Grain storage bag

A grain and size technology, applied in bags, sacks, containers, etc., can solve problems such as hanging on metal workpieces, poor strength, grain entry, etc., to achieve the effect of enhancing air permeability and strength, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

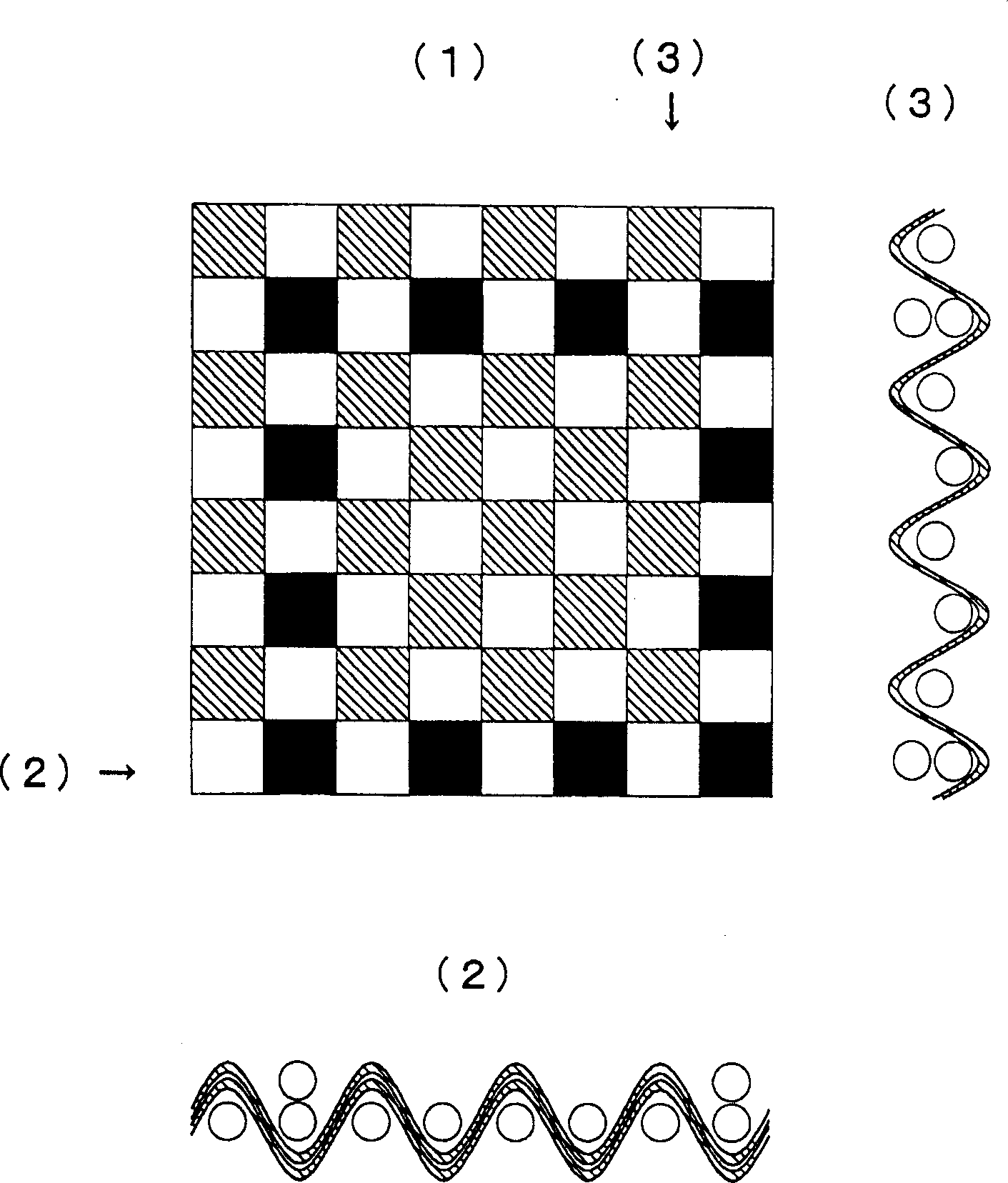

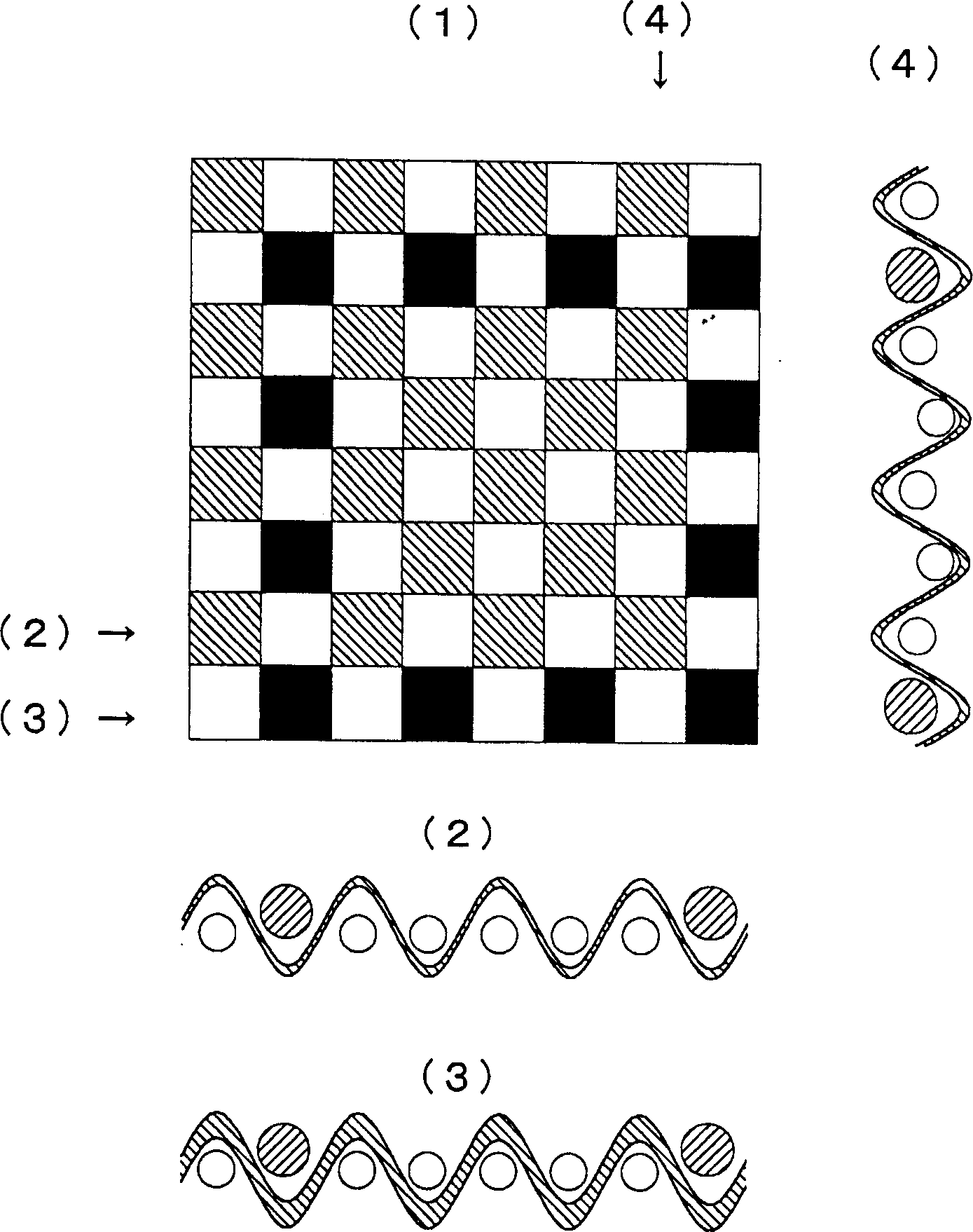

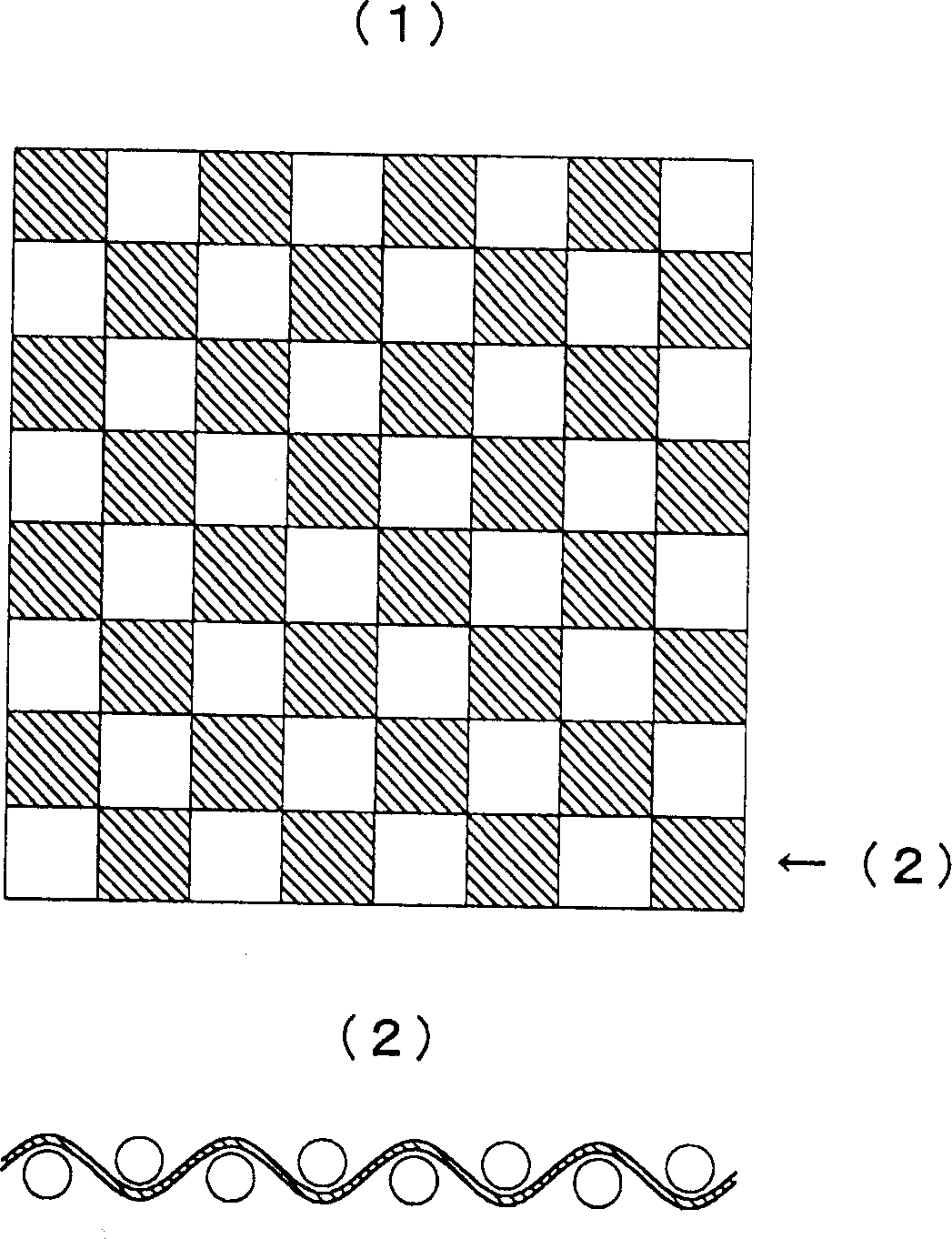

[0015] Next, preferred embodiments of the present invention will be described with reference to the accompanying drawings. figure 1 It is an example of the material weaving method adopted in the bag disclosed by the present invention, (1) is a structure diagram showing the relationship between the warp row and the weft row, and (2) and (3) respectively show the structure of the weaving method. In addition, in the structure diagrams (2) and (3), the structure of the column shown is shown by the arrow. The feature of this embodiment is that this special plain weave material is used in the bag. In the warp row and weft row, the composite tape of two warp tapes or weft tapes is used as a warp row at regular intervals. or weft columns. Here, the warp row is an element constituting the warp direction of the fabric weave, and is composed of one or more warp bands. Similarly, the weft column is the element that constitutes the weft direction of the fabric weave, and is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com