Rail transit rubber anti-vibration pad mold with anti-displacement and anti-sliding functions

A rail transit and rubber vibration damping technology, applied in the field of hot pressing molds, can solve the problems of increasing the length of personnel and production equipment, increasing equipment procurement costs, and expanding production sites, reducing personnel and operating procedures, increasing production efficiency, and shortening The effect of the venue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

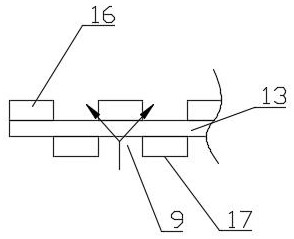

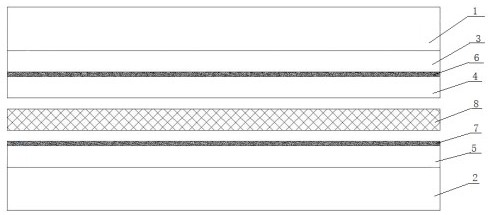

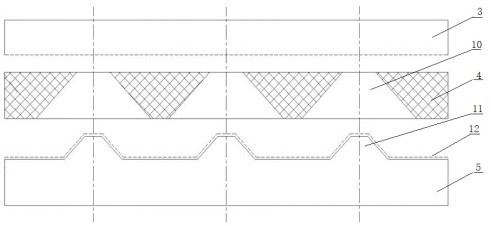

[0023] Please refer to figure 1 , figure 2 , image 3 and Figure 4 , an embodiment of the present invention provides a rubber damping pad mold for anti-displacement and sliding function rail transit, including an upper plate 1 of a vulcanization press, a hot-press forming mold, and a lower plate 2 of a vulcanization press arranged from top to bottom. The compression molding mold includes an upper template 3, a middle template 4 and a lower template 5 combined from top to bottom, the upper template 3 is fixedly installed on the lower surface of the upper plate 1 of the vulcanization press, and the lower template 5 is fixedly installed on the lower plate of the vulcanization press The upper surface of 2; the lower surface of the upper template 3 is fixedly provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com