Square battery formation clamp device

A prismatic battery and fixture device technology, applied in workpiece clamping devices, secondary batteries, electrochemical generators, etc., can solve the problems of inability to locate the battery, poor adaptability, low conversion efficiency, etc., and achieve convenient and economical negative pressure conversion. Fixture cost, effect of saving space cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

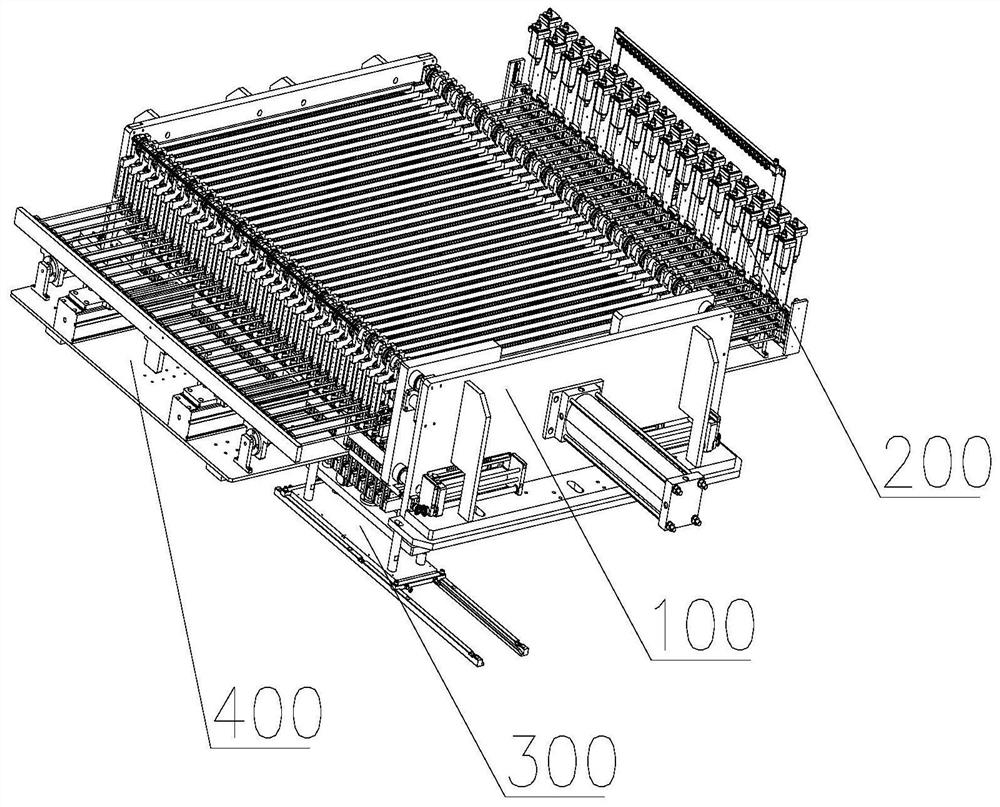

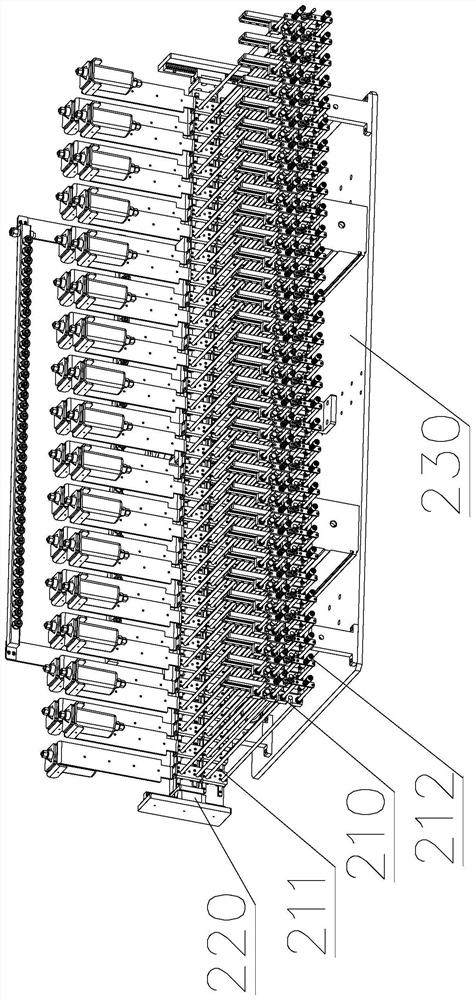

[0055] Embodiment 1 A prismatic battery formation fixture device according to the present invention includes a fixture mechanism 100, a negative pressure formation probe mechanism 200, a formation probe mechanism 400, and a positioning mechanism 300. The negative pressure formation probe mechanism 200 and the The formation probe mechanism 400 is respectively arranged on opposite sides of the clamp mechanism 100, and is used to extend into the clamp channel of the clamp mechanism to contact the tab of the prismatic battery; the positioning mechanism 300 is arranged on the side of the clamp mechanism 100 Bottom, used to adjust the position of the square battery;

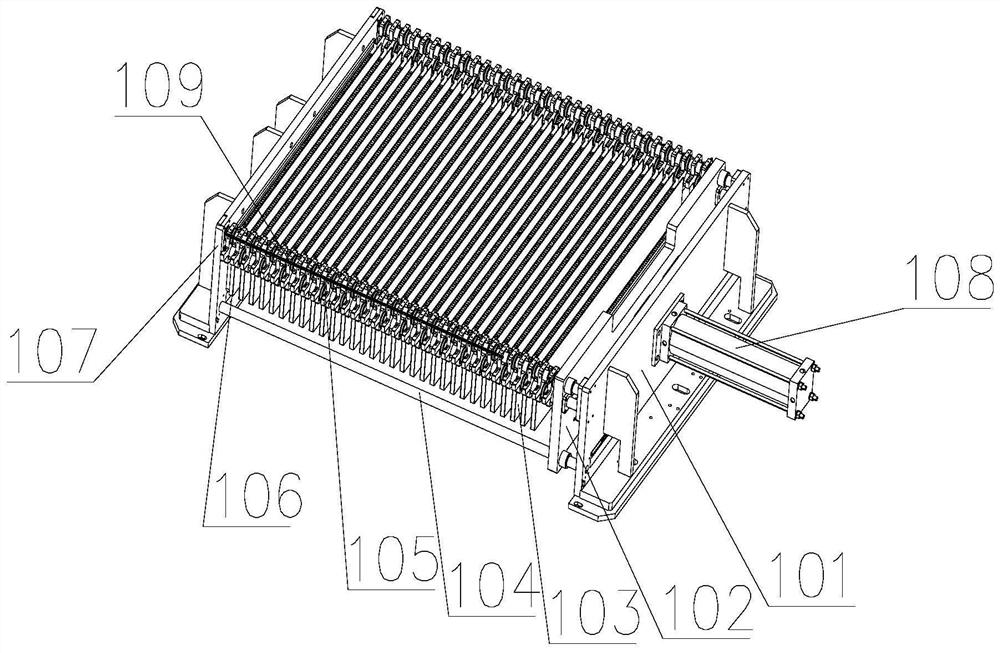

[0056] The clamp mechanism 100 includes a support frame body, a clamping device and a driving device, the support frame body is provided with a battery clamping area; the clamp device is slidably arranged in the battery clamping area of the support frame body, It includes a plurality of clamp middle aluminum plates 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com