a spray pump

A spray pump and spray chamber technology, applied in the field of micro-sprayers, can solve the problems of lower product market competitiveness, high production cost of sprayers, spray failure, etc., achieve the effects of stable spray volume, increase market competitiveness, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

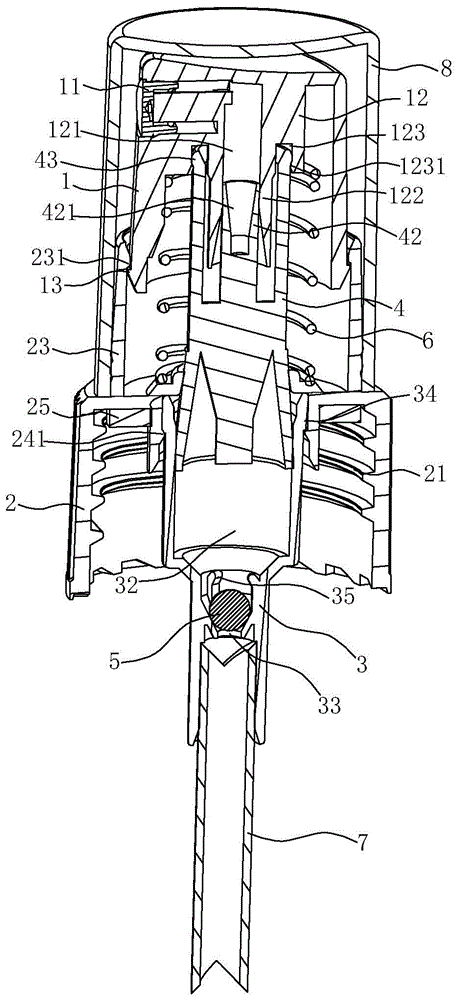

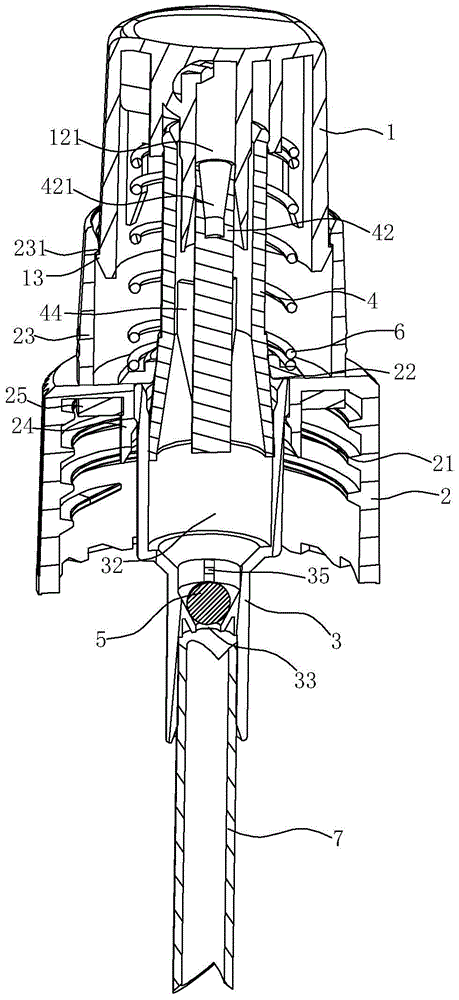

[0042] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

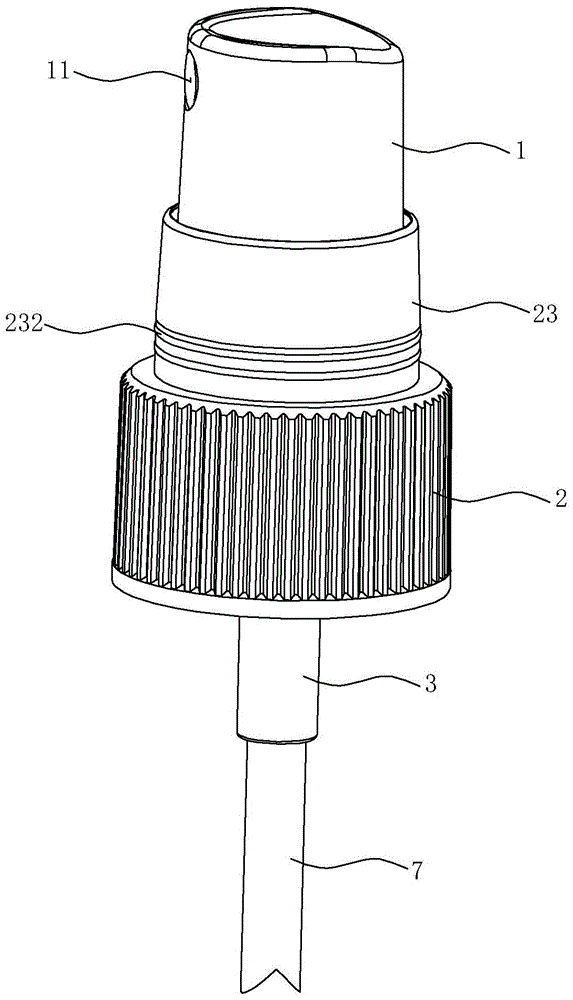

[0043] Such as Figure 1~10 As shown, the spray pump of this embodiment includes a head cap 1, a bottle cap 2, a pump body 3, a piston 4, a marble 5, a spring 6, a straw 7 and an outer cover 8. One side of the head cap 1 is provided with a spray head 11, the inner top surface of the head cap 1 has a downwardly extending connecting piece 12, and the connecting piece 12 has a spray chamber 121 communicating with the nozzle of the spray head 11; The internal thread 21 is used to connect the spray pump to the bottle body, and the head cap 1 is arranged on the bottle cap 2 so that it can move up and down. Specifically, the upper end surface of the bottle cap 2 has a connecting sleeve 23 arranged upward, and the inner peripheral wall of the upper end of the connecting sleeve 23 has a second convex ring 231 arranged in the circumferential direction. Correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com