Steel wire rope nondestructive testing equipment, system and method

A non-destructive testing, steel wire rope technology, applied in the direction of material magnetic variables, etc., can solve the problem of low precision of steel wire rope, achieve the effect of improving the universality of application, realizing quantum precision measurement, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

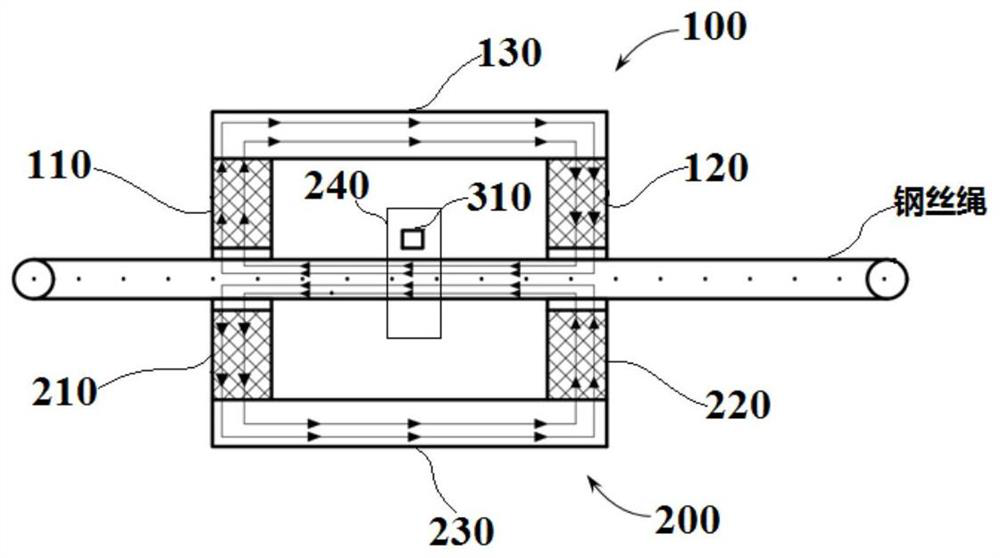

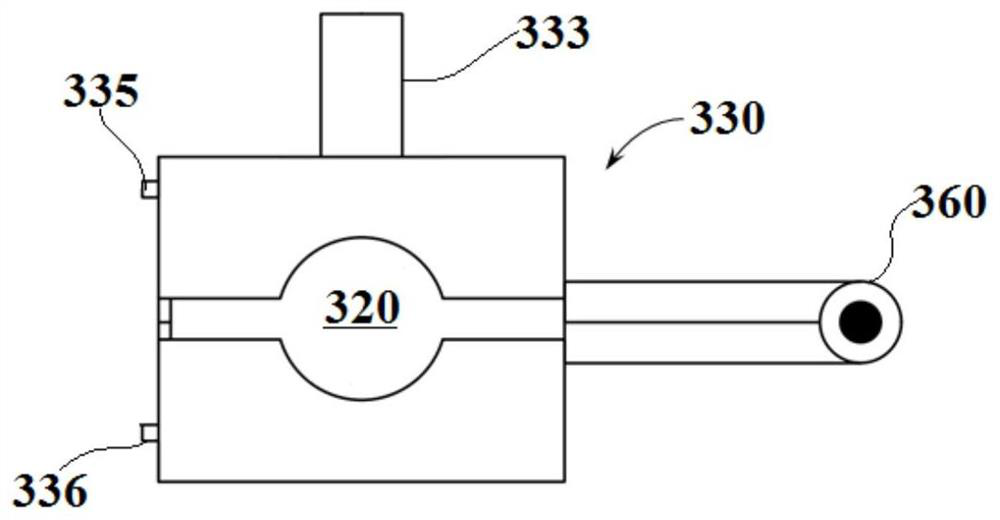

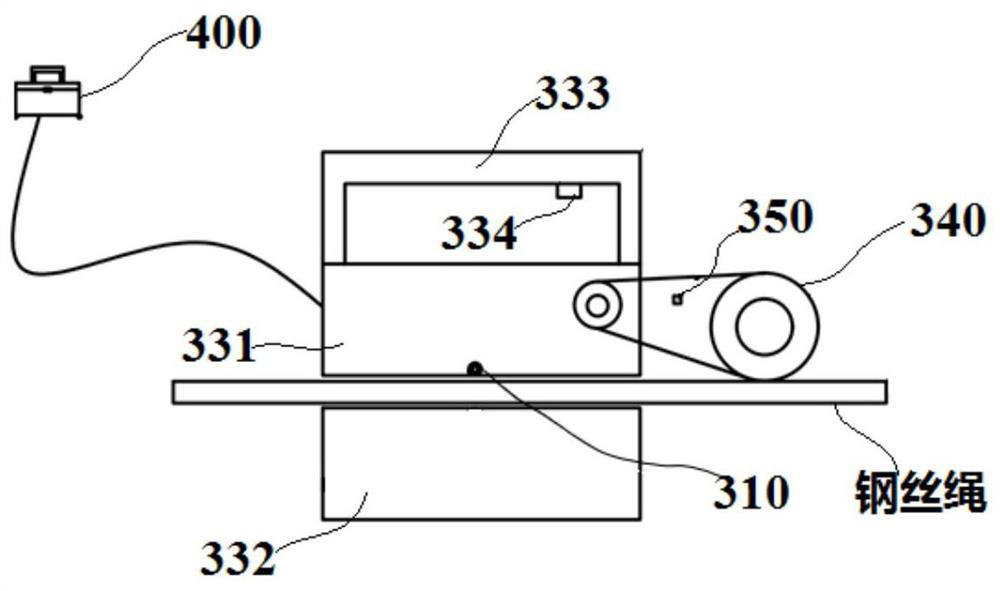

[0041] like figure 1As shown, a steel wire rope non-destructive testing equipment of the present invention includes a first magnet unit 100 and a second magnet unit 200, the first magnet unit 100 is arranged opposite to the second magnet unit 200, and the first magnet unit 100 and the second magnet unit A cavity 320 is provided between the units 200, and the cavity 320 is used to place a steel wire rope; it is worth noting that the first magnet unit 100 is used to generate a magnetization circuit according to the steel wire rope, and the second magnet unit 200 is used to generate a magnetization circuit according to the steel wire rope. The magnetization circuit of the magnet unit 100 is relatively symmetrical to the magnetization circuit. It is worth noting that by setting the first magnet unit 100 and the second magnet unit 200, a double magnetization circuit can be generated, which can eliminate the unilateral suction force, and can keep the steel wire rope constant magnetis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com