Atomizing system for electrolytic copper foil penetration point and pinhole detection and application of atomizing system

An atomization system and electrolytic copper foil technology, which is applied in the field of electrolytic copper foil, can solve the problems such as the inability to detect copper foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

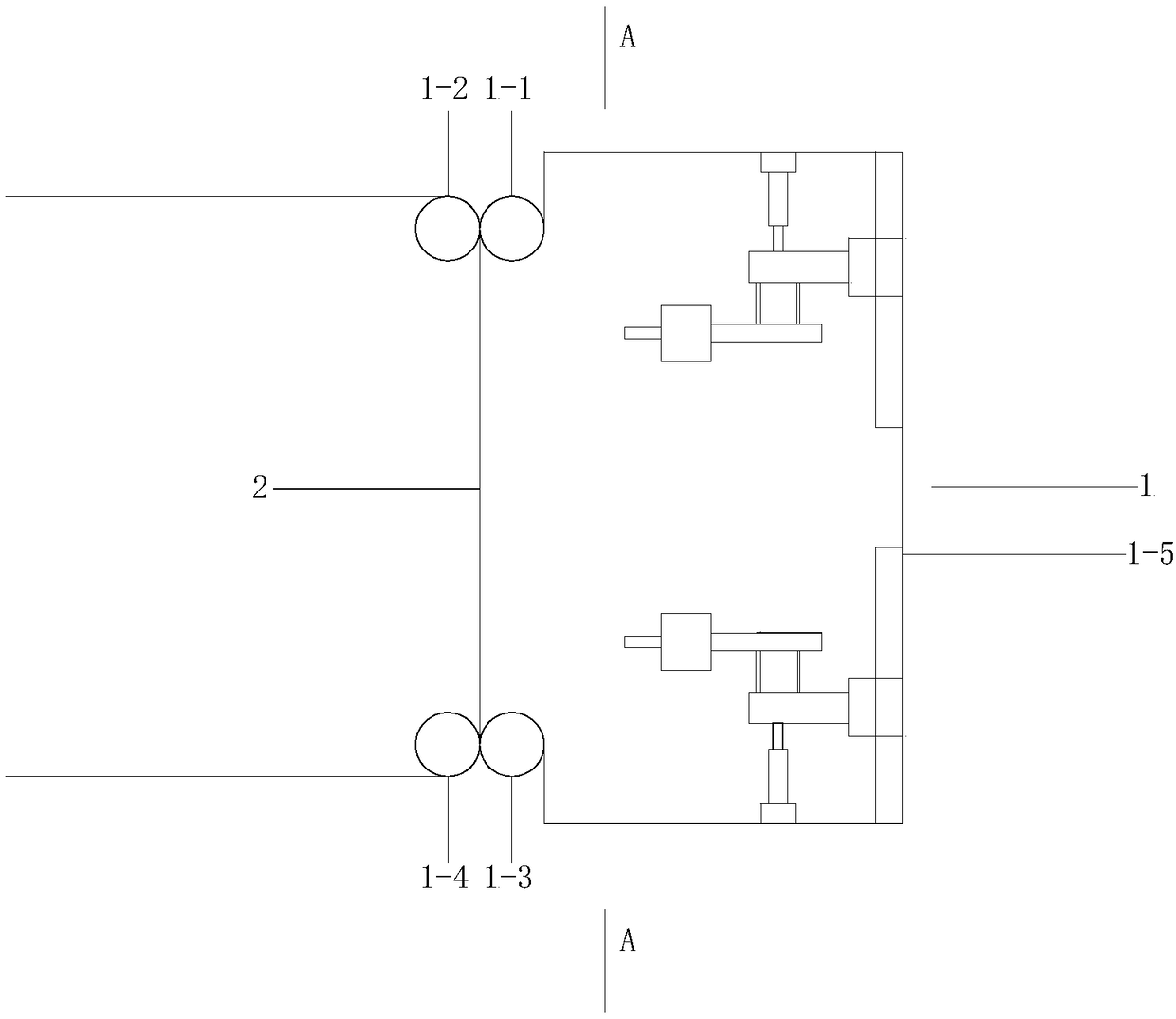

[0080] Embodiment 1: The detection equipment for penetration point and pinhole of electrolytic copper foil, including: atomization system (1) and copper foil (2).

[0081] Atomization system (1) includes: atomization system frame, top guide roller (1-1), top drive roller (1-2), bottom guide roller (1-3), bottom drive roller (1-4), shell body (1-5); top guide roller (1-1), top drive roller (1-2), bottom guide roller (1-3), bottom drive roller (1-4), and housing (1-5 ) are fixed on the atomization system frame;

[0082] The top guide roller (1-1), the top drive roller (1-2), the bottom guide roller (1-3), and the bottom drive roller (1-4) are arranged horizontally;

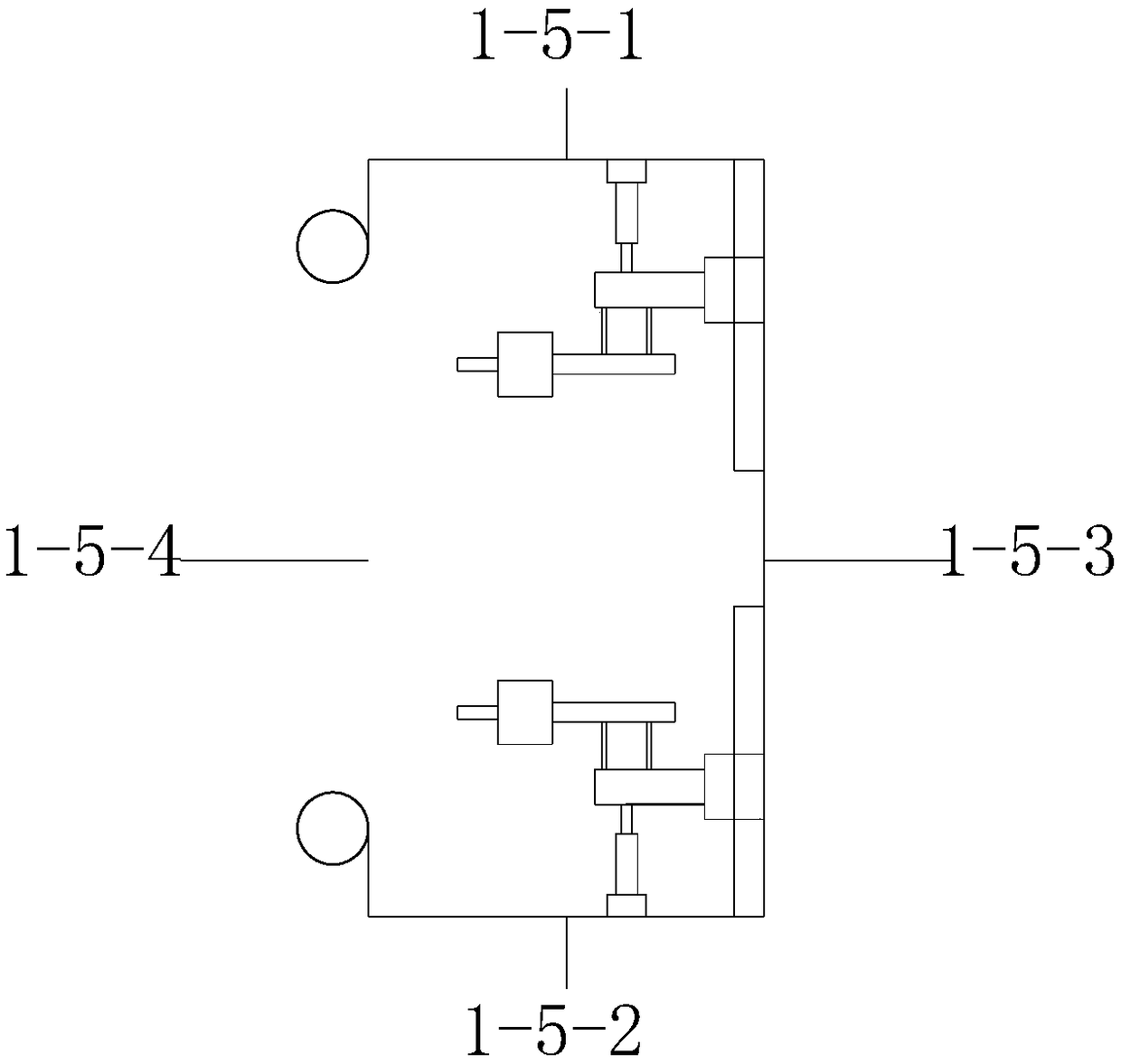

[0083] The housing includes: an upper plate (1-5-1), a lower plate (1-5-2), and a side wall plate (1-5-3), and an opening (1-5-4 ); the shell can be cuboid or cylinder;

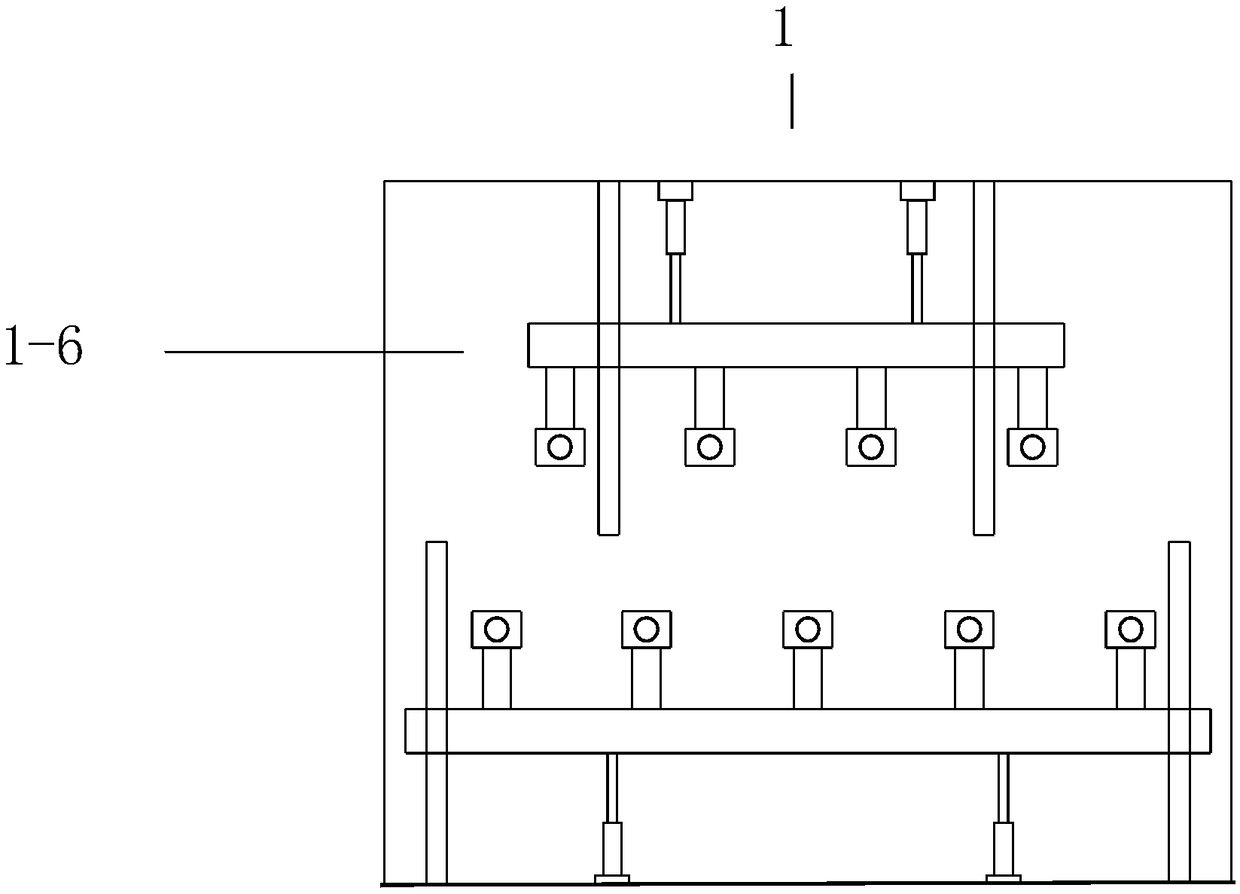

[0084] Also includes: a first mobile spray system (1-6), a second mobile spray system (1-7), the first mobile spray system (1-6) includes: seve...

Embodiment 2

[0117] Embodiment 2: The bottom guide roller (1-3) and the bottom drive roller (1-4) in embodiment 1, the copper foil passes through the bottom guide roller (1-3) and the bottom drive roller (1-4). Squeeze, so that the dilute sulfuric acid solution can enter the penetration point and pinhole more fully after being squeezed.

[0118] However, the first embodiment has the following difference. When the equipment is running for a long time, the bottom of the atomization system (1), especially the bottom guide roller (1-3) and the bottom driving roller (1-4) will Agglomerated solution. The purpose of the second embodiment is to solve the above problems.

[0119]The difference from Embodiment 1 is that: the bottom guide roller (1-3), the bottom driving roller (1-4) are cancelled. The lower plate of the shell of the atomization system (1) is provided with an L-shaped plate body (1-8), and a third telescopic power mechanism (1-9) is fixed on the vertical part of the L-shaped plate ...

Embodiment 3

[0122] Embodiment three: on the basis of embodiment two, further improvement. Bottom guide rollers (1-3) and bottom drive rollers (1-4) are set under the casing (1-5), that is, the copper foil is initially removed through rubber blocks (1-10) and vertical supports (3) After moisture, then through the bottom guide roller (1-3) and the bottom driving roller (1-4) to make the copper foil run from vertical to horizontal, so that the dilute sulfuric acid solution can enter the penetration point and pinhole; finally in The lower surface of the lower plate of the housing is equipped with a fourth telescopic power mechanism, the other end of the fourth telescopic power mechanism is connected with a compression plate, and the surface of the compression plate is provided with a number of compression rubber blocks at intervals. The width of the rubber block is the same as that of copper. The foils are the same width.

[0123] The way of the third embodiment is that after the copper foil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com