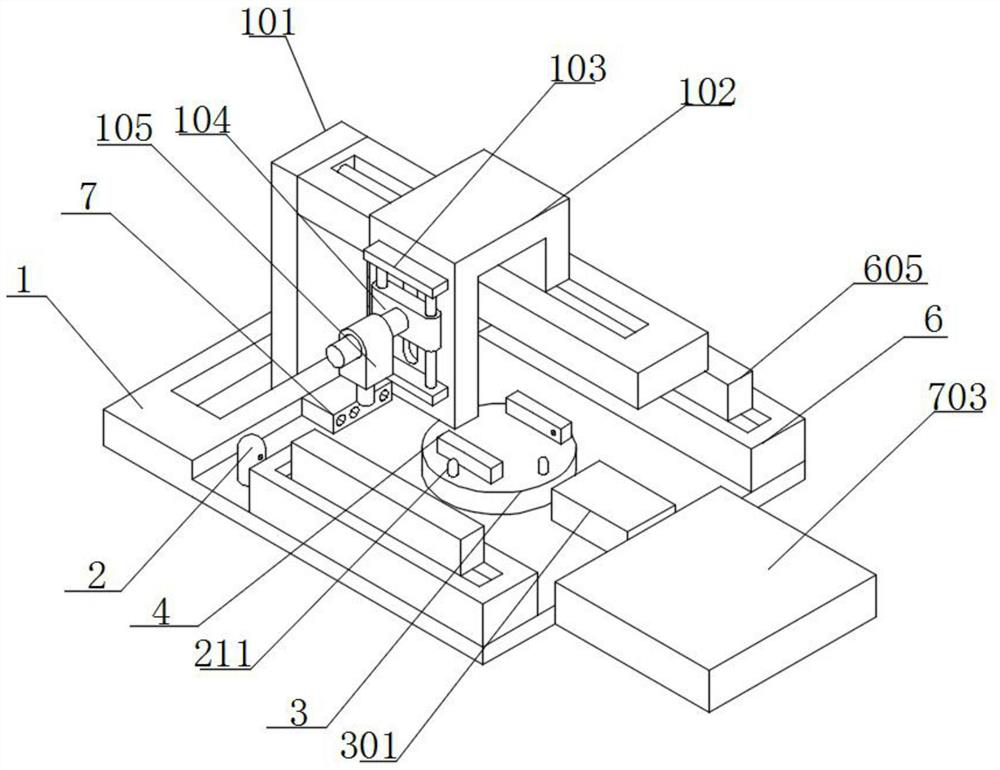

A welding device for a six-axis robot with a calibration structure

A six-axis robot and welding equipment technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of lack of eye protection structure, lack of automatic clamping structure, lack of calibration structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

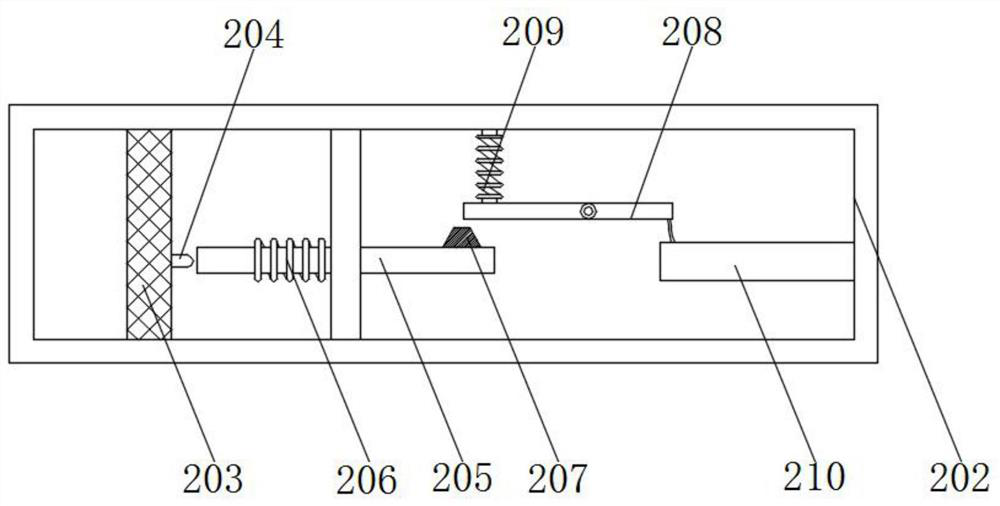

[0044] Example 2: See figure 2 and image 3 , an embodiment provided by the present invention: a welding device for a six-axis robot with a calibration structure, an electric telescopic rod 201 is installed on the inner bottom wall of the bottom plate 1, and the top of the electric telescopic rod 201 extends out of the top of the bottom plate 1 A ball bearing is installed on the top of the electric telescopic rod 201, a trigger 202 is installed on the inner bottom wall of the bottom plate 1, a piezoelectric ceramic 203 is installed on the inner wall of the trigger 202, and a trigger lever 204 is installed on the outer wall of the piezoelectric ceramic 203, and the trigger The inner wall of 202 is equipped with a fixed plate, and the fixed plate is located on one side of the piezoelectric ceramic 203, the outer wall of the fixed plate is installed with a moving rod 205, the outer wall of the moving rod 205 is surrounded by a return spring 206, and the outer wall of the moving ...

Embodiment 3

[0045] Example 3: See Figure 4 and Figure 5 , an embodiment provided by the present invention: a welding device for a six-axis robot with a calibration structure, a cleaning fan 701 is installed on the inner wall of the cleaner 7, and a blower port 702 is provided on the outer wall of the cleaner 7, and the outer wall of the bottom plate 1 A collector 703 is installed, and the inner wall of the collector 703 is staggered with a plurality of inclined baffles 704. When cleaning debris, start the cleaning fan 701, and the cleaning fan 701 drives the air flow, and then the air blows the welding debris to move. In the protective groove 6, the debris moves toward the outer wall of the bottom plate 1, and then enters the interior of the collector 703. The staggered baffles 704 can effectively block the debris from moving outward, and realize the function of collecting debris.

Embodiment 4

[0046] Example 4: See Figure 6 , an embodiment provided by the present invention: a welding device for a six-axis robot with a calibration structure, a driving motor 601 is installed on the inner bottom wall of the protective groove 6, and a reciprocating screw rod 602 is installed on the output end of the driving motor 601, The outer wall of the reciprocating screw mandrel 602 is equipped with a fixed ring 603, the top of the protective groove 6 is equipped with a lifting groove, the top of the lifting groove is penetrated with a lifting block 605, the outer wall of the lifting block 605 is connected with the fixed ring 603 through a connecting rod, and the protective groove 6 A hinge 604 is installed on the inner bottom wall of the hinge 604, and a protective net is connected between the hinges 604. The top of the hinge 604 is connected with the bottom of the lifting block 605. When welding, the drive motor 601 is started, and the drive motor 601 drives the reciprocating scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com