Polymer soft package lithium battery aluminum plastic film shell punching and trimming die

A soft-packed lithium battery and edge trimming die technology, applied in battery pack components, circuits, electrical components, etc., can solve problems such as poor position accuracy, reduce scrap rate, improve dimensional accuracy, and increase productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

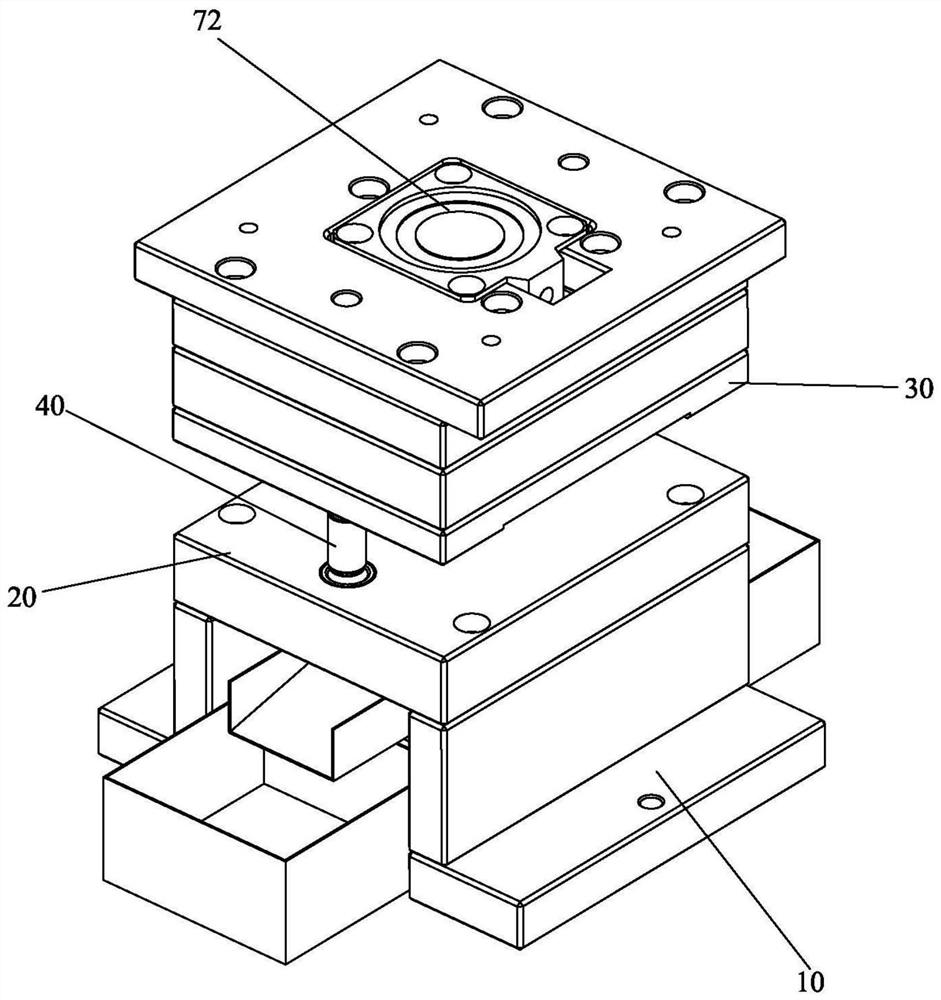

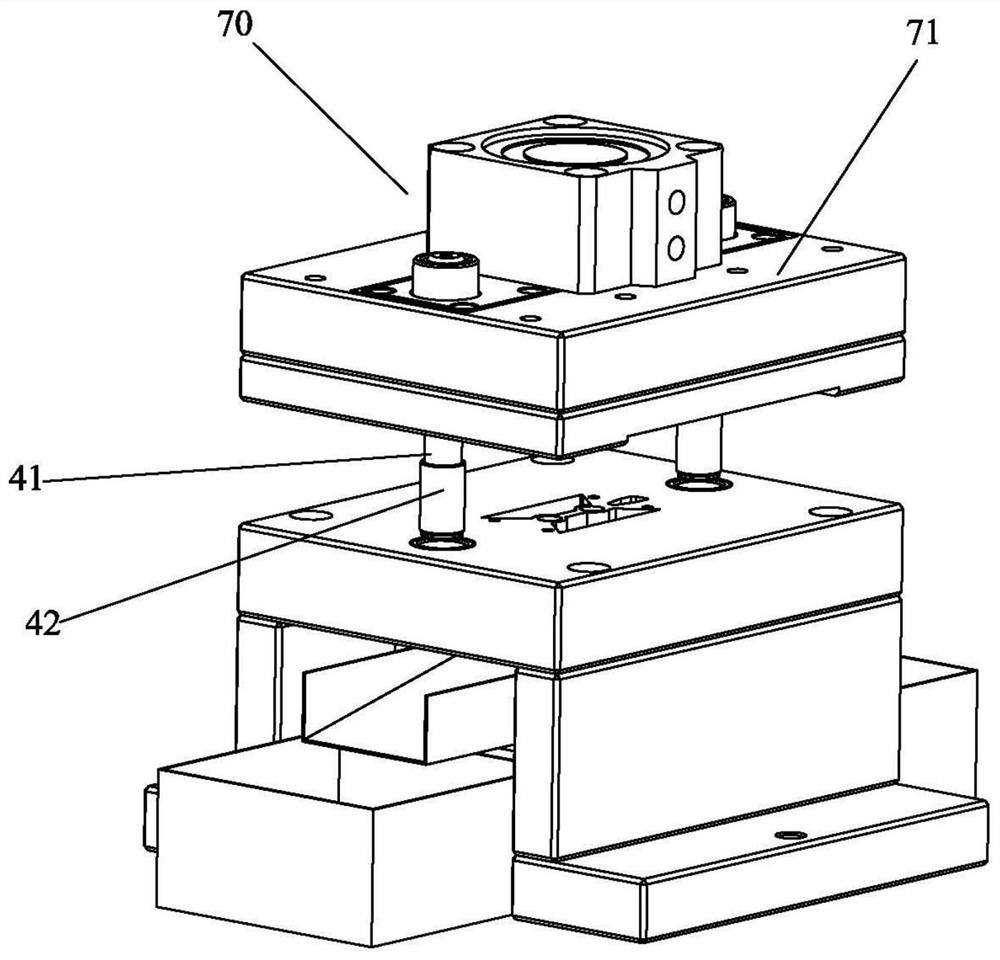

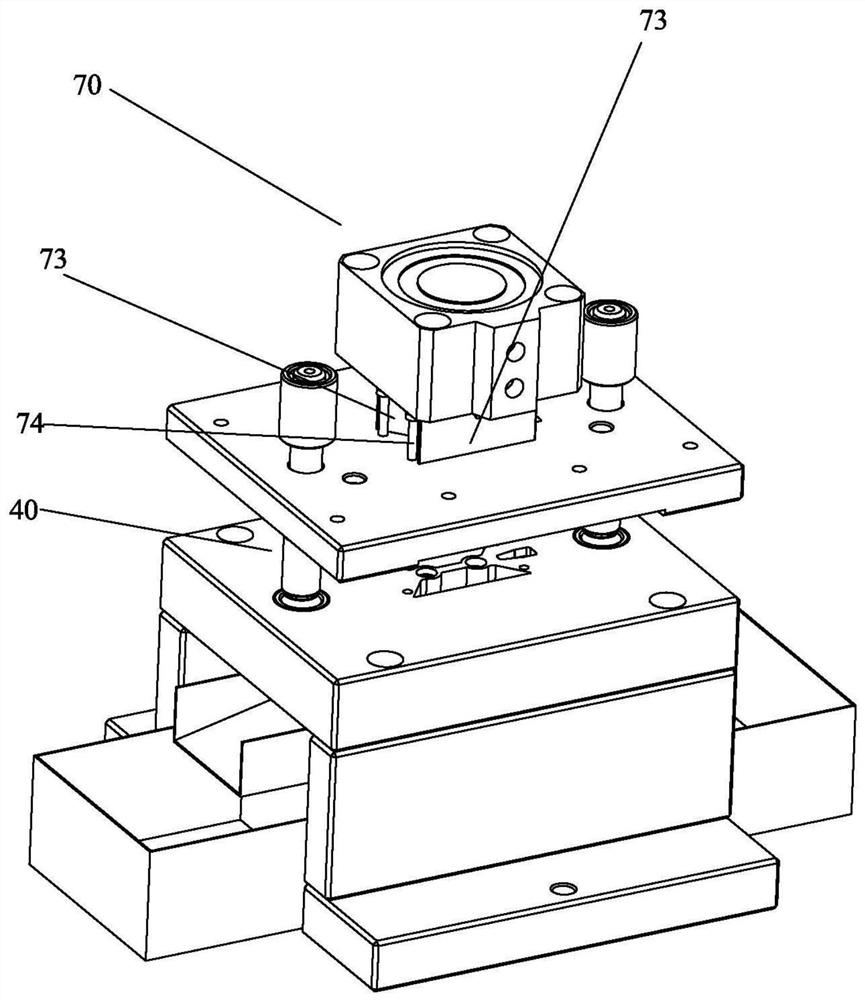

[0026] The present invention as Figure 1 to Figure 7 As shown, a polymer soft-packed lithium battery aluminum-plastic film punching and trimming mold includes a discharge plate 20 for placing materials, and a liftable lifter for extruding the materials on the discharge plate 20. Holder plate 30, guide member 40 for guiding the hold-down plate 30 in the lifting process, punch assembly 50 for punching the material on the discharge plate 20 out of the pit body model, and punch assembly for aligning 50 guide assembly 60 that acts as a guide, edge trimming assembly 70 for trimming the material punched out of the pit body model by the punch assembly 50, and a waste material collection box for collecting waste obtained after edge trimming by the edge trimming assembly 70 80.

[0027] The clamping plate 30 is connected to the clamping plate drive cylinder, and the clamping plate drives the cylinder to drive the clamping plate 30 to descend. The board 20 is corresponding; the trimmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com