Ultrasonic guided-wave optimal excitation frequency selection method and device, equipment and storage medium

A technology of excitation frequency and ultrasonic guided wave, applied in mechanical equipment, design optimization/simulation, gas/liquid distribution and storage, etc., can solve problems such as pipe wall thinning, gas or liquid leakage, pipe corrosion, etc., to improve intuitive The effect of visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

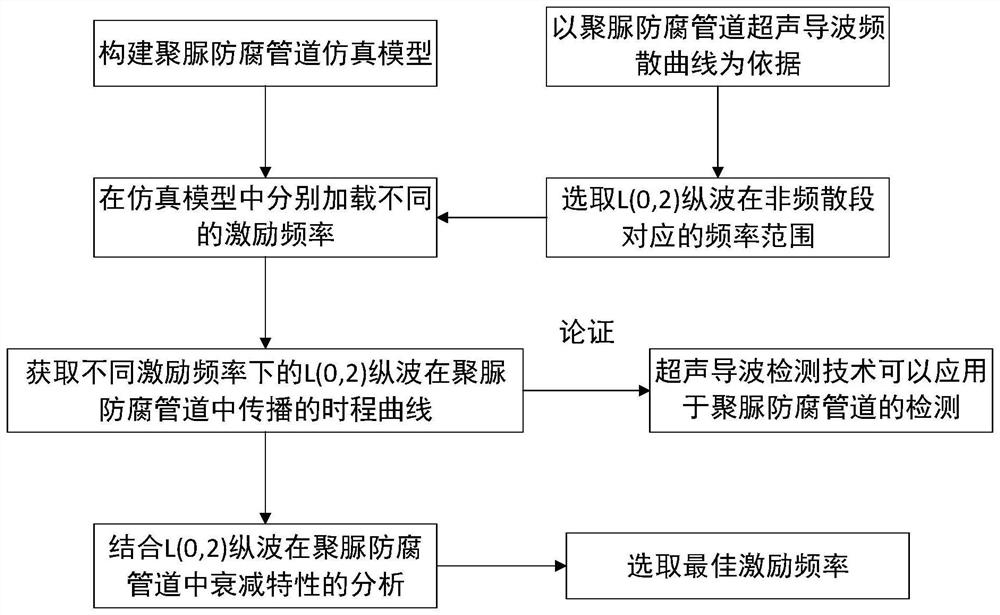

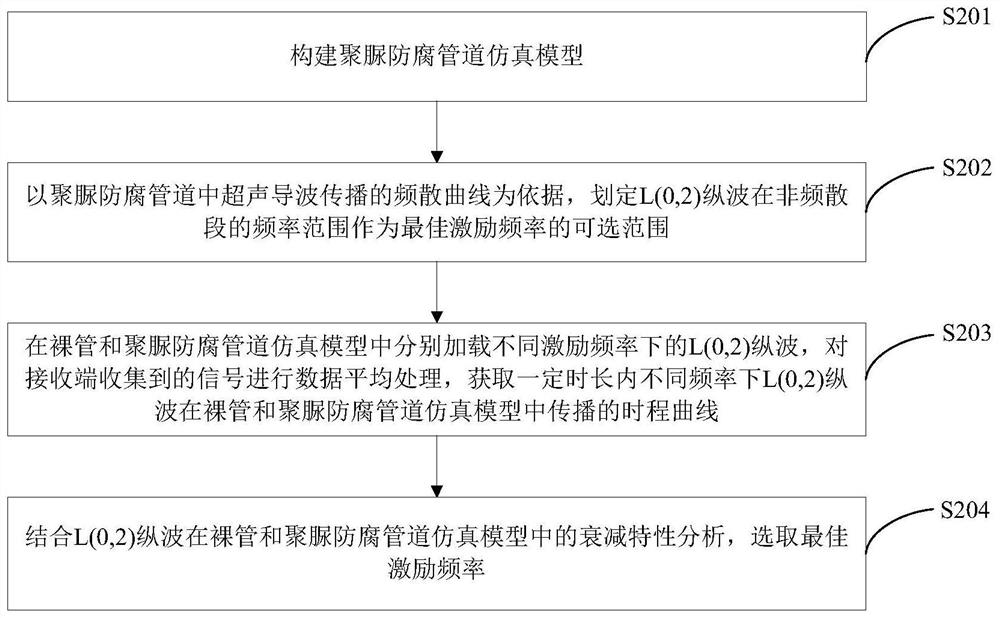

[0068] Such as figure 1 with figure 2 As shown, this embodiment provides a method for selecting the optimal excitation frequency of ultrasonic guided waves, which is applied to the detection of ultrasonic guided waves for polyurea anti-corrosion pipelines, including the following steps:

[0069] S201. Construct a polyurea anticorrosion pipeline simulation model.

[0070] Further, this step S201 specifically includes:

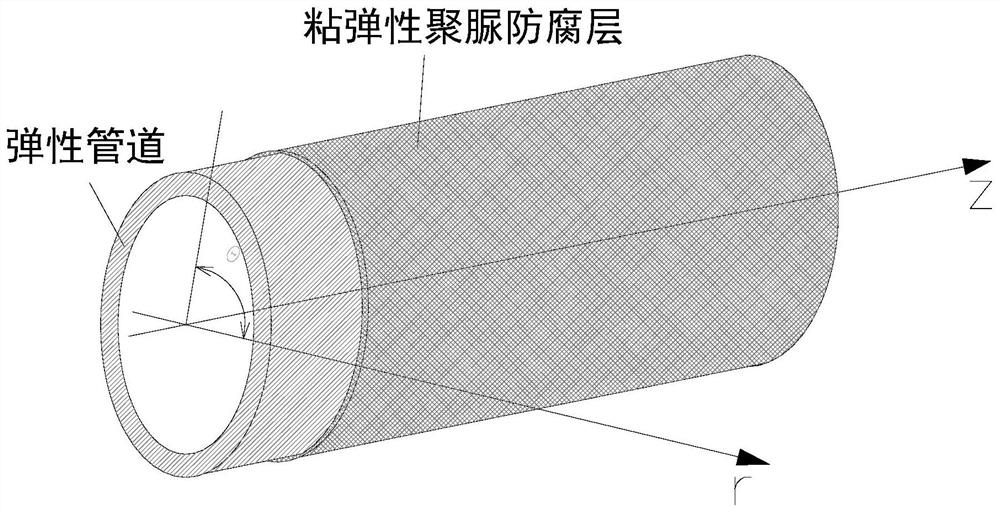

[0071] S2011. By analyzing the analytical model of the polyurea anticorrosion pipeline, it is judged that the polyurea anticorrosion pipeline is approximately an idealized structure of an isotropic viscoelastic-elastic material double-layer cylinder, and it is assumed that the viscoelastic polyurea anticorrosion layer and the elastic pipeline have an ideal structure The contact surfaces are tightly bonded without any relative displacement.

[0072] S2012. Select a three-dimensional solid unit as the elastic pipe, and set the material density, Young's modulus...

Embodiment 2

[0110] This embodiment provides a defect location simulation analysis method applied to different damage levels in polyurea anticorrosion pipelines. The polyurea anticorrosion pipeline defect location system adopted is as follows: Figure 8 As shown, the specific implementation process is as follows:

[0111] S1: Based on the polyurea anti-corrosion pipeline simulation model in the above-mentioned embodiment 1, circumferential cracks with different cross-sectional loss rates are set at a distance of 1.2m from the signal excitation end, such as Figures 9a-9d As shown (a is intact, b is the circumferential length of the crack is π / 6, c is the circumferential length of the complete crack is π / 5, d is the circumferential length of the complete crack is π / 4), the width is 2mm, and the depth Both are 3mm. The settings of circumferential crack defects are shown in Table 3 below.

[0112] Table 3 Settings of circumferential crack defects

[0113]

[0114] S2: According to the l...

Embodiment 3

[0121] Such as Figure 10 As shown, this embodiment provides a device for selecting the optimal excitation frequency of ultrasonic guided waves, which is applied to the detection of ultrasonic guided waves for polyurea anti-corrosion pipelines, including a construction module 1001, a demarcation module 1002, a loading module 1003 and a selection module 1004 , the specific functions of each module are as follows:

[0122] The construction module 1001 is used to construct a polyurea anticorrosion pipeline simulation model.

[0123] Delineation module 1002, used to delineate the frequency range of L(0,2) longitudinal wave in the non-dispersion section as the optional range of optimal excitation frequency based on the dispersion curve of ultrasonic guided wave propagation in polyurea anticorrosion pipeline .

[0124] The loading module 1003 is used to load L(0,2) longitudinal waves at different excitation frequencies in the bare pipe and polyurea anti-corrosion pipeline simulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com