Full-automatic running train intelligent operation and maintenance management platform and method

An operation and maintenance management platform, fully automatic technology, applied in the direction of data processing applications, instruments, resources, etc., can solve problems that cannot be corrected in time, technical decision-making, production execution links are out of touch, and it is difficult to exert the economic benefits of big data, so as to promote operation , Strengthen the effectiveness of safety and service risk management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

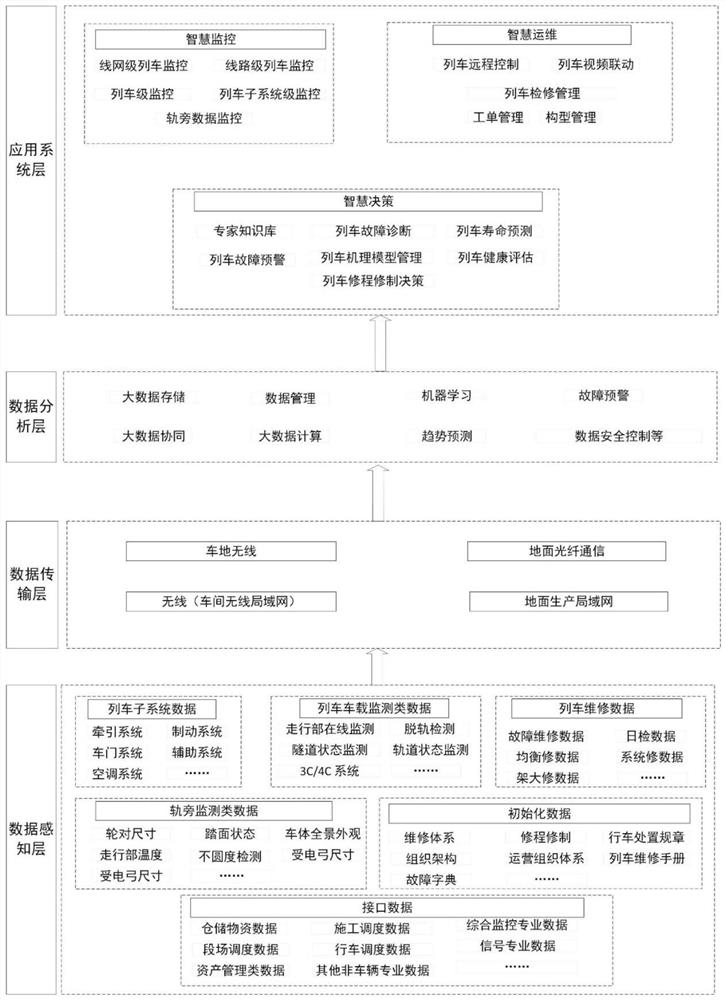

[0069] A fully automatic operating train intelligent operation and maintenance management platform described in this embodiment, the system architecture is detailed in the attached figure 1 , including: data perception layer, used to obtain multi-dimensional data and send it to the data transmission layer; data transmission layer, used to receive data and send it to the data analysis layer; data analysis layer, to analyze, explore and construct the received data Early warning and trend prediction; the application system layer uses the analysis results of the data analysis layer to carry out real-time monitoring, health diagnosis and operation and maintenance suggestions for trains.

[0070] Specifically, the multi-dimensional data acquired by the data perception layer includes: train subsystem data, train monitoring data, trackside monitoring data, train maintenance data and interface data. The data of the train subsystem is the full data of the whole vehicle, which is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com