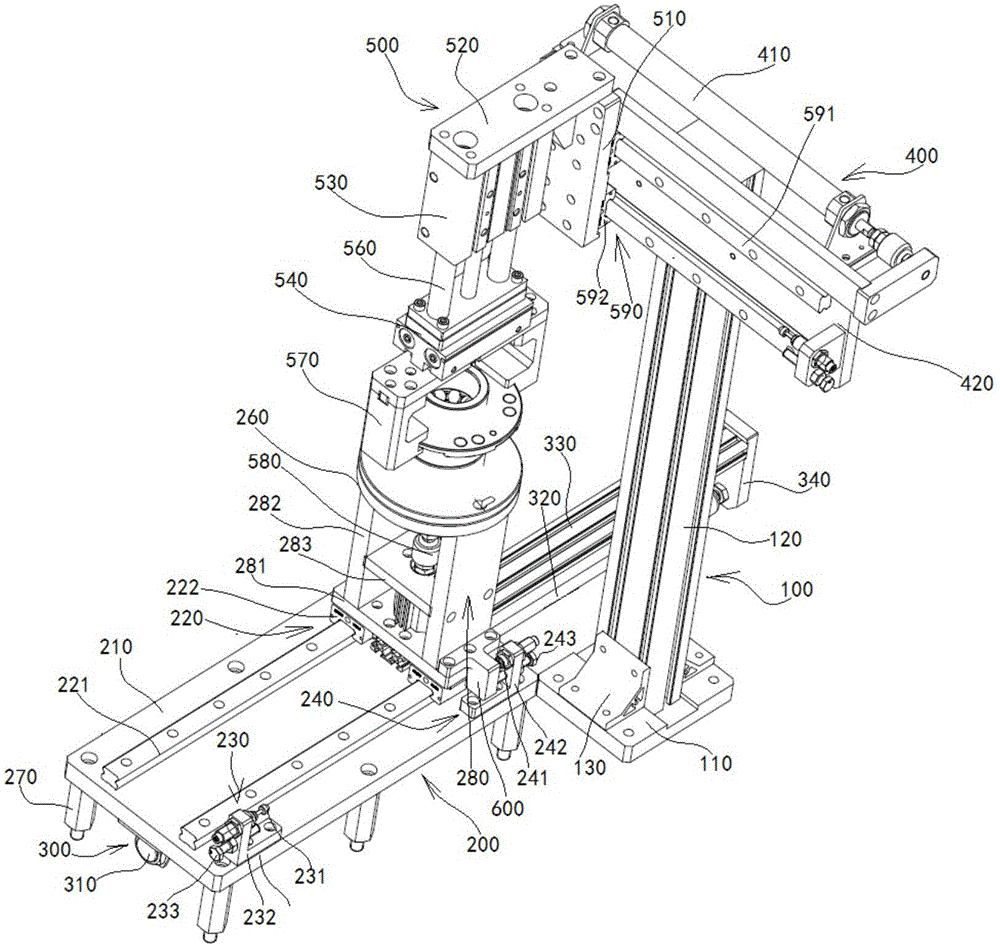

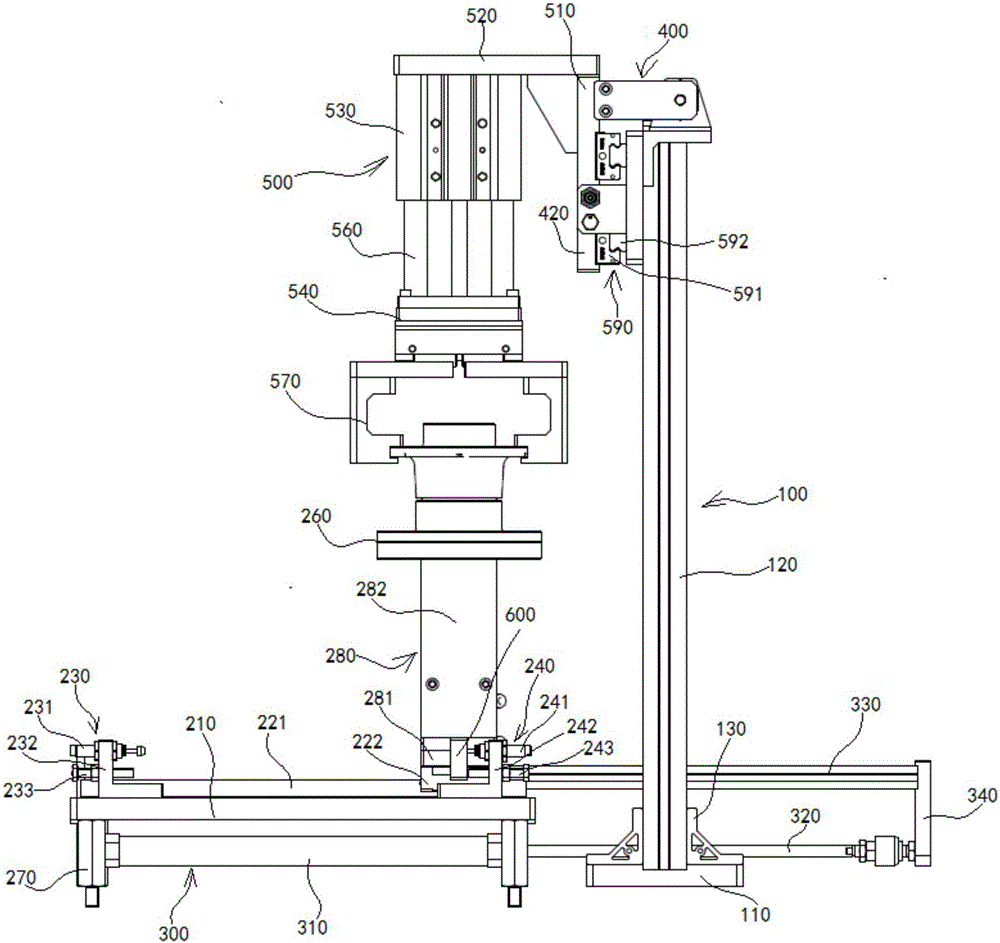

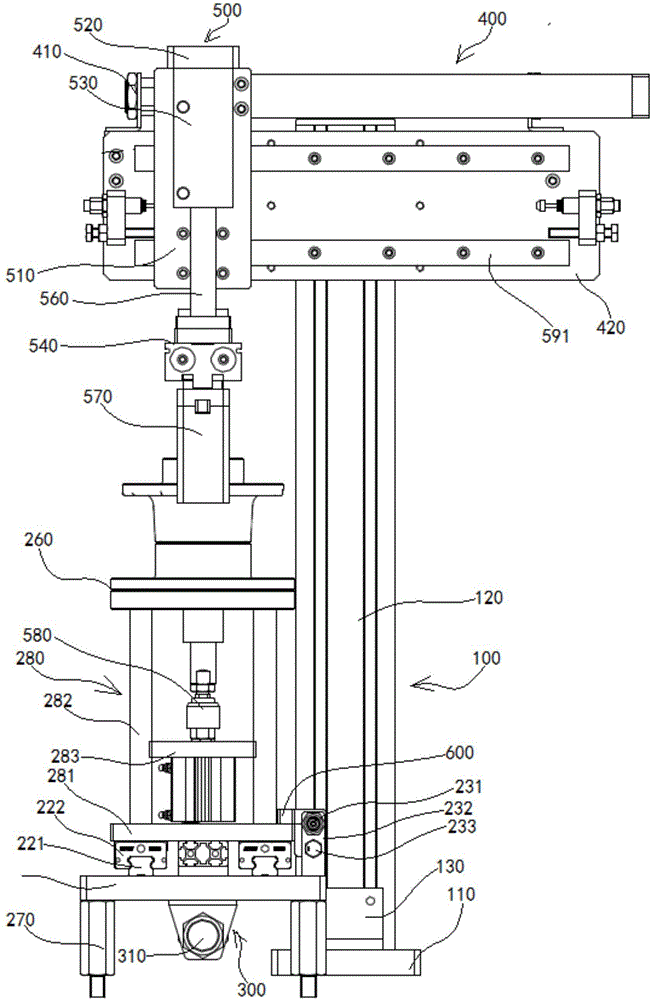

Hub bearing cage assembly press-fitting device

A technology of wheel hub bearing and press-fitting device, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reducing production efficiency, increasing labor costs, inconvenience, etc., achieving high speed, high installation efficiency, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The first-generation hub bearing press-fitting process is as follows:

[0053] A feeding device puts two sets of cage components on the workbench behind the two sides of the ferrule on the workbench, and the stretching cylinder pushes out the connecting plate, thereby driving the push rod, so that the first slider under the supporting and fixing device moves along the guide rail , until the second buffer device, the lifting cylinder will pass through the lifting cylinder joint and connecting rod, according to the direction of the guide sleeve, push the cage assembly on the lower mold to the designated position inside the ferrule and fix it, and at the same time, the clamping cylinder will go down and clamp 1 The first-generation wheel hub bearing, and the upper pressure block fixed on the lower part of the clamping cylinder presses the cage assembly on the other side to the designated position inside the ferrule, and completes the simultaneous pressing of the cage assemb...

Embodiment 2

[0055] The press-fitting process of the second-generation hub bearing is as follows:

[0056] A feeding device puts the outer ring on the lower mold of the workbench, puts the positioning block in the outer ring, then puts the cage and steel balls, and then presses them in; the stretching cylinder pushes out the connecting plate, drives the push rod, and makes The first slider under the support and fixing device moves to the second buffer device along the guide rail; the lifting cylinder moves in the direction of the guide sleeve through the connecting head and connecting rod of the lifting cylinder, and pushes the cage assembly on the lower mold to the inside of the ferrule. The specified position is fixed, and at the same time, the lifting cylinder controls the clamping cylinder to descend to clamp the second-generation hub bearing. When it is placed and pressurized, the outer ring falls off; when the clamping mechanism exits the ferrule, the stretching cylinder pulls back th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com