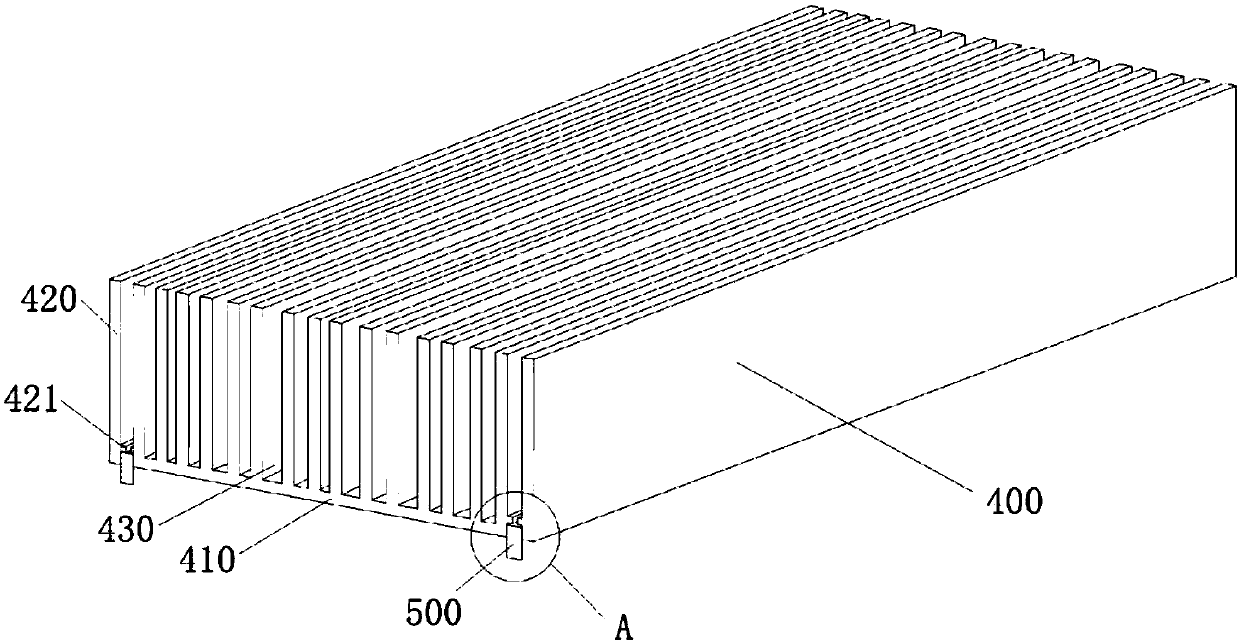

Pin pressing device

PendingCN107716743APush inRealize automatic processing of press-fit heat sink bodyMetal-working feeding devicesHeat exchange apparatusEngineeringHeat sink

The invention relates to a pin pressing device, which includes a transmission mechanism, a riveting mechanism and a bending mechanism. The transmission mechanism includes a conveyor belt. The riveting mechanism includes a first cylinder and two movable riveting heads. The riveting head is driven and connected, the two riveting heads are arranged opposite to the conveyor belt, and the two riveting heads respectively protrude toward the conveyor belt to form at least two first pressing parts; the bending mechanism includes a second cylinder and two pressing parts, The number of the second cylinder is two, and each second cylinder is fixedly connected with a press-fit part respectively, and each second cylinder includes a second cylinder body and a piston rod, and a press-fit part is fixedly connected with a piston rod, two The pressing parts are arranged oppositely, and are respectively arranged on two sides of the conveyor belt. Each pressing part protrudes toward the conveyor belt to form at least two second pressing parts. Through the automatic feeding of the conveyor belt, the pins are pressed on the heat sink by the riveting mechanism and the bending mechanism, which realizes the automatic processing of the pins into the heat sink, and improves the efficiency and safety.

Owner:惠州市创欣隆五金制品有限公司

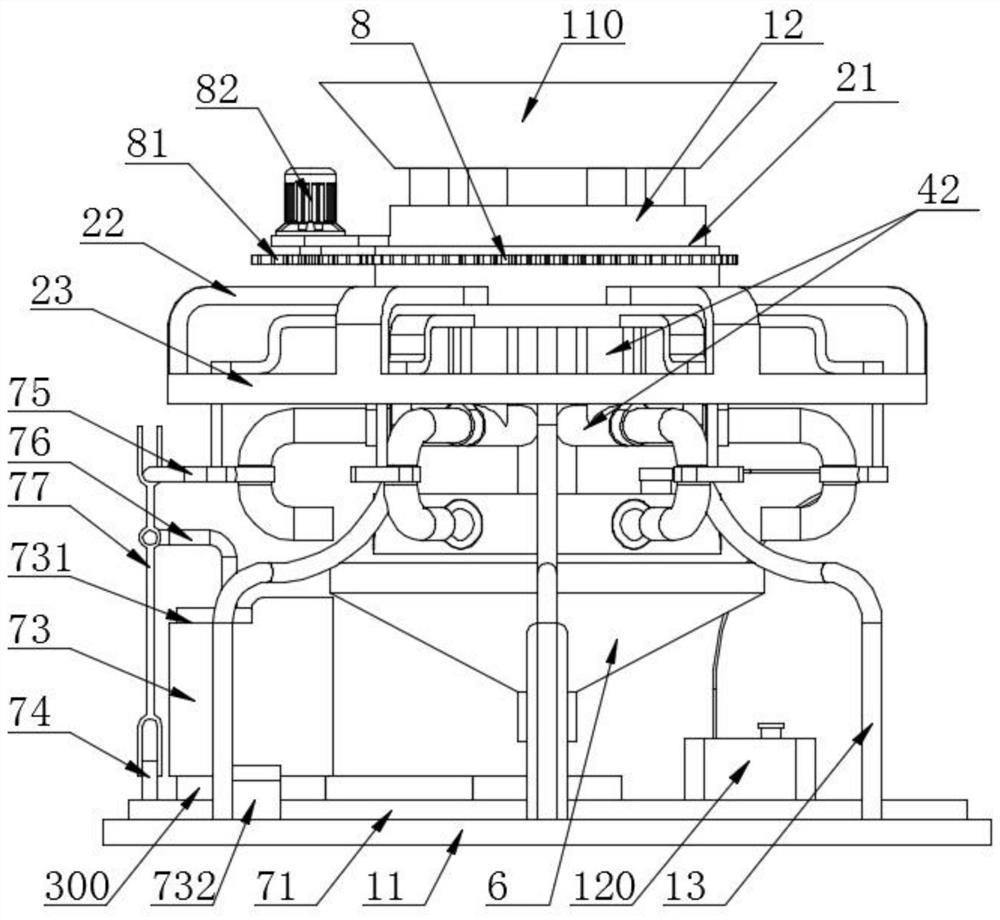

Lead-acid storage battery multi-station welding unit

ActiveCN105382475AImprove the efficiency of the pole group welding processFit closelyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPosition sensor

The invention discloses a lead-acid storage battery multi-station welding unit. The technical problem that a pole group welding technology of an existing lead-acid storage battery is low in efficiency is solved. The lead-acid storage battery multi-station welding unit comprises a mounting seat, a rotary disc rotatably connected to the mounting seat, a control motor for driving the rotary disc to rotate at a certain frequency and a pressing mechanism; a plurality of comb die automatic clamping mechanisms are arranged on the rotary disc, and are provided with assembling holes capable of defining a clamping pole group; a through hole capable of penetrating the rotary disc is formed in the position below each comb die automatic clamping mechanism, and the through holes penetrate the assembling holes to form a channel capable of allowing the pole group to pass through; the pressing mechanism comprises a pressing block arranged above a rotation path of the channels, a pressing air cylinder for driving the pressing block to vertically move and a roller cylinder conveyor located below the through holes and used for conveying battery boxes; and a position sensor is arranged on the roller cylinder conveyor.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

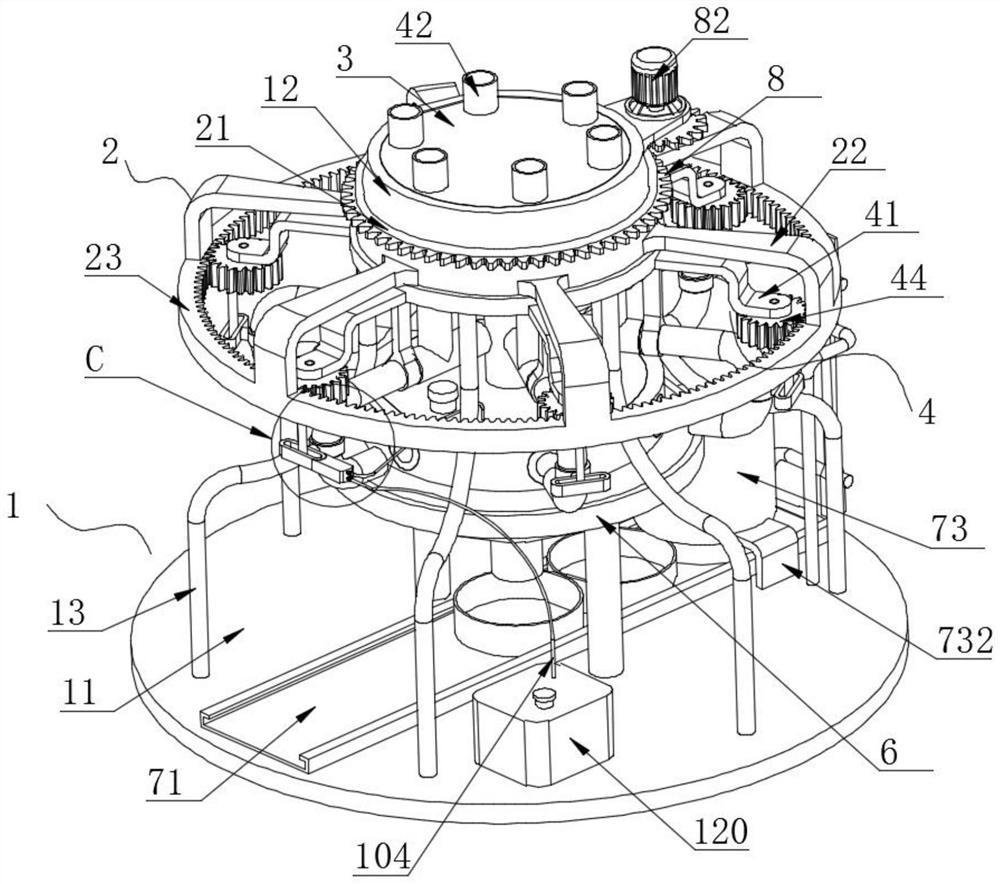

High-efficiency batch marking device for lottery balls

The invention discloses a high-efficiency batch marking device for lottery balls, and particularly relates to the technical field of lottery ball production equipment. The high-efficiency batch marking device comprises a mounting frame, wherein the mounting frame comprises a chassis; a mounting cylinder is arranged above the chassis; a plurality of supporting rods are arranged between the chassisand the mounting cylinder in the circumferential direction; the chassis and the mounting cylinder are fixedly connected through the supporting rods; and a rotating disc is arranged at the upper end ofthe mounting frame. According to the high-efficiency batch marking device, a transmission gear and an eccentric shaft are driven to rotate through the rotation of an inner gear ring, so that a pushing piece moves back and forth, the lottery balls can be pressed in from the upper end of a horizontally-arranged J-shaped pipe, and the marking of one lottery ball at the bottom end of the horizontally-arranged J-shaped pipe can be realized; moreover, a plurality of groups of marking movable mechanisms are arranged, so that the printing of one set of lottery balls can be completed at one time, andthe production speed is high; and meanwhile, the purpose of pushing ball containing boxes is achieved by driving a shifting fork to swing, one ball containing box corresponds to one set of lottery balls, the situation of disordered box packing cannot occur, and the production convenience is greatly improved.

Owner:李党伟

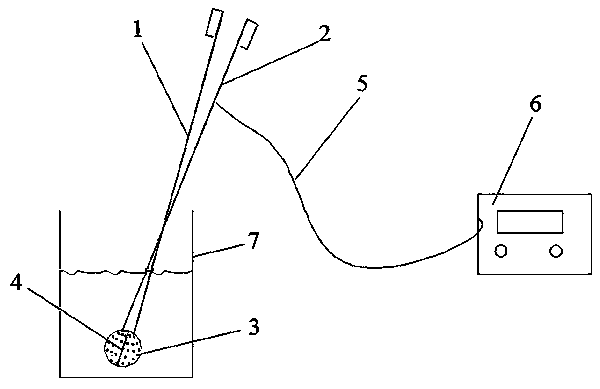

Temperature measurable aluminum smelting bell jar

The invention provides a temperature measurable aluminum smelting bell jar comprising a first handle, a second handle, a thermocouple and a digital display, the first handle and the second handle are same in length and are in hinge joint by a rotating shaft, the first handle is internally hollow and provided with a wire, the wire connects the thermocouple and the digital display, and the temperature measurable aluminum smelting bell jar also includes a first clip and a second clip; the first handle is connected with the first clip by a barrel type fastening connector, the second handle is connected with the second clip by a barrel type fastening connector, the first clip and the second clip both comprise a connecting rod and a porous hollow hemisphere, the connecting rod of the first clip is internally hollow, the porous hollow hemispheres are same in diameter and coaxial, the porous hollow hemispheres can be combined into a hollow sphere, and the thermocouple is located within the first clip. The temperature measurable aluminum smelting bell jar can realize the additive clamping, pressing and other operation, can display temperature of a melt in real time, has the advantages of simple structure, graphite clip material, small pollution to the melt, detachable clips and handles, and easy installation and replacement.

Owner:HOHAI UNIV

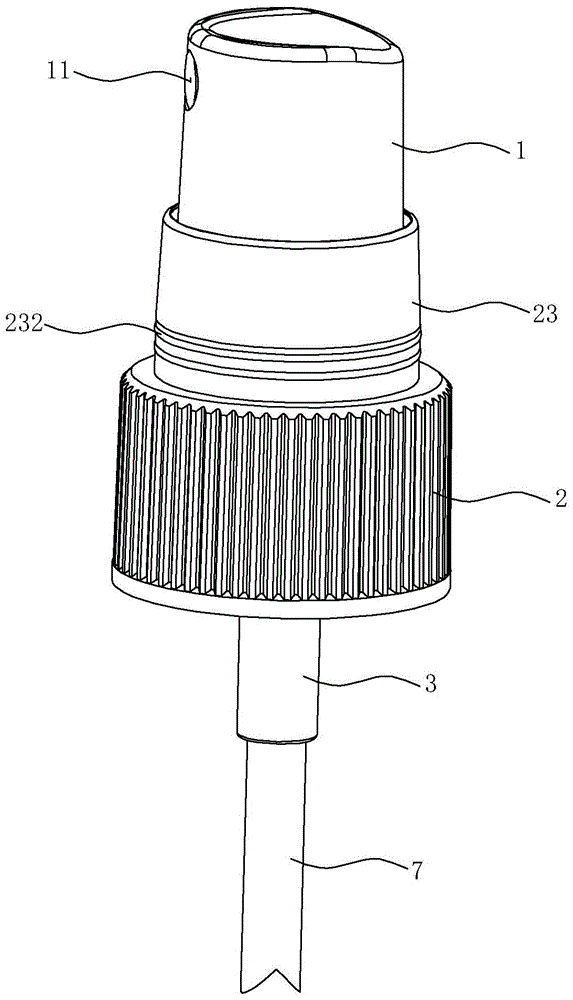

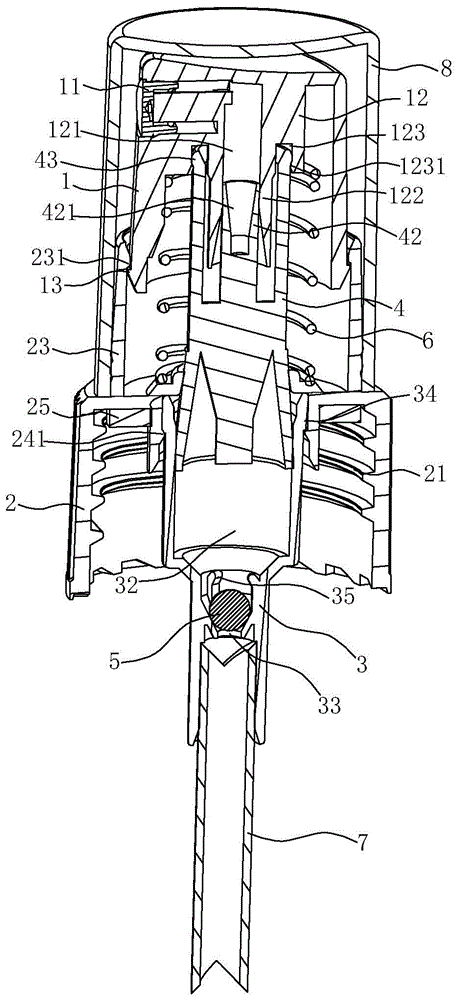

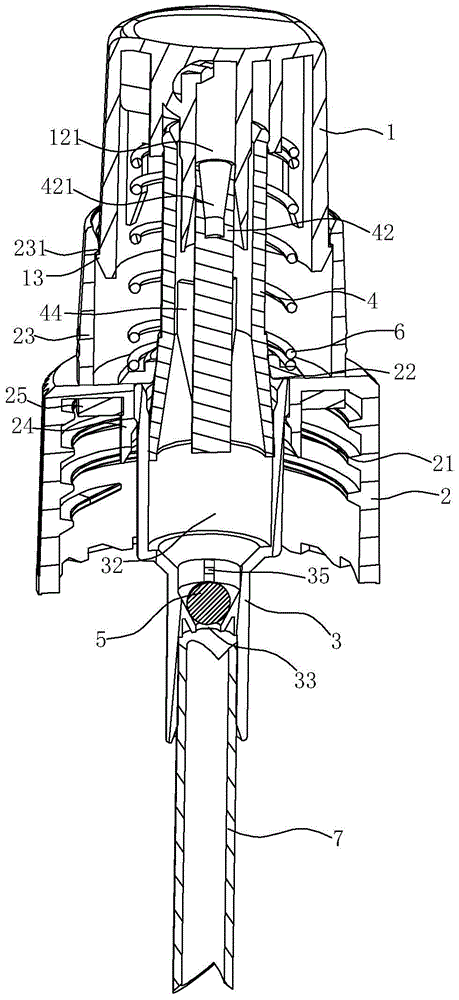

a spray pump

ActiveCN104858080BSimple structureRealize the liquid out functionLiquid spraying apparatusSprayerEngineering

The invention relates to an atomizing pump. The atomizing pump comprises a head cap, a bottle cap, a pump body, a piston, a hoodle and a spring, wherein one side of the head cap is provided with a sprayer; the bottle cap is used for connecting the atomizing pump to a bottle body; the pump body is arranged at the lower side of the top face of the bottle cap; the lower portion of the piston penetrates through a through hole to be connected into an extruding cavity in a mode capable of moving up and down and maintain a tightly matched state with the inner wall of the extruding cavity all the time. The atomizing pump simplifies the structure of an atomizing pump in the prior art, the structure of the atomizing pump is simpler and more reasonable, the manufacturing and the assembly are convenient, therefore the production cost of the atomizing pump is reduced, and the market competitiveness of the atomizing pump is improved; meanwhile, the atomizing pump ingeniously uses the connection structure between the piston and the head cap, a seal structure is not needed to be additionally arranged, the seal of the atomizing pump is achieved, therefore, the liquid leakage problem when the bottle body is inverted is avoided, the connection between the piston and the body is simple and good in sealing performance, the liquid is pressed into a spraying cavity conveniently, the atomizing volume of the atomizing pump is large and stable, and the use is convenient.

Owner:YUYAO SUN RAIN SPRAYER

Atomizing system for electrolytic copper foil penetration point and pinhole detection and application of atomizing system

InactiveCN109142384AAutomate operationPush inMovable spraying apparatusOptically investigating flaws/contaminationElectrolysisCopper foil

The invention relates to an atomizing system for electrolytic copper foil penetration point and pinhole detection and an application of the atomizing system. The atomizing system is characterized in that a fourth telescopic power mechanism is mounted on the lower surface of the lower portion of a shell, the other end of the fourth telescopic power mechanism is connected with a clamping plate, a plurality of clamping rubber blocks are arranged on the surface of the clamping plate at intervals, and the width of each rubber block is as same as that of a copper foil. By the aid of the atomizing system for electrolytic copper foil penetration point and pinhole detection and the application of the atomizing system, whole dilute sulfuric acid can be automatically applied in copper foil penetration point and pinhole detection.

Owner:苏州绣创投资发展有限公司

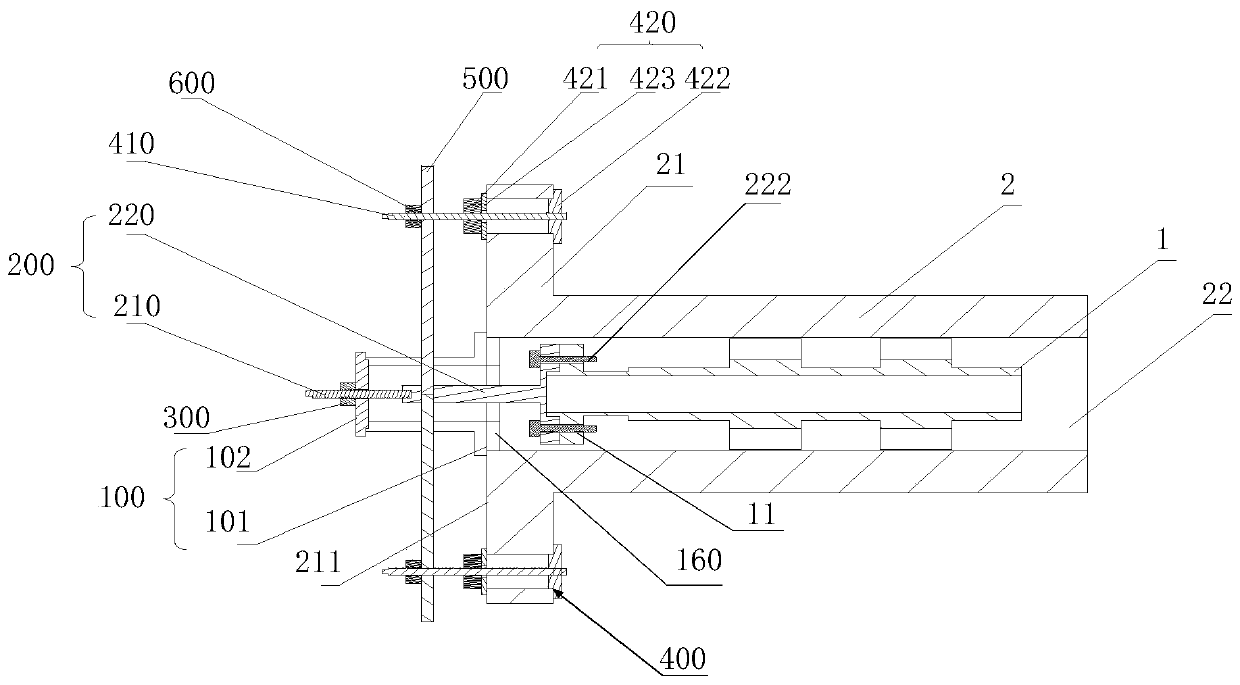

Hub bearing cage assembly press-fitting device

The invention discloses a hub bearing cage assembly press-fitting device. The hub bearing cage assembly press-fitting device comprises a bottom frame and a bracket, wherein the bracket further comprises a supporting base and a supporting stand column, a supporting plate on which a first slide assembly, a first buffer device, a second buffer device, a first drive device and a workbench are placed is arranged on the bottom frame; a second drive device and a clamping lifting device are mounted on the bracket; and the first slide assembly and a second slide assembly are separately arranged on the bottom frame and the bracket. When the hub bearing cage assembly press-fitting device can be independently used, a plurality of cage assemblies of a hub bearing can be simultaneously pressed in; when the hub bearing cage assembly press-fitting device is matched with a connecting line (automatic production line) for use, automation is provided for equipment; and the hub bearing cage assembly press-fitting device is high in mounting efficiency and is high in speed, so that production efficiency is greatly improved.

Owner:广德中隆轴承有限公司

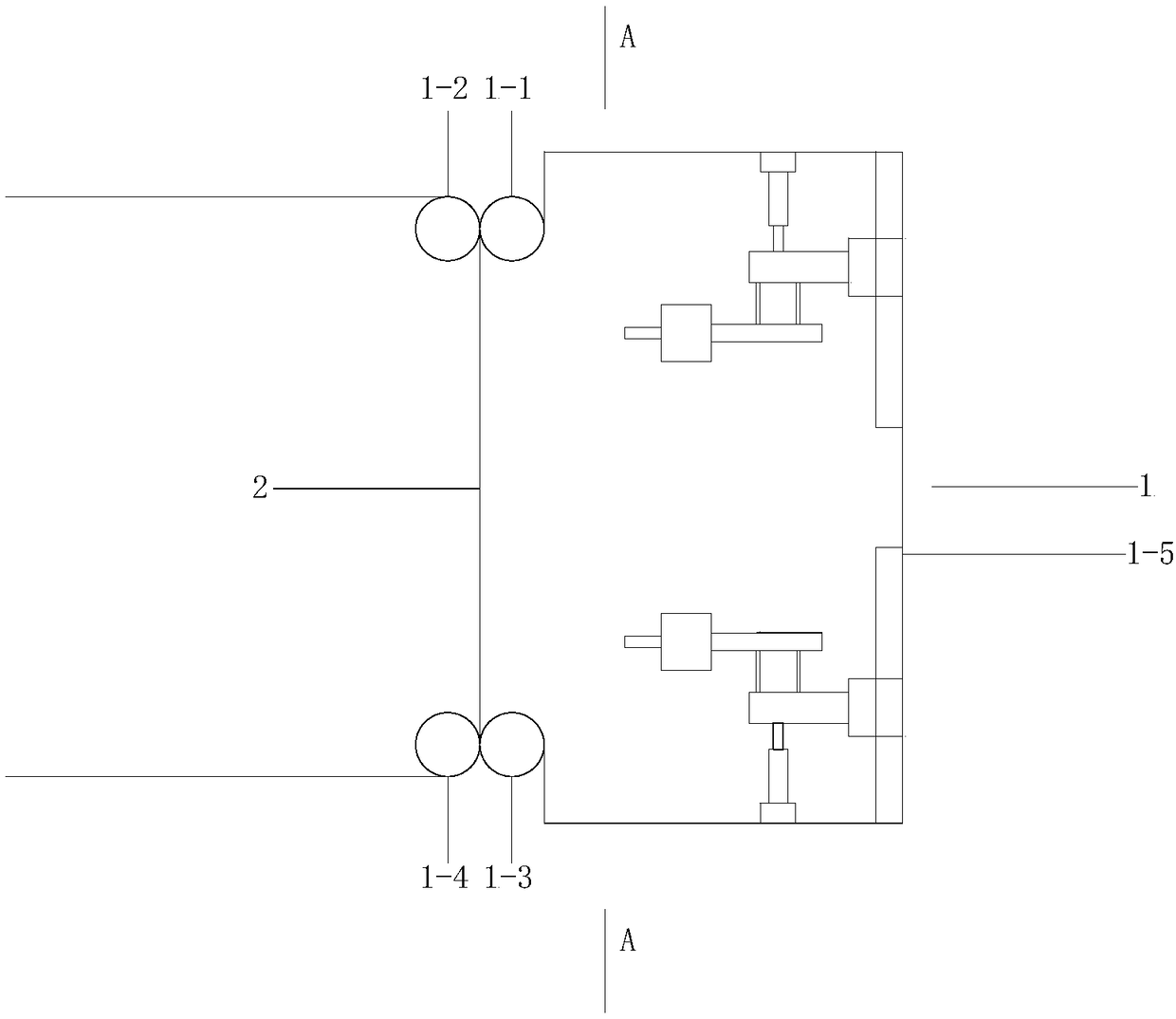

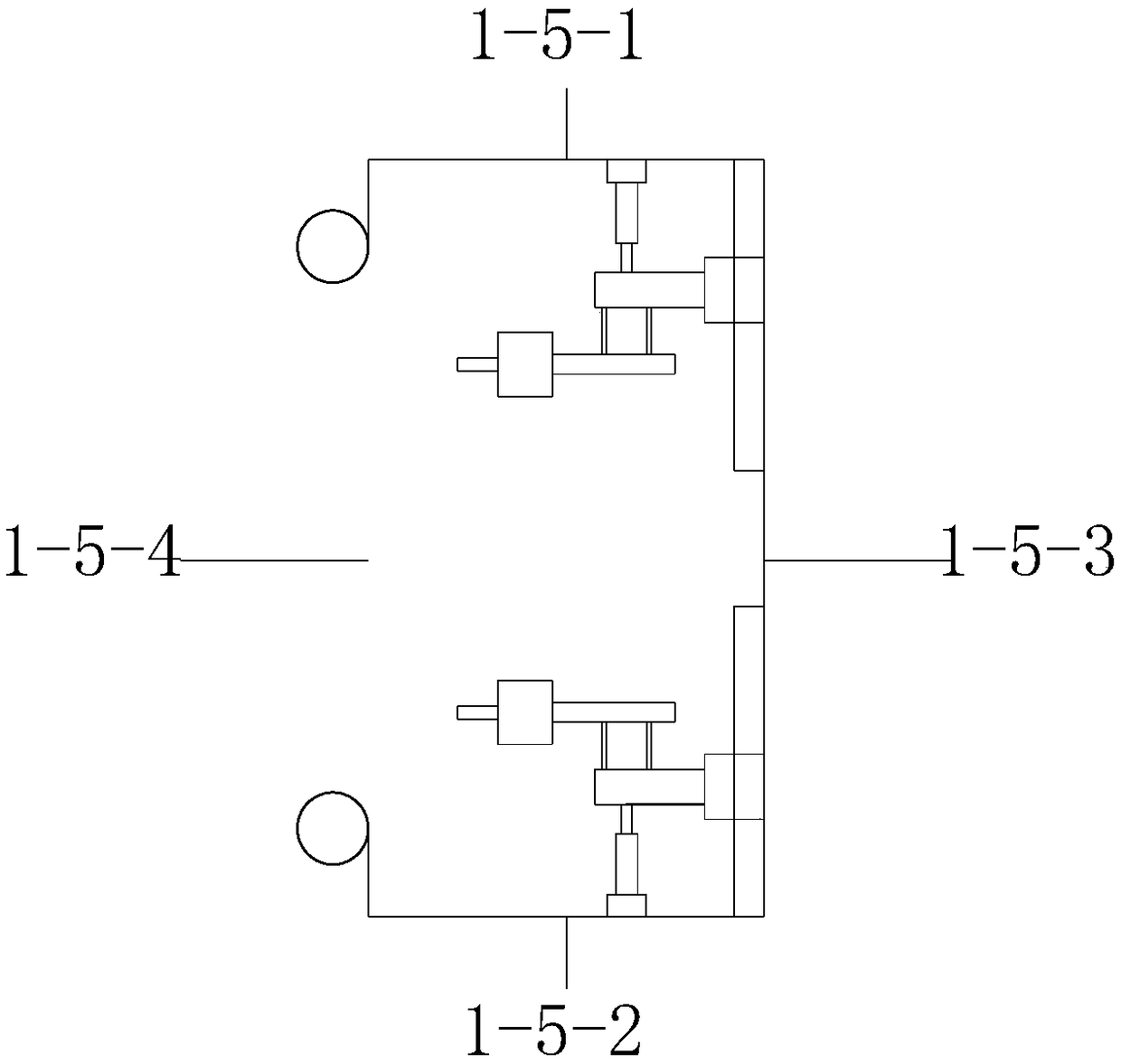

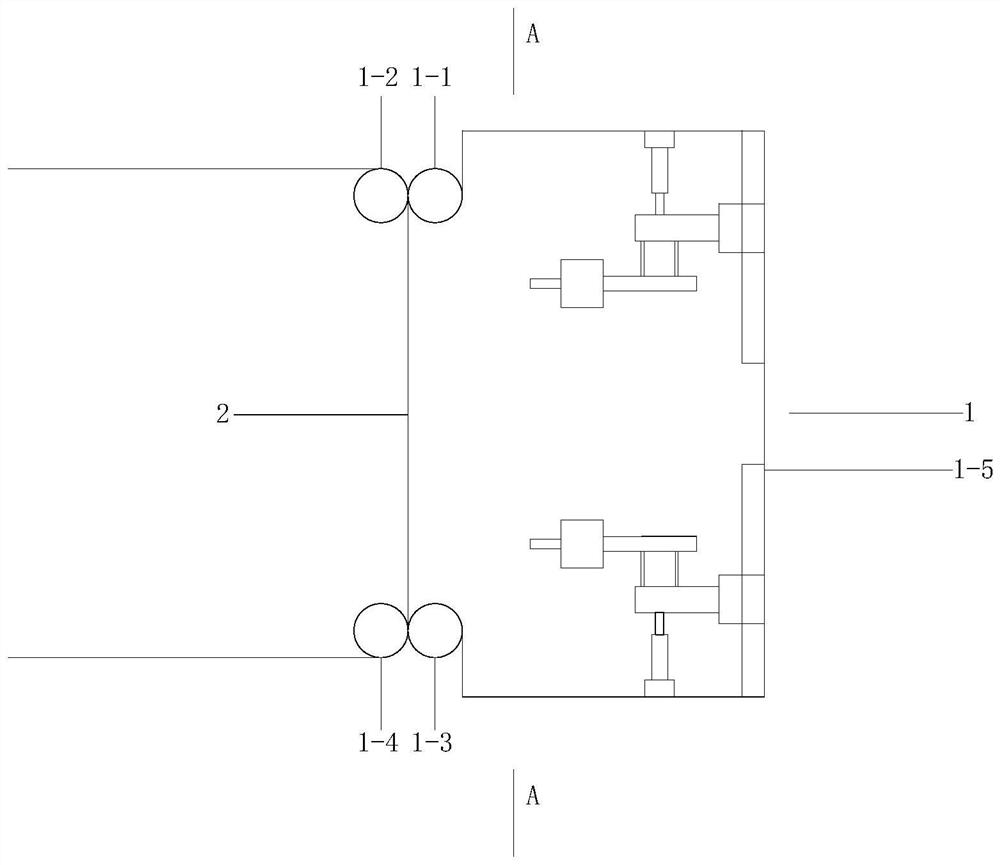

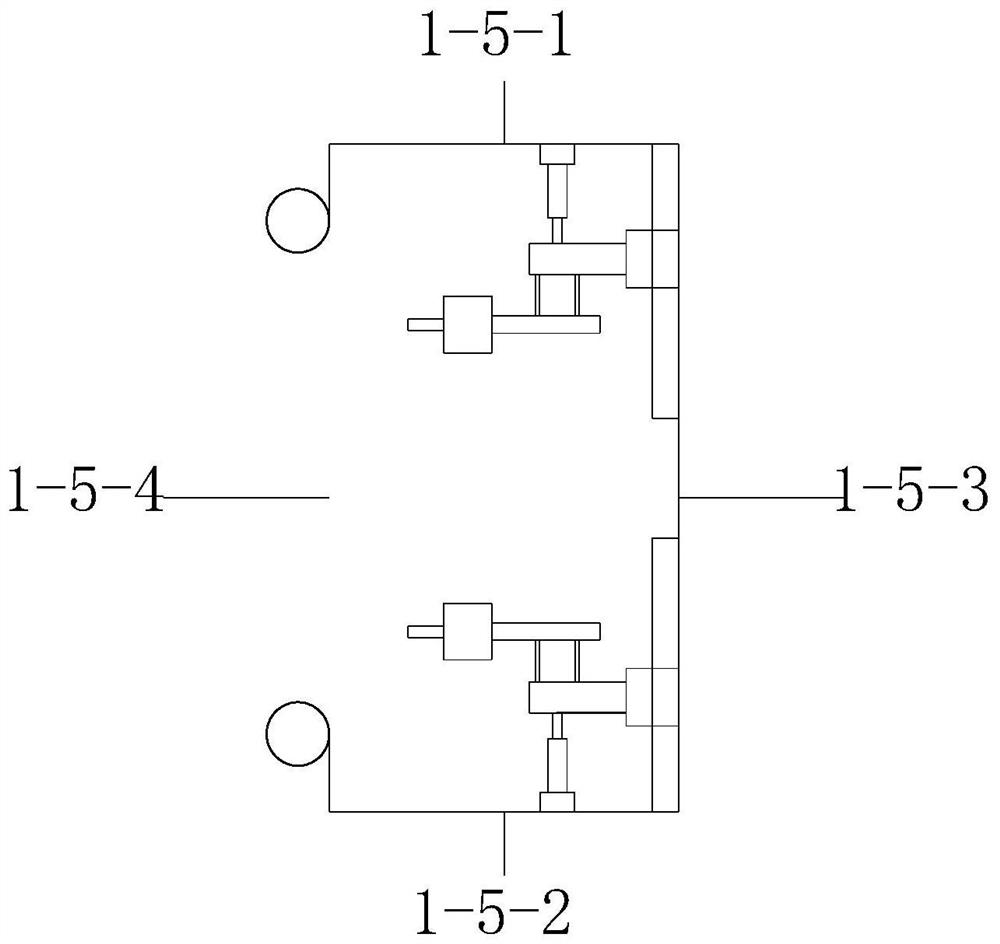

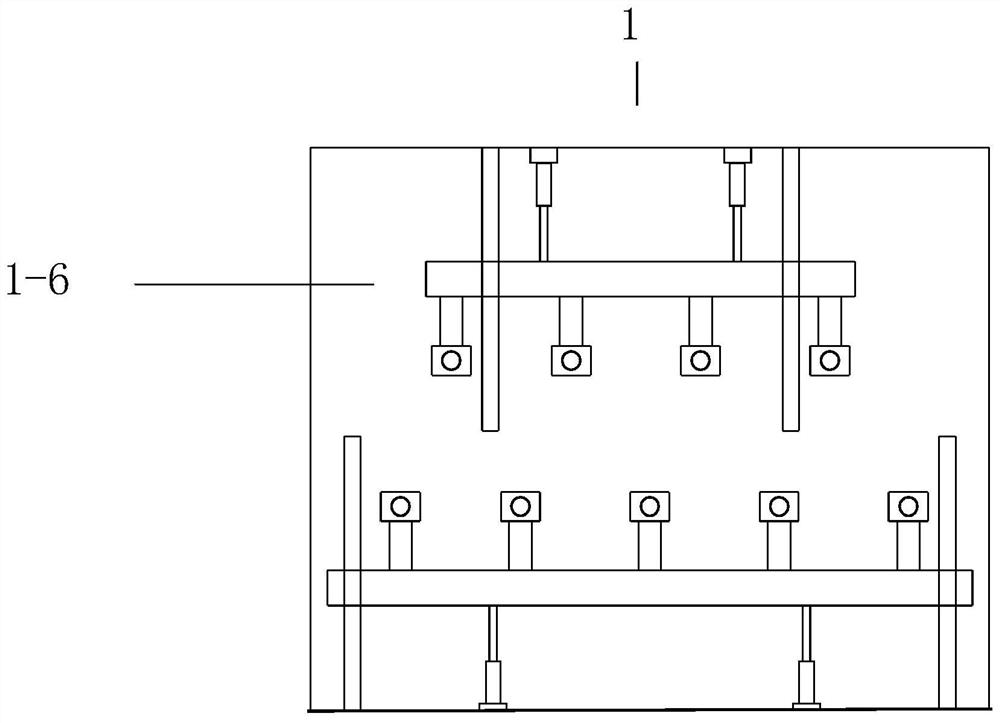

Detection equipment for permeation point and needle hole of electrolytic copper foil

ActiveCN109001223AAutomate operationPush inOptically investigating flaws/contaminationSurface mountingCopper foil

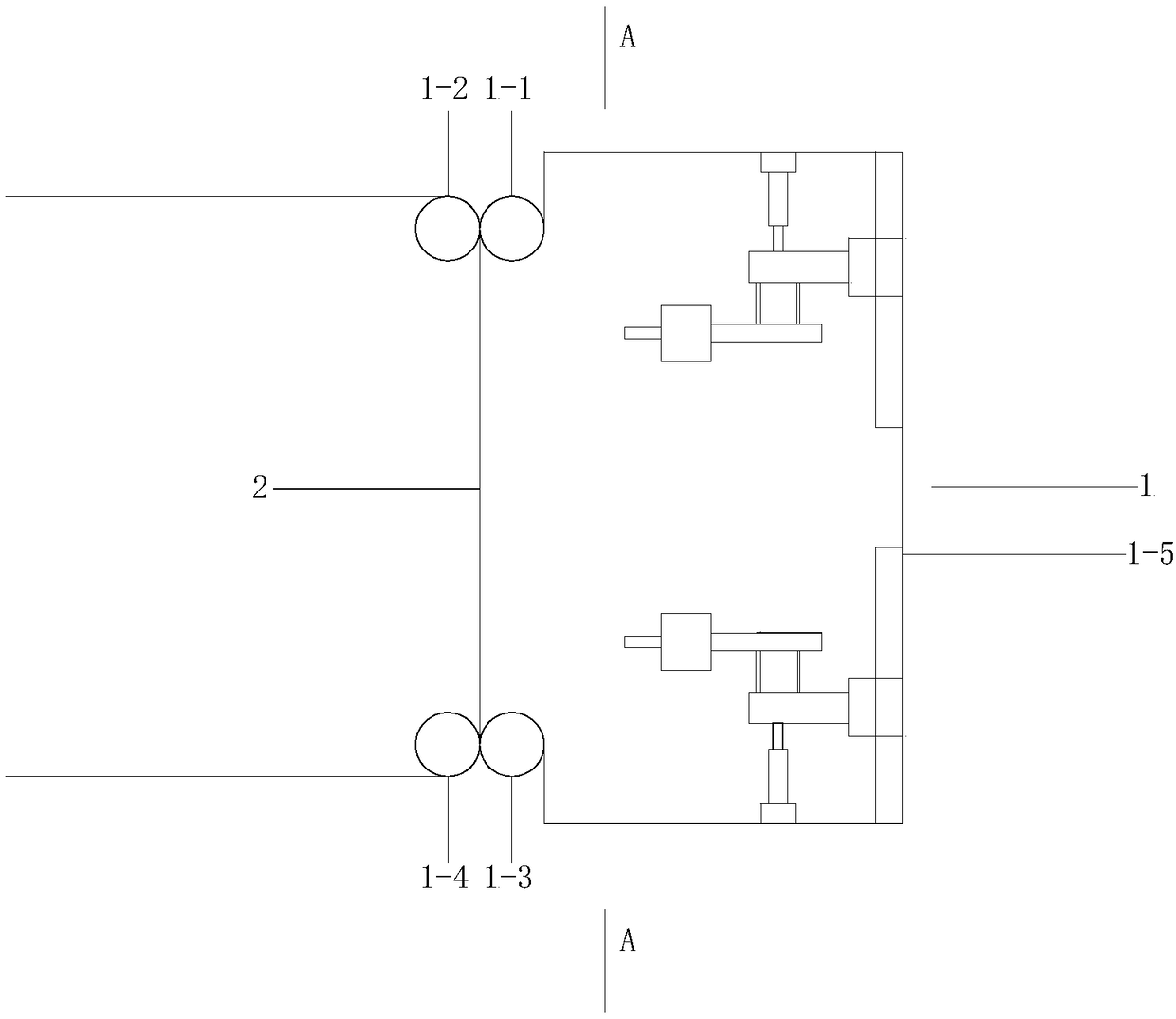

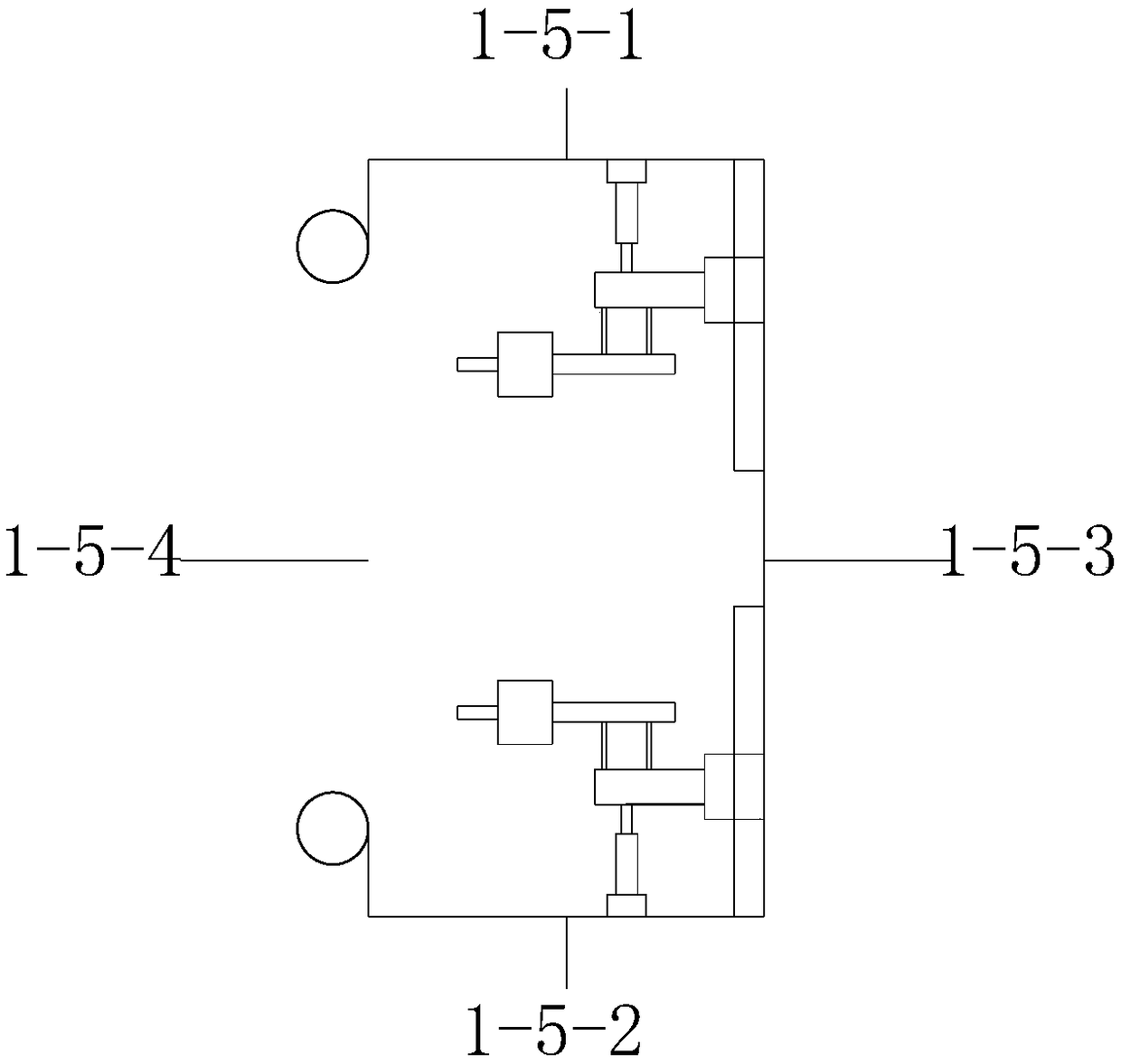

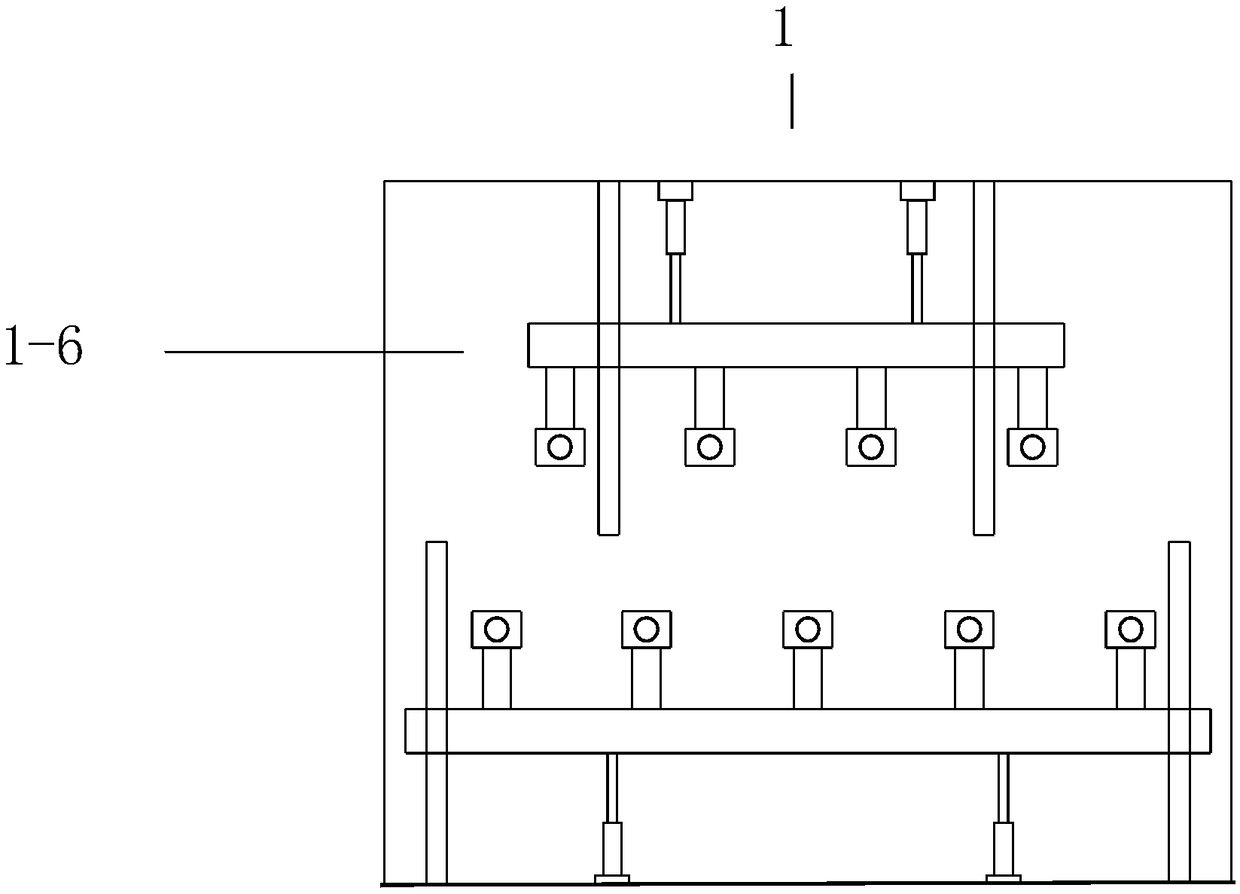

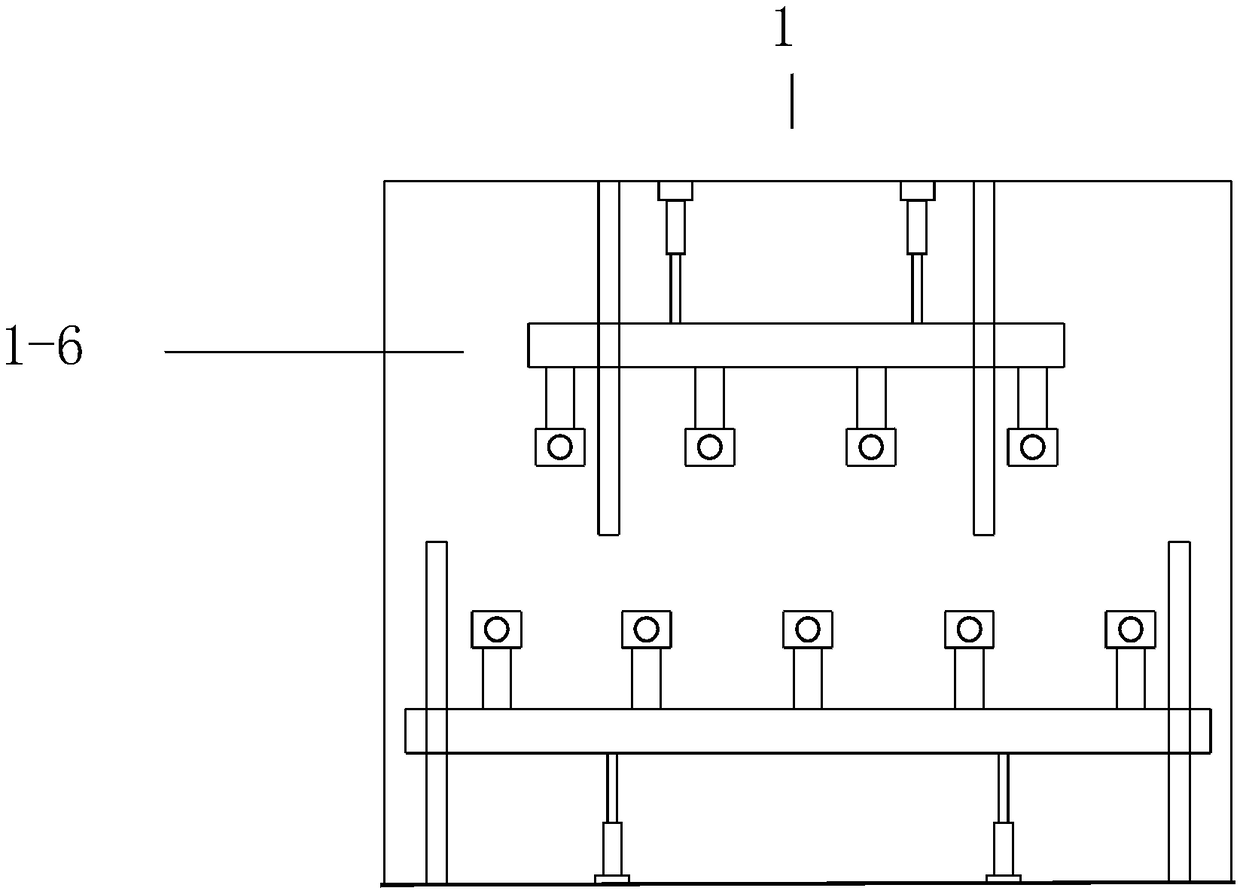

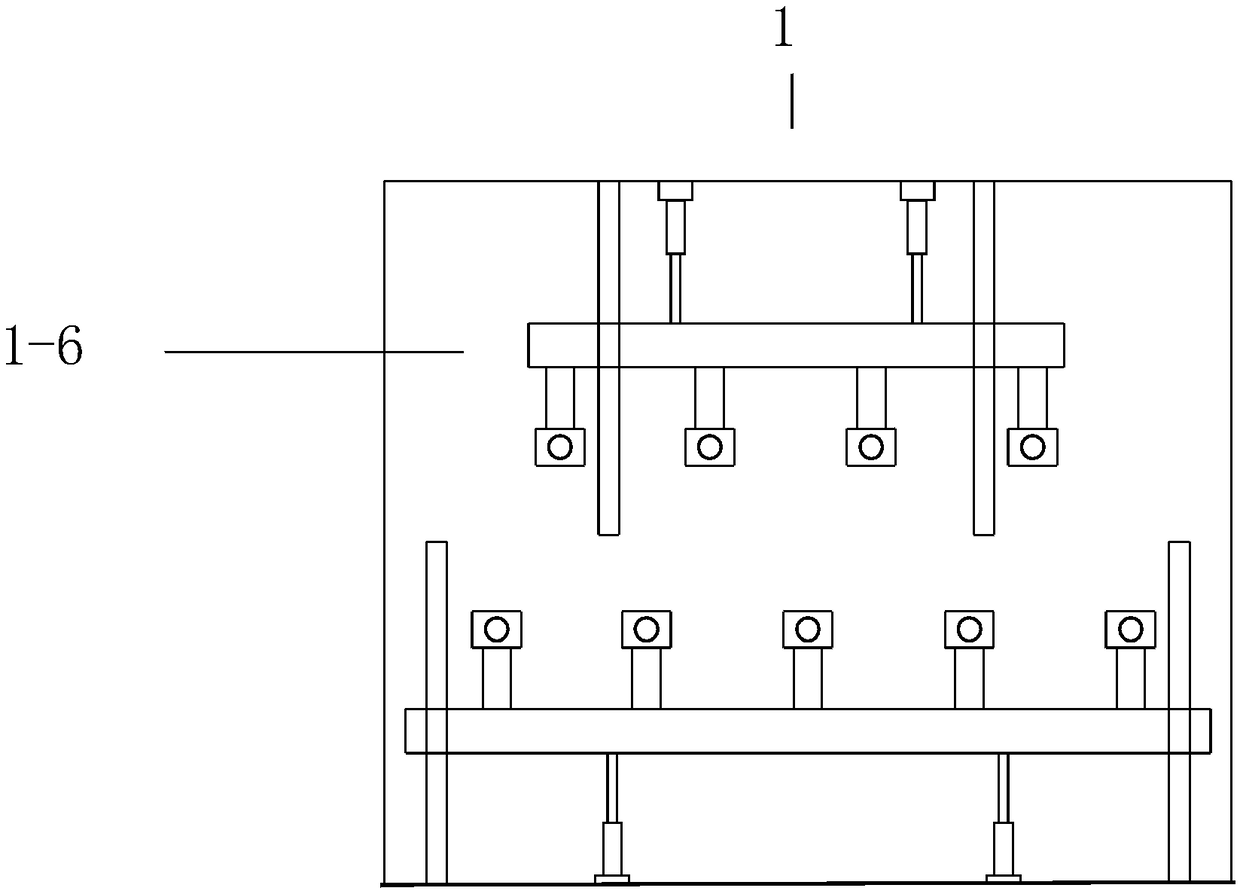

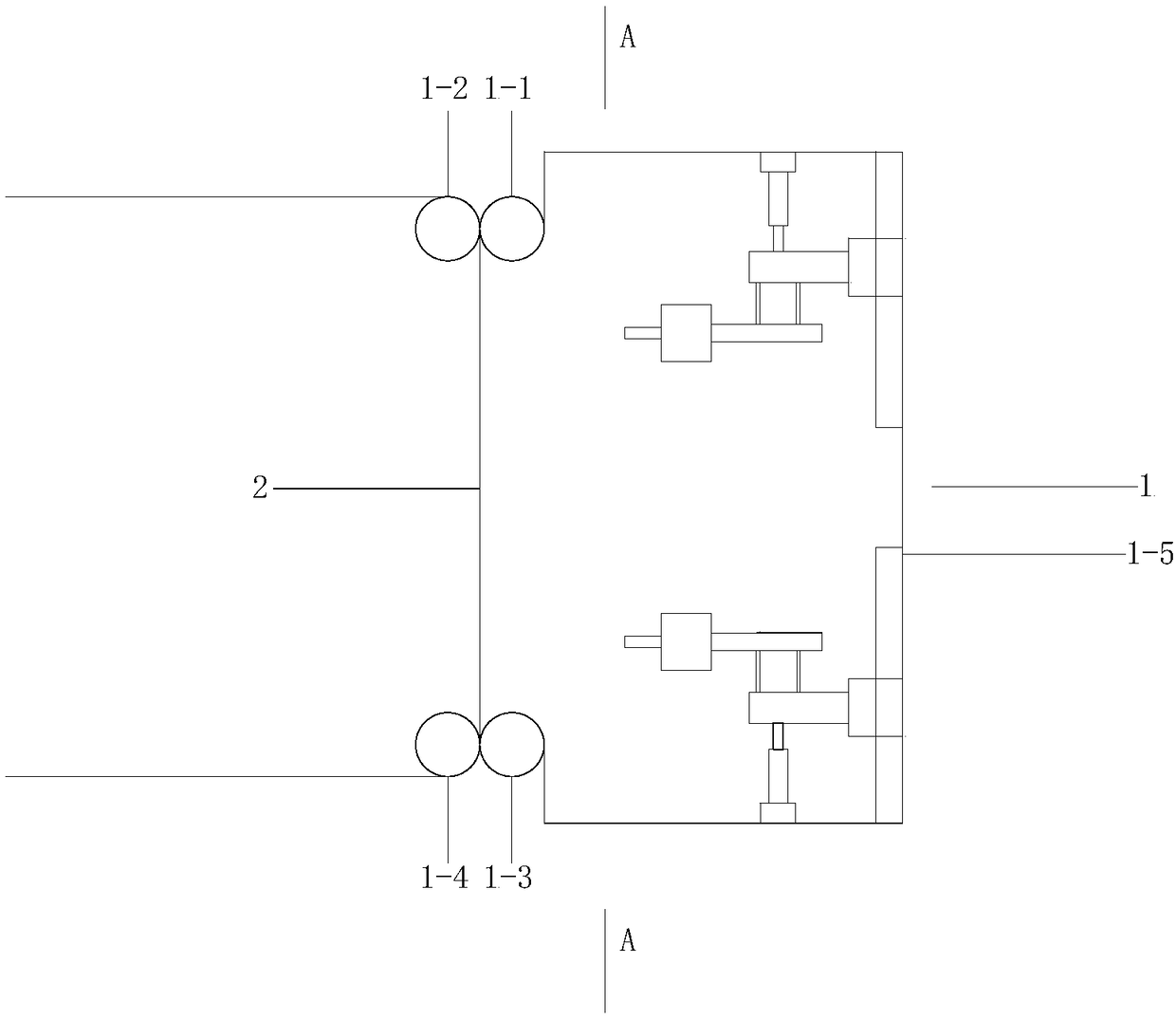

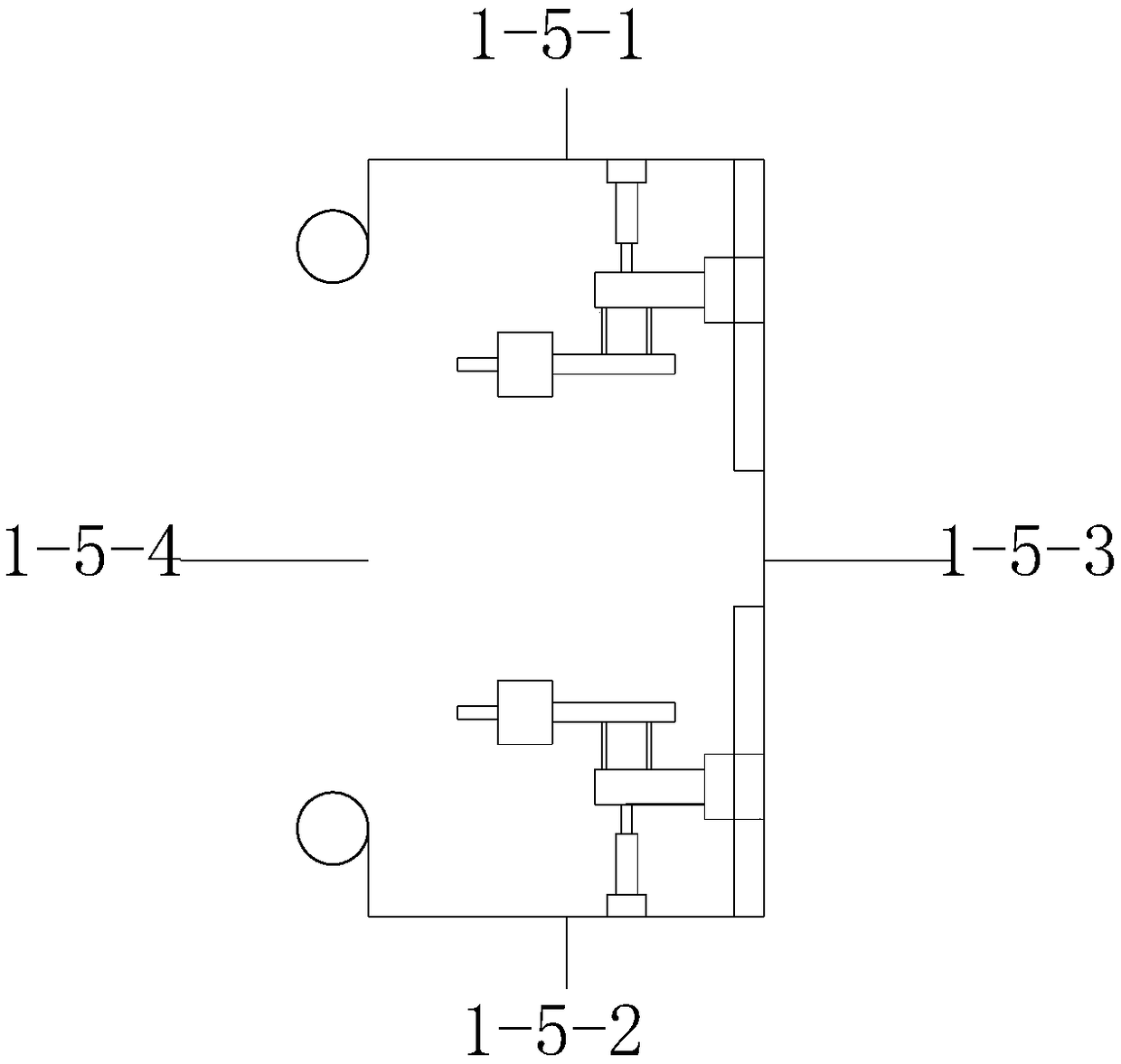

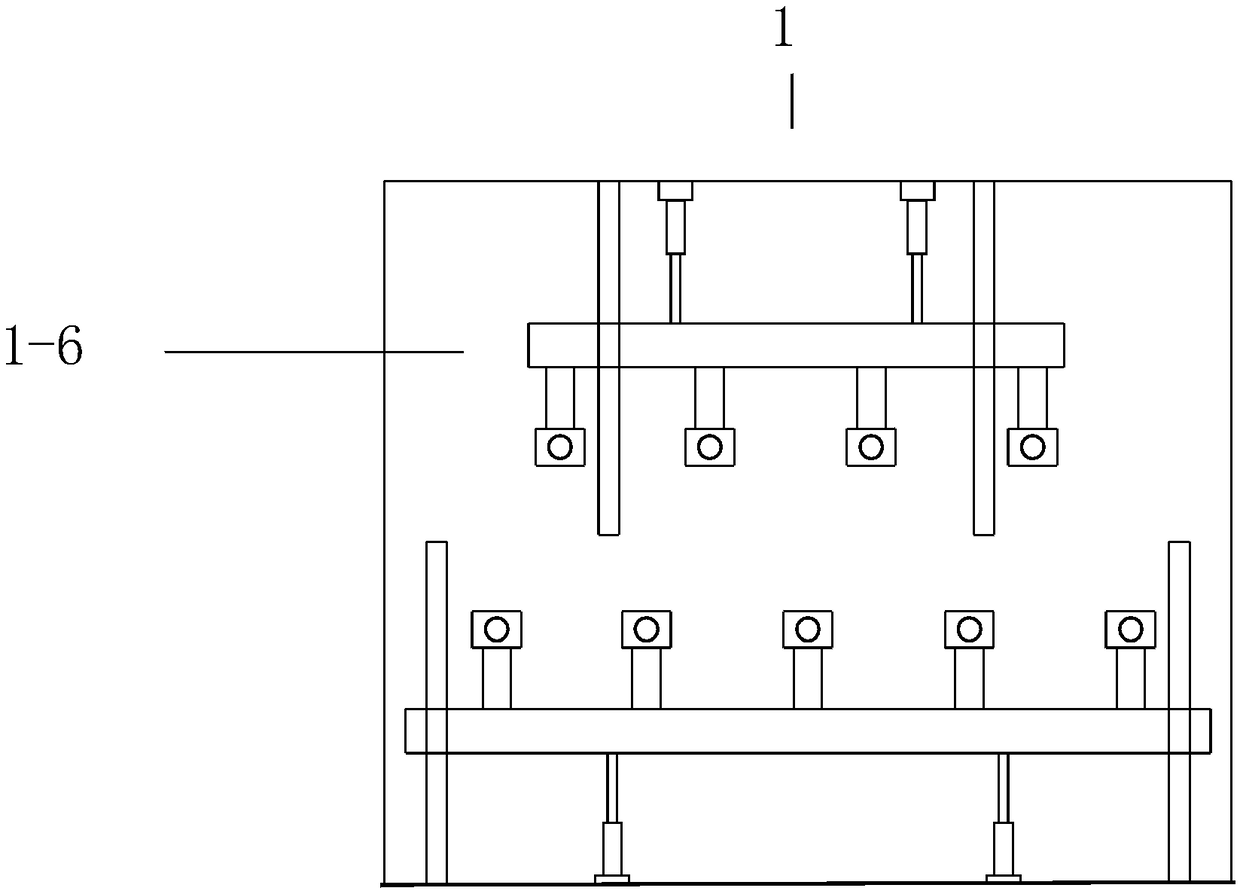

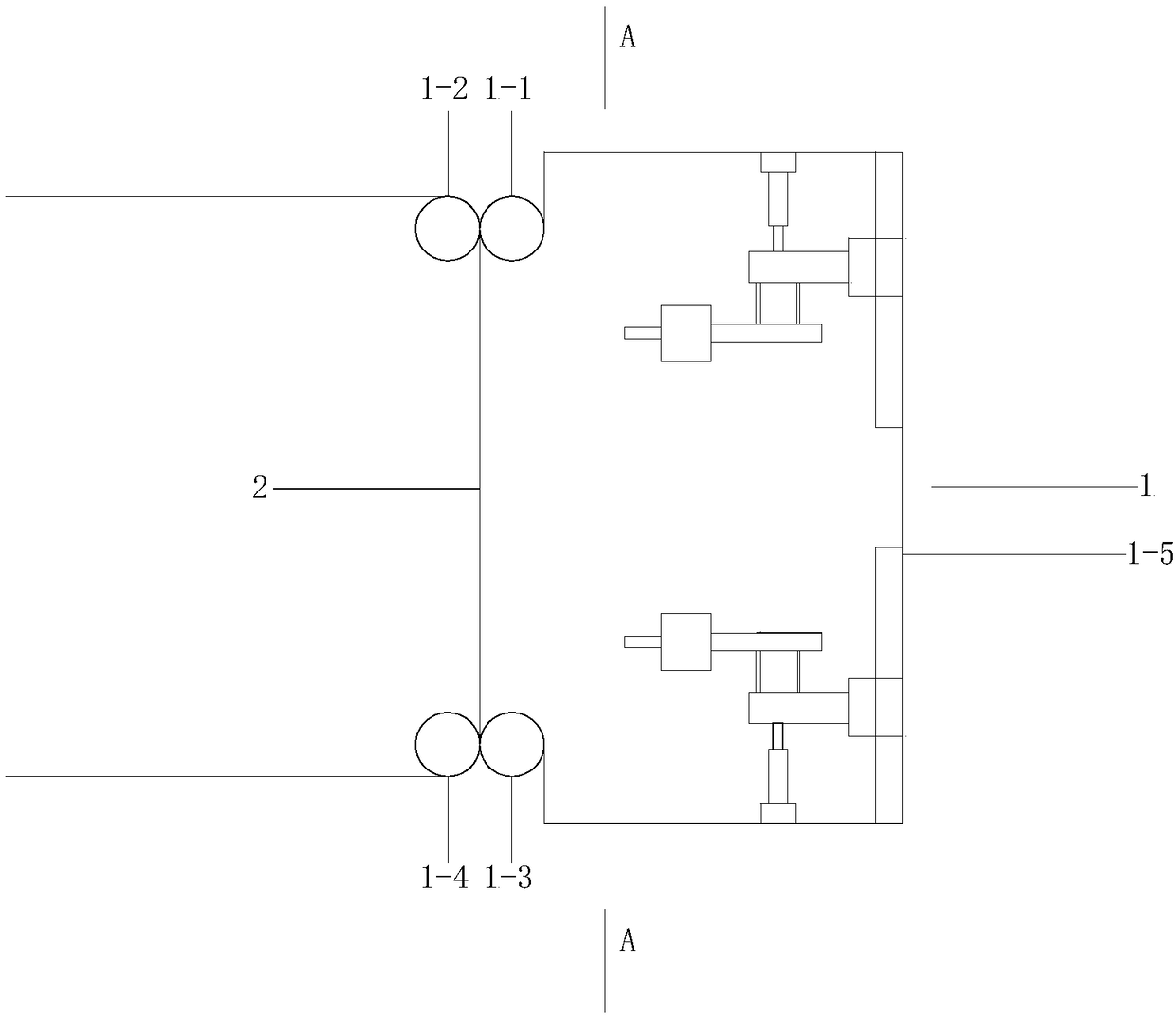

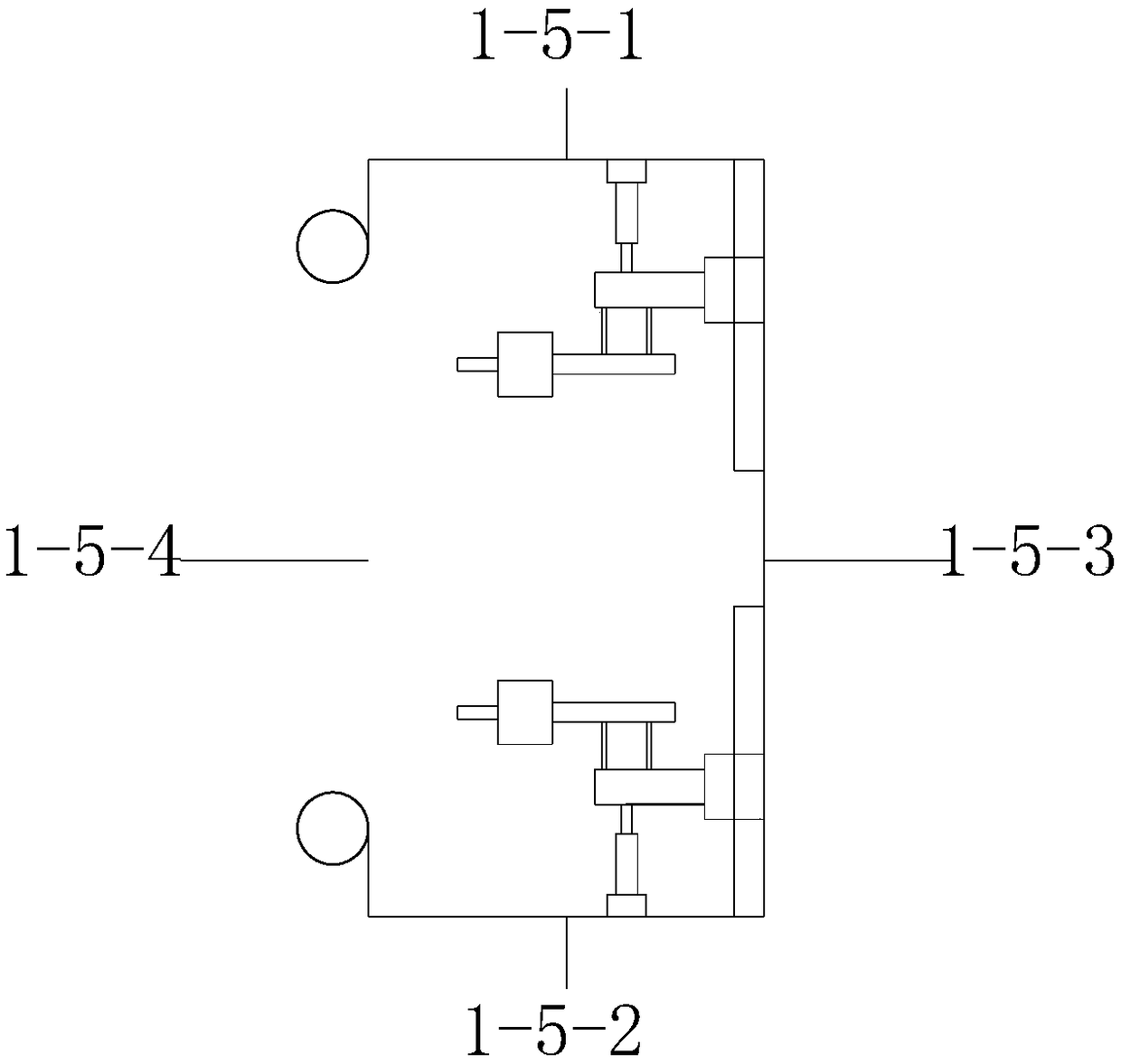

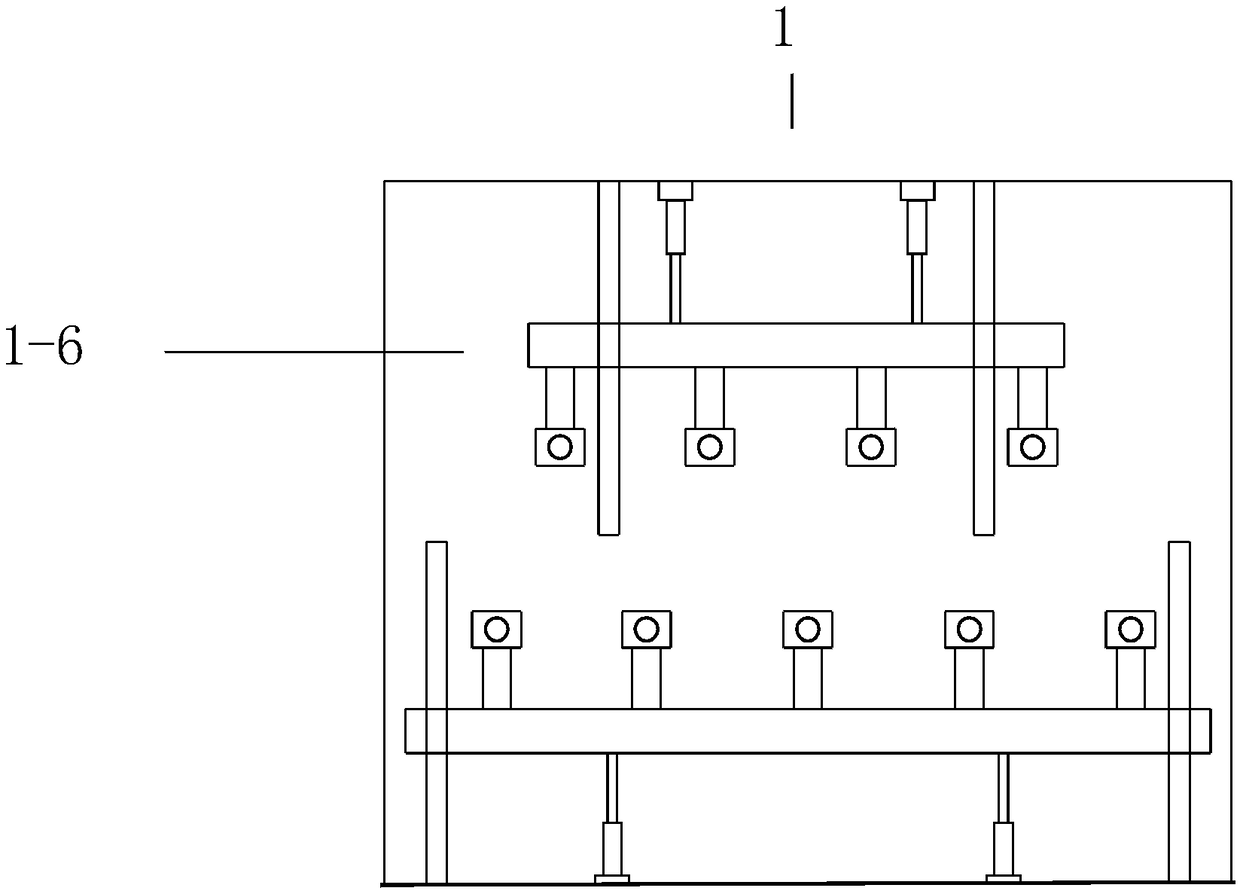

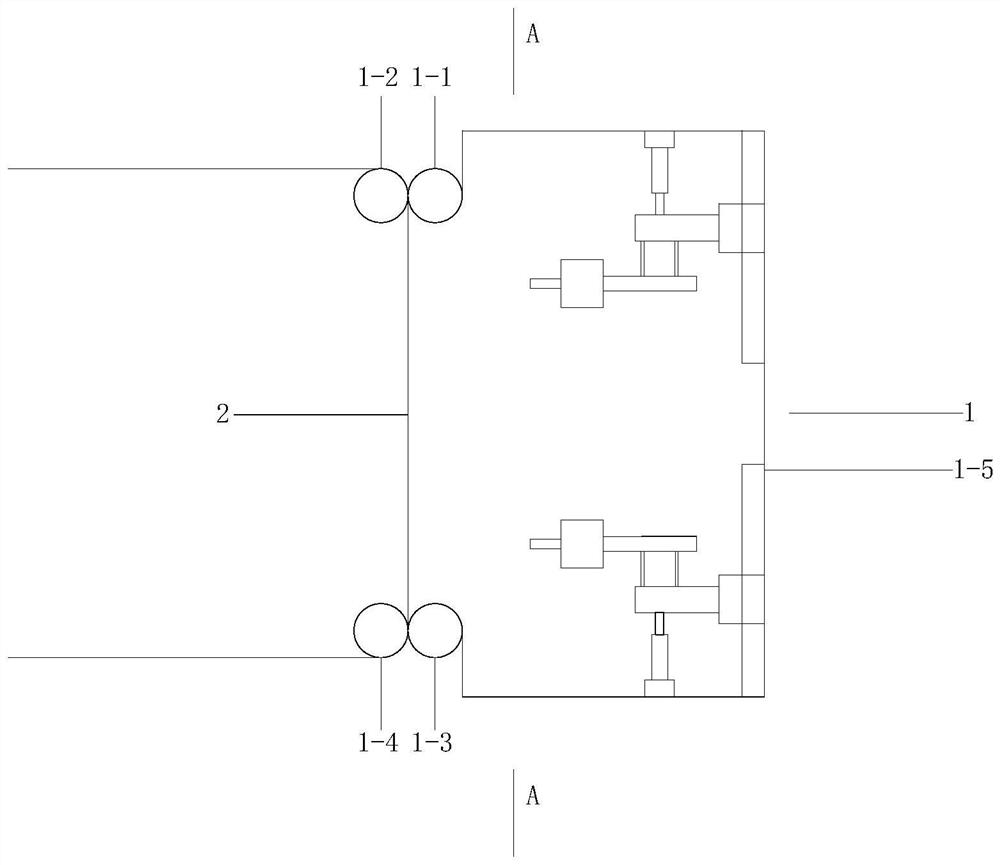

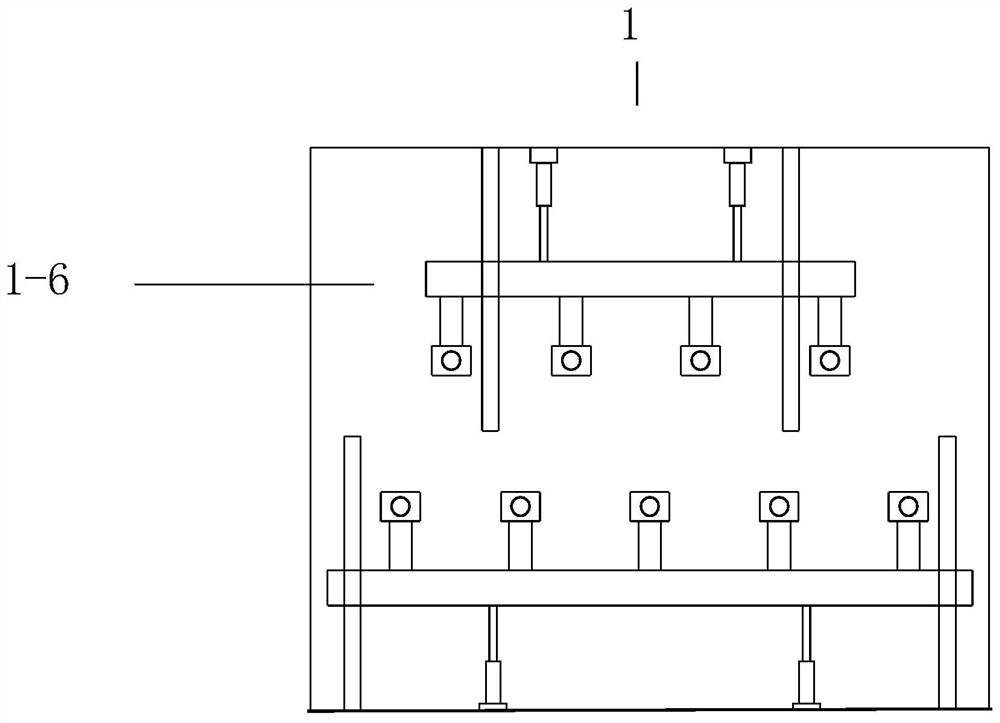

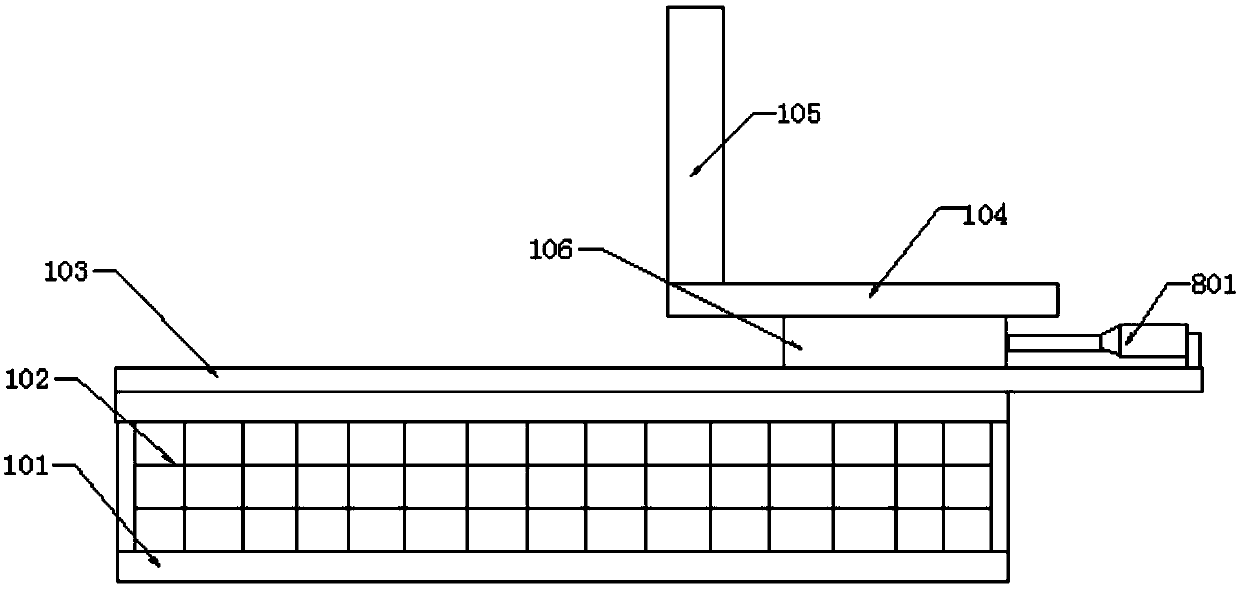

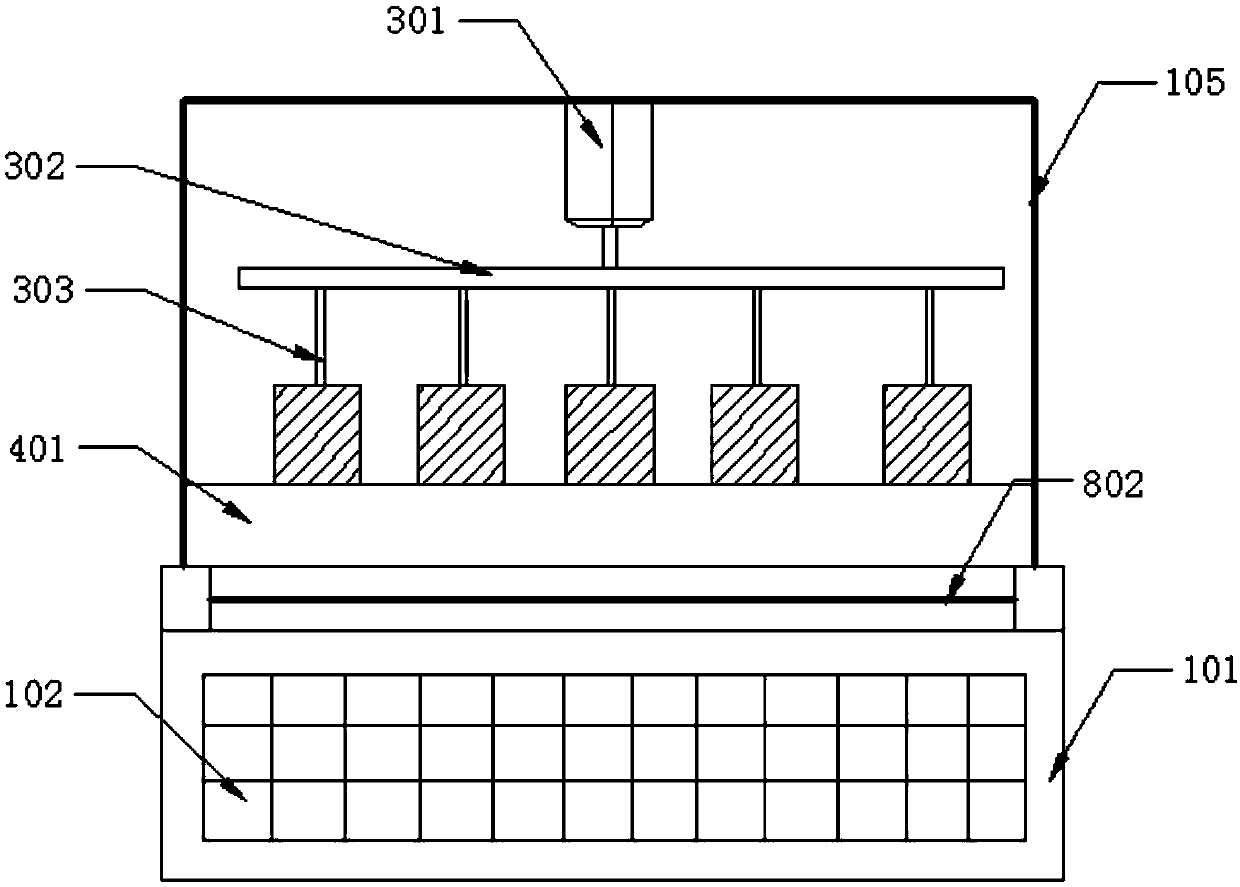

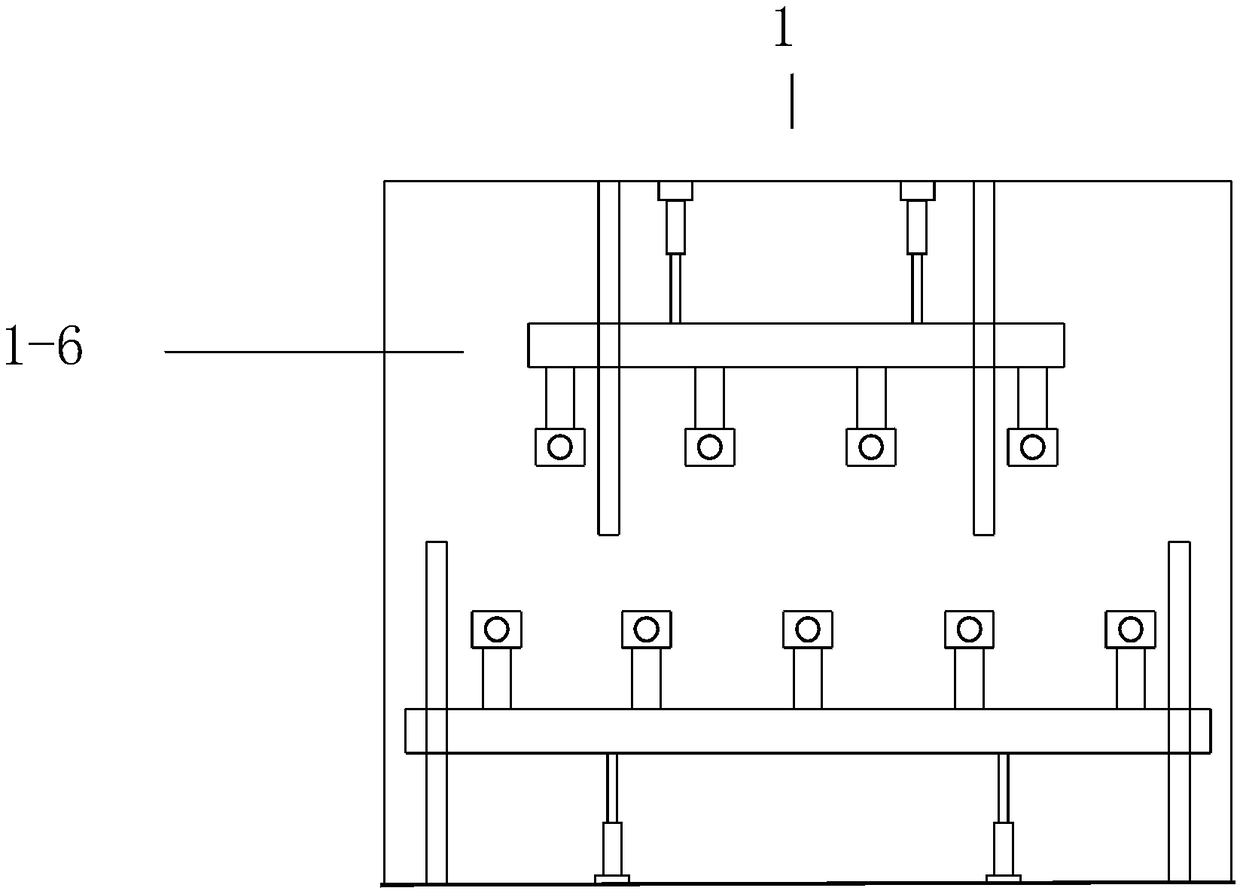

The invention relates to detection equipment of a permeation point and a needle hole of an electrolytic copper foil. The detection equipment comprises an atomization system (1) and a copper foil (2),wherein a dilute sulphuric acid solution is sprayed onto a smooth surface of the copper foil by a first moving atomization system (1-6) and a second moving atomization system (1-7), the copper foil isinitially subjected to moisture removal by a rubber block (1-10) and a vertical support (3), the copper foil is changed to horizontal running from vertical running by a bottom guide roller (1-3) anda bottom driving roller (1-4), the dilute sulphuric acid solution can enter the permeation point and the needle hole, a fourth telescopic power mechanism is arranged at a lower surface of a lower plate of a shell, the other end of the fourth telescopic power mechanism is connected with a press plate, a plurality of press rubber blocks are arranged at a surface of the press plate at intervals, andthe widths of the rubber blocks are same as the width of the copper foil. With the adoption of the device, the whole dilute sulphuric acid capable of coating can be achieved during detection of the permeation point and the needle hole.

Owner:福州宇卓科技有限公司

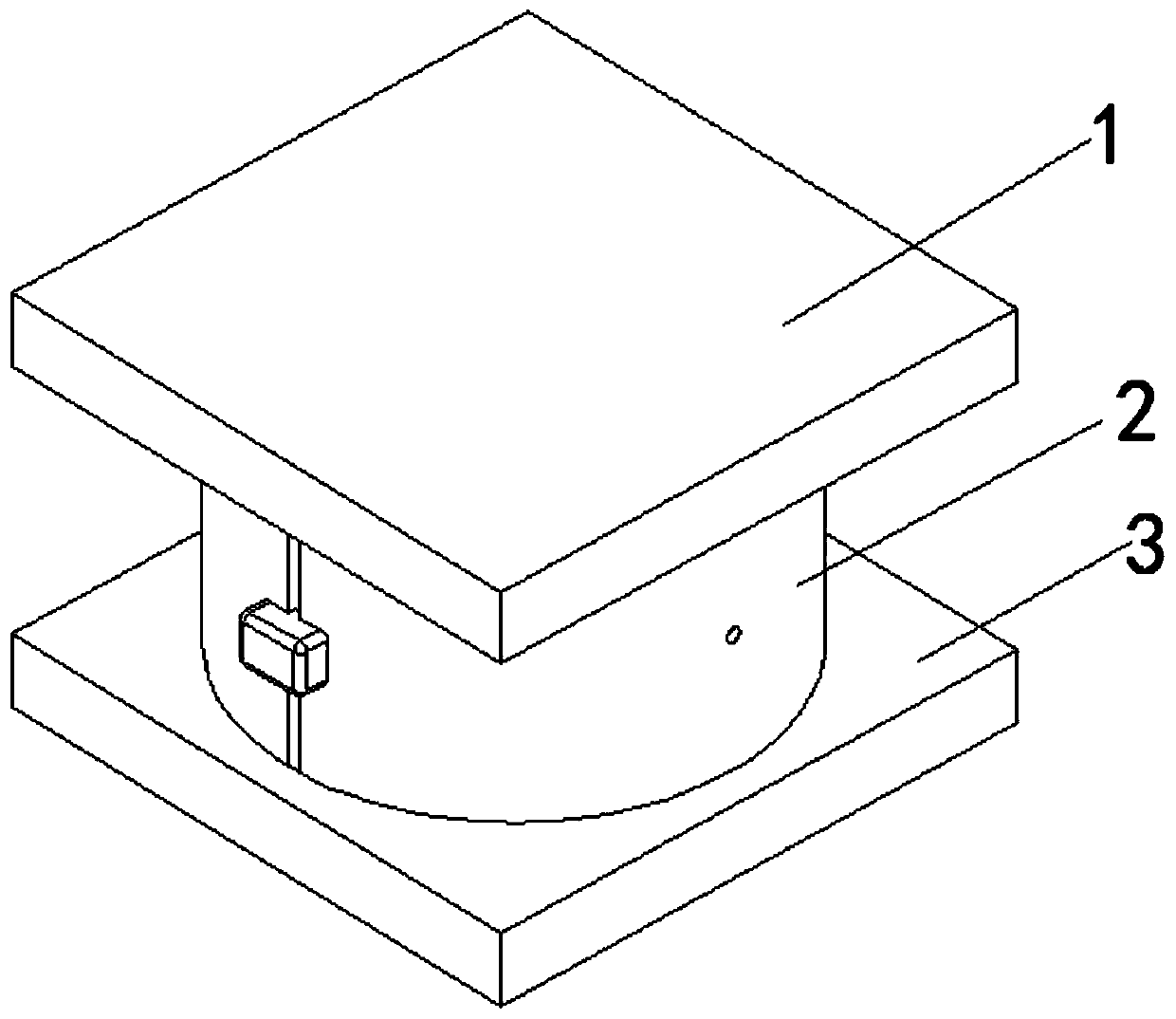

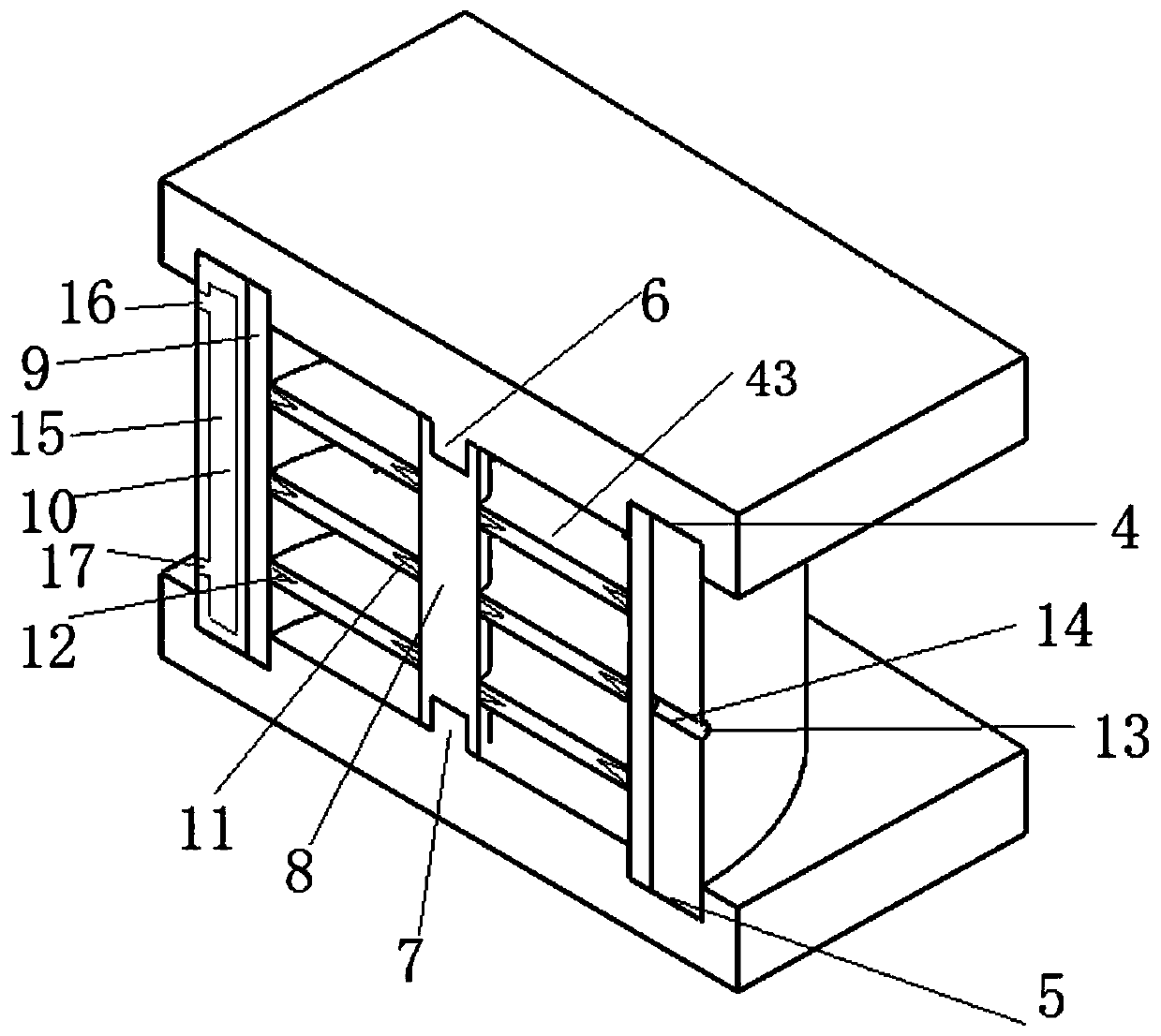

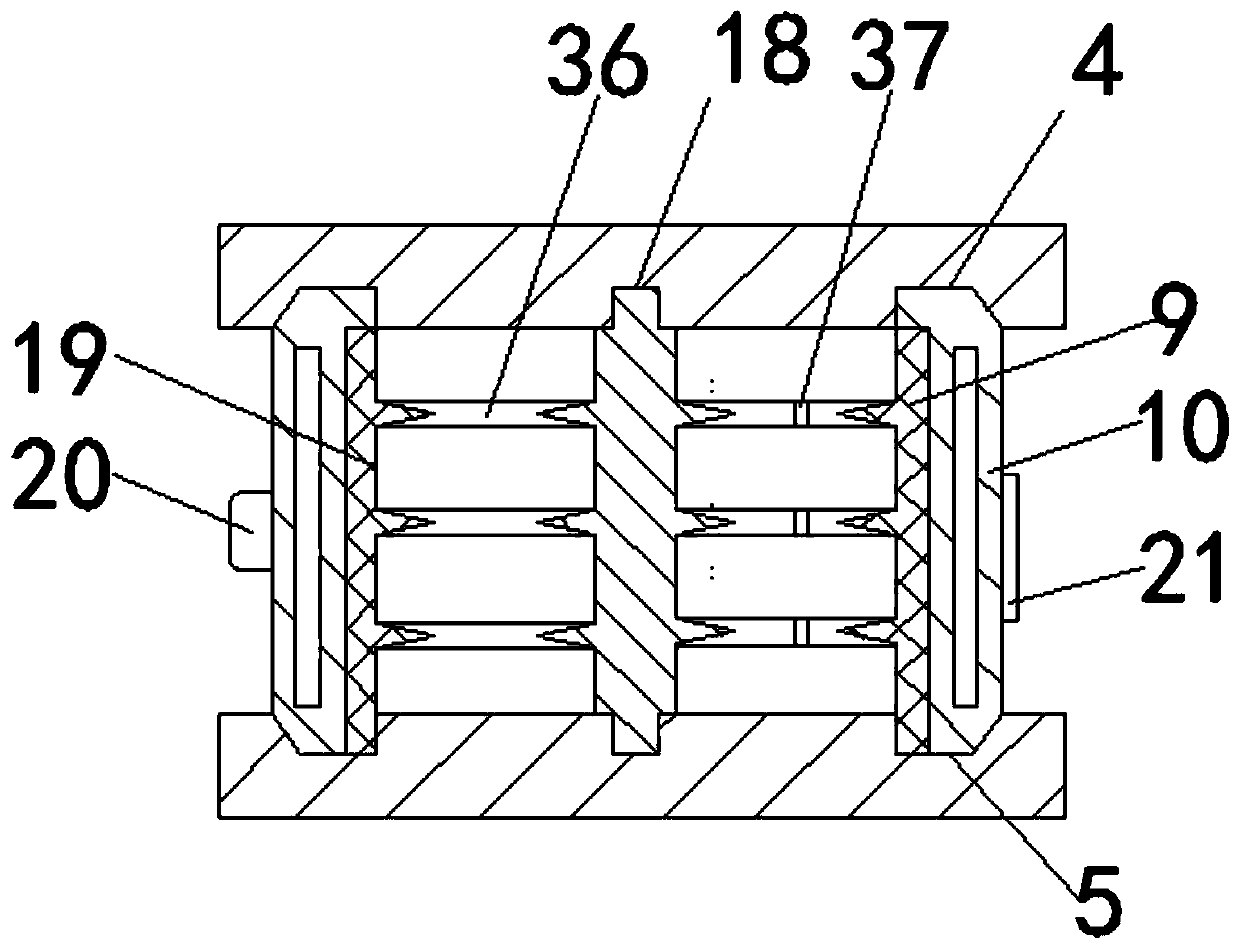

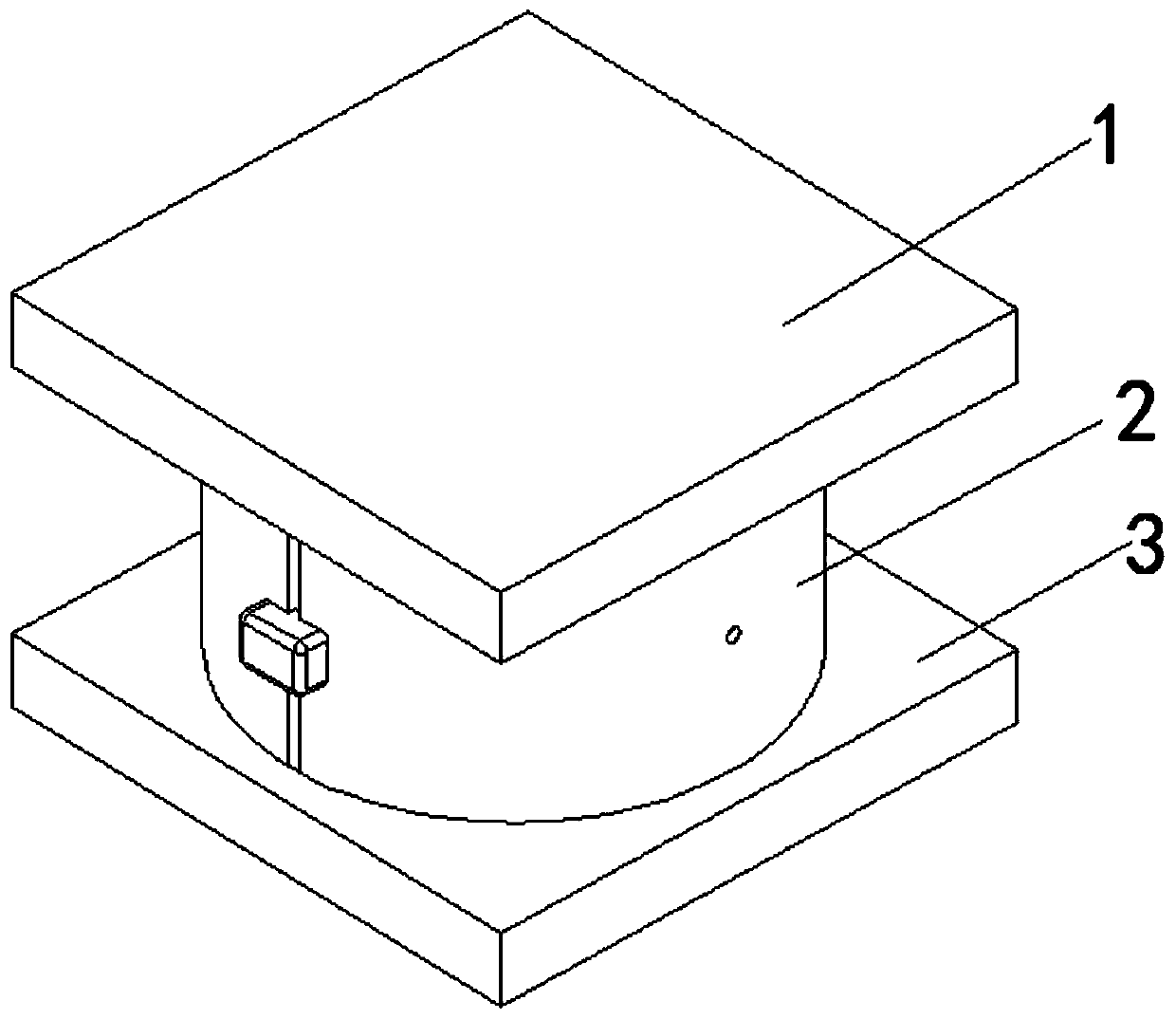

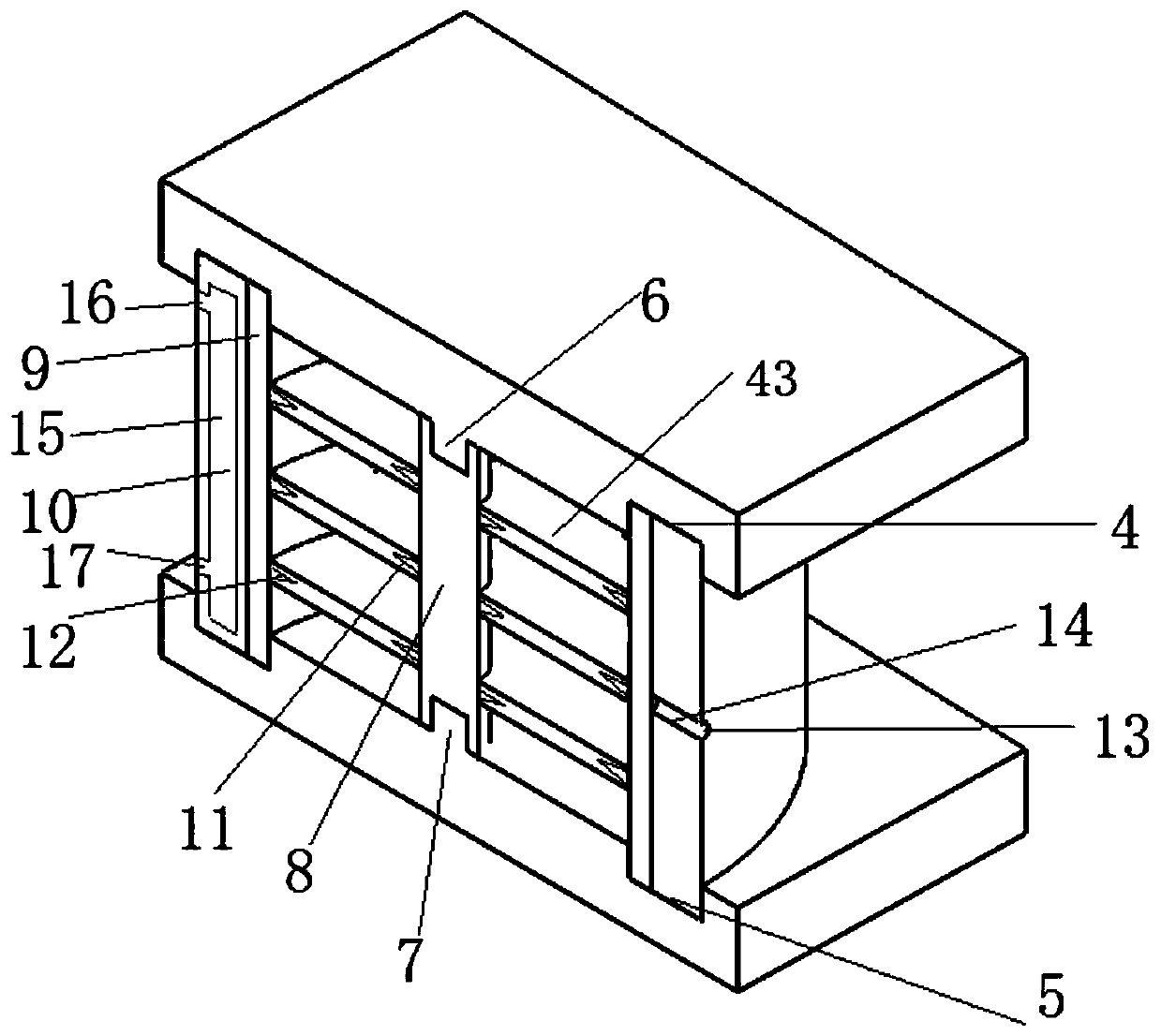

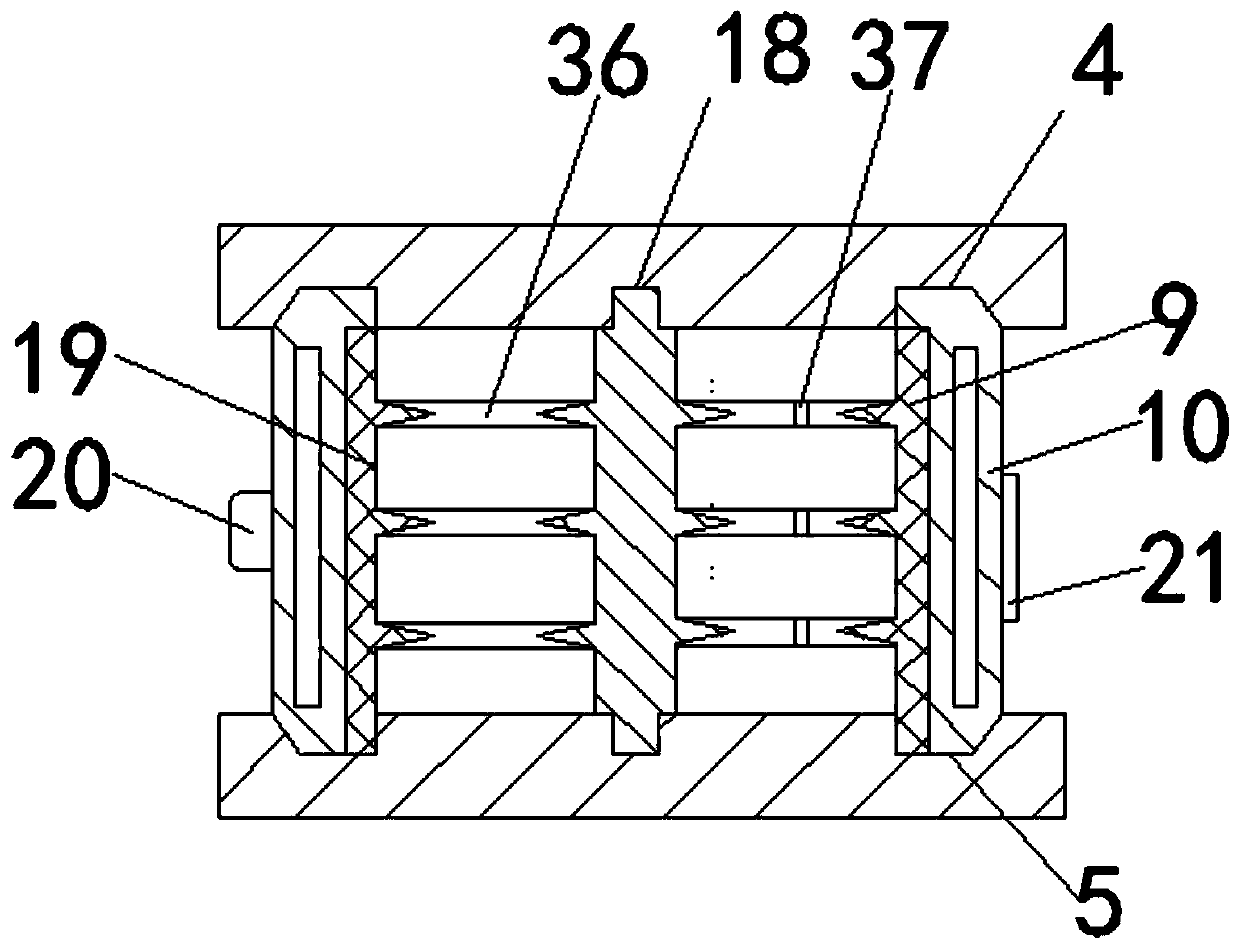

Integrated-type shock insulation supporting seat mould

The invention belongs to the technical field of shock insulation supporting seat mould, and particularly relates to an integrated-type shock insulation supporting seat mould. The integrated-type shockinsulation supporting seat mould includes an upper mould, a middle mould and a lower mould, wherein the upper mould is placed at the top of the middle mould, the lower mould is placed at the bottom of the middle mould, the middle mould includes a spindle, an inner middle mould and an outer middle mould, the spindle is a cylinder, a first limiting device is movably arranged on the outer cylindrical surface of the spindle, the inner middle mould is an annular column-shaped body, a second limiting device is arranged on the inner cylindrical surface of the inner middle mould, the first limiting device and the second limiting device are used in a matched mode, the outer middle mould is an annular column-shaped body, a pouring opening is formed in the outer cylindrical surface of the outer middle mould, the pouring opening communicates with a pouring channel, the pouring channel penetrates through the inner cylindrical surface of the outer middle mould, a heating oil cavity is formed in theinner part of the outer middle mould, and the outer middle mould arranged on the outer part of the inner middle mould in a sleeving mode. According to the integrated-type shock insulation supportingseat mould, compression of a rubber layer and a steel plate layer and pressing-in of an outer sealing layer and a pencil lead of the rubber layer and the steel plate layer can be manufactured througha set of moulds, all the processes are integrated as a whole, time and labor are saved, cost expenditure of the moulds is reduced, and the application rang is wide.

Owner:广东宇泰制震装备股份有限公司

Electrolytic copper foil penetration point and pinhole detection device

ActiveCN109142186AAutomate operationPush inPermeability/surface area analysisElectrolysisEngineering

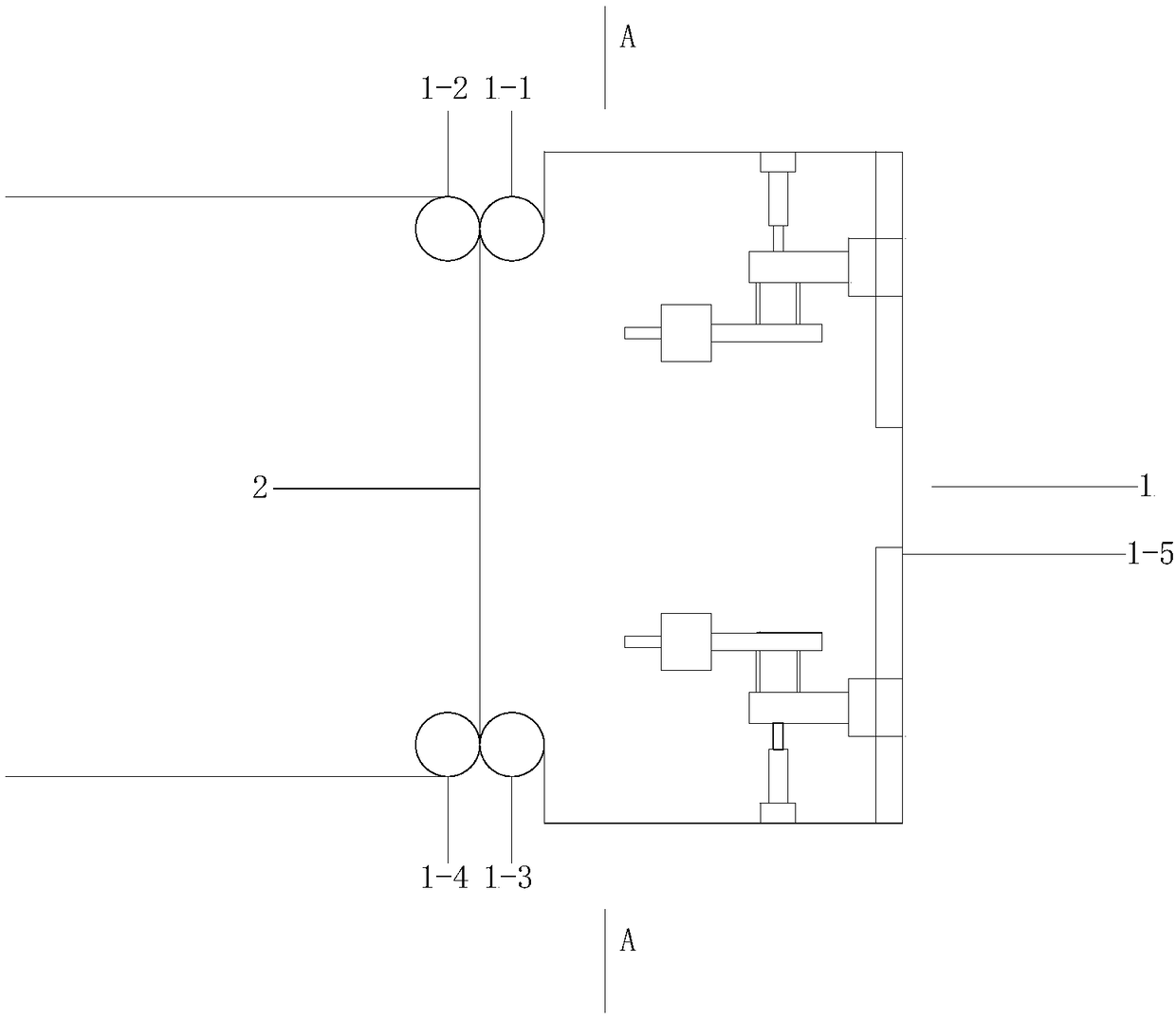

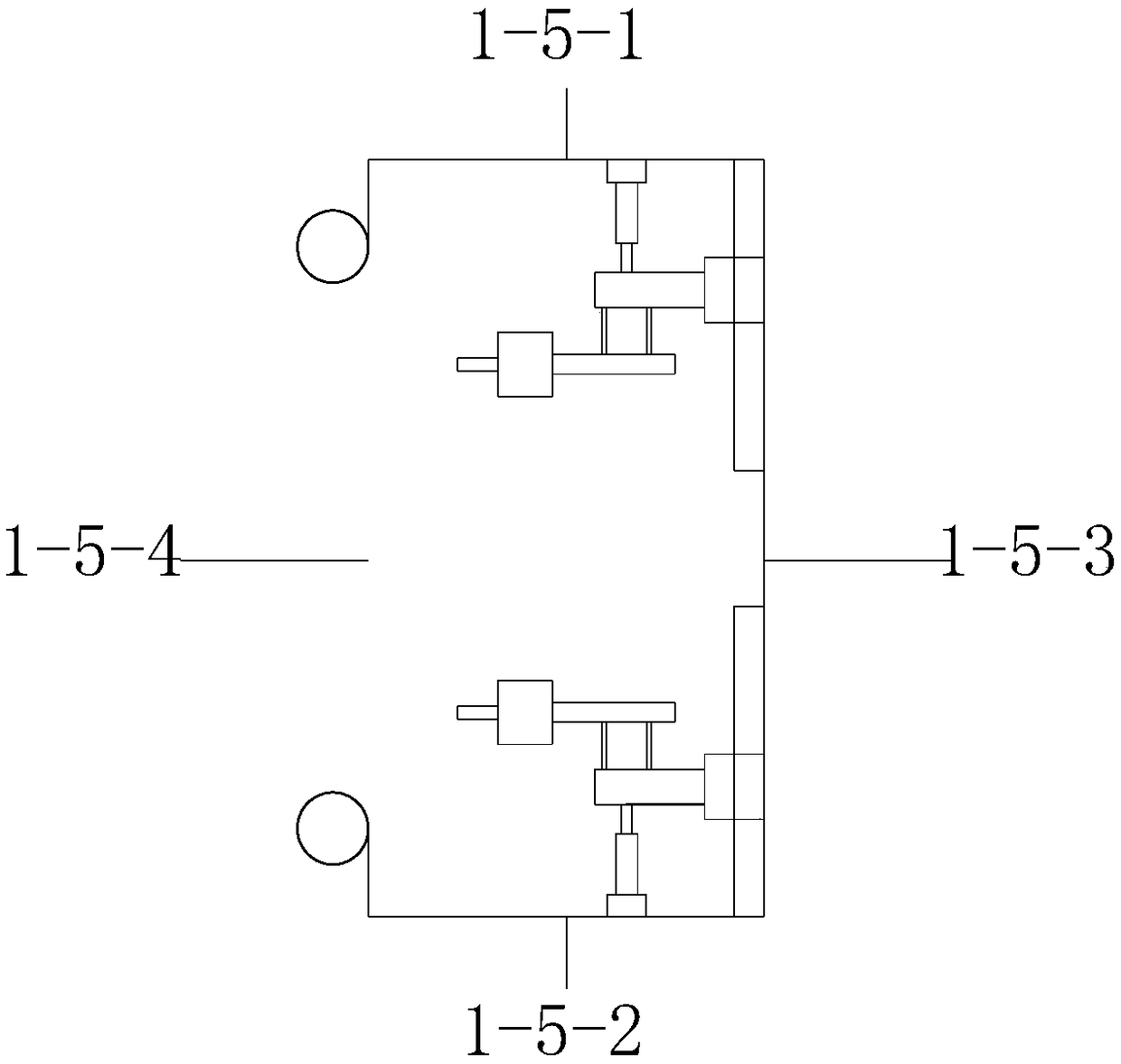

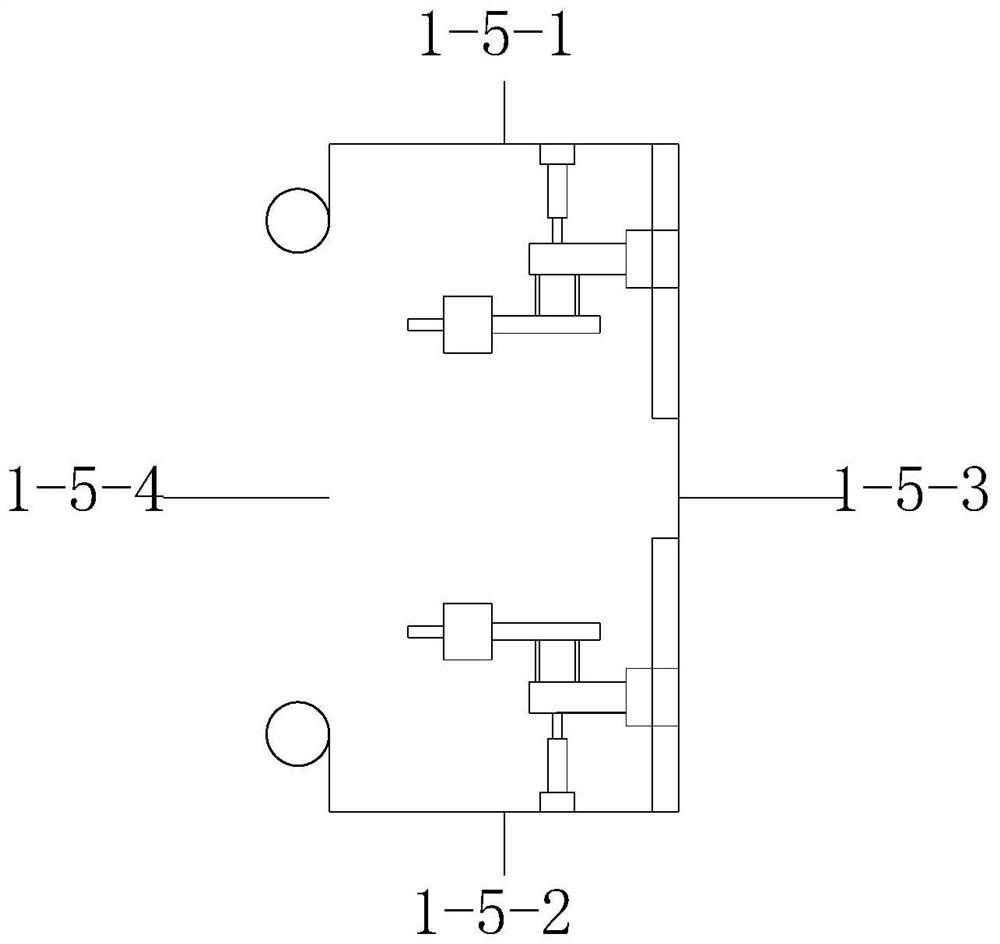

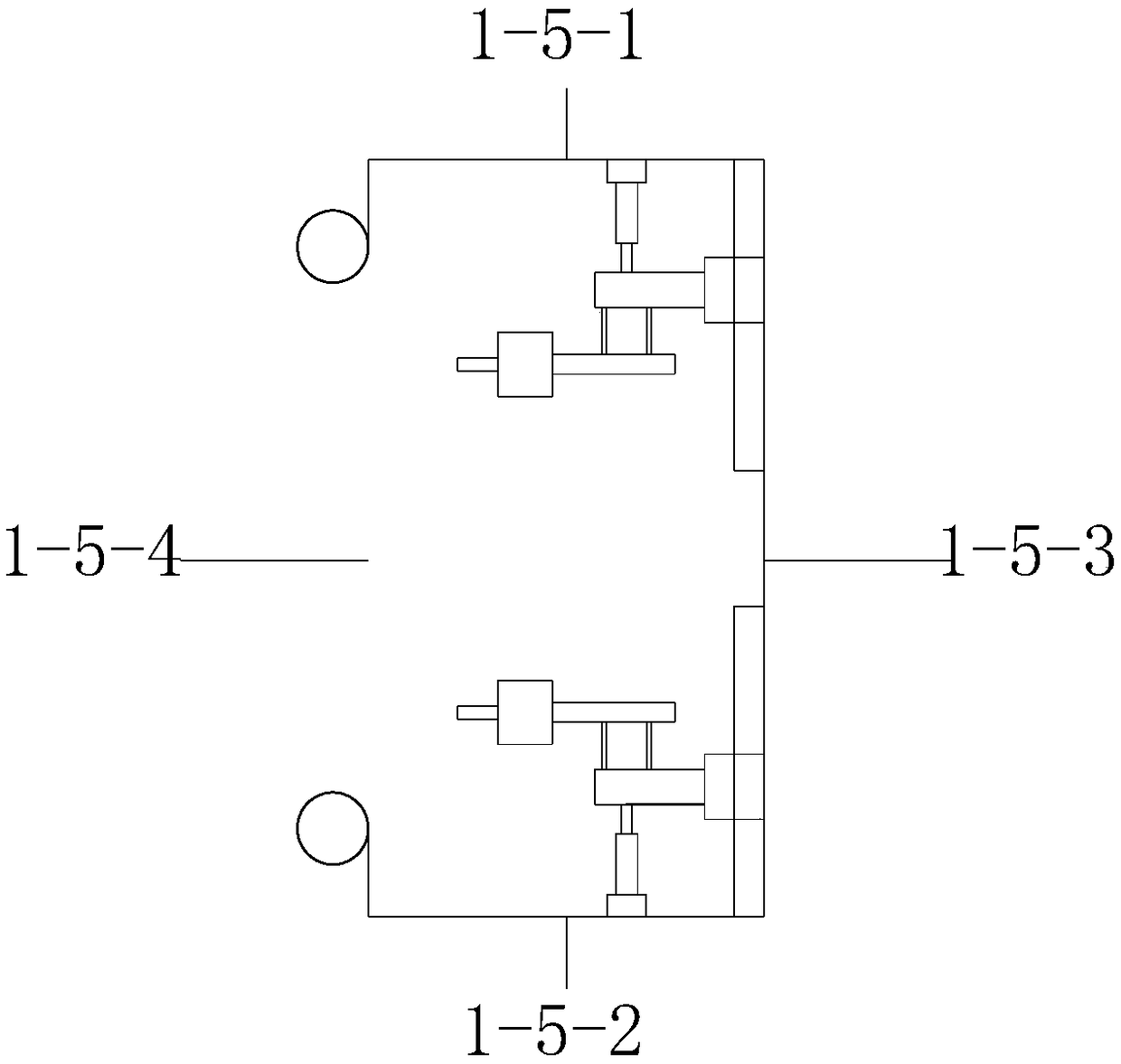

The invention relates to an electrolytic copper foil penetration point and pinhole detection device which comprises an atomizing system (1) and a copper foil (2). The atomizing system (1) comprises anatomizing system frame, a top guide roller (1-1), a top driving roller (1-2), a bottom guide roller (1-3), a bottom driving roller (1-4), a shell (1-5), a first movable spray system (1-6) and a second movable spray system (1-7), the copper foil passes the top guide roller (1-1) and the top driving roller (1-2), switches horizontal movement into vertical movement, passes the bottom guide roller (1-3) and the bottom driving roller (1-4) and switches vertical movement into horizontal movement, and the first movable spray system (1-6) and the second movable spray system (1-7) spray dilute sulfuric acid solution to a smooth surface of the copper foil. By the aid of the device, whole dilute sulfuric acid can be automatically applied in copper foil penetration point and pinhole detection.

Owner:福州宇卓科技有限公司

A mold for an integrated shock-absorbing support

The invention belongs to the technical field of shock insulation supporting seat mould, and particularly relates to an integrated-type shock insulation supporting seat mould. The integrated-type shockinsulation supporting seat mould includes an upper mould, a middle mould and a lower mould, wherein the upper mould is placed at the top of the middle mould, the lower mould is placed at the bottom of the middle mould, the middle mould includes a spindle, an inner middle mould and an outer middle mould, the spindle is a cylinder, a first limiting device is movably arranged on the outer cylindrical surface of the spindle, the inner middle mould is an annular column-shaped body, a second limiting device is arranged on the inner cylindrical surface of the inner middle mould, the first limiting device and the second limiting device are used in a matched mode, the outer middle mould is an annular column-shaped body, a pouring opening is formed in the outer cylindrical surface of the outer middle mould, the pouring opening communicates with a pouring channel, the pouring channel penetrates through the inner cylindrical surface of the outer middle mould, a heating oil cavity is formed in theinner part of the outer middle mould, and the outer middle mould arranged on the outer part of the inner middle mould in a sleeving mode. According to the integrated-type shock insulation supportingseat mould, compression of a rubber layer and a steel plate layer and pressing-in of an outer sealing layer and a pencil lead of the rubber layer and the steel plate layer can be manufactured througha set of moulds, all the processes are integrated as a whole, time and labor are saved, cost expenditure of the moulds is reduced, and the application rang is wide.

Owner:广东宇泰制震装备股份有限公司

An atomization system for electrolytic copper foil penetration point and pinhole detection and its application

InactiveCN109142384BAutomate operationPush inMovable spraying apparatusOptically investigating flaws/contaminationElectrolysisCopper foil

Owner:苏州绣创投资发展有限公司

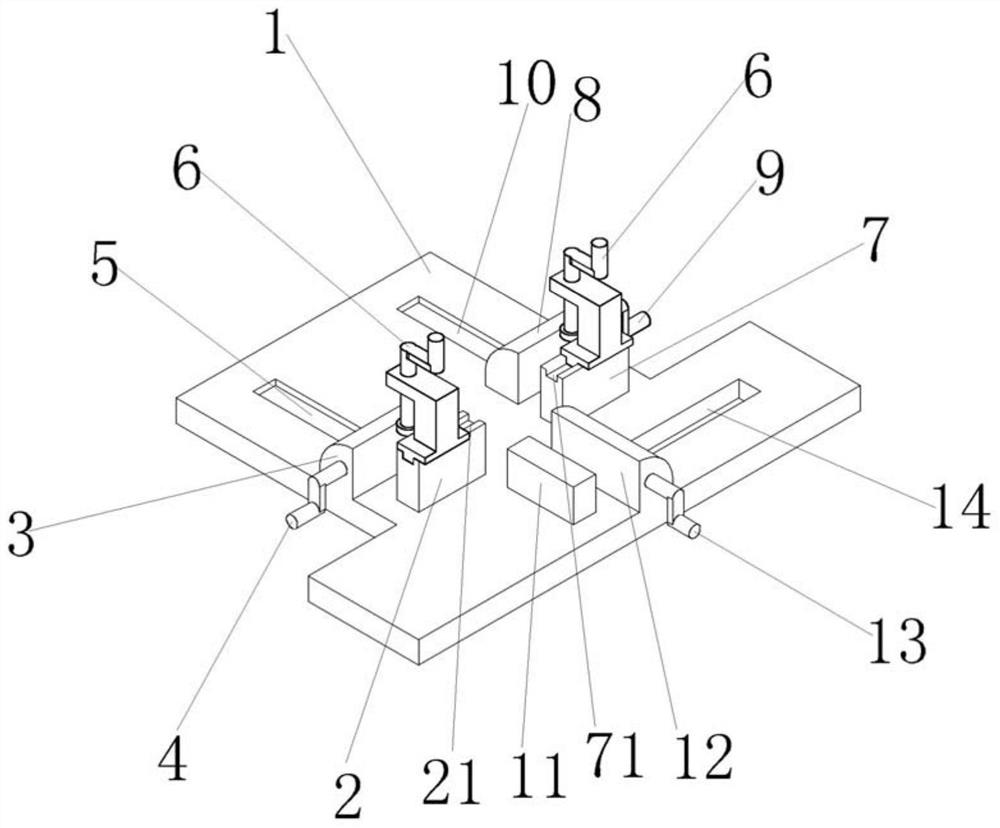

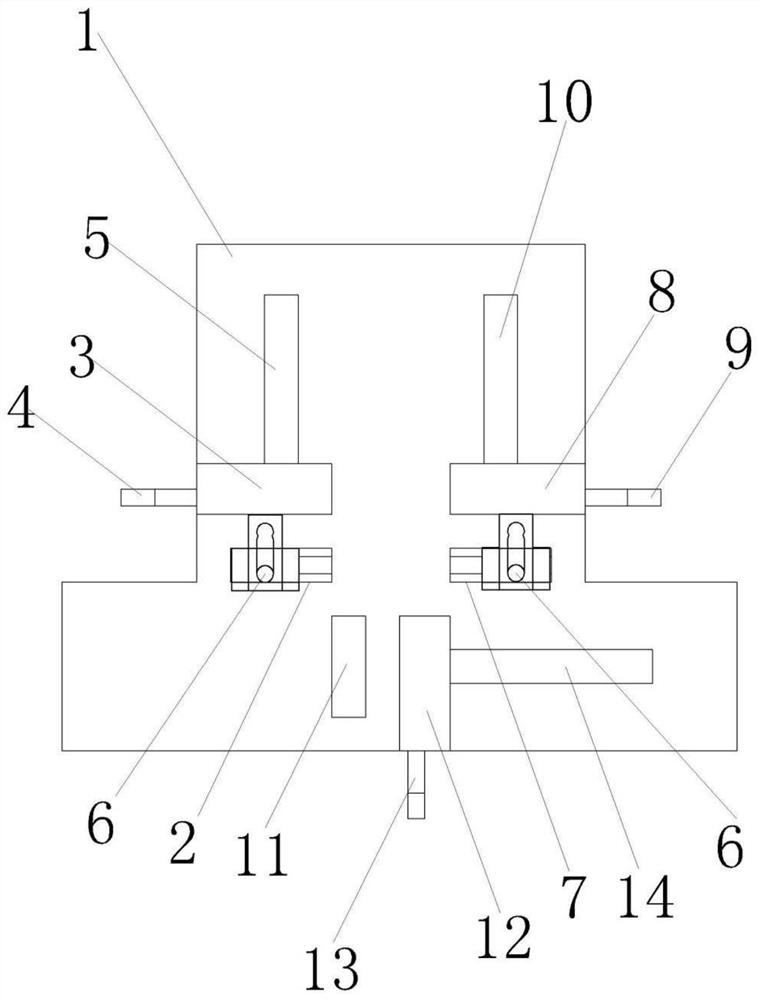

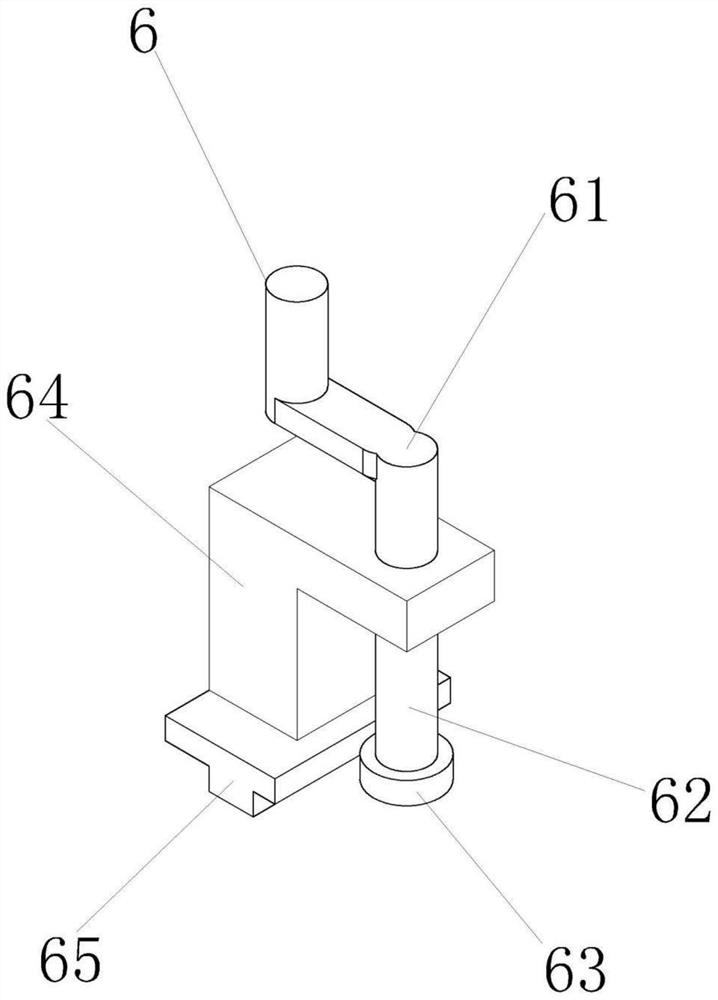

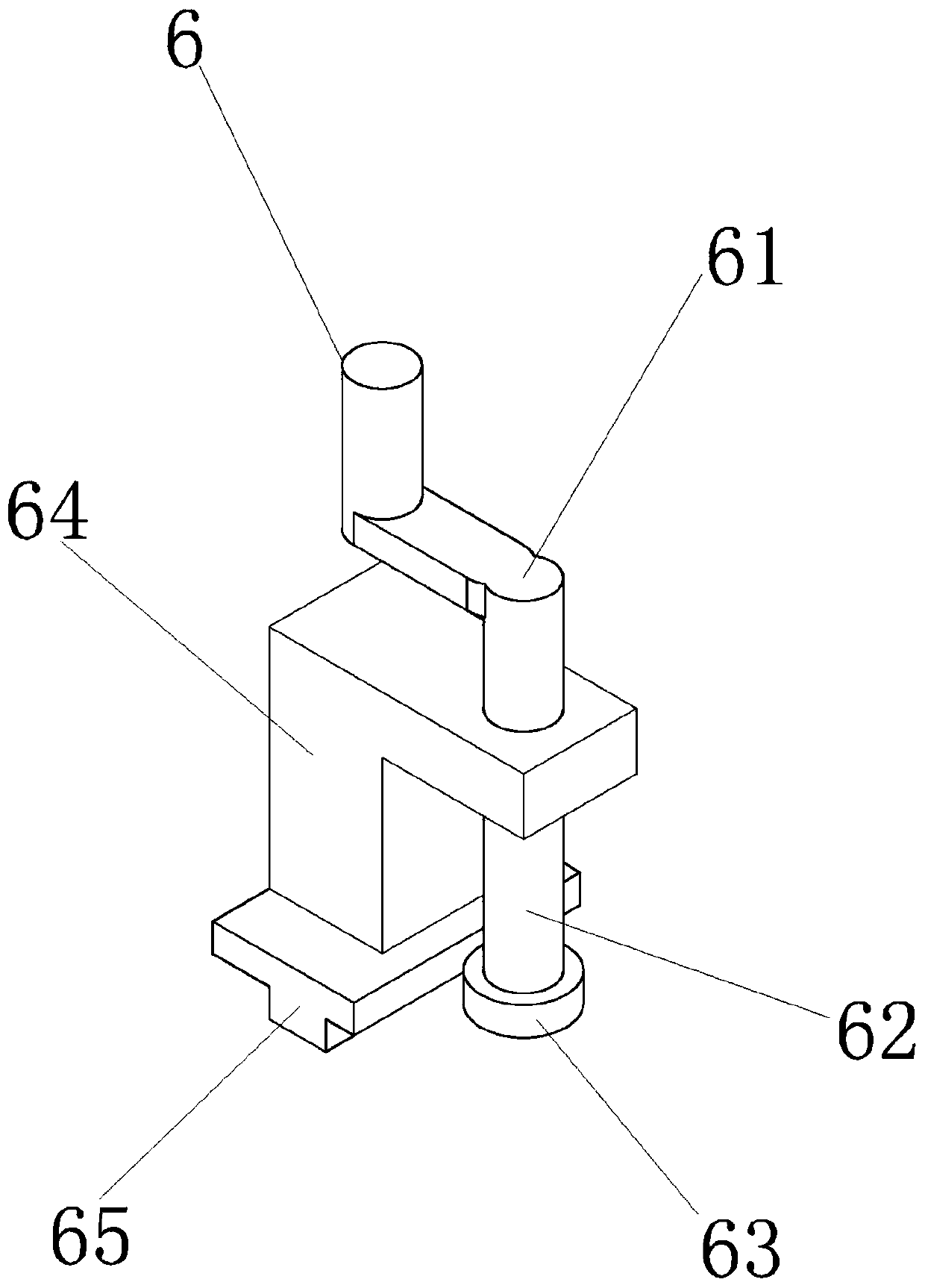

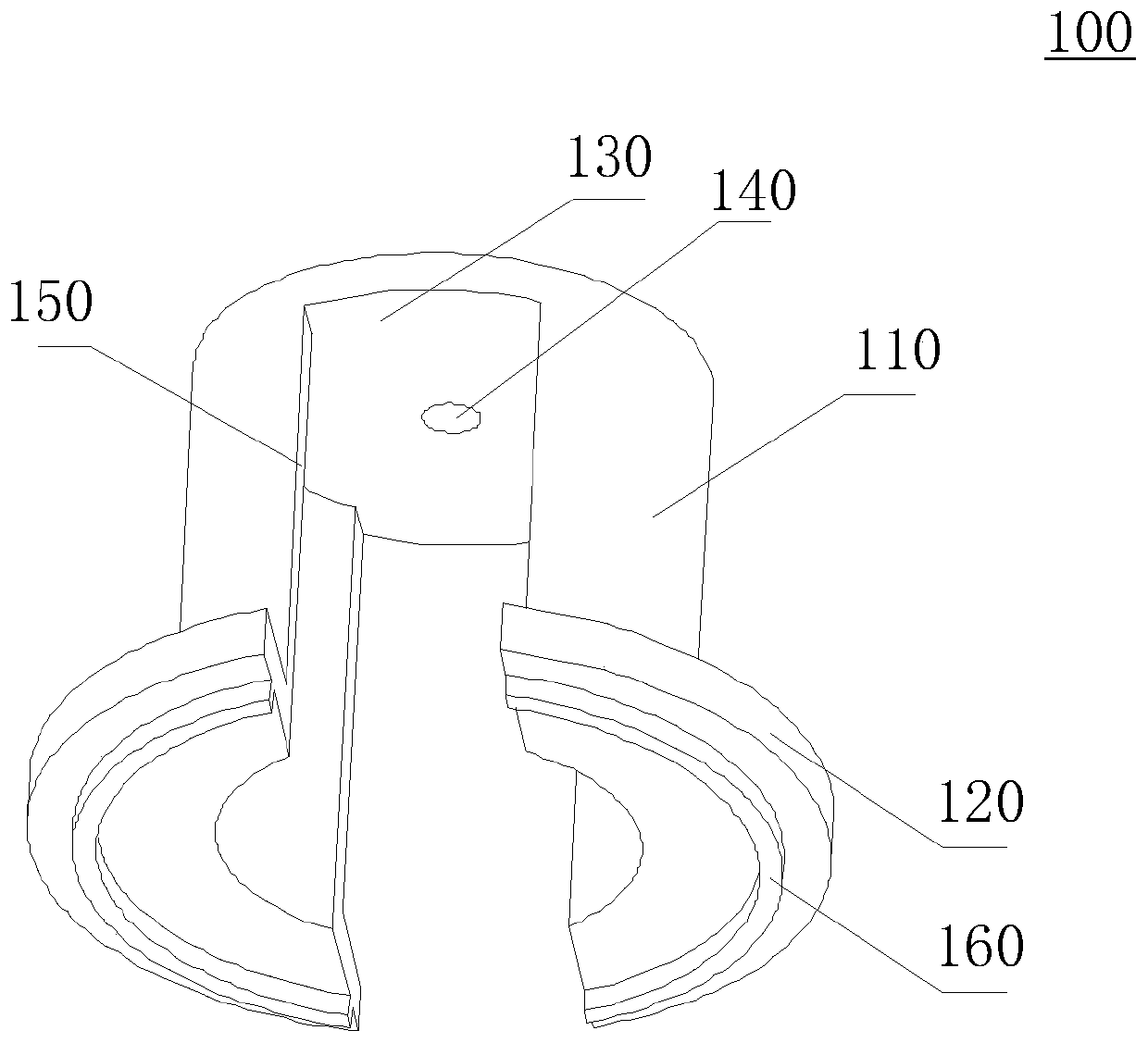

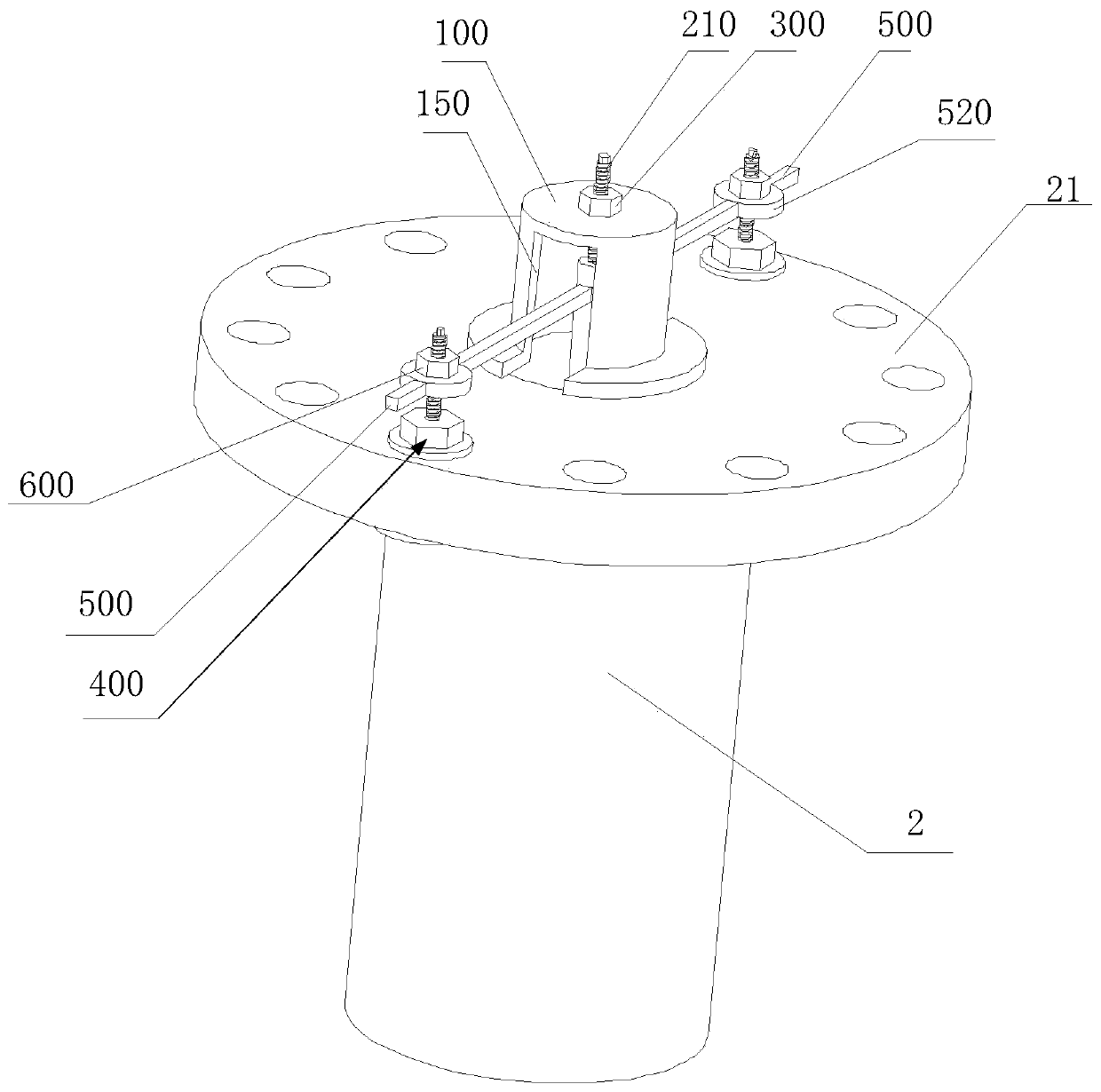

A suspension control arm bush press-in tooling device

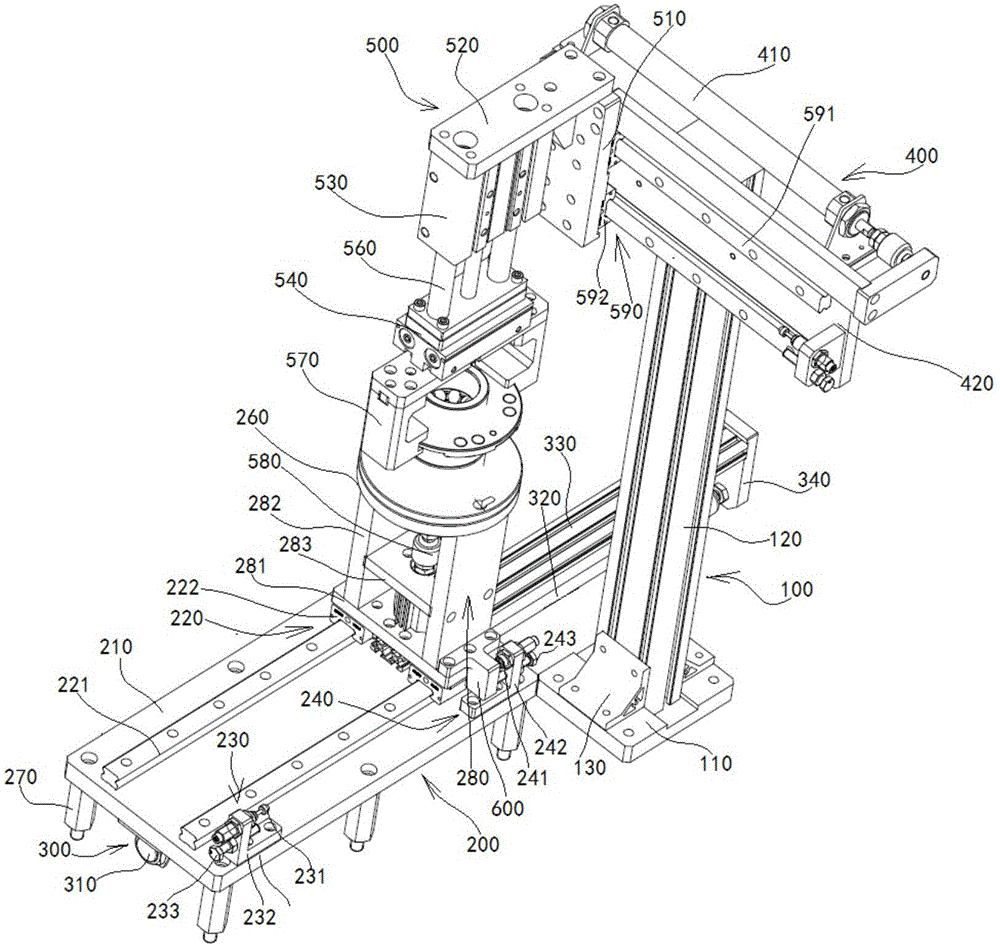

ActiveCN111347373BImprove installation efficiencyPush inMetal-working hand toolsControl armMobile end

The invention discloses a tooling device for pressing a bushing of a suspension control arm, which comprises a tooling base, a plurality of positioning blocks, a plurality of calipers, a plurality of base guide grooves, and a rotary press-fitting device; The caliper moves in the guide groove of the base to adapt to the clamping. At the same time, one end of the caliper has a rocker mechanism, and the other end of the moving caliper is equipped with a positioning block. The positioning block and the caliper realize clamping together; two of the positioning blocks have guide grooves , there is a rotary press-fitting device with a slider on it, the rotary press-fitting device has an L-shaped support block, the rotary device is driven by a pressure rod, and there are threads on the pressure rod, and there is a pressure block at the bottom of the moving end of the rotary press-fitting device; the design of the present invention It is novel and can adapt to control arms of various specifications and sizes, realizes the clamping and positioning of the control arm and the installation and pressing of the bushing. It has a wide range of applications and a large adjustment range, and can realize two-position bushing press-fitting at one time; obvious Improve bushing installation efficiency.

Owner:SOUTH CHINA UNIV OF TECH

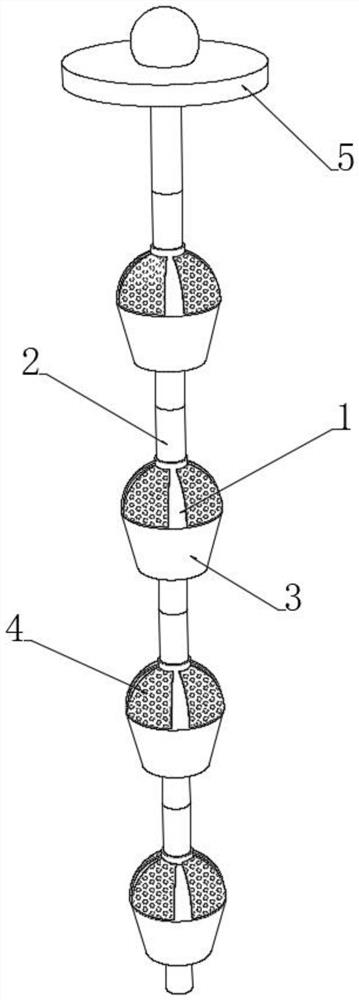

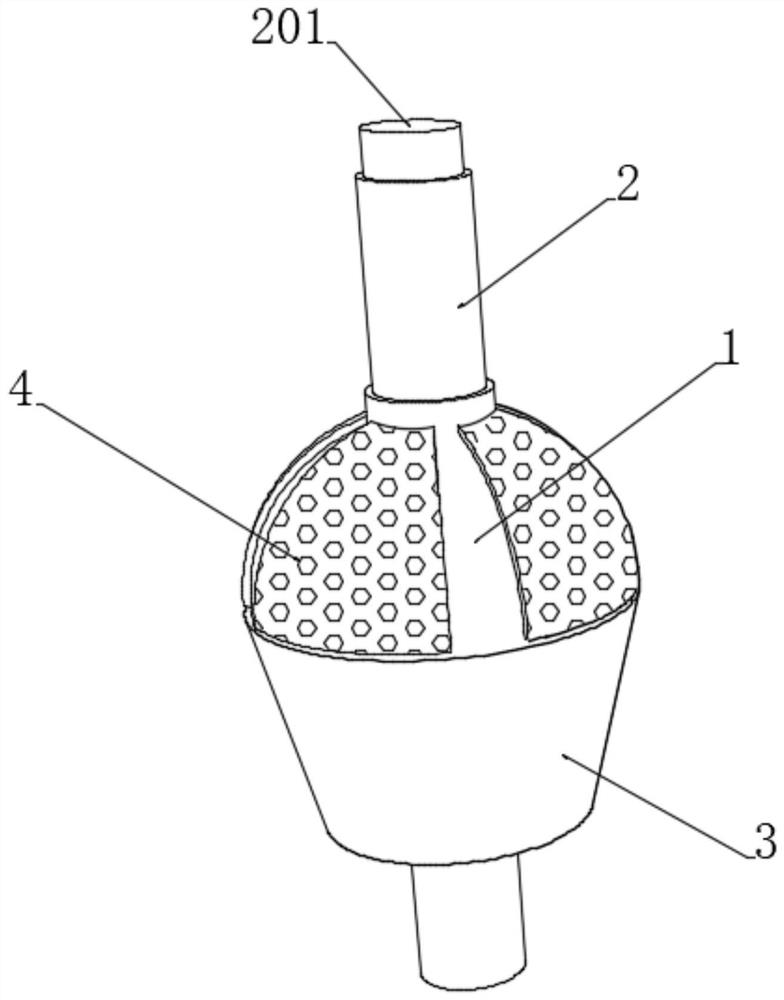

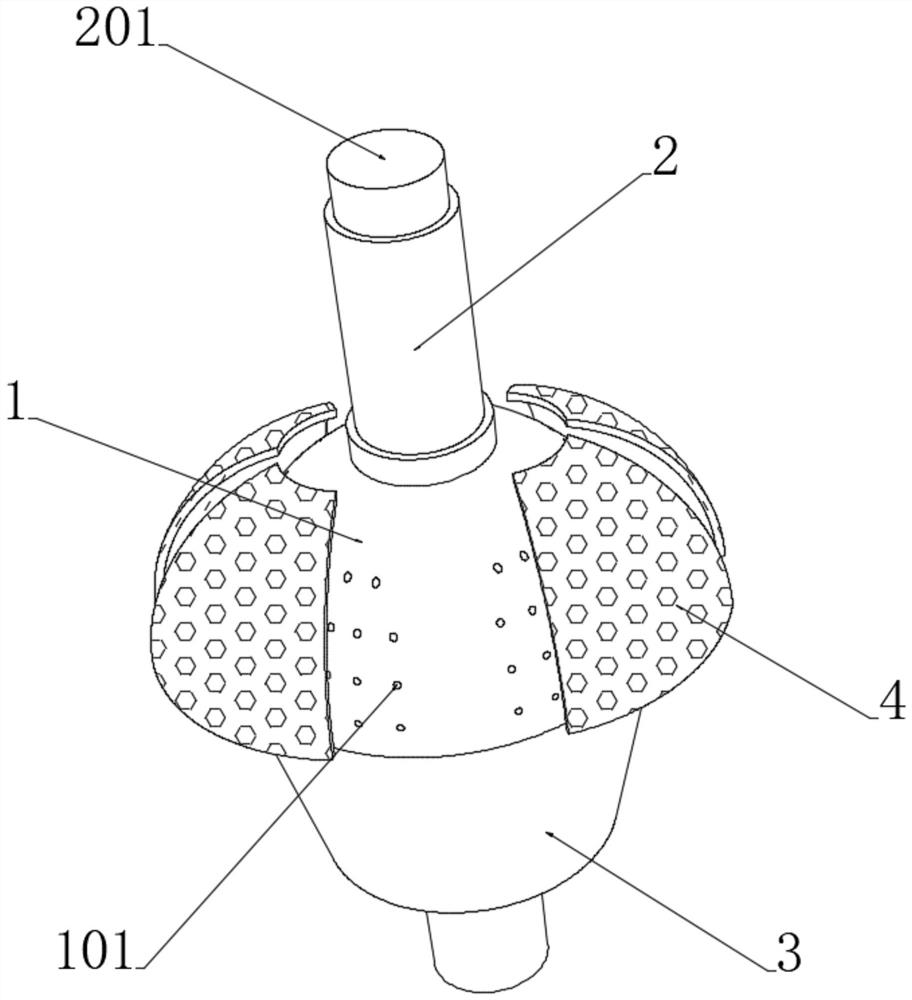

Garden soil unfreezing pre-embedded rod body

InactiveCN113229013AEasy to thawPersistent feverSoil lifting machinesPlant protectionThermodynamicsSoil science

The invention discloses a garden soil unfreezing pre-embedded rod body, and belongs to the technical field of garden anti-freezing. A plurality of unfreezing monomers are distributed in the vertical direction, unfreezing of different depths of soil is facilitated, when the temperature of the soil around the unfreezing monomers is very low, a temperature-sensitive cracking sealing sheet on the outer end wall of a heat conduction ball is frozen to crack due to the low temperature, and a heat conduction hole is exposed; at the moment, air in the soil enters heat conduction balls to react with reducing iron powder on a multi-sector attachment, the reducing iron powder reacts with oxygen to generate heat, and the heat is transferred into the soil through the heat conduction balls to unfreeze the soil; and after continuous warming of the heat conduction balls, a thermal expansion morphological body deforms due to the influence of temperature and compresses oxygen in a connecting pipe to be guided into the heat conduction balls, so that oxygen is supplemented into the heat conduction balls, the situation that heat generation unfreezing is affected due to insufficient oxygen in soil is avoided, high heating continuity is achieved, self-heating can be carried out according to the specific temperature conditions of different depths in the soil, flexibility is high, and the unfreezing effect is good.

Owner:郑乐海

Hub bearing cage assembly press-fitting device

The invention discloses a hub bearing cage assembly press-fitting device. The hub bearing cage assembly press-fitting device comprises a bottom frame and a bracket, wherein the bracket further comprises a supporting base and a supporting stand column, a supporting plate on which a first slide assembly, a first buffer device, a second buffer device, a first drive device and a workbench are placed is arranged on the bottom frame; a second drive device and a clamping lifting device are mounted on the bracket; and the first slide assembly and a second slide assembly are separately arranged on the bottom frame and the bracket. When the hub bearing cage assembly press-fitting device can be independently used, a plurality of cage assemblies of a hub bearing can be simultaneously pressed in; when the hub bearing cage assembly press-fitting device is matched with a connecting line (automatic production line) for use, automation is provided for equipment; and the hub bearing cage assembly press-fitting device is high in mounting efficiency and is high in speed, so that production efficiency is greatly improved.

Owner:广德中隆轴承有限公司

A reconfigurable flexible teaching aid used to demonstrate the dual relationship between degrees of freedom and constraints in the teaching of mechanical principles

The invention discloses a reconfigurable flexible teaching aid for demonstrating the duality relation of freedom degree and restraint in mechanical principle teaching. The teaching aid comprises a movable platform, a static platform and six rod pieces, wherein the six rod pieces are arranged between the movable platform and the static platform. According to the teaching aid designed, on one hand, teaching aid configurations with different freedom degrees can be lapped by utilizing the modularized rod pieces and the platforms, on the other hand, the duality relation between the freedom degree and the restraint can be verified by utilizing the lapped teaching aid configurations. Through the direct observation of the teaching aid, students can directly master the concepts of freedom degree and restraint and the like as well as the duality relation between the concepts.

Owner:BEIHANG UNIV

Diluted sulfuric acid atomizing system and application thereof

ActiveCN109187306AAutomate operationPush inTesting metalsPermeability/surface area analysisCopper foilEngineering

The invention relates to a diluted sulfuric acid atomizing system and an application thereof. The system is characterized in that an L-shaped plate (1-8) is arranged on the lower plate of a shell of an atomizing system (1); a third telescopic power mechanism (1-9) is fixed in the vertical part of the L-shaped plate (1-8); a compression plate is connected with the other end of the third telescopicpower mechanism (1-9); a plurality of compression rubber blocks (1-10) are alternately arranged on the surface of the compression plate, and are as wide as that of a copper foil. By adopting the diluted sulfuric acid atomizing system and application thereof, the whole site of diluted sulfuric acid can be automatically applied to copper foil penetrating point and pinhole detection.

Owner:JIAXING DAMING INDAL

Atomization system, detection device using atomization system and operating method of detection device

ActiveCN109115795AAutomate operationPush inSpraying apparatusOptically investigating flaws/contaminationEngineeringSmooth surface

The invention relates to an atomization system, a detection device using the atomization system and an operating method of the detection device. Copper foil passes through a top guide roller (1-1) anda top driving roller (1-2) and turns from horizontal movement to downward movement; the cooper foil passes through a bottom guide roller (1-3) and a bottom driving roller (1-4) and turns from downward movement to horizontal movement; a first movable atomization system (1-6) and a second movable atomization system (1-7) are arranged on one side of the smooth surface of the cooper foil. Through adoption of the atomization system, the detection device using the atomization system and the operating method of the detection device, whole-range dilute sulfuric acid can be automatically coated in detection of penetration points and pinholes of the copper foil.

Owner:嘉兴鼎尚信息科技有限公司

Electrolytic copper foil penetration point and pinhole detection equipment

ActiveCN109001223BAutomate operationPush inOptically investigating flaws/contaminationElectrolysisCopper foil

The invention relates to detection equipment of a permeation point and a needle hole of an electrolytic copper foil. The detection equipment comprises an atomization system (1) and a copper foil (2),wherein a dilute sulphuric acid solution is sprayed onto a smooth surface of the copper foil by a first moving atomization system (1-6) and a second moving atomization system (1-7), the copper foil isinitially subjected to moisture removal by a rubber block (1-10) and a vertical support (3), the copper foil is changed to horizontal running from vertical running by a bottom guide roller (1-3) anda bottom driving roller (1-4), the dilute sulphuric acid solution can enter the permeation point and the needle hole, a fourth telescopic power mechanism is arranged at a lower surface of a lower plate of a shell, the other end of the fourth telescopic power mechanism is connected with a press plate, a plurality of press rubber blocks are arranged at a surface of the press plate at intervals, andthe widths of the rubber blocks are same as the width of the copper foil. With the adoption of the device, the whole dilute sulphuric acid capable of coating can be achieved during detection of the permeation point and the needle hole.

Owner:福州宇卓科技有限公司

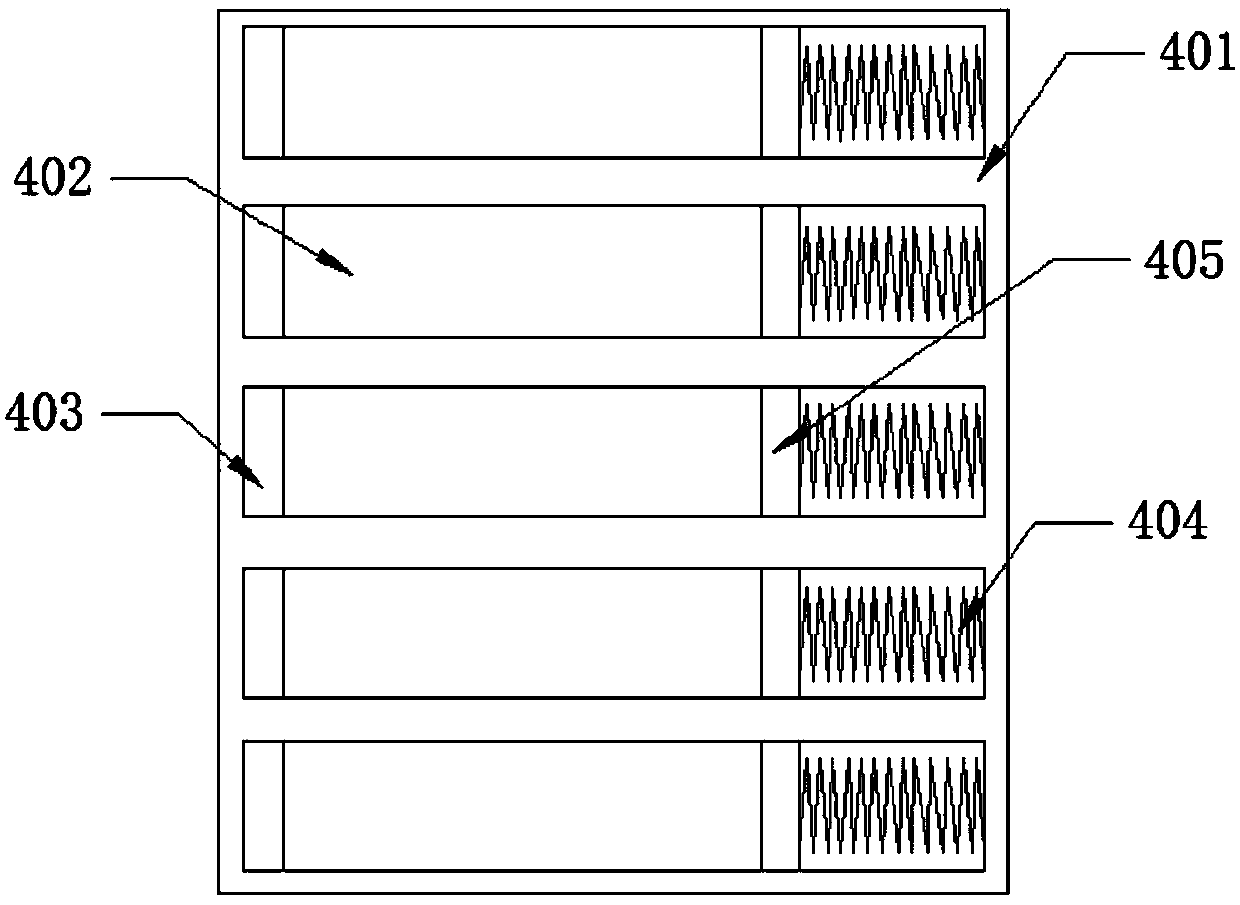

Automatic sheet inserting machine

The invention discloses an automatic sheet inserting machine. The machine comprises a frame, a sheet feeding assembly and a sheet pressing assembly, a screen net is detachably connected into the frame, the sheet feeding assembly comprises a sheet containing plate in sliding connection with the top end of the frame and a driving assembly used for driving the sheet containing plate to slide, multiple sheet containing grooves are formed in the top face of the sheet containing plate in a spaced sinking manner, and are mounted in the moving direction of the sheet containing plate, one ends of the sheet containing grooves are provided with a sheet pushing assembly used for pushing sheets to move, the bottoms of the other ends of the sheet containing grooves are provided with sheet outlets in a penetrating manner, the sheet pressing assembly comprises a supporting frame fixedly mounted on the sheet containing plate, a first air cylinder fixedly connected to the supporting frame and a horizontal rod detachably connected with an output shaft of the first air cylinder, multiple needle rods are fixedly mounted on the horizontal rod in a spaced manner, and are in one-to-one corresponding to the sheet containing grooves, the first air cylinder drives the needle rods to move downwards to be discharged from the sheet outlets, through the sheet feeding assembly and the sheet pressing assembly,automatic sheet inserting is achieved, and work efficiency is improved.

Owner:廊坊京磁精密材料有限公司

A multi-station welding machine for lead-acid batteries

ActiveCN105382475BImprove the efficiency of the pole group welding processFit closelyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPosition sensor

The invention discloses a lead-acid storage battery multi-station welding unit. The technical problem that a pole group welding technology of an existing lead-acid storage battery is low in efficiency is solved. The lead-acid storage battery multi-station welding unit comprises a mounting seat, a rotary disc rotatably connected to the mounting seat, a control motor for driving the rotary disc to rotate at a certain frequency and a pressing mechanism; a plurality of comb die automatic clamping mechanisms are arranged on the rotary disc, and are provided with assembling holes capable of defining a clamping pole group; a through hole capable of penetrating the rotary disc is formed in the position below each comb die automatic clamping mechanism, and the through holes penetrate the assembling holes to form a channel capable of allowing the pole group to pass through; the pressing mechanism comprises a pressing block arranged above a rotation path of the channels, a pressing air cylinder for driving the pressing block to vertically move and a roller cylinder conveyor located below the through holes and used for conveying battery boxes; and a position sensor is arranged on the roller cylinder conveyor.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

Suspension control arm bushing press-in tool device

ActiveCN111347373AImprove installation efficiencyPush inMetal-working hand toolsControl armStructural engineering

The invention discloses a suspension control arm bushing press-in tool device which comprises a tool base, a plurality of positioning blocks, a plurality of calipers, a plurality of base guide groovesand rotary pressing devices. Sliding blocks are arranged at the bottoms of the calipers so that the calipers can move in the base guide grooves to adapt to clamping, a rocker mechanism is arranged atone ends of the calipers, the positioning blocks are arranged at the other ends of the movable calipers, and the positioning block and the caliper jointly realize clamping; two of the positioning blocks are provided with guide grooves, the rotary pressing devices with sliding blocks are arranged on the guide grooves, each rotary pressing device is provided with an L-shaped supporting block, the rotary devices are driven by pressing rods, threads are arranged on the pressing rods, and pressing blocks are arranged at the bottoms of the moving ends of the rotary pressing devices. The device is novel in design, can adapt to control arms of various specifications and sizes, realizes the clamping positioning of the control arms and the installation pressing-in of bushings, has wide applicationrange and large adjustment range, can realize pressing-in of the bushings at two positions at a time, and obviously improves the installation efficiency of the bushings.

Owner:SOUTH CHINA UNIV OF TECH

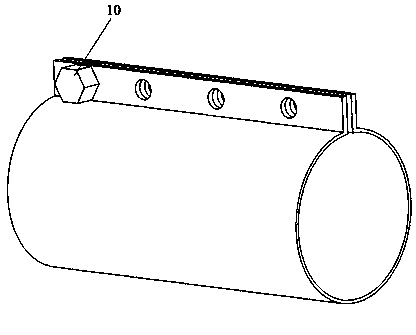

An oil pipe moving device

Owner:WUHAN MARINE MACHINERY PLANT

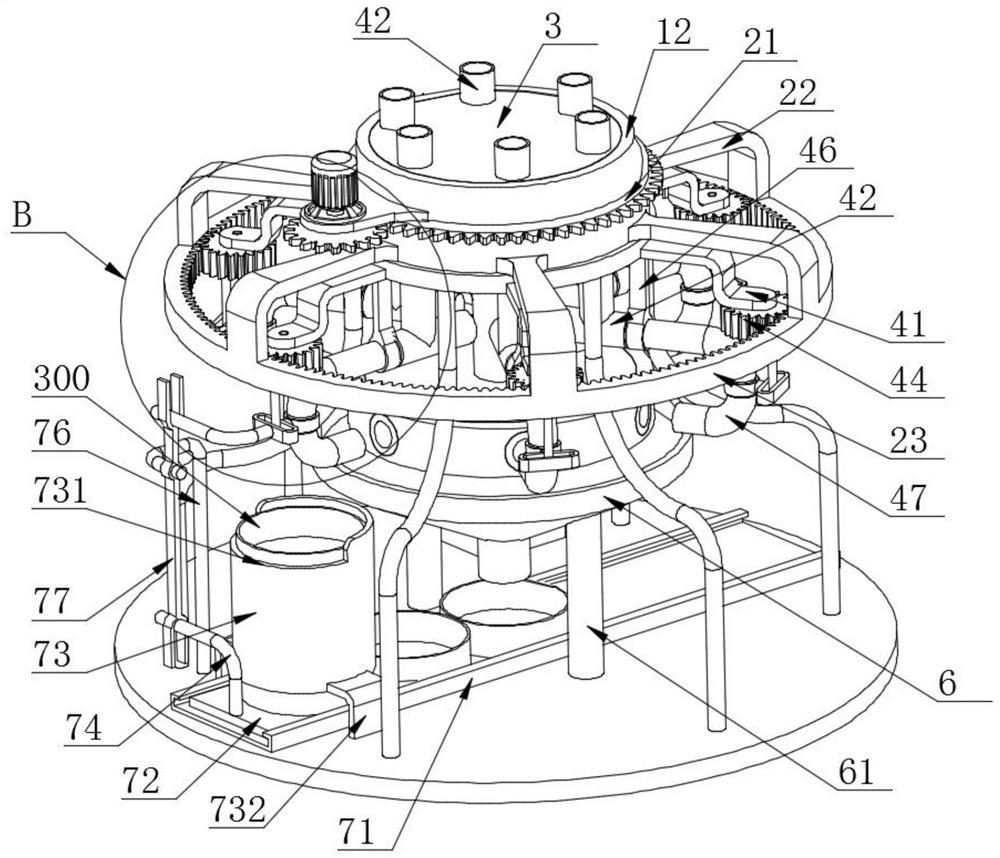

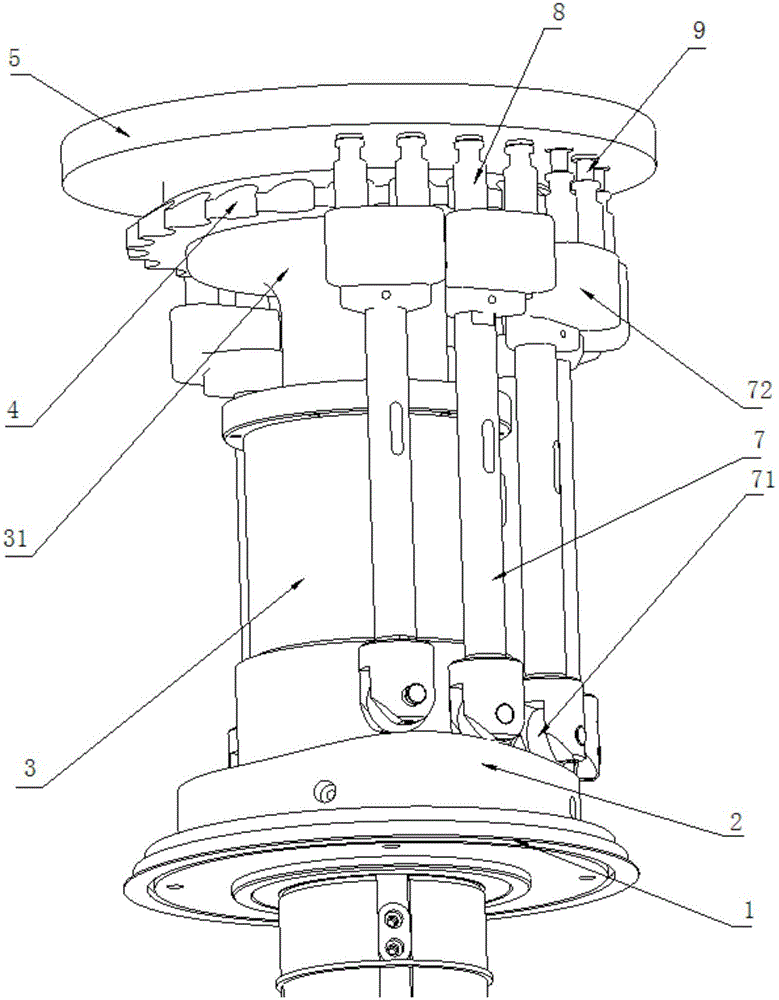

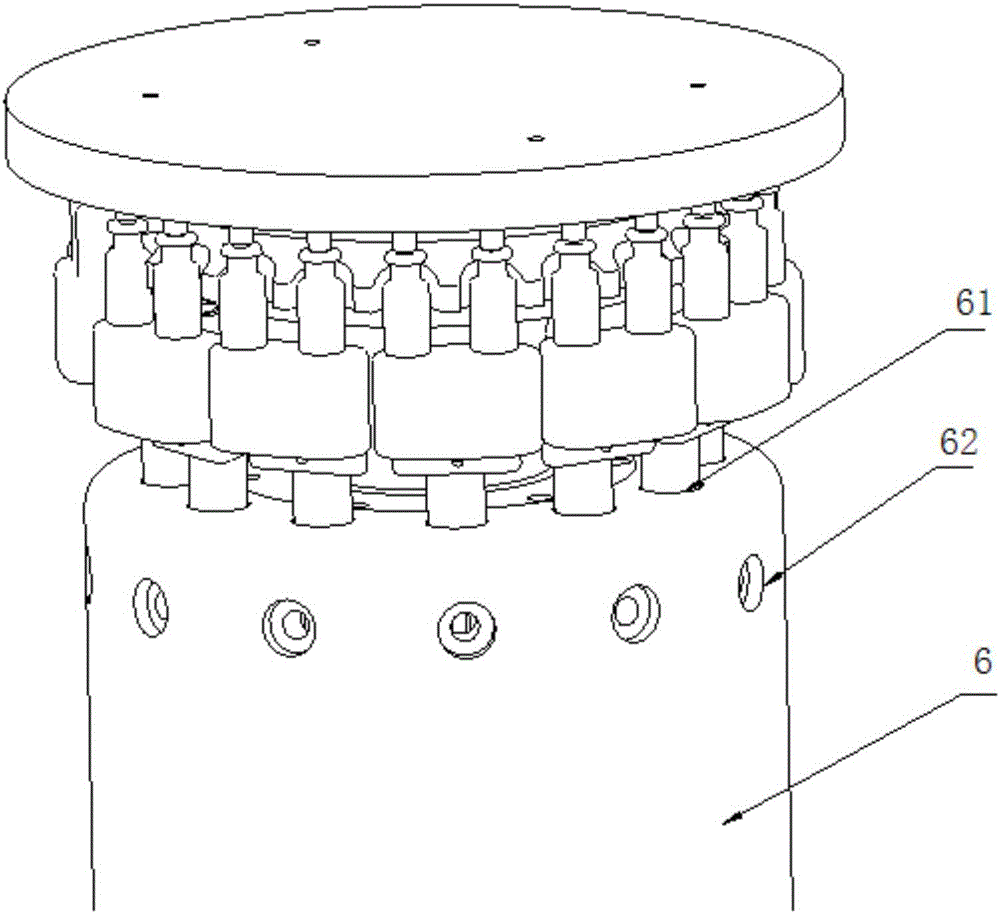

Medicine bottle lifting type press plugging mechanism

The invention discloses a medicine bottle lifting type press plugging mechanism, comprising a horizontal ring-shaped cam track, a cam fixing seat, a rotating shaft, a rotary star wheel, a plug suction top cover, a protective cover and a plurality of lifting rods, wherein the cam fixing seat is used for fixing the cam track; the rotating shaft vertically passes through the cam track; the rotary star wheel is horizontally fixed at one end of the rotating shaft and is used for driving all medicine bottles to synchronously rotate along with the rotating shaft; the plug suction top cover is horizontally fixed at one end of the rotating shaft arranged above the rotary star wheel and synchronously rotates along with the rotating shaft; the protective cover covers the rotating shaft and synchronously rotates along with the rotating shaft; one end of each lifting rod is provided with a bearing capable of rolling along the cam track, and the other end of each lifting rod is provided with a lifting block used for lifting the medicine bottle; a plurality of locating holes are formed in the top of the protective cover, and the plurality of lifting rods can vertically pass through the locating holes. The medicine bottle lifting type press plugging mechanism can avoid that the medicine bottles fall off and prevent dust produced by friction among the medicine bottles from contaminating liquid medicine.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

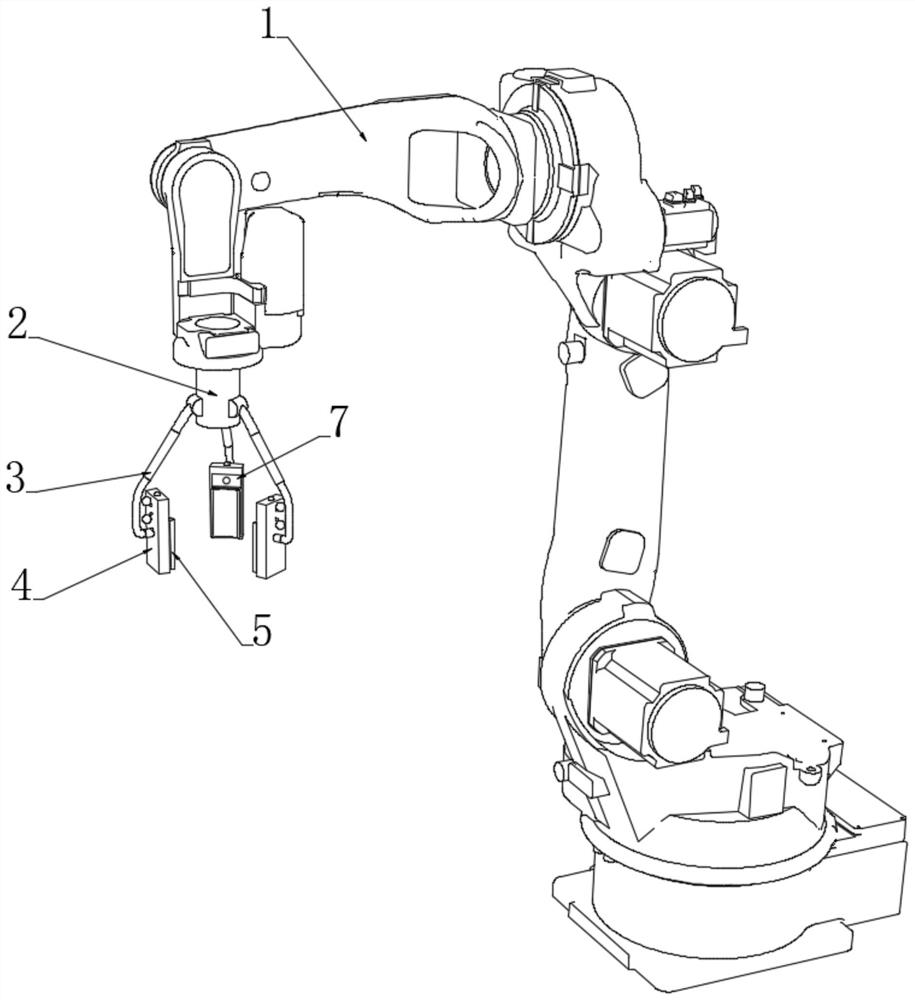

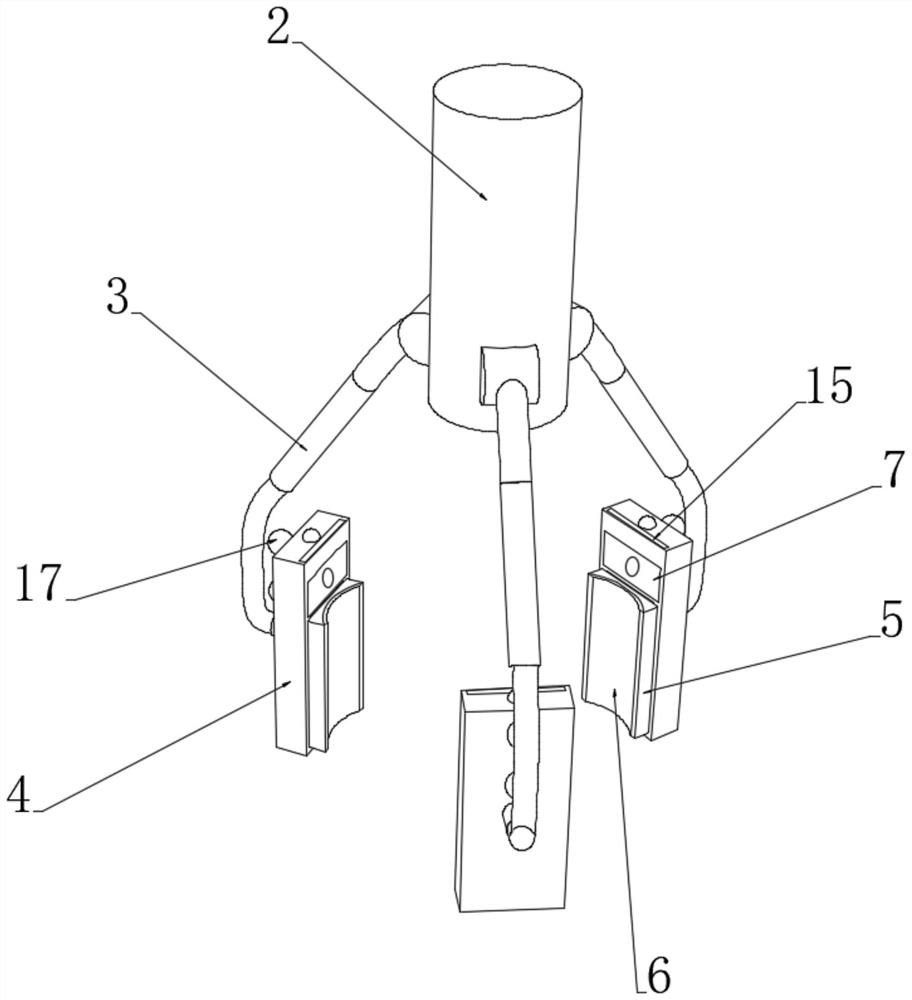

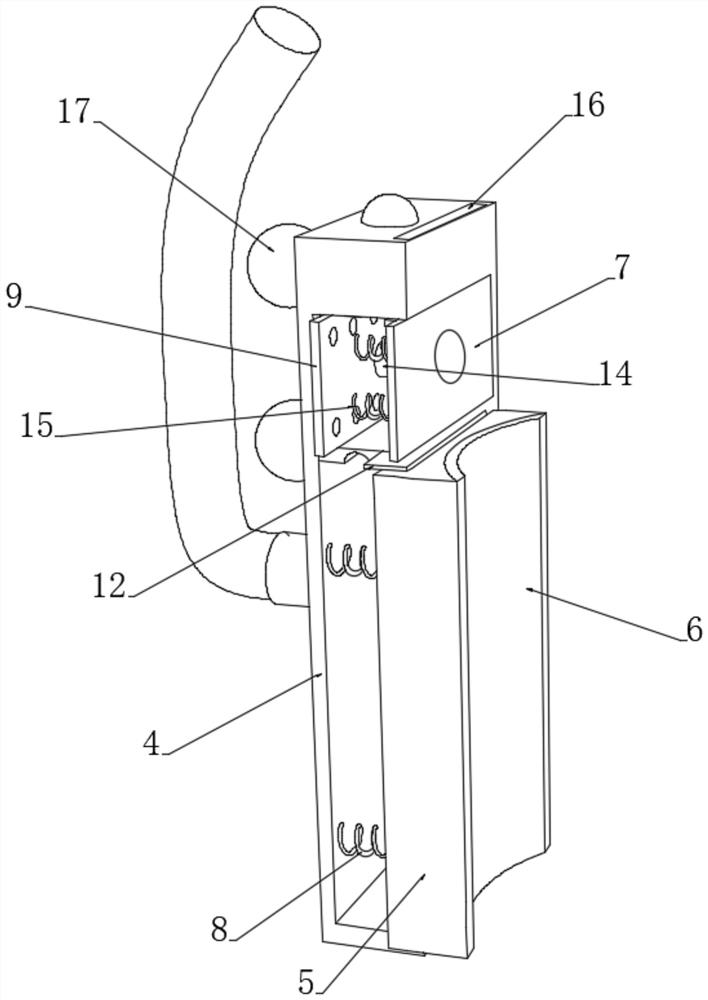

Abnormality discrimination type manipulator for automatic production

ActiveCN113510087AImprove protectionPlay a strong magnetic roleGripping headsSortingManipulatorEngineering

The invention discloses an abnormality discrimination type manipulator for automatic production, and belongs to the technical field of automatic manipulators. Grabbing clacks are movably embedded in grabbing identification bodies, when products are grabbed, the grabbing clacks move into a buffer cavity due to elastic extrusion between the grabbing identification bodies and the products, a magnetic attraction body moves along with the grabbing clacks and is buckled at a magnetic attraction cavity, the magnetic shielding effect of the magnetic shielding layer on the magnetic attraction body is separated, the magnetic attraction body plays strong magnetic attraction effect on a magnetic suction plate, so that the magnetic suction plate moves towards the interior of a detection cavity, air at the position of the product is conveniently sucked into the detection cavity, gas is detected through a detection rod, whether the product has an abnormal leakage condition or not is judged, after defective products are picked out, the products are separated from the plurality of grabbing identification bodies, the magnetic attraction body outwards retreats to the magnetic shielding layer along with the grabbing clacks under the elastic reset of a lower compression spring, at the moment, the magnetic suction plate retreats to an one-way gas collection plate under the action of an upper compression spring, and the detected gas is pressed into a gas filtering layer to be filtered and discharged.

Owner:江苏师范大学科文学院

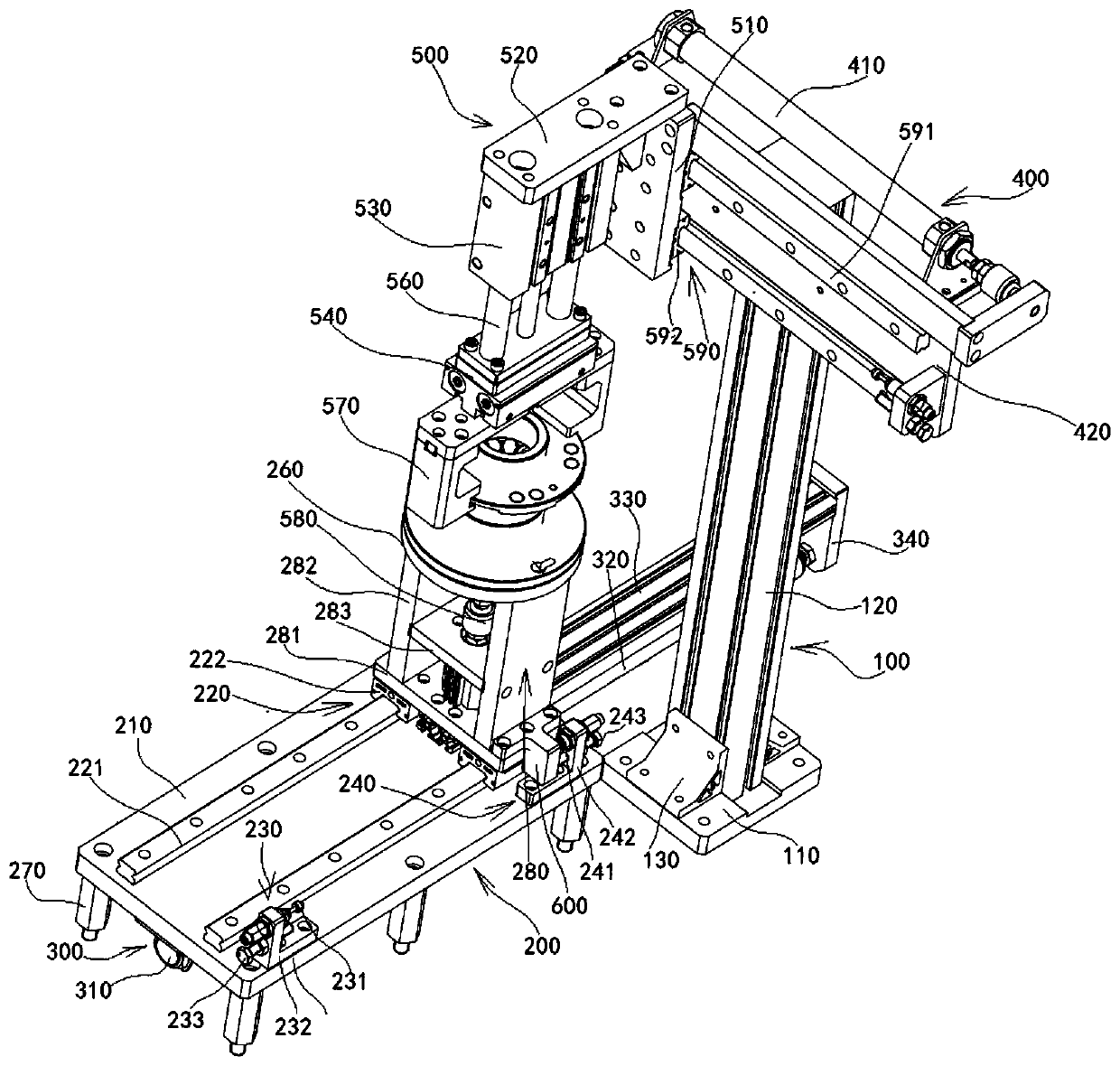

An automatic assembly machine for electrical connectors

ActiveCN104009367BNo human intervention requiredImplement automatic truncationContact member assembly/disassemblyElectricityAutomatic transmission

The invention discloses an automatic assembly machine for electrical connectors, which simultaneously integrates a terminal fixing device, a terminal feeding device, a first plastic core feeding device, a second plastic core feeding device, a plastic core pushing device, a terminal cutting device, Terminal crimping device, primary folding soldering foot device, secondary folding soldering foot device and third folding soldering foot device, so that the equipment can not only automatically transport the terminal material tape and rubber core, but also realize the automatic cutting, automatic bending, Automatic press-in, and automatic bending of welding feet, the entire process of electrical connector production does not require manual participation, greatly reducing labor costs, speeding up production, and improving product quality.

Owner:JIANGSU ZHONGHAI HUA HE ENVIRONMENTAL PROTECTION CO LTD

Detection device for penetration points and pinholes of electrolytic copper foil

InactiveCN109115794AAutomate operationPush inSpraying apparatusOptically investigating flaws/contaminationElectrolysisEngineering

The invention relates to a detection device for penetration points and pinholes of electrolytic copper foil. The detection device comprises an atomization system (1) and the copper foil (2). The atomization system (1) comprises an atomization system frame, a top guide roll (1-1), a top driving roll (1-2) and a shell (1-5), and the copper foil passes through the top guide roll (1-1) and the top driving roll (1-2) to run vertically instead of horizontally. The atomization system (1) further comprises a first moving spraying system (1-6) and a second moving spraying system (1-7), and a dilute sulphuric acid solution is sprayed to the smooth surface of the copper foil through the first moving spraying system (1-6) and the second moving spraying system (1-7). By adopting the device provided bythe invention, the dilute sulphuric acid can be automatically smeared on the whole surface of the copper foil during detection of the penetration points and pinholes of the copper foil.

Owner:苏州绣创投资发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com