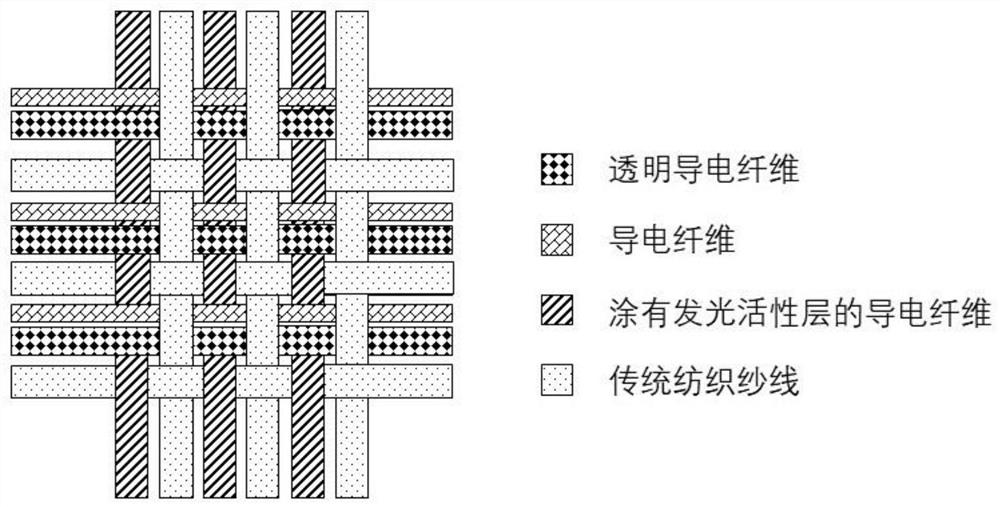

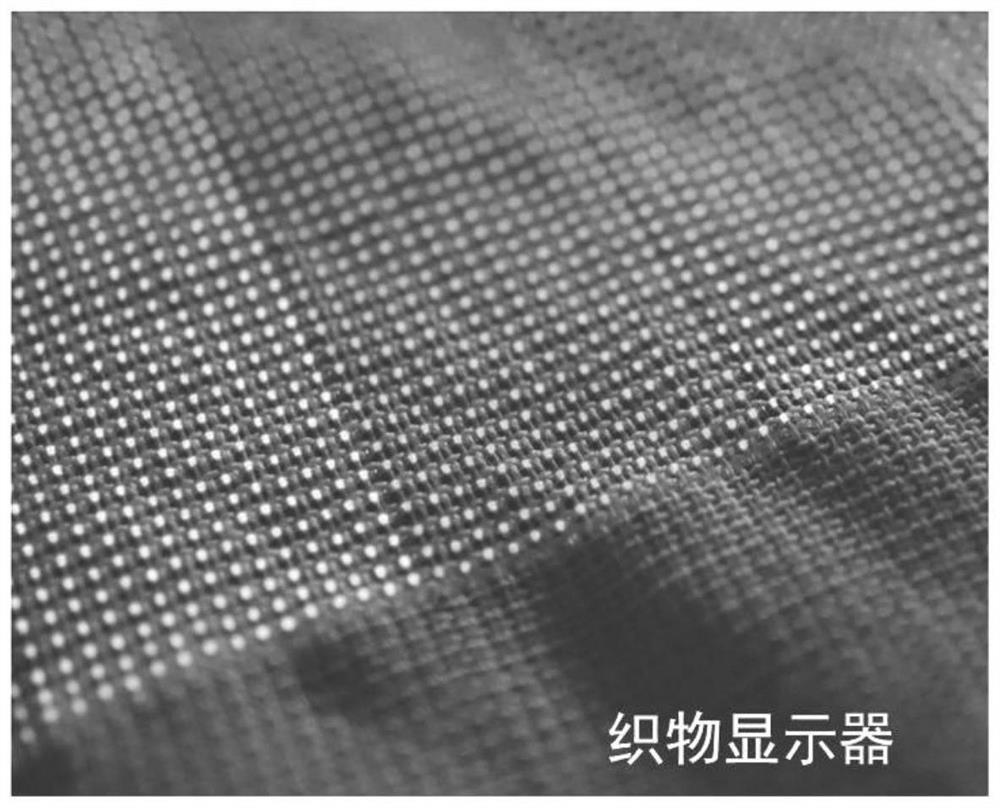

A kind of transparent conductive fiber and its preparation method and application in fabric display

A transparent conductive and conductive fiber technology, which is applied in the direction of fabric, fiber treatment, fiber type, etc., can solve problems such as easy cracks, limited bonding force between the film layer and the substrate, and easy oxidation of the nano-silver structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific implementation cases, exemplary descriptions and help to further understand the present invention, but the specific details of the implementation cases are only to illustrate the present invention, do not represent all the technical solutions under the concept of the present invention, therefore should not be construed as a general description of the present invention The limitations of the technical solutions, some insubstantial additions and changes that do not deviate from the concept of the present invention, such as simple replacement or replacement of technical features with the same or similar technical effects, all belong to the protection scope of the present invention.

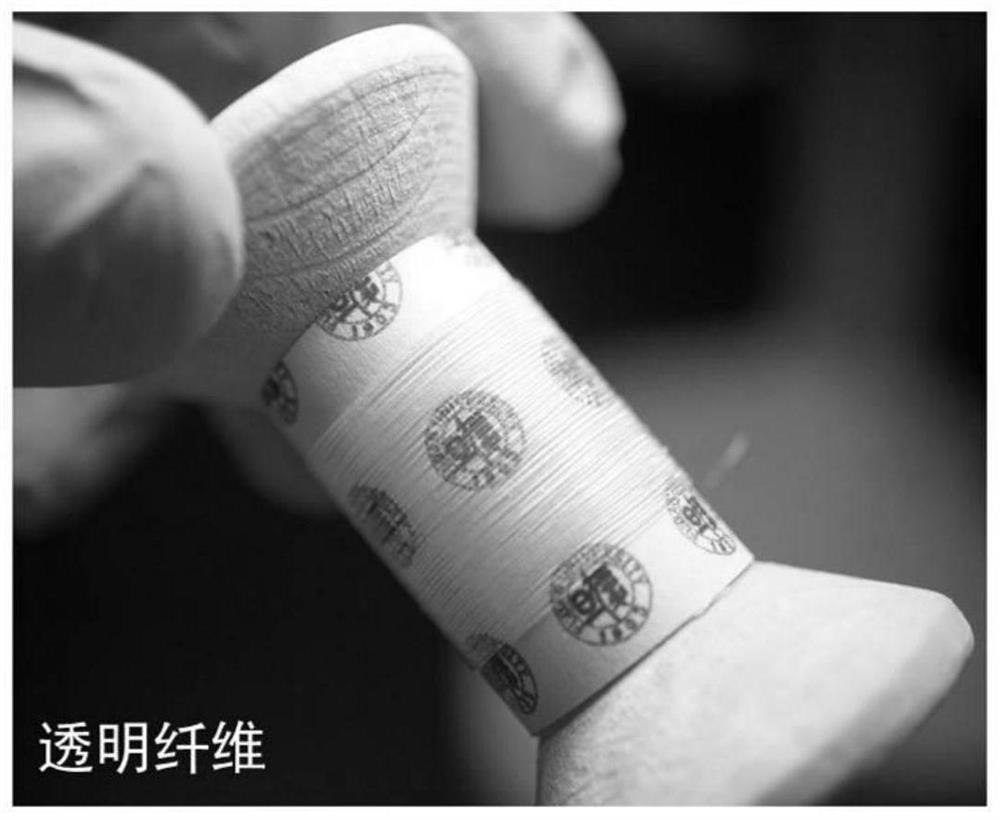

[0028] 1. Preparation of transparent conductive fibers: Weigh 10g polyester polyurethane (polyester segment is polyethylene adipate, Mn1000), dissolve it in 40g N,N'-dimethylformamide, add 10g1- Ethyl-3-methylimidazole bis-trifluoromethanesulfonimide salt, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com