Mounting and fixing assembly of LED down lamp

A technology of LED downlights and fixing components, which is applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of poor adaptability, inconvenient installation and disassembly of downlights, etc., so as to improve adaptability and ensure installation Fixed effect, convenience-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

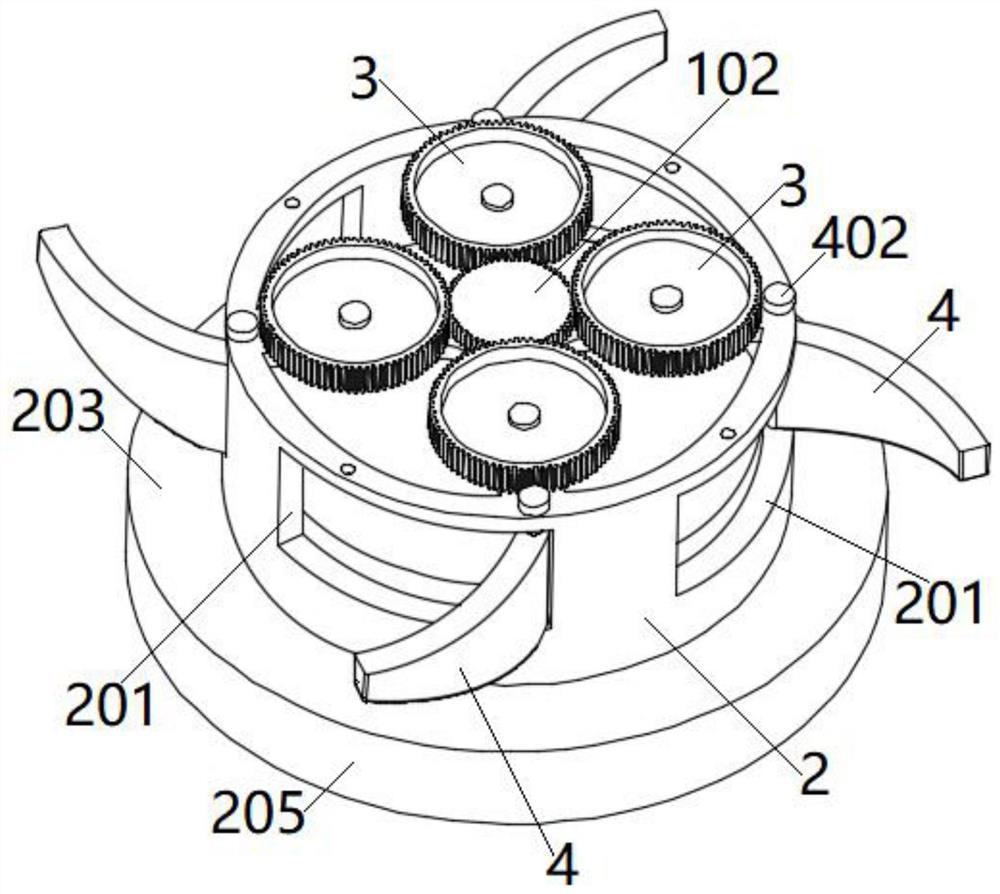

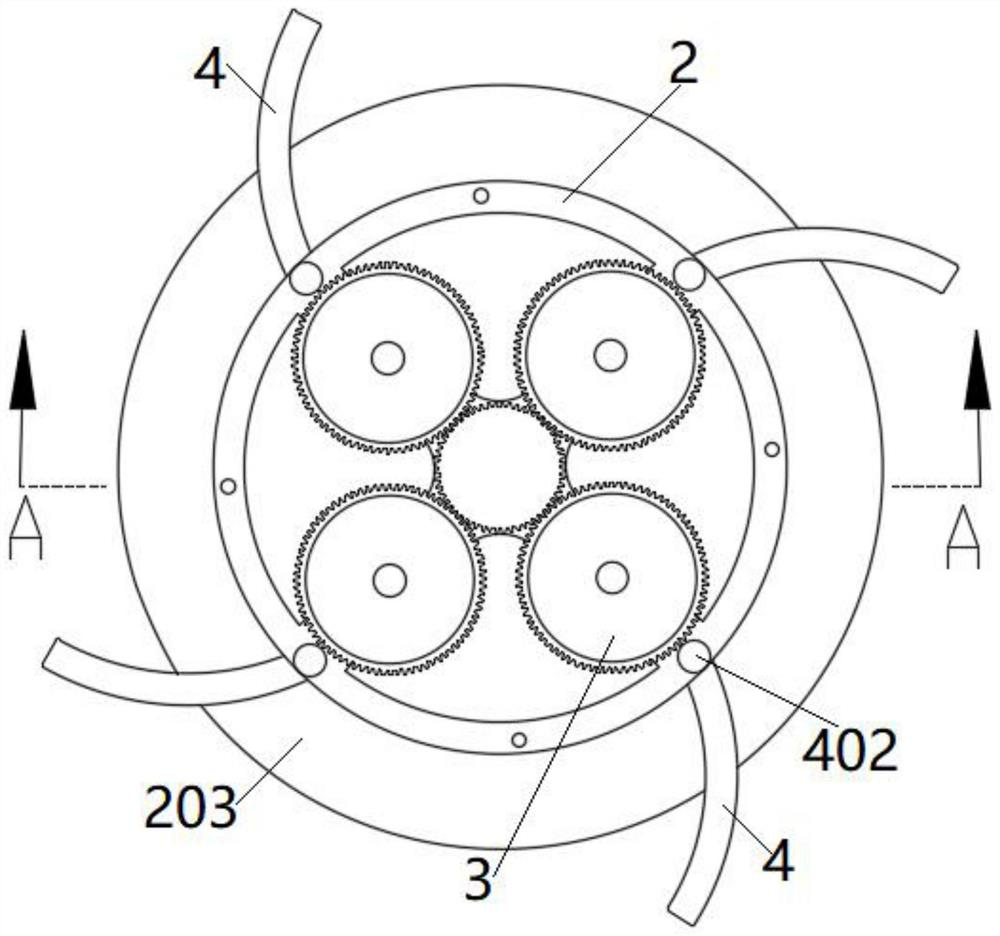

[0034] see figure 1 and 2 As shown, the present invention is an installation and fixing assembly of an LED downlight, including a lamp canister 1, an outer tube 2 is sleeved on the outer wall of the lamp canister 1, and a receiving slot 201 is evenly distributed on the circumference of the side wall of the outer tube 2. The receiving slot The number of 20 is three to six, preferably four.

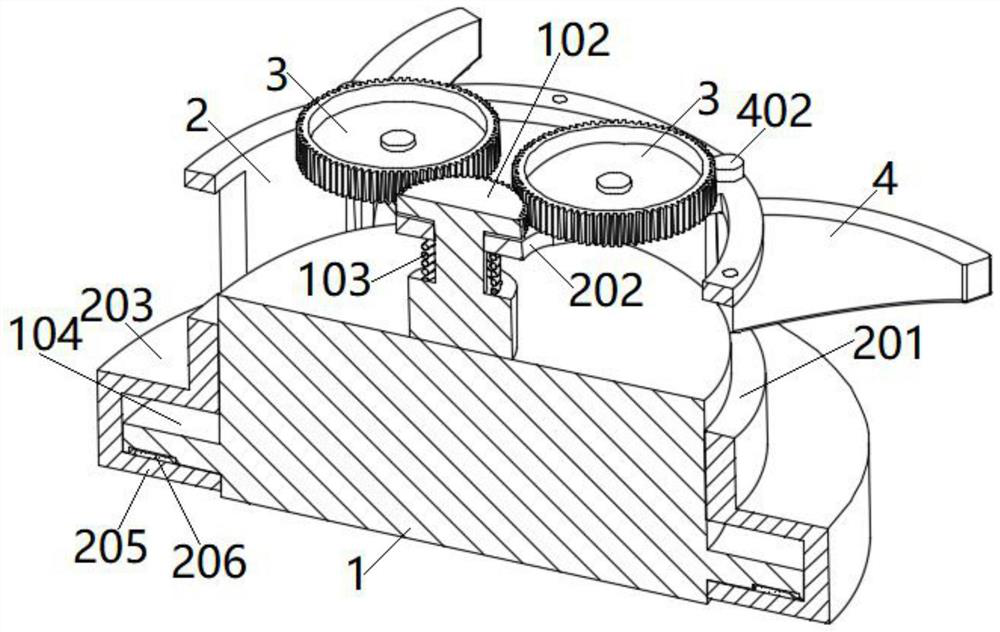

[0035] like Figure 3-6 As shown, a mounting plate 202 is fixedly connected to the upper end surface of the outer cylinder 2, and a flange 203 is provided at the lower end of the outer cylinder 2; The mounting plate 202 is provided with connecting holes 204 , and four transition wheels 3 are rotatably connected;

[0036] like Figure 7 As shown, the wedge-shaped plate 4 is rotatably connected in the receiving slot 201 , the inner bottom surface and the inner top surface of the receiving slot 201 are both provided with mounting holes, and the mounting hole on the inner top surface is a t...

Embodiment 2

[0043] like Figure 4-6 As shown, on the basis of the first embodiment, the connecting shaft 101 has a stepped shaft structure; the connecting shaft 101 is sleeved with a compression spring 103 ; offset.

[0044] At the same time, an annular folded plate 205 is fixedly connected to the peripheral side surface of the flange 203 , and the flange 203 and the annular folded plate 205 can be fixed by clip connection or screw connection or adhesion. The cross-sectional shape of the annular folded plate 205 is L-shape; the upper surface of the bottom wall of the annular folded plate 205 is provided with limit blocks 206 evenly distributed around the circumference.

[0045]The outer wall of the lamp tube 1 is provided with a retaining ring 104 ; the retaining ring 104 is located between the flange 203 and the annular folded plate 205 , and limiting notches 105 corresponding to the limiting blocks 206 are evenly distributed on the lower surface of the retaining ring 104 . Through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com