A multi-station welding machine for lead-acid batteries

A lead-acid battery, multi-station technology, used in manufacturing tools, metal processing, welding equipment and other directions, can solve the problem of low efficiency of welding process, and achieve the effect of improving welding process efficiency, high degree of automation, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

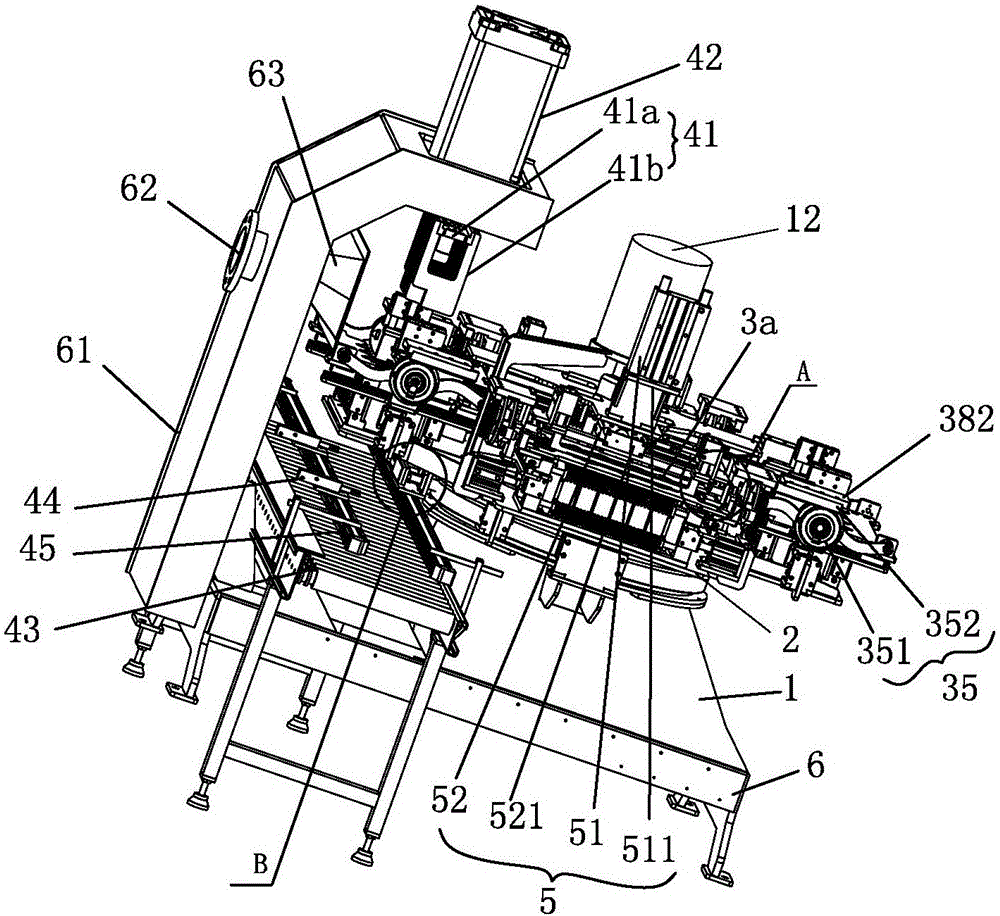

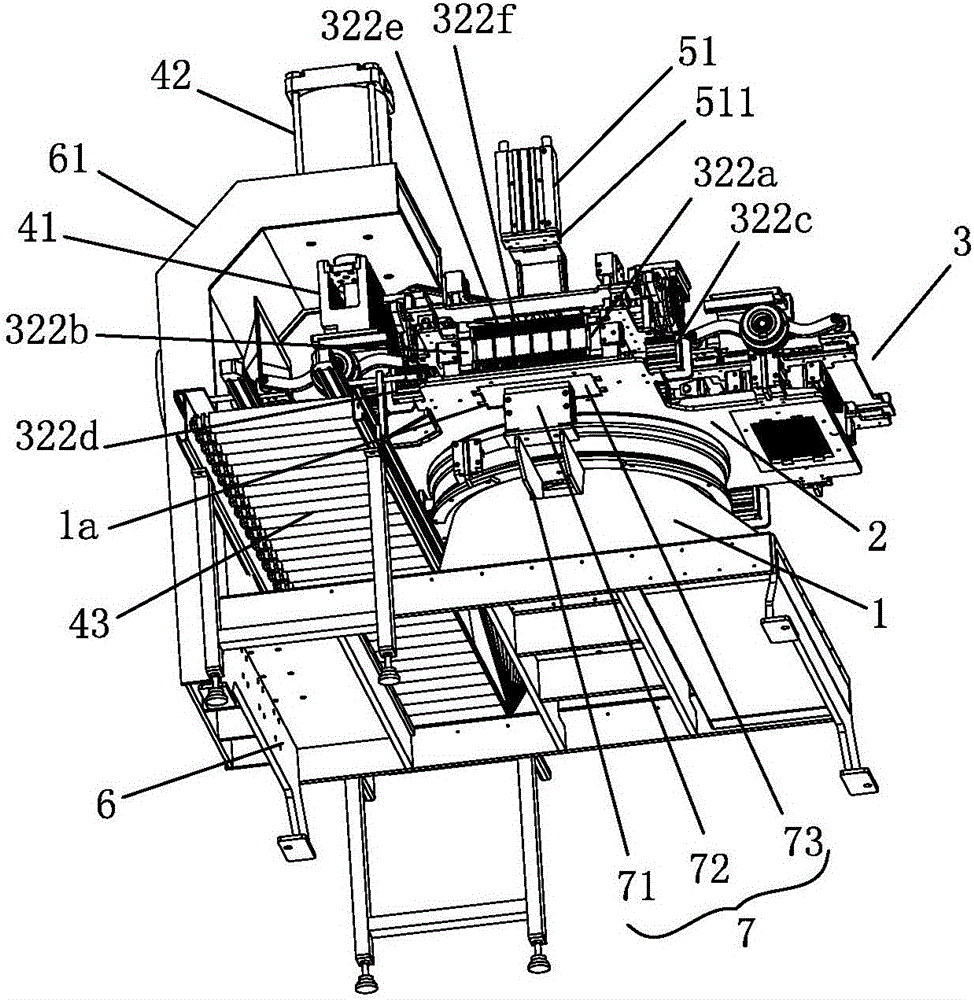

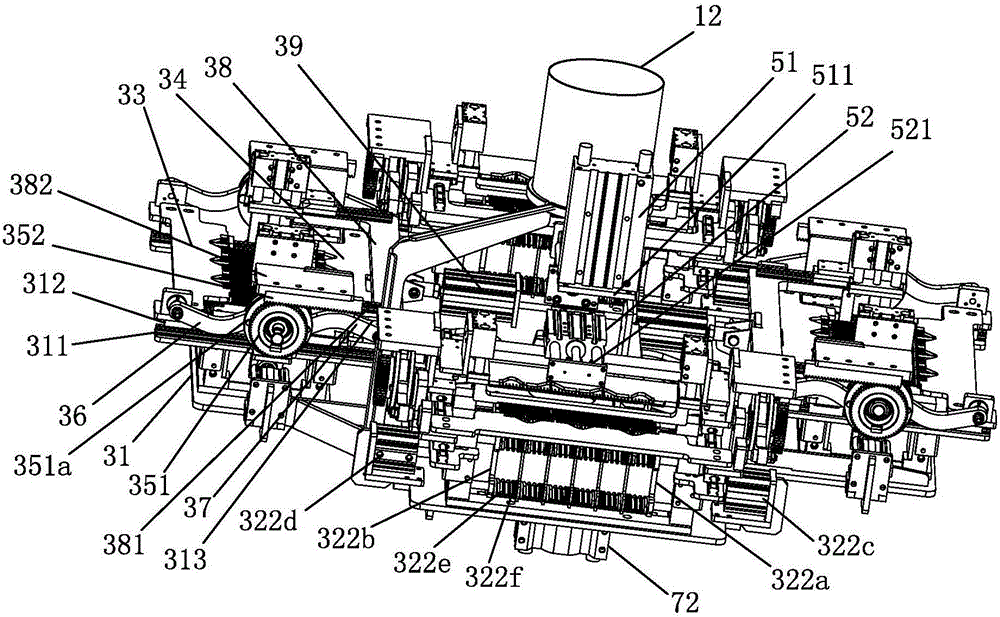

[0026] refer to Figures 1 to 5, a multi-station welding machine for lead-acid batteries, comprising a mounting base 1, a turntable 2 connected to the mounting base 1, a control motor 12 for driving the turntable 2 to rotate at a certain beat, and a pressing mechanism, and the turntable 2 is provided with There are a plurality of automatic clamping mechanisms 3 for comb molds. The automatic clamping mechanisms 3 for comb molds have assembly holes 3a that enclose and form clamping pole groups. The bottom of each automatic mold clamping mechanism 3 for comb molds is provided with a through hole 1a through the turntable. , the through hole 1a passes through the assembly hole 3a to form a passage that can pass through the pole group. The pressing mechanism includes a pressing block 41 arranged above the turning path of the passage, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com