Steel ball feeding device for sealing lithium battery

A lithium battery and sealing technology, which is applied in the manufacture of battery pack parts, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems that steel balls are easy to fall and affect the production efficiency of lithium batteries, so as to avoid falling and reduce labor burden , the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

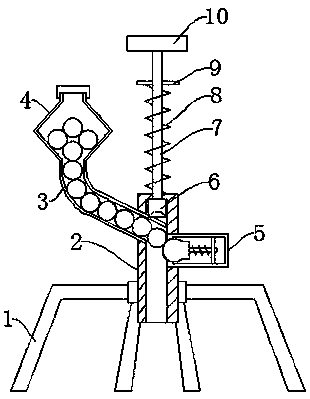

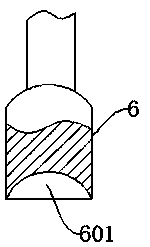

[0025] The first embodiment: see Figure 1-Figure 3 As shown, the present invention provides a steel ball feeding device for lithium battery sealing, comprising a support frame 1, a storage bin 4 and a blanking sleeve 2, the support frame 1 is installed on the outside of the blanking sleeve 2 through threads, and the blanking The inside of the casing 2 is provided with a vertically downward feeding channel, and a feeding pipe 3 is arranged on the upper side of the feeding casing 2. The feeding pipe 3 has two sections, the upper section is vertically arranged, and the top is connected with the storage bin 4. The lower section is inclined downwards and inserted into the blanking casing 2, the feeding channel inside the feeding pipeline 3 is connected with the feeding channel, and a stopper 5 is provided on the side of the connection between the feeding channel and the feeding channel;

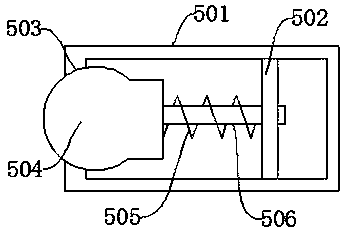

[0026] The stopper device 5 includes an outer shell 501 and a ball head 504, the end of the o...

no. 2 approach

[0034] The second embodiment: as shown in claim 1, a steel ball feeding device for lithium battery sealing, comprising two sets of support frames 1, a storage bin 4 and a blanking sleeve 2, the inside of the blanking sleeve 2 is A vertically downward feeding channel is provided, and a feeding pipe 3 is arranged above the side of the feeding casing 2. The feeding pipe 3 has two sections in total, the upper section is vertically arranged, and the top is connected with the storage bin 4 Through, the lower section is inclined downward, inserted into the feeding casing 2, the feeding channel inside the feeding pipe 3 is connected with the feeding channel, and a stopper device is provided on the side of the connection between the feeding channel and the feeding channel 5;

[0035]The stopper device 5 includes an outer casing 501 and a ball head 504, the end of the outer casing 501 is provided with a limiting hole 503, and the ball head 504 protrudes through the limiting hole 503, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com