Unmanned heavy gantry transfer clamping claw

A technology of transfer clips and gantry, which is applied in the field of gantry lifting machinery, can solve the problems of low safety factor, few contact points, and small amount of goods to be grabbed, and achieve the effect of improving efficiency and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

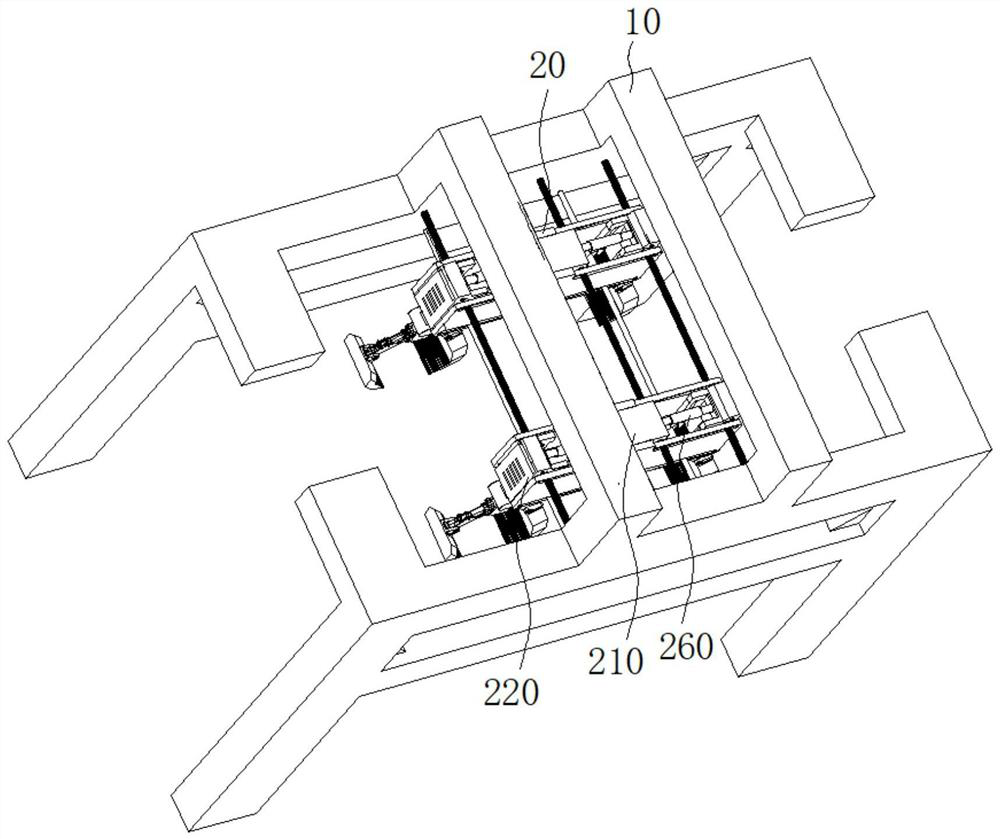

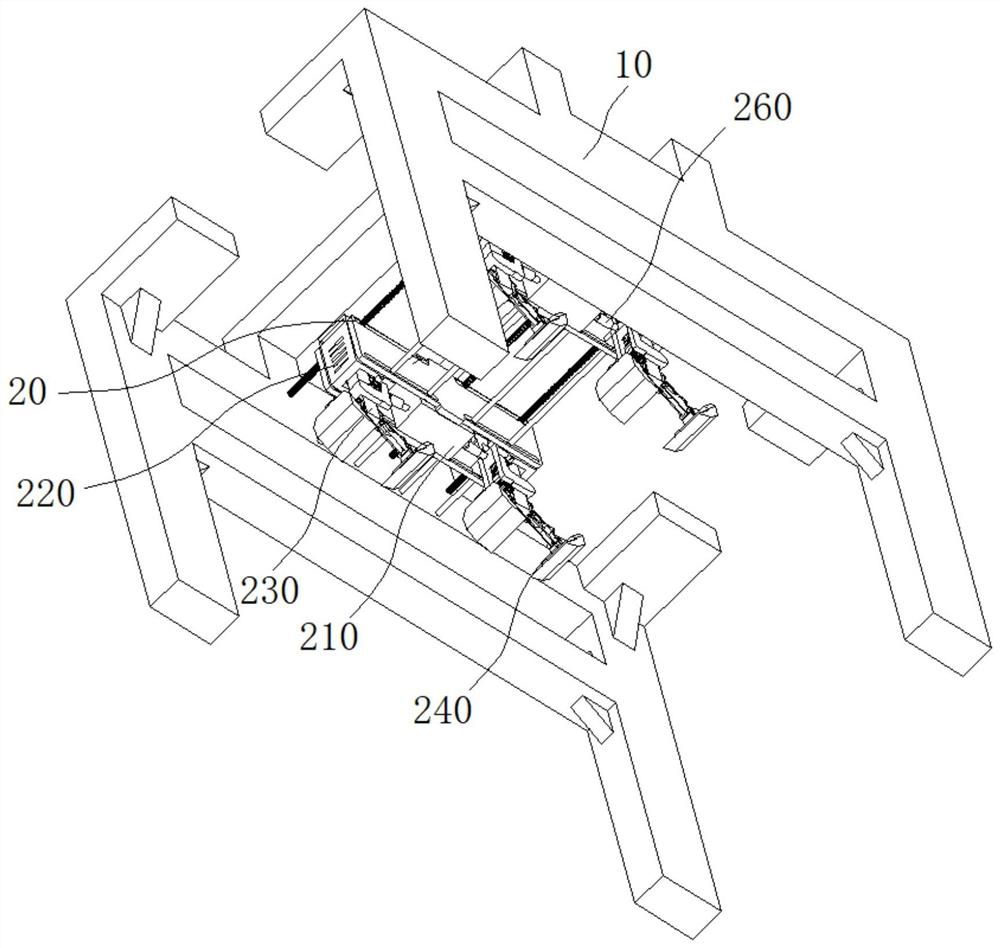

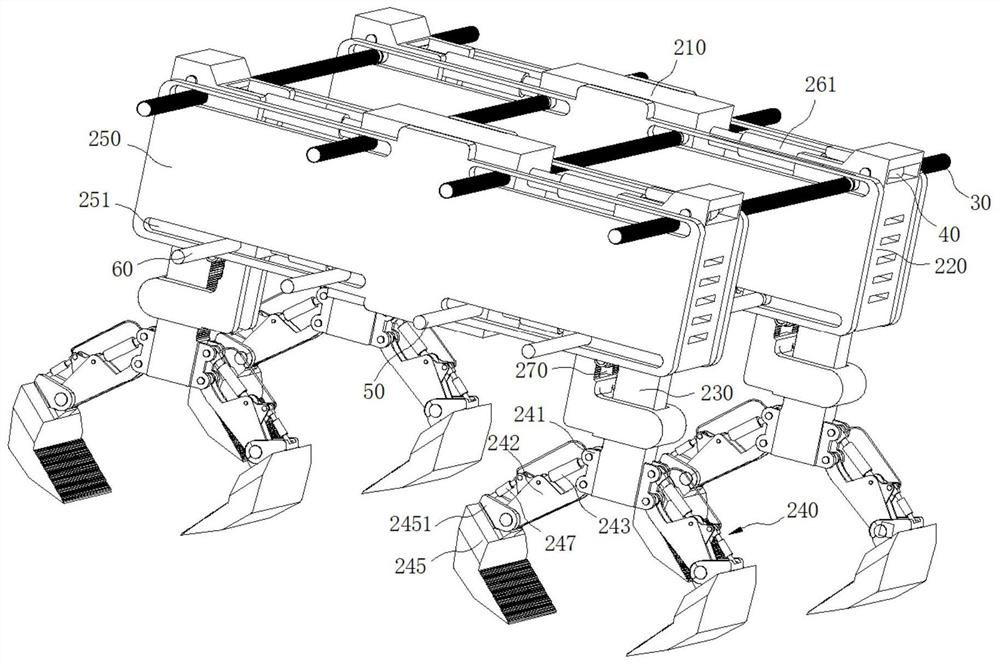

[0024] refer to figure 1 , figure 2 , an unmanned heavy-duty gantry transfer jaw, including a gantry 10, the inner wall of the gantry is provided with at least two frames 20 that can move relative to each other, and the two opposite side walls of the frame base 210 are provided with telescopic movement along the inner cavity of the frame. The fixed sleeve 220 is provided with a movable block 230 capable of telescopic displacement along its vertical direction, and the bottom end of the movable block is rotated to be provided with a claw assembly 240 for grabbing objects. Now, with two frames, the clamped goods Take container objects as an example. When in use, the gantry plays the role of the main support frame, and the frame is used to move along an axial direction inside the gantry to drive the claw clamp assembly to move to both sides of the cargo, and then through the fixed sleeve Telescopic movement along the base to move the claw clip assembly along another axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com