Pressure-sensitive adhesive tape

A pressure-sensitive adhesive and adhesive tape technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc. The effect of improving visibility and suppressing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

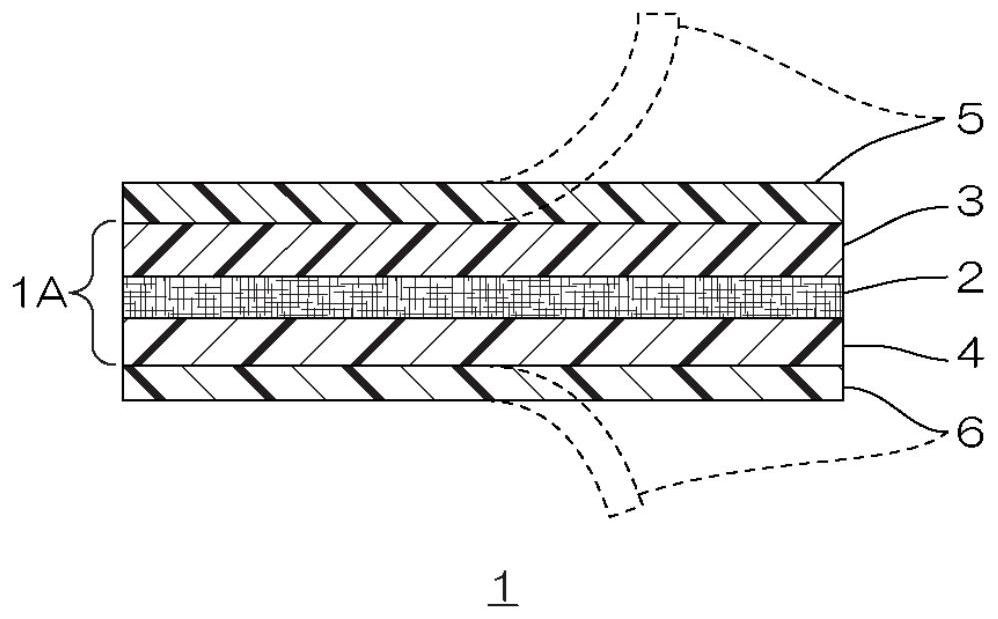

Image

Examples

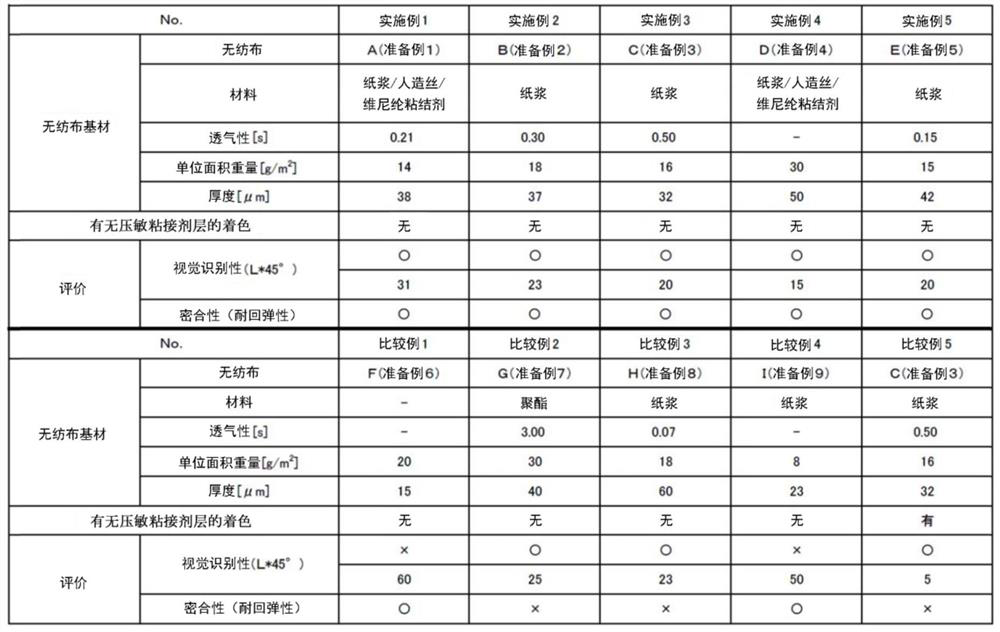

Embodiment 1~5 and comparative example 1~4

[0145] 60 parts by mass of distilled water and 0.1 part by mass of an emulsifier (sodium polyoxyethylene alkyl ether sulfate, trade name: LATEMUL E-118B, manufactured by Kao Corporation) were placed in the reaction container. The reaction container is equipped with a container main body, a stirrer, a thermometer, a reflux condenser, a dropping device, and a nitrogen gas introduction tube.

[0146] Then, the polymerization initiator (2,2'-azobis[N-(2-carboxyethyl)-2-methylpropionamidine]hydrate, trade name: VA-057, Wako Pure Chemical Industries, Ltd. Kogyo Co., Ltd.) 0.1 parts by mass.

[0147] In addition, 85 parts by mass of 2-ethylhexyl acrylate, 13 parts by mass of methyl acrylate, 1.5 parts by mass of acrylic acid, 0.5 parts by mass of methacrylic acid, 3-methacryloxypropyltrimethoxysilane (trade name : KBM-503 (manufactured by Shin-Etsu Chemical Co., Ltd.) 0.02 parts by mass, 0.033 parts by mass of a chain transfer agent (dodecyl mercaptan), 1.9 parts by mass of the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com