High-speed bag scraping device for pillow type bag collator and control method

A sorting machine and bag scraping technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of restricting the requirements of connecting equipment and speed improvement, and achieve the effect of saving return time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

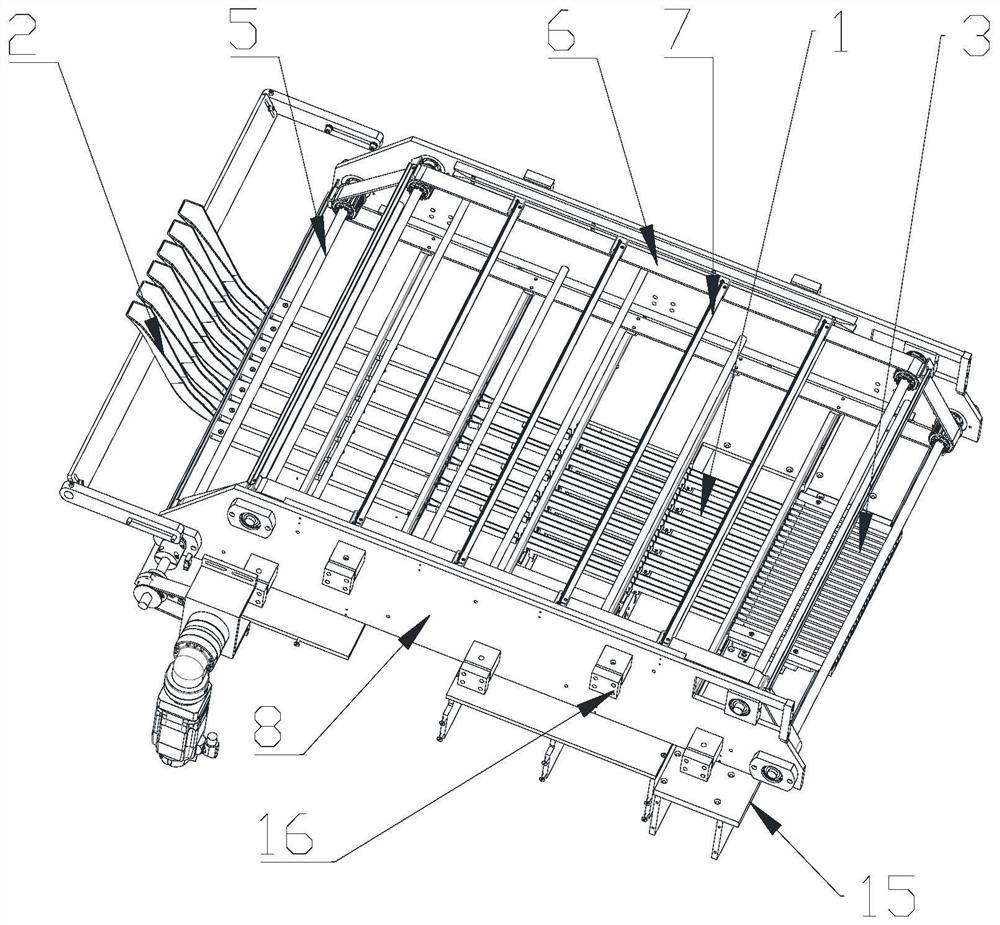

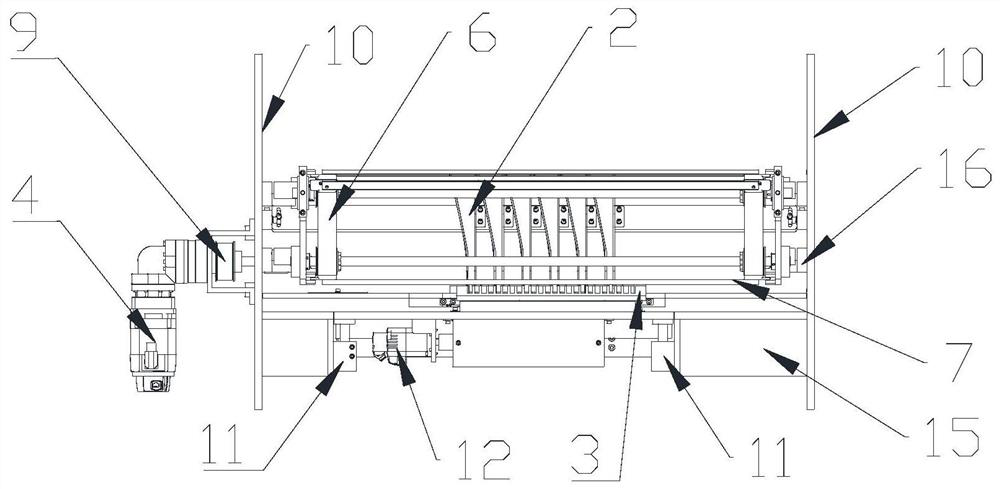

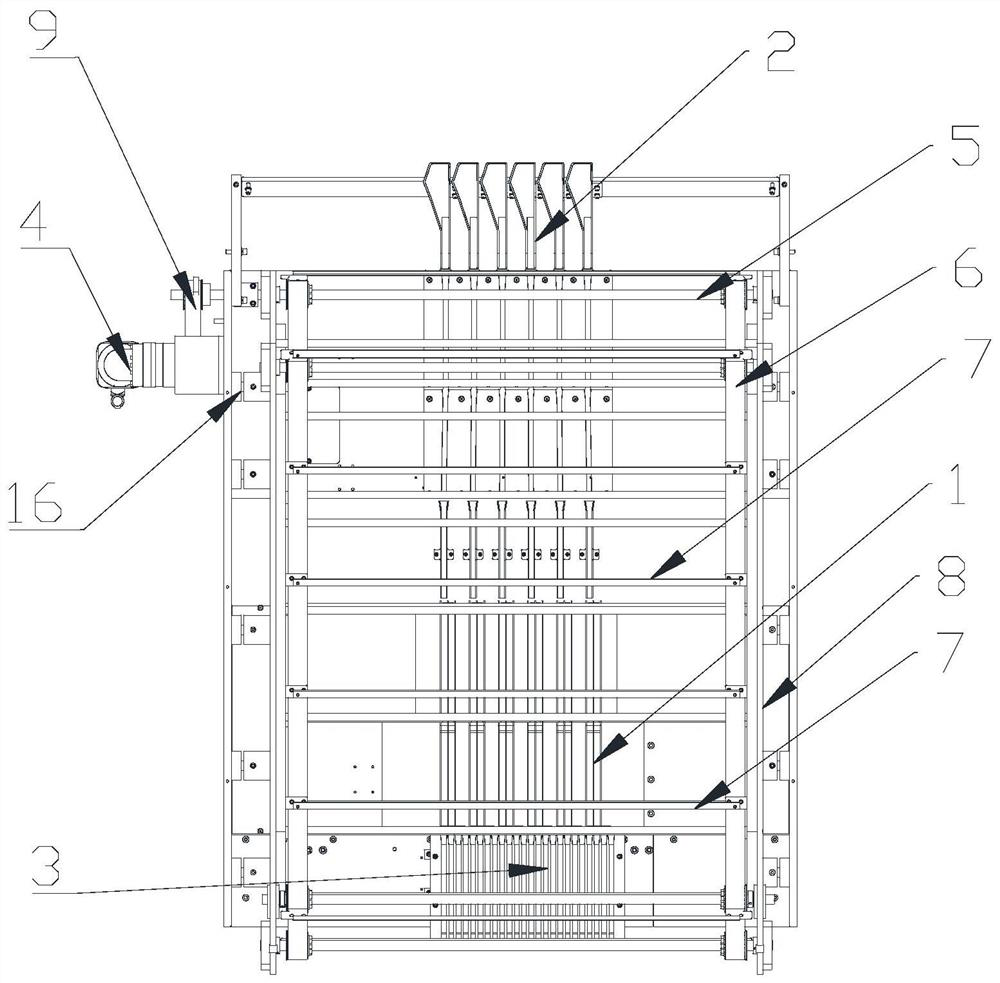

[0035] like figure 1 , Figure 2-1 , Figure 2-2 and Figure 2-3 As shown, the present invention proposes a high-speed bag scraping device for a pillow bag finishing machine, including a mounting frame 10, a detection part, a collection part and a bag scraping part.

[0036] The detection part includes a fixed rod connected to the front end of the mounting frame 10, a material bag slide plate 2 is provided from the inner side of the fixed rod to the bottom of the mounting frame 10, and N guide chute 1 is provided on the material bag slide plate 2 , the depth of the guide chute 1 is 1 / 2 of the side height of the material bag, the front end of the guide chute 1 is the inlet end of the material bag, and the rear end of the guide chute 1 is the outlet of the material bag end. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap