Escalator main drive hoisting tool and operation method

A technology of escalator and main drive, which is applied in the direction of hoisting equipment braking device, hoisting device, transportation and packaging, etc. It can solve the problems of difficult operation, cumbersome disassembly and installation process, and loss of man-hours, and achieve the goal of simplifying the replacement steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

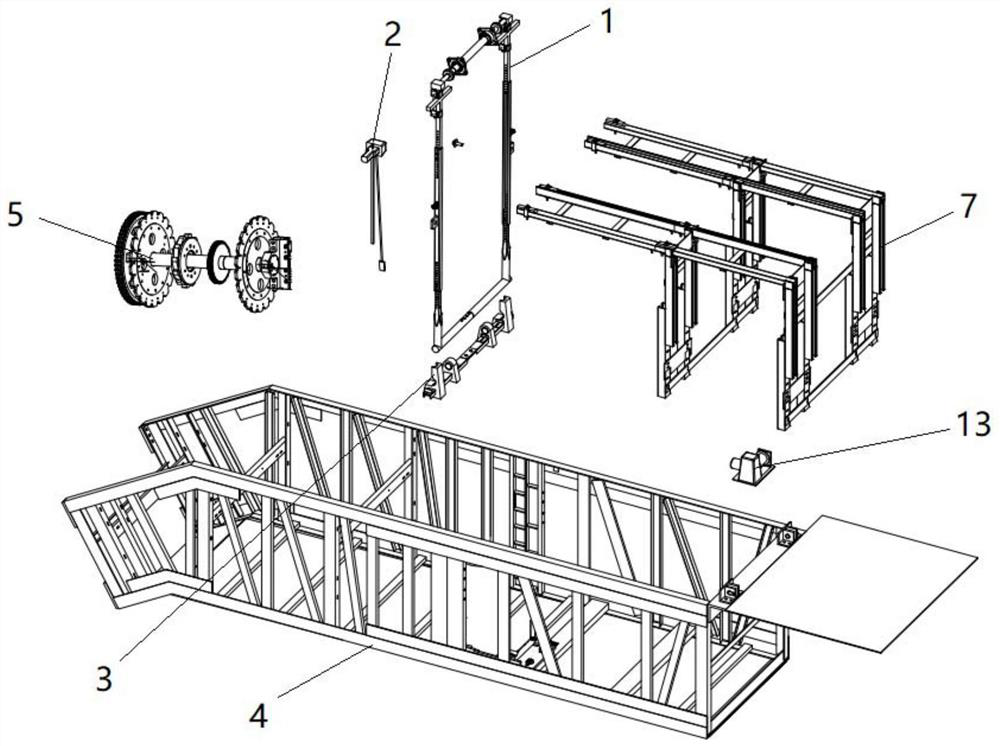

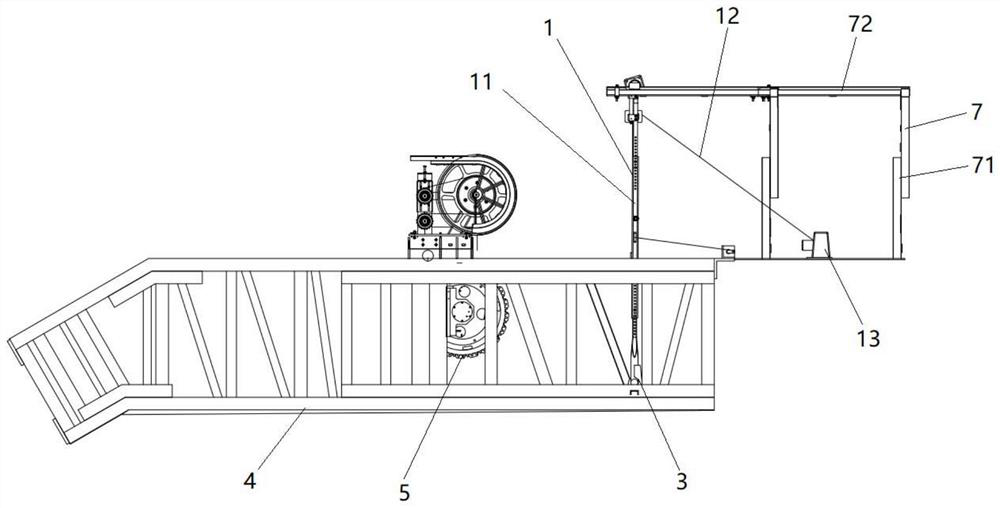

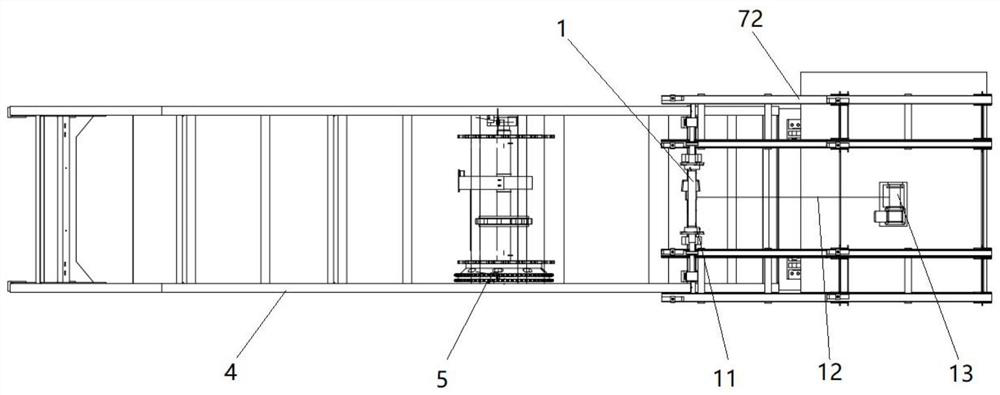

[0047] Such as Figure 1-9 As shown, the present embodiment provides a hoisting tool for the main drive of an escalator, which is composed of a rotating bracket 1 , a hoisting mechanism 2 , a base 3 , a rail frame 7 and an auxiliary mechanism 6 .

[0048]The lower truss 4 of the escalator extends to the outside of the end of the escalator, so that the length of the hoistway formed by the truss 4 is increased, which is convenient for matching the hoisting tooling of this embodiment. Before hoisting the main drive 5, it is necessary to disassemble the floor on the side of the escalator to expose the shaft formed by the truss 4, and install the auxiliary mechanism 6 in the shaft. The bracket 62 is fixed on the truss 4, and the telescopic screw 61 is set horizontally, one end of which is fixed on the bracket 62, and the other end is installed with a limit piece 63, and the main drive 5 is pushed through the limit clamp 63, so that the auxiliary mechanism 6 pushes the main drive ho...

Embodiment 2

[0057] Such as Figure 1-9 As shown, this embodiment provides an operation method for the main drive hoisting tool of the escalator, adopts the main drive hoisting tool of the escalator in Embodiment 1, and implements the following steps:

[0058] Step 1: In the preparation stage, the base 3 is installed on the bottom of the well, the guide rail frame 7 is installed on the ground at the edge of the well, the rotating bracket 1 extends into the well and is hinged to the base 3, the hoist 13 is fixed on the ground or on the guide rail frame 7, The electric chain hoist is installed on the roller 115 on the top of the rotating support 1 .

[0059] Step 2: During the hoisting stage, the hoist 13 puts the rope, at this time the main structure of the frame body 11 of the rotating bracket 1 tilts towards the direction of the main drive 5, until the electric chain hoist approaches the faucet of the escalator and stops, at this time, the position of the rotating bracket 1 is maintained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com