Metal zipper burr removing device and burr removing method

A technology for removing burrs and metal zippers, which is applied in the field of metal zipper production equipment, can solve problems such as hidden dangers, difficult operation, and safety problems in the method of burning and removing burrs with alcohol lamps, and achieves the goals of improving efficiency, ensuring stability, and improving safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

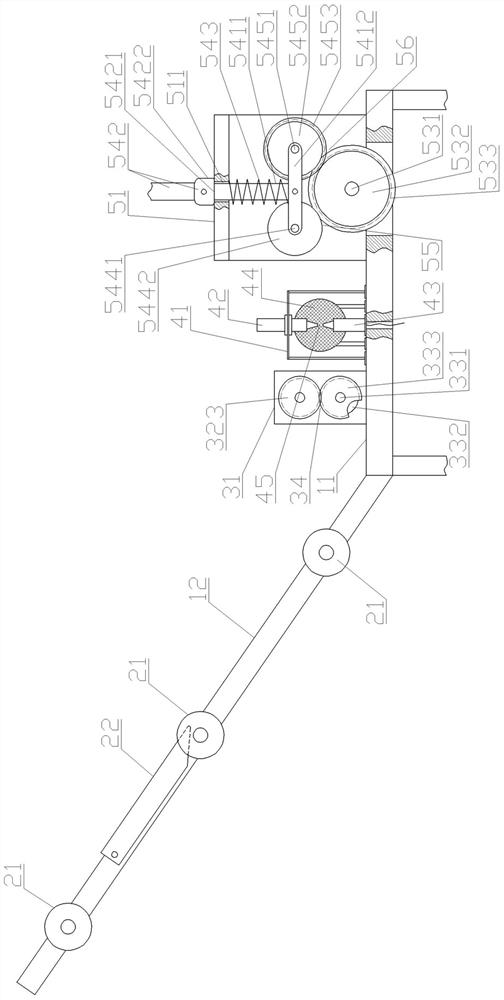

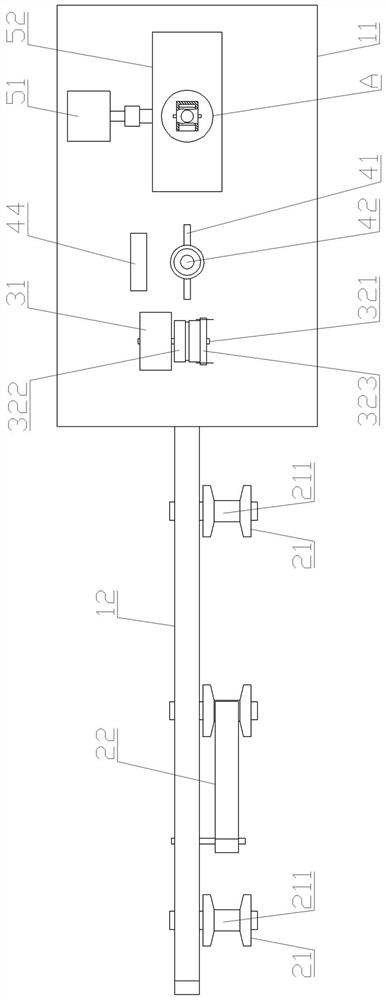

[0043] Such as Figure 1-3 As shown, the metal zipper burr removal device includes a frame, a zipper tilting mechanism, a cloth strip flattening mechanism, a hot air melting thorn mechanism and a cloth strip advancing mechanism.

[0044] The frame includes a base 11 and a slanting rod 12 fixedly connected to one end of the base 11 and extending obliquely upward.

[0045] The zipper support mechanism includes three guide wheels 21 arranged at intervals along the extension direction of the slant bar 12 on the slant bar 12 , and each guide wheel 21 is provided with a zipper limiting groove 211 .

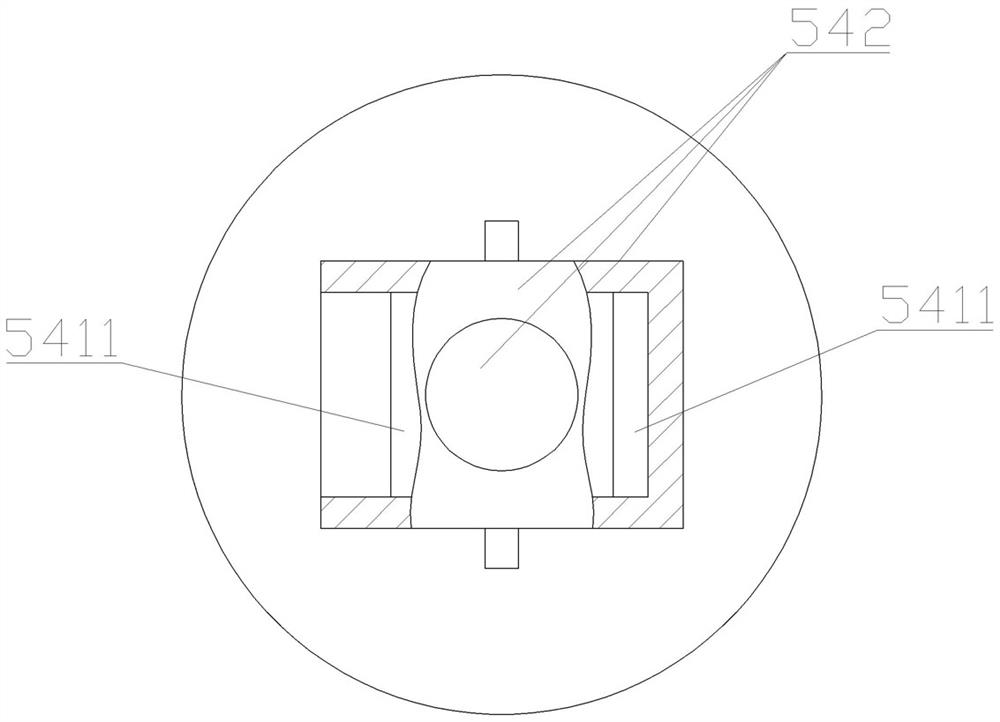

[0046] The cloth strip flattening mechanism includes a mounting frame A31, an upper wheel body A and a lower wheel body A. The installation frame A31 is fixedly installed on the base 11 . The upper wheel body A includes an upper rotating shaft 321 and an upper roller A322 and an upper gear A323 fixedly mounted on the upper rotating shaft 321, and the lower wheel body A includes a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com