Optical disk apparatus

An optical disc device and optical disc technology, applied to the configuration/installation of the head, optical recording/reproduction, instruments, etc., can solve the problems of large contact area, cost increase, thick plate spring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

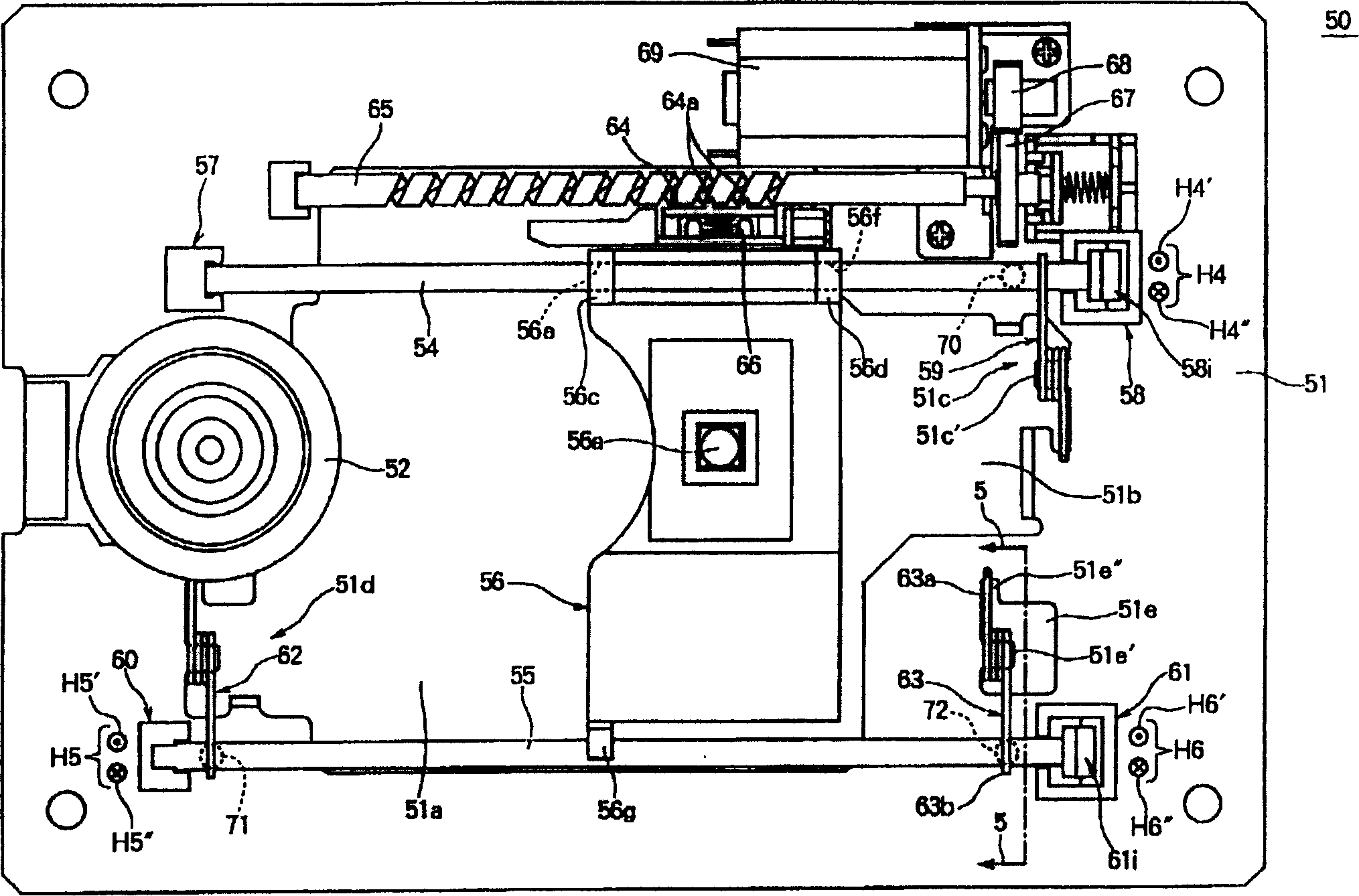

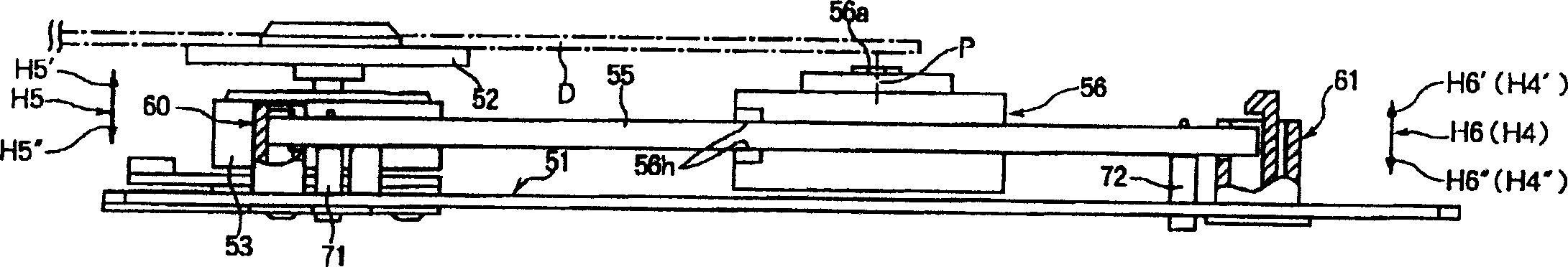

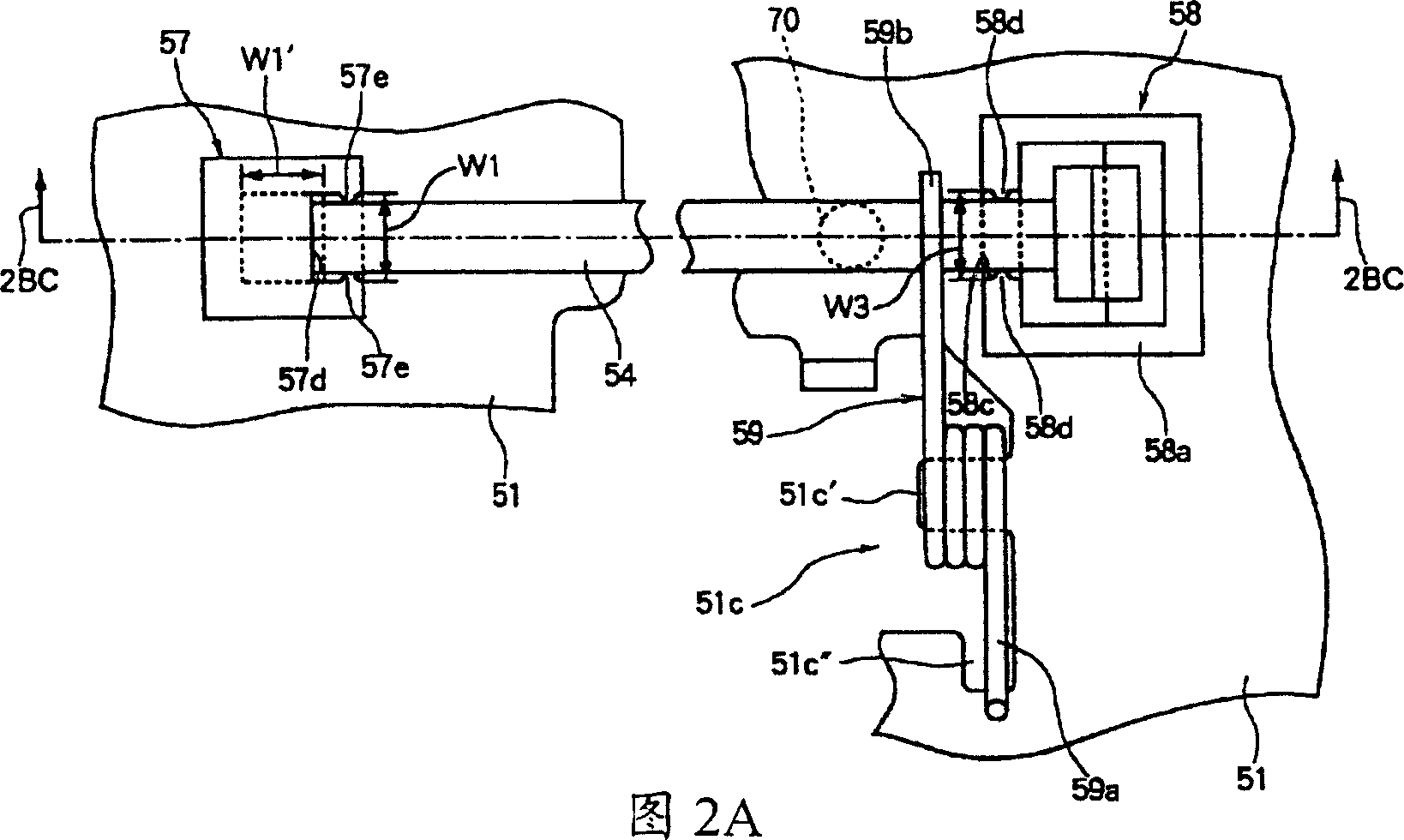

[0031] Referring to accompanying drawings 1 to attached Figure 5 , an optical disc device as an embodiment of the present invention will be described.

[0032] Figure 1A , Figure 1B It is a plan view and a partially cutaway side view showing an optical disc device 50 as an embodiment of the present invention. The optical disc device 50 mainly includes a rectangular frame housing 51 made of sheet metal, and a spindle motor 53 disposed on the frame housing 51 and integrally formed coaxially with the turntable 52 is arranged parallel to each other. The guide shafts 54, 55 have an optical sensor 56 having a partially arcuate recessed portion of the objective lens 56a arranged between the guide shafts 54, 55, and a substantially rectangular shape, and along the guide shafts 54, The longitudinal direction of 55 implements the transmission mechanism which will be described later for the optical sensor 56 .

[0033] Next, the configuration of the optical disc device 50 will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com