Temperature measurable aluminum smelting bell jar

A technology for aluminum smelting and bell jars, which is applied in the field of temperature-measurable bell jars for aluminum smelting. It can solve the problems that the bell jar has no support function and cannot add additives, and achieves the effects of simple structure, easy installation and replacement, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

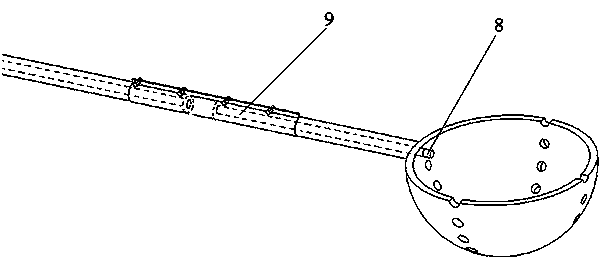

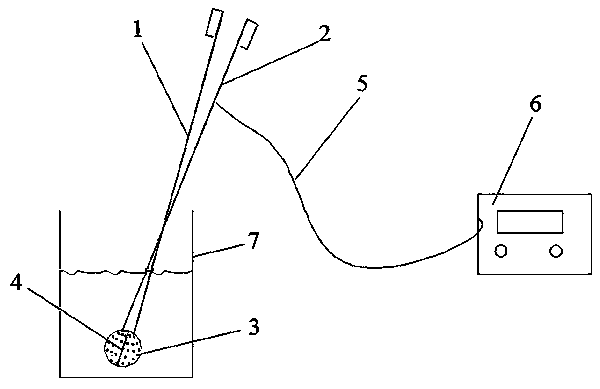

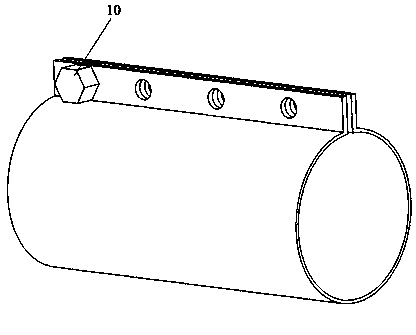

[0016] like Figure 1~3 As shown, a temperature-measuring bell jar for aluminum smelting includes a first handle 1, a second handle 2, a thermocouple 8 and a digital display 6. The first handle 1 and the second handle 2 are equal in length and hinged by a rotating shaft , the first handle 1 is hollow inside and equipped with a wire 5, the wire 5 is connected to a thermocouple 8 and a digital display 6, and also includes a first chuck 3 and a second chuck 4, the first handle 1 and the first chuck 3 , the second handle 2 and the second chuck 4 are respectively connected by a cylindrical fastening connector 9, and the first chuck 3 and the second chuck 4 are both composed of a connecting rod and a porous hollow hemisphere, wherein the first chuck The connecting rod of the head 3 is hollow inside, and the porous hollow hemispheres have the same diameter and are coaxial, and form a hollow sphere after merging. The thermocouple 8 is located in the first chuck 3 . The barrel fasteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com