An automatic assembly machine for electrical connectors

An automatic assembly machine and electrical connector technology, which is applied in the assembly/disassembly of contacts, etc., can solve the problems of poor quality, difficult processing, and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

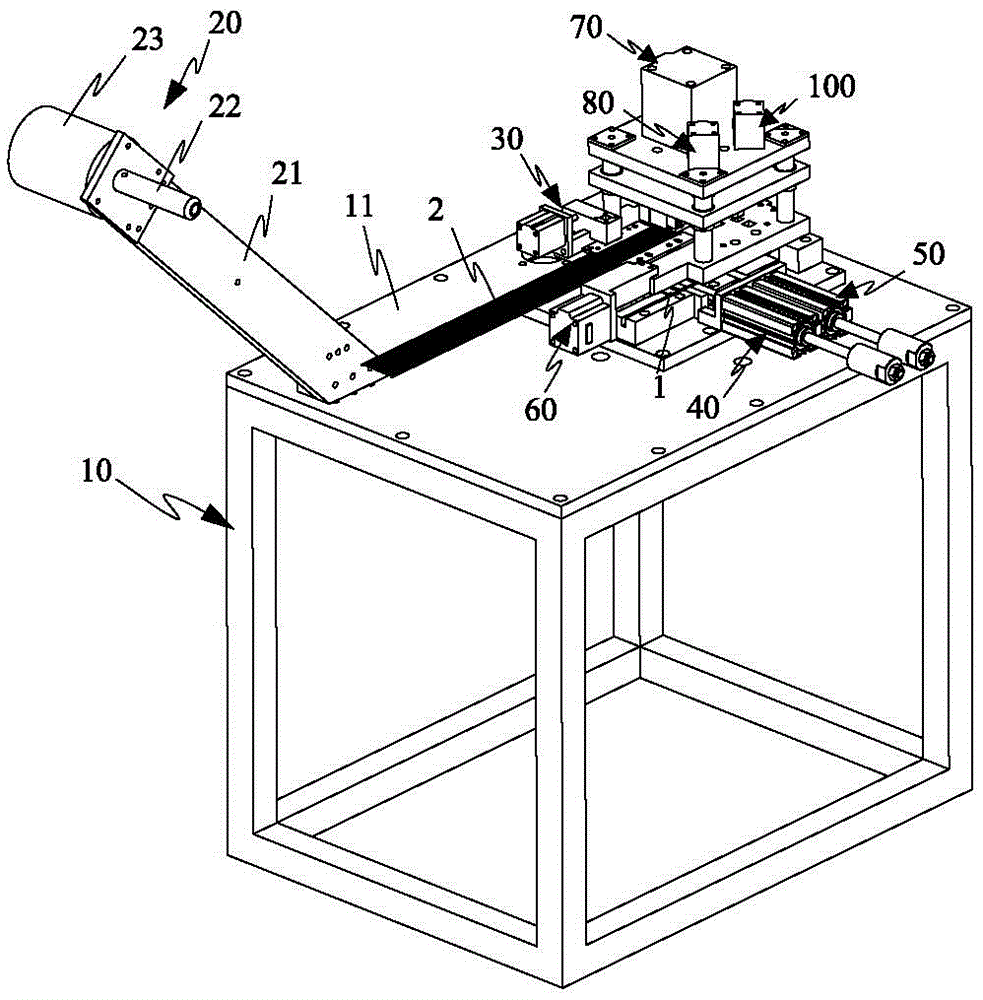

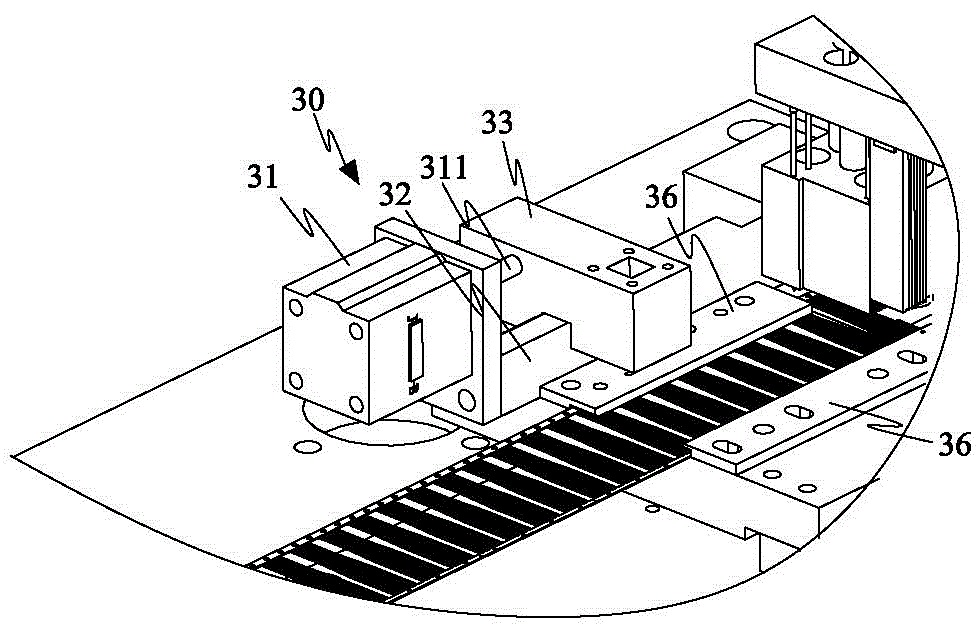

[0065] Please refer to figure 1 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a frame 10, a fixed terminal device 20, a terminal feeding device 30, a first rubber core device 40, a second rubber core device 50, The rubber core pushing device 60 , the terminal cutting device 70 , the terminal pressing device 80 , the primary welding leg folding device 90 , the secondary welding leg folding device 100 and the triple welding leg folding device 110 .

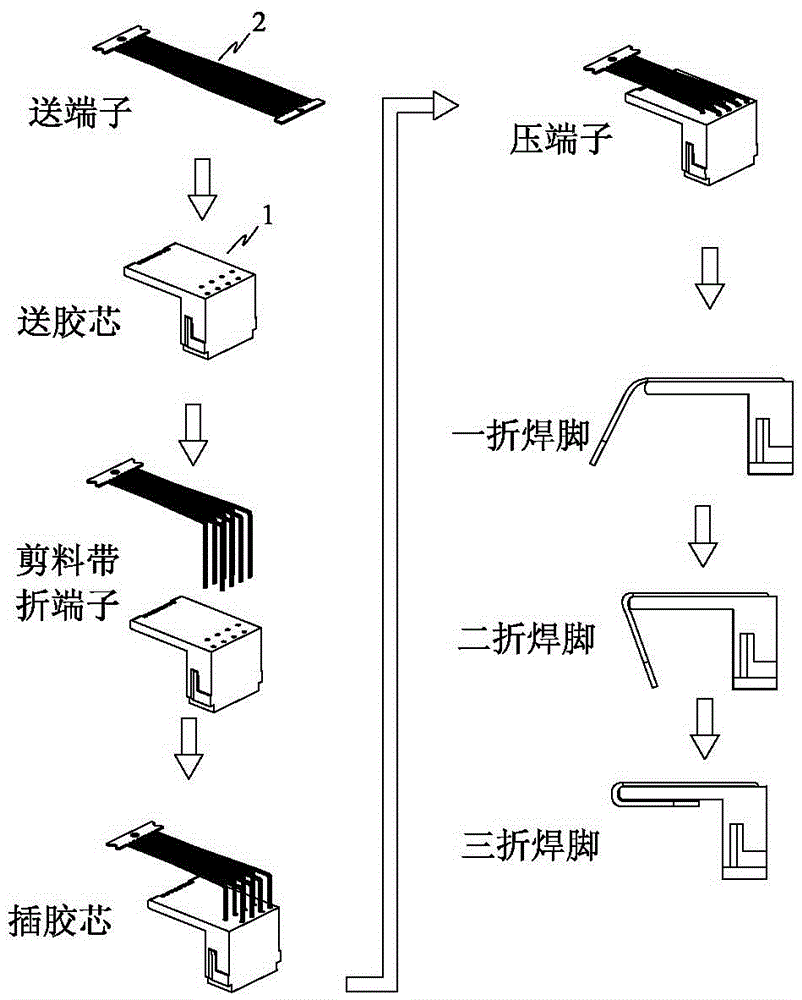

[0066] figure 2It shows the processing technology of the automatic assembly machine for electrical connectors. First, the terminal 2 is conveyed by the terminal feeding device 30, and the rubber core 1 is conveyed by the first rubber core feeding device 40, the second rubber core feeding device 50 and the rubber core pushing device 60. After the terminal 2 is transported in place, the terminal cutting device 70 presses down to cut off the strip and bends the terminal 2 at 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com