Medicine bottle lifting type press plugging mechanism

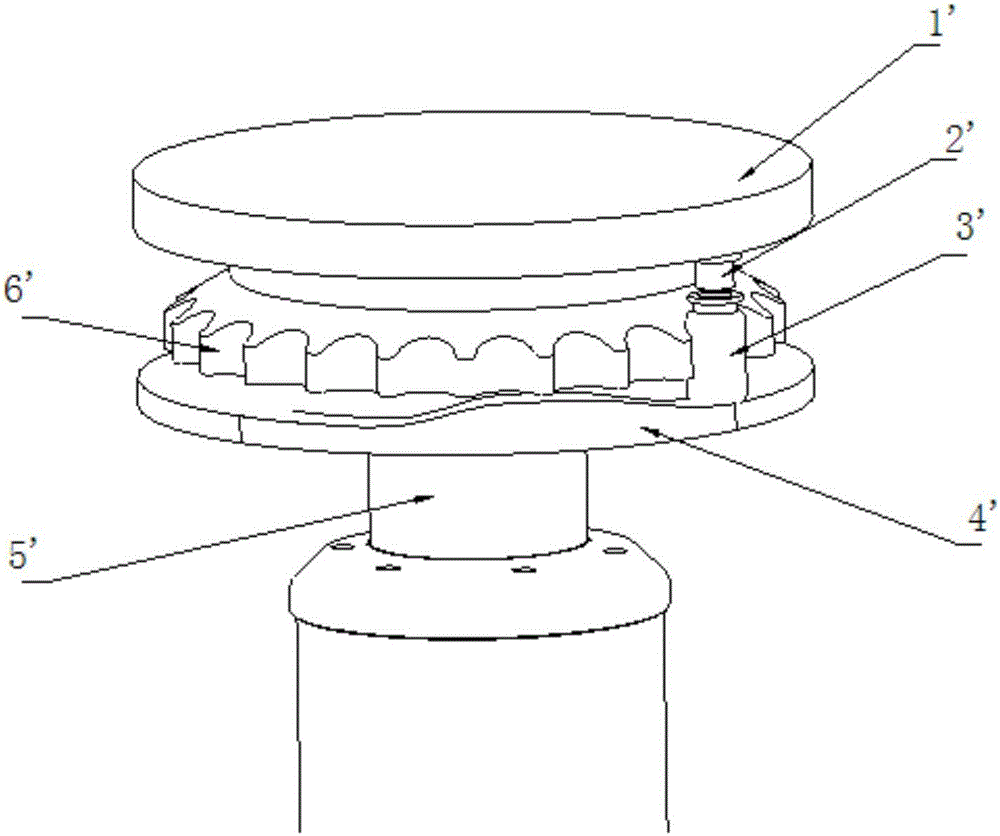

The technology of a medicine bottle and a rotating shaft is applied in the field of corking mechanism, which can solve the problems of easy inclination of the bottle when climbing, inaccurate alignment of the cork and the bottle, dust contamination of the medicine in the bottle, etc., so as to achieve accurate alignment and stable corking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

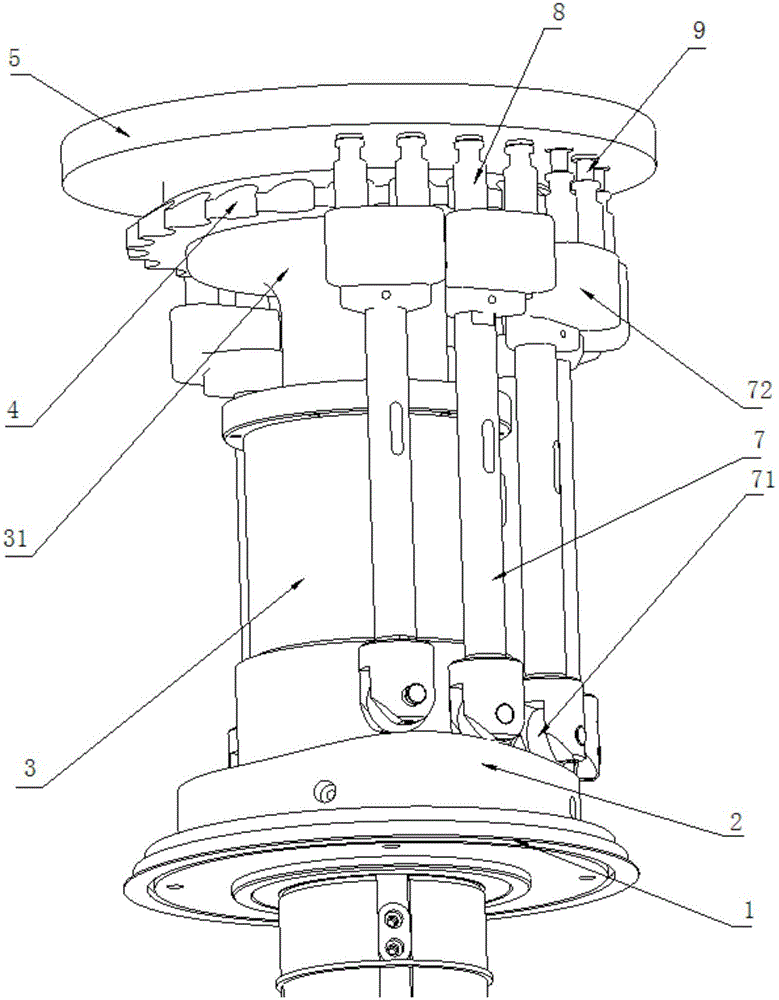

[0020] The present invention will be further described below in conjunction with accompanying drawing.

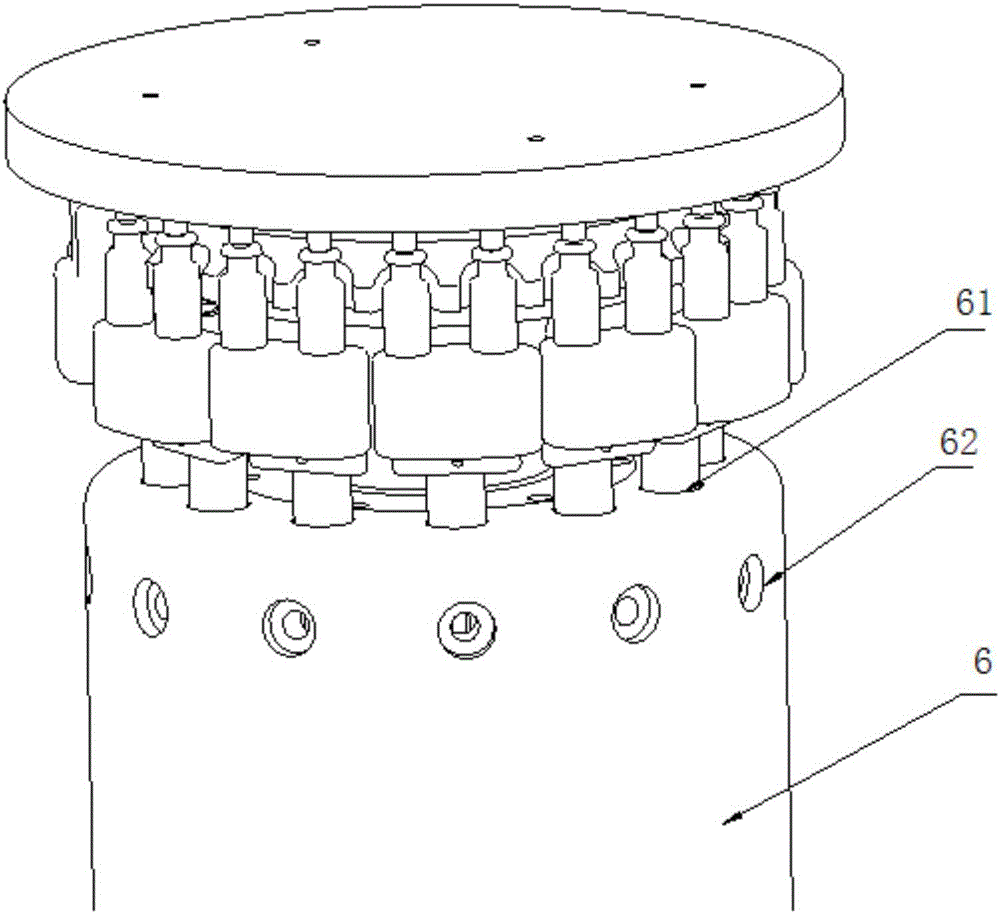

[0021] see figure 2 and image 3 , the lifting medicine bottle type stoppering mechanism of the present invention includes a cam holder 1, an annular cam track 2, a rotating shaft 3, a rotating star wheel 4, a suction plug top cover 5, a protective cover 6 and a plurality of lifting rods 7.

[0022] The cam track 2 is horizontally fixed on the cam holder 1.

[0023] The top of the rotating shaft 3 is fixed with a horizontal rotating star wheel 4 and a horizontal suction plug top cover 5, which drives the rotating star wheel 4 and the suction plug top cover 5 to rotate synchronously. Suction stopper top cover 5 is above rotating star wheel 4, and suction stopper top cover 5 is loaded with rubber stopper 9, and rotation star wheel 4 drives each medicine bottle 8 to rotate synchronously while limiting each medicine bottle.

[0024] The bottom end of the rotating shaft 3 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com